Adhesive as well as preparation method and application thereof

An adhesive, wet-adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, polymer adhesive additives, etc., can solve problems such as non-flammability and troublesome use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

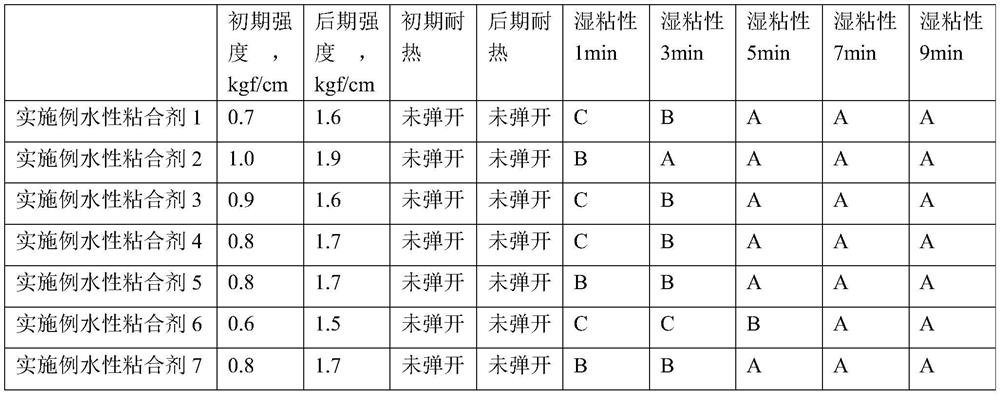

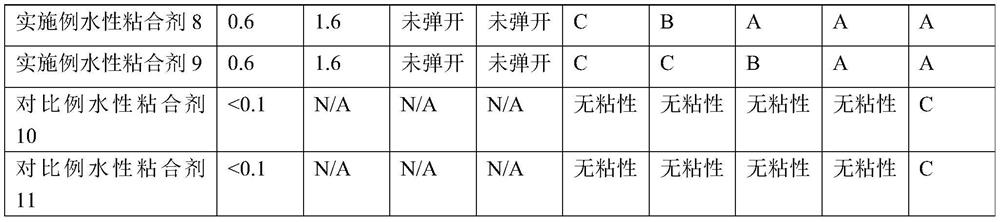

Examples

Embodiment 1

[0121] A water-based adhesive is made up of the following components by weight:

[0122] Waterborne polyurethane dispersion A99 parts

[0123] Wet adhesion promoter Texanol 0.5 parts

[0124] BYK-024 (defoamer) 0.05 part

[0125] 0.2 parts of TEGO-KL245 (wetting agent)

[0126] U604 (thickener) 0.5 parts

[0127] The present example water-based case and bag composite hemming adhesive is prepared through the following steps:

[0128] Add water-based polyurethane dispersion, wet adhesion promoter, defoamer BYK-024, and wetting agent TEGO-245 into the stirring tank at a stirring speed of 400 rpm for 20 minutes; then add the thickener 604, the stirring speed is 700 rpm, stirring for 30 minutes, the viscosity is adjusted to 50000-80000cps, and the water-based adhesive 1 is obtained by discharging.

Embodiment 2

[0130] A water-based adhesive is made up of the following components by weight:

[0131] Waterborne polyurethane dispersion B 96 parts

[0132] Wet adhesion promoter ethylene glycol butyl ether 3 parts

[0133] BYK-024 (defoamer) 0.05 parts

[0134] TEGO-KL245 (wetting agent) 0.2 parts

[0135] U604 (thickener) 0.3 parts

[0136] The present example water-based case and bag composite hemming adhesive is prepared through the following steps:

[0137] Add water-based polyurethane dispersion, wet adhesion promoter, defoamer BYK-024, and wetting agent TEGO-245 into the stirring tank at a stirring speed of 500 rpm for 12 minutes; then add a thickener 604, the stirring speed is 800 rpm, stirring for 30 minutes, adjusted to a viscosity of 50000-80000cps, and the water-based adhesive 2 is obtained by discharging.

Embodiment 3

[0139] A water-based adhesive is made up of the following components by weight:

[0140] Waterborne polyurethane dispersion C 95 parts

[0141] Wet adhesion promoter Hexylene Glycol Butyl Ether Acetate 4 parts

[0142] BYK-024 (defoamer) 0.05 parts

[0143] TEGO-KL245 (wetting agent) 0.2 parts

[0144] U604 (thickener) 0.5 parts

[0145] The present example water-based case and bag composite hemming adhesive is prepared through the following steps:

[0146] Add water-based polyurethane dispersion, wet adhesion promoter, defoamer BYK-024, and wetting agent TEGO-KL 245 into the stirring tank at a stirring speed of 350 rpm for 20 minutes; then add the thickener 604, the stirring speed is 900 rpm, stirring for 20 minutes, the viscosity is adjusted to 50000-80000cps, and the water-based adhesive 3 is obtained by discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com