Preparation method of novel hydrophilic fat-soluble vitamin microcapsules

A technology of fat-soluble vitamins and microcapsules, which is applied in the direction of adding food elements, resisting vector-borne diseases, forming or processing animal feed, etc., and can solve the problems of animal protein glue, such as high safety hazards, difficult processes, and low efficiency. , to achieve the effect of high microencapsulation yield, wide application range and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Under the protection of nitrogen, crystallize 130 grams of vitamin A and melt 8 grams of BHT at 75°C to make vitamin A melt oil. 95 grams of sodium starch octenyl succinate (Lyckeby PU 41032 produced by Lyckeby starch in Sweden) and 39 grams of glucose were dissolved in 180 grams of 60° C. water to form a 43% starch glucose aqueous solution. Wherein, preferably before "being made into 43% starch glucose aqueous phase solution", the aqueous solution of sodium starch octenyl succinate was boiled separately at 80° C. for 10 minutes.

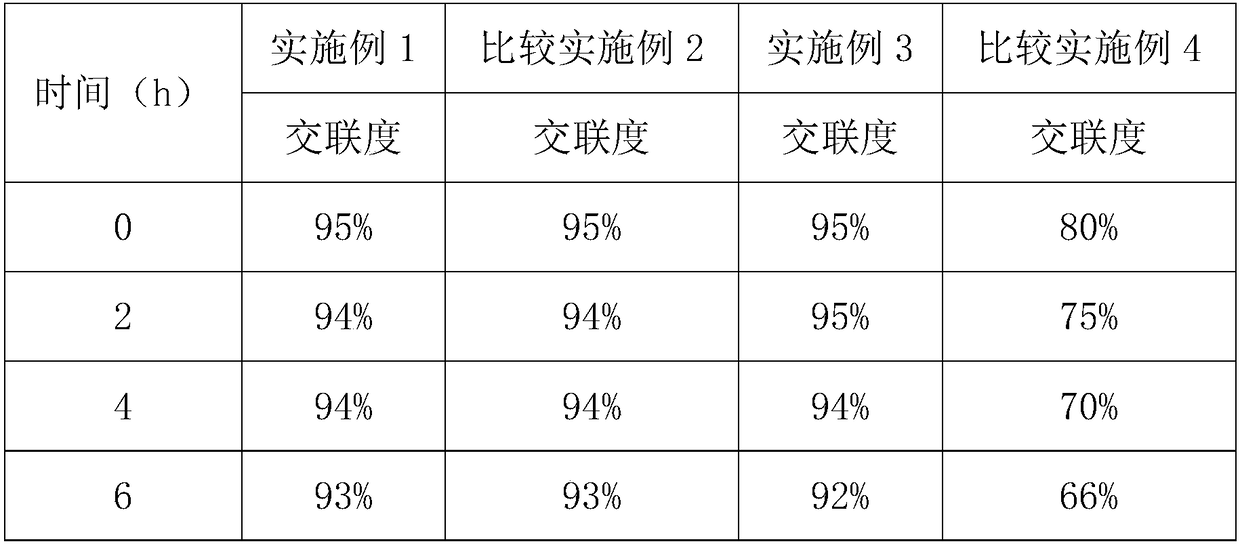

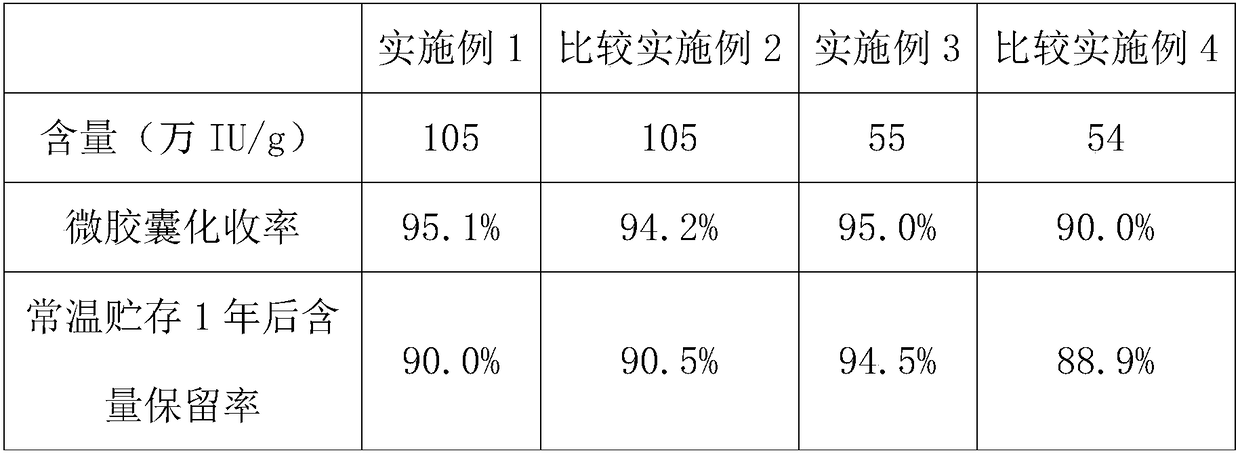

[0039] Under the condition of high-speed shearing, the melted vitamin A oil is poured into the above-mentioned aqueous phase solution for emulsification and homogenization to obtain a stable emulsion. The emulsion was fully mixed with 5 grams of sodium hexametaphosphate, then sent into a starch bed for spray granulation, then fluidized and dried, and cross-linked at a high temperature of 110°C to obtain 318 grams of water-repellent vitamin A ...

Embodiment 3

[0044] Under the protection of nitrogen, 40 grams of vitamin A crystals and 5 grams of TBHQ were melted at 75°C to make vitamin A melt oil. 56 grams of sodium starch octenyl succinate (N912 produced by National Starch), and 50 grams of glucose were dissolved in 110 grams of 60°C water to form a 49% starch glucose aqueous phase solution. Wherein, preferably before "being made into 49% starch glucose aqueous phase solution", the aqueous solution of sodium starch octenyl succinate was boiled separately at 75°C for 15 minutes.

[0045] Under the condition of high-speed shearing, the melted vitamin A oil is poured into the above-mentioned aqueous phase solution for emulsification and homogenization to obtain a stable emulsion. The emulsion was fully mixed with 3 grams of potassium dihydrogen phosphate, then sent into a starch bed for spray granulation, then fluidized and dried, and cross-linked at a high temperature of 120°C to obtain 183 grams of water-repellent vitamin A microcap...

Embodiment 5

[0055] Under nitrogen protection, crystallize 20 grams of vitamin D3 and melt 2.5 grams of tocopherol at 75°C to prepare vitamin D3 melted oil. Dissolve 50 grams of sodium starch octenyl succinate (N912 produced by National Starch), and 100 grams of fructose in 160 grams of 65° C. water to form a 48% starch-fructose aqueous phase solution. Wherein, preferably before "being made into 48% starch glucose aqueous phase solution", the aqueous solution of starch sodium octenyl succinate was boiled separately at 75°C for 20 minutes.

[0056] Under the condition of high-speed shearing, the melted vitamin D3 oil is poured into the above water phase solution for emulsification and homogenization to obtain a stable emulsion. The emulsion was fully mixed with 3 grams of sodium dihydrogen phosphate, and then sent into a starch bed for spray granulation, then fluidized and dried, and cross-linked at a high temperature of 100°C to obtain 242 grams of vitamin D3 microcapsules. The microcapsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com