Method for preparing starch ester by recycling octenyl succinic anhydride

A technology of octenyl succinic anhydride and octenyl succinic acid, which is applied in the field of food chemistry, can solve problems such as high viscosity, uneven substitution, difficult control, etc., to improve reaction efficiency, save raw material costs, and process is simple and easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Mix 100kg dry waxy cornstarch with 100kg water at 30°C and homogeneously emulsify for 5 minutes to obtain a finely dispersed emulsion, then add 3% sodium hydroxide to adjust the pH value of the above emulsion to 8;

[0035] 2) 3kg of octenyl succinic anhydride is dissolved in 100kg of ethanol with a mass concentration of 80% to obtain an octenyl succinic anhydride solution;

[0036] 3) Add the emulsion obtained in step 1) into the octenyl succinic anhydride solution described in step 2) under 1000r / min stirring in the form of a spray, control the reaction temperature to 60°C, and react for 0.5 hours. After the reaction is completed, adjust the reaction with hydrochloric acid pH value of the solution to 5.5;

[0037]4) quickly filter the reaction solution to obtain the product and the octenyl succinic anhydride raffinate, then use 30kg water, 30kg ethanol, 30kg mass concentration respectively as 80% ethanol to wash the product once, and the washing liquid is mixed wit...

Embodiment 2

[0040] 1) 100kg of cornstarch on a dry basis and 150kg of water were mixed at 60°C and homogeneously emulsified for 30 minutes to obtain a finely dispersed emulsion, and then 3% sodium carbonate was added to adjust the pH of the above emulsion to 10;

[0041] 2) 3kg of octenyl succinic anhydride is dissolved in 150kg of ethanol with a mass concentration of 85% to obtain an octenyl succinic anhydride solution;

[0042] 3) Add the emulsion obtained in step 1) into the octenyl succinic anhydride solution described in step 2) under 2000r / min stirring in the form of a spray, control the reaction temperature to 30°C, and react for 1 hour. After the reaction is completed, adjust the reaction with hydrochloric acid pH value of the solution to 6.5;

[0043] 4) quickly filter the reaction solution to obtain the product and the octenyl succinic anhydride raffinate, then use 30kg water, 30kg ethanol, and 30kg mass concentration as 83% ethanol to wash the product once respectively, and the...

Embodiment 3

[0046] 1) 100kg of dry wheat starch and 120kg of water were mixed and homogeneously emulsified at 40°C for 10 minutes to obtain a finely dispersed emulsion, and then 3% sodium hydroxide was added to adjust the pH value of the above emulsion to 9;

[0047] 2) 3kg octenyl succinic anhydride is dissolved in 120kg ethanol to obtain octenyl succinic anhydride solution;

[0048] 3) Add the emulsion obtained in step 1) into the octenyl succinic anhydride solution described in step 2) under 1500r / min stirring in the form of a spray, control the reaction temperature to 50°C, and react for 40 minutes. After the reaction is completed, adjust the reaction with hydrochloric acid pH value of the solution to 6;

[0049] 4) quickly filter the reaction solution to obtain the product and the octenyl succinic anhydride raffinate, then use 50kg water, 30kg ethanol, and 30kg mass concentration of 85% ethanol to wash the product once respectively, and the washing solution is filtered with octenyl s...

PUM

| Property | Measurement | Unit |

|---|---|---|

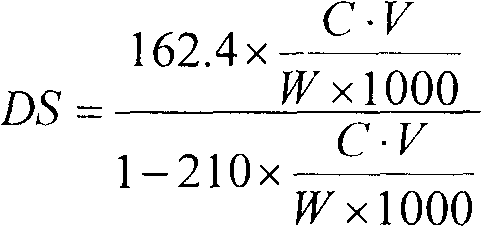

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com