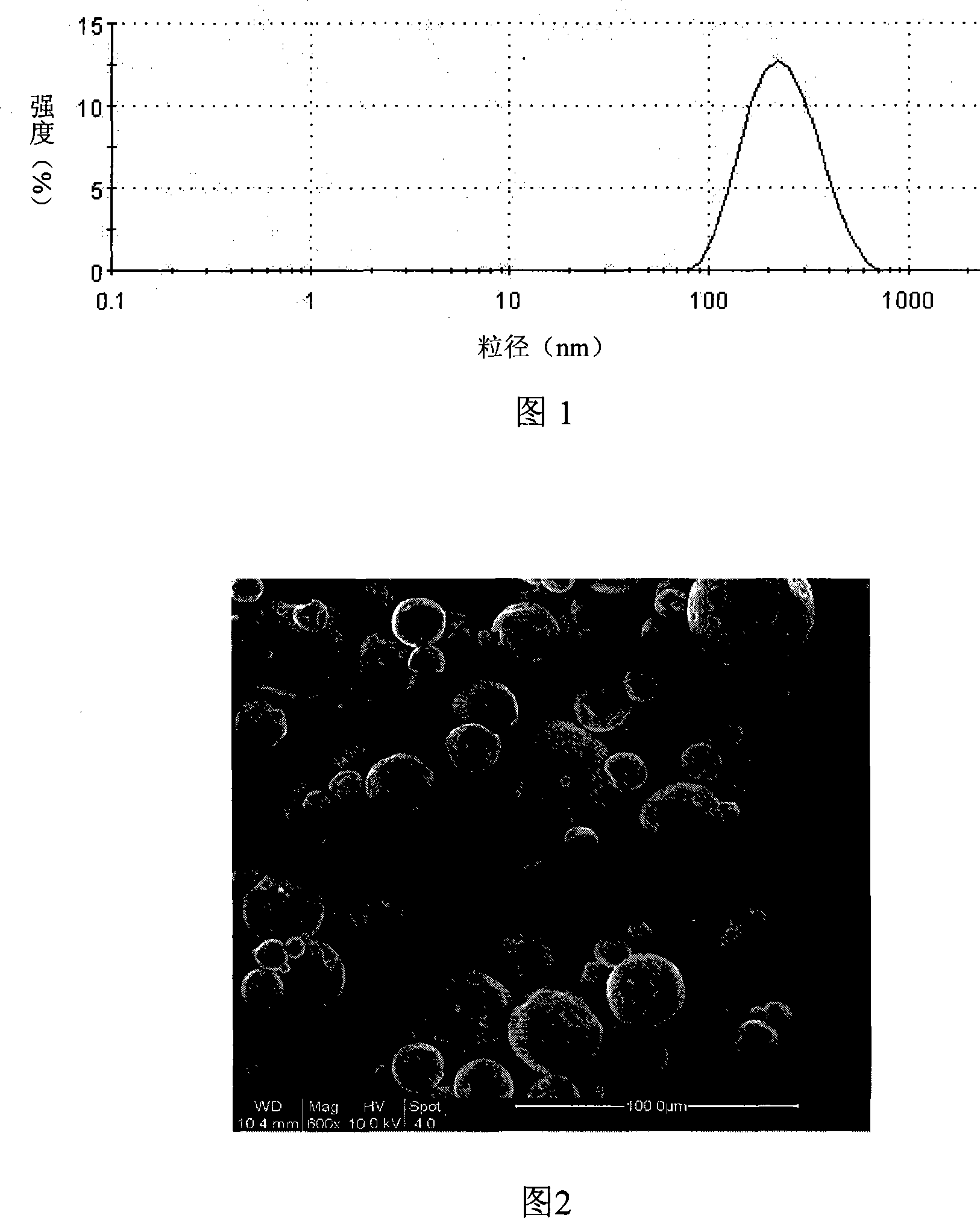

Method for preparing vitamin A and vitamin E nano-sphere/microsphere double-embedding system

A vitamin and nanosphere technology, which is applied to medical preparations containing active ingredients, pharmaceutical formulations, metabolic diseases, etc., can solve the problems of difficult preservation, difficult processing, and the inability of wall materials to provide slow-release effects, so as to avoid mutual Interfere and improve the effect of bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Accurately weigh 20g of monoglyceride, heat it to melt at 70°C, accurately weigh 5g of vitamin A oil, add it to the melted monoglyceride, stir and mix. Accurately weigh 160g of octenyl succinic esterified starch (modified starch Hi-CAP100) added with Tween-80, dissolve it in 600mL of water at 70°C, add molten monoglyceride added with vitamin A to the modified In the starch Hi-CAP100 solution, stir vigorously and disperse at high speed (10000r / min, 30s). Accurately weigh 55g of vitamin E oil, add it to the above-mentioned modified starch solution, disperse at high speed (20500r / min, 1min), and homogenize at high pressure (40MPa), repeat 3 times, all operations are carried out at 70°C. Rapidly cool in an ice-water bath to below the melting point of monoglyceride, spray-dry, the air inlet temperature is 190°C, and the air outlet temperature is 90°C to obtain a nanosphere / microsphere double embedding system embedding vitamin A and vitamin E.

Embodiment 2

[0019] Accurately weigh 42g of monoglyceride, heat it to melt at 70°C, accurately weigh 10.5g of vitamin A oil, add it to the melted monoglyceride, stir and mix. Accurately weigh 340g of modified starch Hi-CAP100, dissolve it in 1050mL of water at 70°C, add the molten monoglyceride added with vitamin A into the modified starch Hi-CAP100 solution, stir vigorously, and disperse at high speed (10000r / min, 30s). Accurately weigh 52g of vitamin E oil, add to the above modified starch solution, high-speed dispersion (20500r / min, 1min), high-pressure homogenization (60MPa), repeat 3 times, all operations are carried out at 70 ° C. Rapidly cool in an ice-water bath to below the melting point of monoglyceride, spray-dry, the air inlet temperature is 190°C, and the air outlet temperature is 90°C to obtain a nanosphere / microsphere double embedding system embedding vitamin A and vitamin E.

Embodiment 3

[0021] Accurately weigh 30g of beeswax, and heat it to melt at 78°C. Accurately weigh 7.5g of vitamin A, add to the melted beeswax, stir and mix. Accurately weigh 150g of modified starch Hi-CAP100, dissolve it in 570mL of water at 78°C, add molten beeswax with added vitamin A into the modified starch Hi-CAP100 solution, stir vigorously, and disperse at high speed (10000r / min, 30s ). Accurately weigh 39g of vitamin E, add to the above-mentioned modified starch solution, high-speed dispersion (20500r / min, 1min), high-pressure homogenization (50MPa), repeat 3 times, all operations are carried out at 78 ° C. Rapidly cool in an ice-water bath to below the melting point of beeswax, spray dry, the air inlet temperature is 185°C, and the air outlet temperature is 85°C to obtain a nanosphere / microsphere double embedding system embedding vitamin A and vitamin E.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com