Xanthophyll-reinforced sweet corn beverage and preparation method thereof

A technology of lutein and sweet corn, which is applied in the field of food processing, can solve the problems of sweet corn drinks that have not yet been enriched with lutein, and achieve the effects of easy implementation, improved stability and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

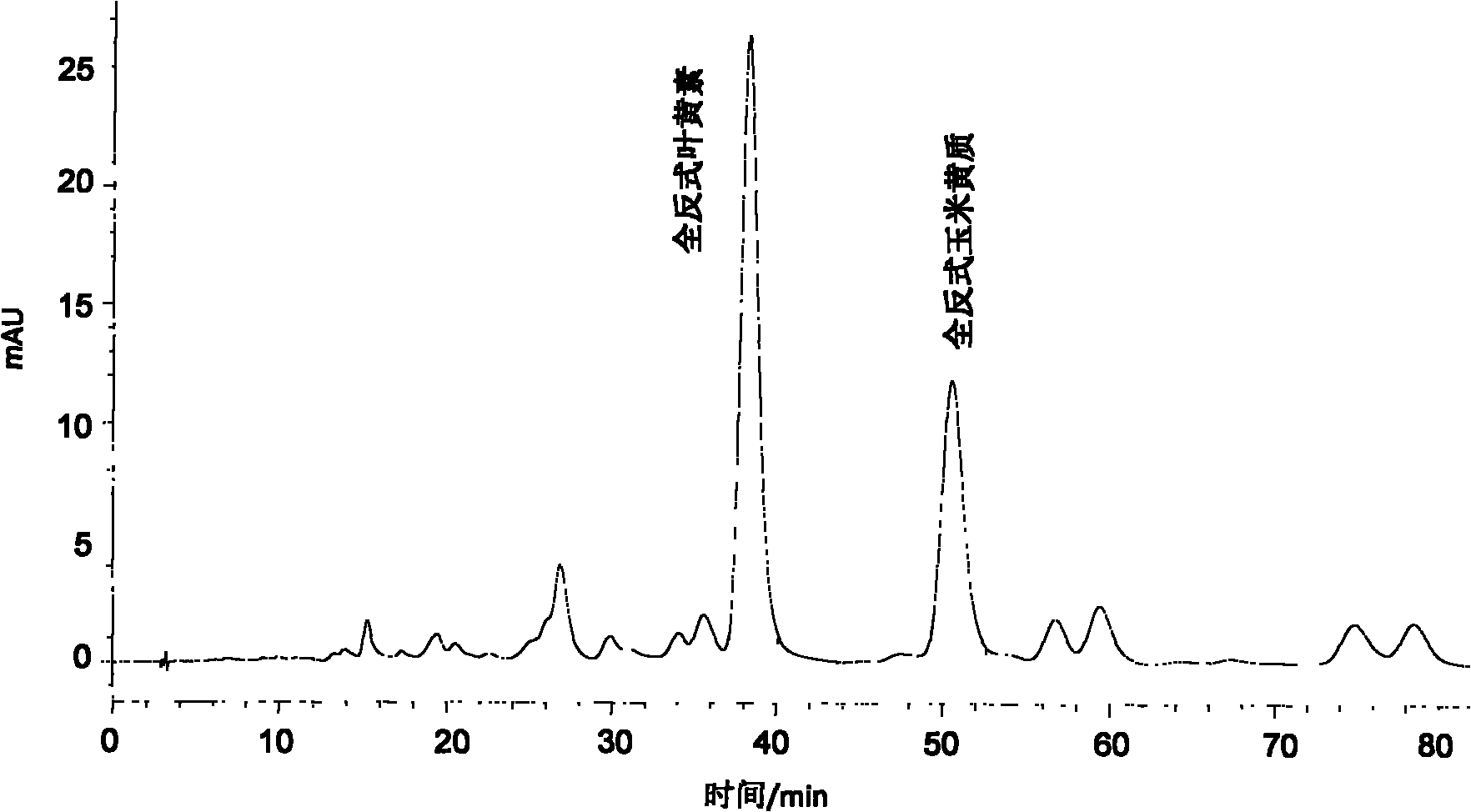

[0041]Weigh 30 g of lutein crystals (purchased from Shaanxi Senfu Biotechnology Co., Ltd.) and dissolve them in 120 mL of edible alcohol, and add 0.5% sucrose ester 13 to make a core material solution; Add 3.2L of water to sucrose (the ratio of sucrose is 10%), stir and dissolve at 55°C to make it swell and disperse to make a wall material solution; add the core material solution to the wall material solution, stir and mix well , the obtained mixed solution was homogeneously emulsified twice in a colloid mill, and then spray-dried at a feed rate of 400mL / h and an inlet and outlet air temperature of 160 / 80°C to make a tangerine with a trans-lutein content of 4.8%. Yellow lutein microcapsule powder, microcapsule efficiency and yield are 91.12% and 90.30% respectively. The obtained product has fine and uniform particles, no peculiar smell, a solubility of 93%, and a water content of 4.2%.

[0042] After thawing 50kg of quick-frozen sweet corn kernel raw materials, add 200L of wa...

Embodiment 2

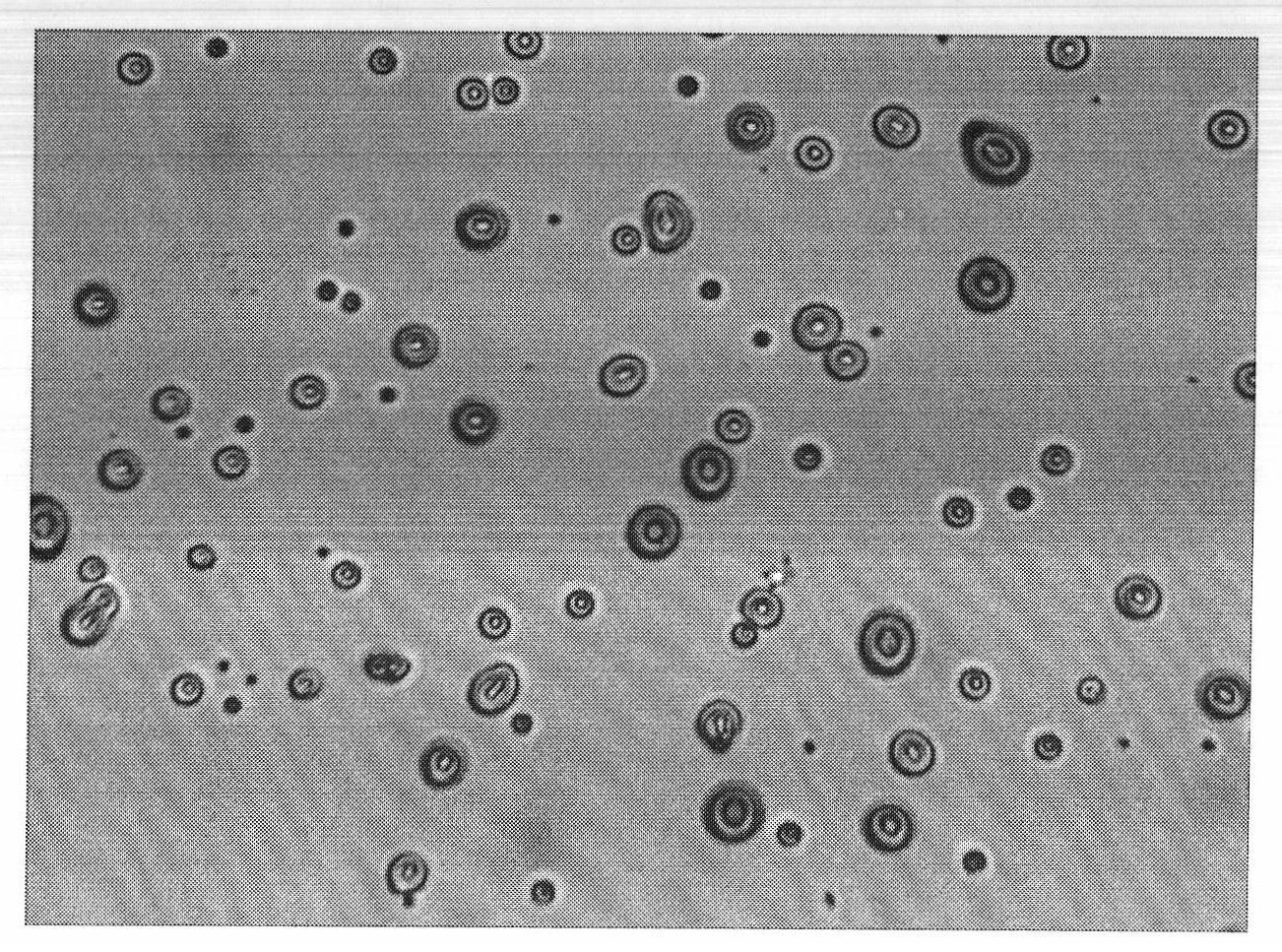

[0045] Weigh 40g of lutein crystals and dissolve in 160mL edible alcohol, and add 0.5% sucrose ester 13 to make a core material solution; add Stir and dissolve 4L of water at 58°C to make it swell and disperse to make a wall material solution; add the core material solution to the wall material solution, stir and mix well, and the obtained mixed solution is homogenized twice through a colloid mill After emulsification, the feed rate was 400mL / h, and the inlet and outlet air temperature was 160 / 80°C for spray drying to make orange-yellow lutein microcapsule powder with a trans-lutein content of 5.1%. Microcapsule efficiency and production The rates are 91.69% and 90.53%, respectively. The obtained product has fine and uniform particles, no peculiar smell, a solubility of 92%, and a water content of 4.4%.

[0046] After thawing 50kg of quick-frozen sweet corn raw materials, add 200L of water to make a slurry, gelatinize with hot water at 70°C for 20 minutes; adjust the pH to 6....

Embodiment 3

[0048] Weigh 50g of lutein crystals and dissolve in 200mL edible alcohol, and add 0.5% sucrose ester 13 to make a core material solution; add 3.6 L of water was stirred and dissolved at 60°C to make it swell and disperse to make a wall material solution; After mass emulsification, the feed rate was 400mL / h, and the inlet and outlet air temperature was 160 / 80°C and spray-dried to make an orange-yellow lutein microcapsule powder with a trans-lutein content of 4.5%. The microcapsule efficiency and The yields were 90.43% and 89.81%, respectively. The obtained product has fine and uniform particles, no peculiar smell, a solubility of 93%, and a water content of 4.3%.

[0049] After thawing 60kg of quick-frozen sweet corn raw materials, add 240L of water for beating, gelatinize with hot water at 70°C for 20 minutes; adjust the pH to 6.5, add 0.3% α-amylase to liquefy at 70°C for 60 minutes; boil the obtained corn steep liquor for 10 minutes Inactivate the enzyme and filter through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com