Cast iron enamel burner and preparation process thereof

A preparation process and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of cumbersome production process, enamel blasting, and complexity, and achieve simple preparation process and enhanced acid and alkali resistance , enhance the effect of antioxidant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0036] The present invention provides a kind of preparation technology of cast iron enamel burner, comprises following processing steps:

[0037] a, prepare enamel glaze slurry;

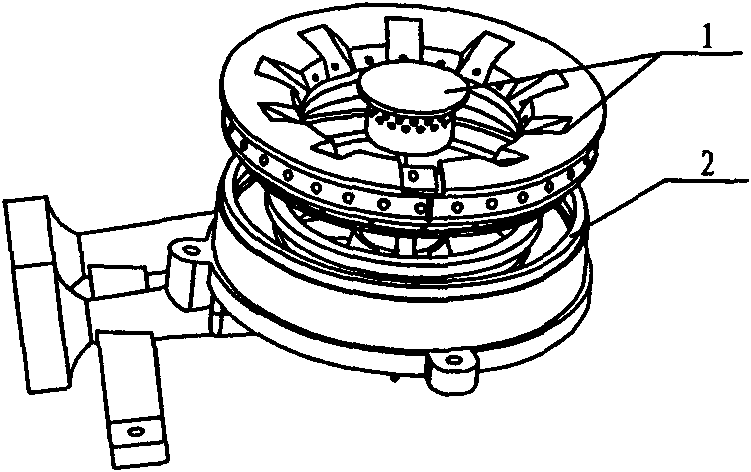

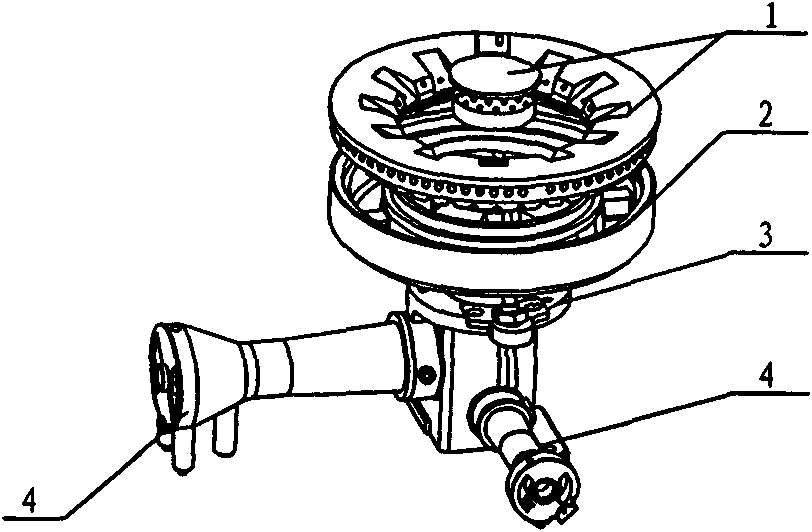

[0038] b. Manufacture the burner, wherein the combustion disc 2 in the burner is made of cast iron material of HT150 to HT250;

[0039] c. Spray the enamel slurry prepared in step a on the surface of the manufactured combustion disc 2 by wet coating process;

[0040] d. Put the combustion plate 2 sprayed with enamel slurry into the furnace for firing, the furnace temperature is between 740°C and 780°C, and the firing time is between 5 minutes and 15 minutes;

[0041] e. The assembly is completed.

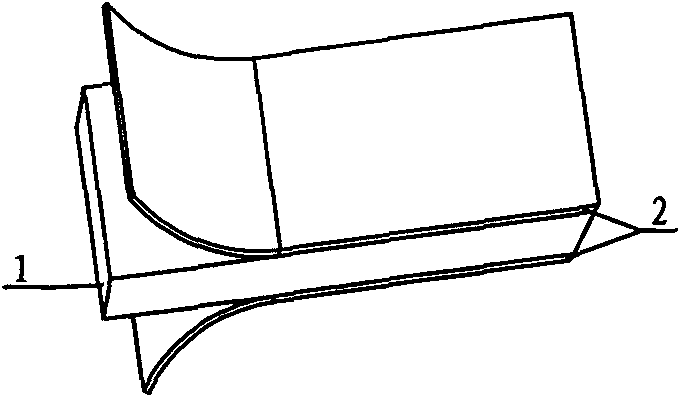

[0042] In the above-mentioned embodiments provided by the present invention, the manufacture of the burner in the step b includes the following process steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com