Synthesis method of octenyl succinate starch ester

A technology of octenyl succinic acid and synthesis method, which is applied in the field of food biochemical industry, can solve problems such as large pollution, unsuitable products for food, complicated purification steps, etc., and achieve the effects of mild conditions, increased contact area, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

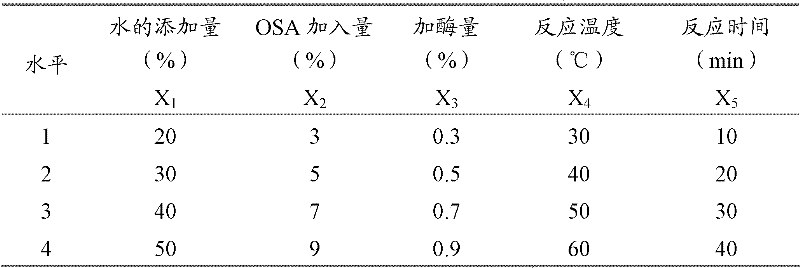

Method used

Image

Examples

Embodiment 1

[0027] (1) Starch pretreatment Weigh 30g of starch, put it into 100ml of water at 55°C and swell for 20 minutes, and filter.

[0028] (2) Esterification Add 110ml of mixed solvent of n-hexane and water to the treated starch, the volume ratio of n-hexane and water is 10 / 1, then add lipase 0.09g, octenyl succinic anhydride 1.5g, 40 The reaction was stirred in a constant temperature water bath for 10 min, and the stirring speed was 100 rpm to obtain starch octenyl succinate. The degree of substitution of starch octenyl succinate was determined to reach 0.00854.

Embodiment 2

[0030] (1) Starch pretreatment Weigh 30g of starch, put it into 100ml of water at 55°C and swell for 20 minutes, and filter.

[0031] (2) esterification reaction Add 120ml of mixed solvent of n-hexane and water to the treated starch, the volume ratio of n-hexane and water is 10 / 2, then add lipase 0.33g, octenyl succinic anhydride 2.7g, 30 ℃ constant temperature water bath stirring reaction for 20min, stirring speed 200rpm, to obtain octenyl succinate starch ester, the degree of substitution of octenyl succinate starch ester reaches 0.00939.

Embodiment 3

[0033] (1) Starch pretreatment Weigh 30g of starch, put it into 100ml of water at 55°C and swell for 20 minutes, and filter.

[0034] (2) Esterification Add 130ml of mixed solvent of n-hexane and water to the treated starch, the volume ratio of n-hexane and water is 10 / 3, then add 0.21g of lipase, 3.3g of octenyl succinic anhydride, 60 The reaction was stirred in a constant temperature water bath for 30 min, and the stirring speed was 150 rpm to obtain starch octenyl succinate. The degree of substitution of starch octenyl succinate was determined to reach 0.00532.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com