A white alkali-soluble photosensitive composition and its preparation method and application

A photosensitive composition and composition technology, applied in the field of photosensitive materials, can solve the problems of increasing the operating procedures and production costs of circuit board factories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

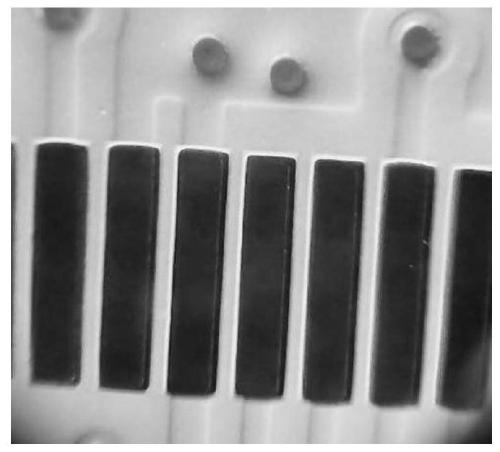

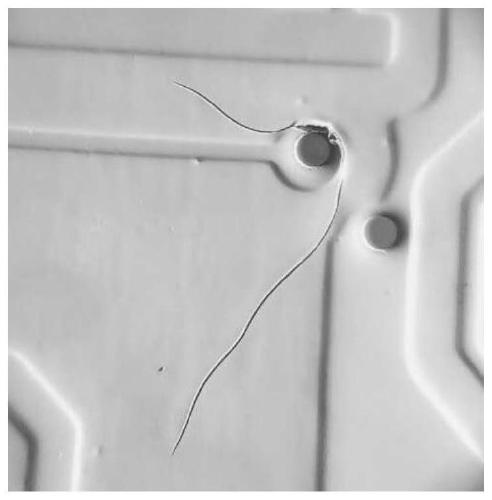

Problems solved by technology

Method used

Image

Examples

Embodiment 1

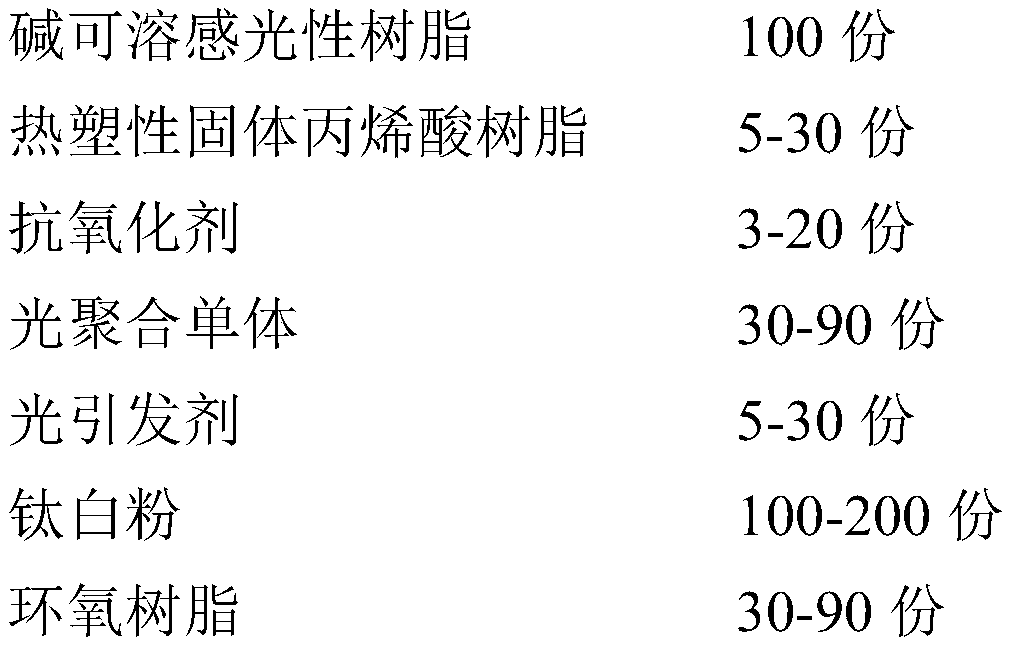

[0037] A preparation method of a white alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0038] (1) First, 100 parts of alkali-soluble photosensitive resin (Chemical Chemical CCR-4969HW), 15 parts of thermoplastic solid acrylic resin (DSM Likang resin B-817), 5 parts of antioxidant (BASF IRGANOX AO 80), 60 parts of photopolymerizable monomers (Eternal Chemical EM265) were mixed, and stirred and dispersed for 20 minutes with a disperser at a speed of 1500 rpm;

[0039] (2) Then add 15.5 parts of photoinitiators (15 parts of Ciba produce Irgacure 907, 0.5 part of Ciba produce IrgacureOXE02), add while stirring, stir and disperse for 10 minutes at a rotating speed of 1500rpm;

[0040] (3) Add 50 parts of epoxy resin (25 parts of Japanese chemical medicine NC3000, 25 parts of Taiwan Changchun CNE202), 0.1 part of amine catalyst (Japan Shikoku Chemical 2E4MZ), 40 parts of diluent (U.S. DOW Chemical Diethylene Glycol Ether Acetate) was sti...

Embodiment 2

[0043] A preparation method of a white alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0044] (1) First, 100 parts of alkali-soluble photosensitive resin (Chemical Chemical CCR-4969HW), 15 parts of thermoplastic solid acrylic resin (DSM Likang resin B-817), 10 parts of antioxidant (BASF IRGANOX AO 80), 60 parts of photopolymerizable monomers (Eternal Chemical EM265) were mixed, and stirred and dispersed for 20 minutes with a disperser at a speed of 1500 rpm;

[0045] (2) Then add 15.5 parts of photoinitiators (15 parts of Ciba produce Irgacure 907, 0.5 part of Ciba produce IrgacureOXE02), add while stirring, stir and disperse for 10 minutes at a rotating speed of 1500rpm;

[0046] (3) Add 50 parts of epoxy resin (25 parts of Japanese chemical medicine NC3000, 25 parts of Taiwan Changchun CNE202), 0.1 part of amine catalyst (Japan Shikoku Chemical 2E4MZ), 40 parts of diluent (U.S. DOW Chemical Diethylene Glycol Ether Acetate) was st...

Embodiment 3

[0049] A preparation method of a white alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0050] (1) First, 100 parts of alkali-soluble photosensitive resin (Chemical Chemical CCR-4969HW), 15 parts of thermoplastic solid acrylic resin (DSM Likang resin B-817), 15 parts of antioxidant (BASF IRGANOX AO 80), 60 parts of photopolymerizable monomers (Eternal Chemical EM265) were mixed, and stirred and dispersed for 20 minutes with a disperser at a speed of 1500 rpm;

[0051] (2) Then add 15.5 parts of photoinitiators (15 parts of Ciba produce Irgacure 907, 0.5 part of Ciba produce IrgacureOXE02), add while stirring, stir and disperse for 10 minutes at a rotating speed of 1500rpm;

[0052] (3) Add 50 parts of epoxy resin (25 parts of Japanese chemical medicine NC3000, 25 parts of Taiwan Changchun CNE202), 0.1 part of amine catalyst (Japan Shikoku Chemical 2E4MZ), 40 parts of diluent (U.S. DOW Chemical Diethylene Glycol Ether Acetate) was st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com