Starch octenyl succinate anhydride preparation process

A technology of octenyl succinic acid and starch ester, applied in the field of starch hydrophobic modification and its deep processing, can solve the problems of difficult to realize industrialization, high production cost, low reaction substitution degree and reaction efficiency, etc., and achieve good market promotion. Prospect, Reaction Efficiency Improvement, Effect of Efficient Preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

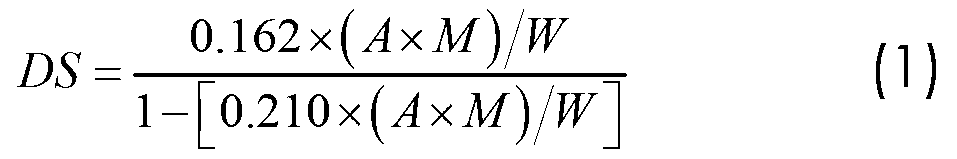

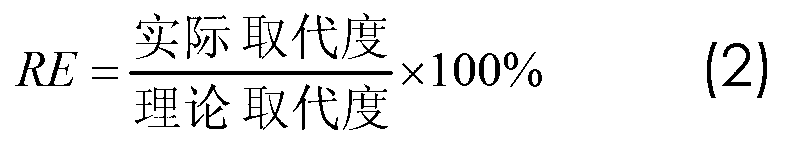

Embodiment 1

[0033] A kind of preparation method of starch octenyl succinate: firstly add common cornstarch and water to adjust milk, the mass percent concentration of starch emulsion is 25%, pump starch milk into pipeline, circulate between pipeline and reaction tank, pipeline A clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type) is installed on it. At an ultrasonic frequency of 15KHz, the ultrasonic intensity is 0.05W / cm 3 Ultrasonic action is carried out on the starch milk, and the temperature of the starch slurry is controlled to be 35°C through the jacketed water bath circulation in the reaction tank, and the pH value is adjusted to 9.0 with a sodium hydroxide solution with a mass percentage concentration of 3%. 0.01% decyl glucoside, stirred evenly, then added dropwise octenyl succinic anhydride accounting for 1% of the dry base of starch for reaction, while maintaining the pH balance of the system with a mass perc...

Embodiment 2

[0036] A kind of preparation method of octenyl succinic acid starch ester: first add waxy cornstarch water to adjust milk, the mass percent concentration of starch emulsion is 35%, starch milk is pumped in pipeline, circulates between pipeline and reaction tank, A clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type) is installed on the pipeline. At an ultrasonic frequency of 20KHz, the ultrasonic intensity is 0.10W / cm 3 Under the action of starch milk, the temperature of the starch slurry is controlled at 40°C through the jacket water bath circulation in the reaction tank, and the pH value is adjusted to 8.5 with a sodium hydroxide solution with a concentration of 3% by mass percentage, and 0.1% of the dry weight of the starch is added. octyl glucoside, stirred evenly, and then added dropwise octenyl succinic anhydride accounting for 3% of the dry weight of the starch for reaction, while maintaining the pH of...

Embodiment 3

[0039]A kind of preparation method of octenyl succinic acid starch ester: firstly, potato starch is added with water to adjust milk, the mass percent concentration of starch emulsion is 30%, starch milk is pumped into pipeline, circulates between pipeline and reaction tank, on pipeline Installed with a clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type), at an ultrasonic frequency of 25KHz, the ultrasonic intensity is 0.20W / cm 3 Under the action of starch milk, the temperature of the starch slurry is controlled at 35°C through the jacketed water bath circulation in the reaction tank, and the pH value is adjusted to 8.5 with a sodium hydroxide solution with a concentration of 5% by mass percentage, and 0.5% of the dry weight of the starch is added. sucrose ester (S-1170, Japan Mitsubishi Chemical Food Co., Ltd.), stir evenly, then add dropwise the octenyl succinic anhydride that accounts for 5% of the dry wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com