Pd-based catalyst prepared through colloid deposition, preparation method and application

A catalyst and deposition technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high equipment and material requirements, high catalyst costs, and high product costs, and achieve high colloidal stability. The effect of good restoration effect and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

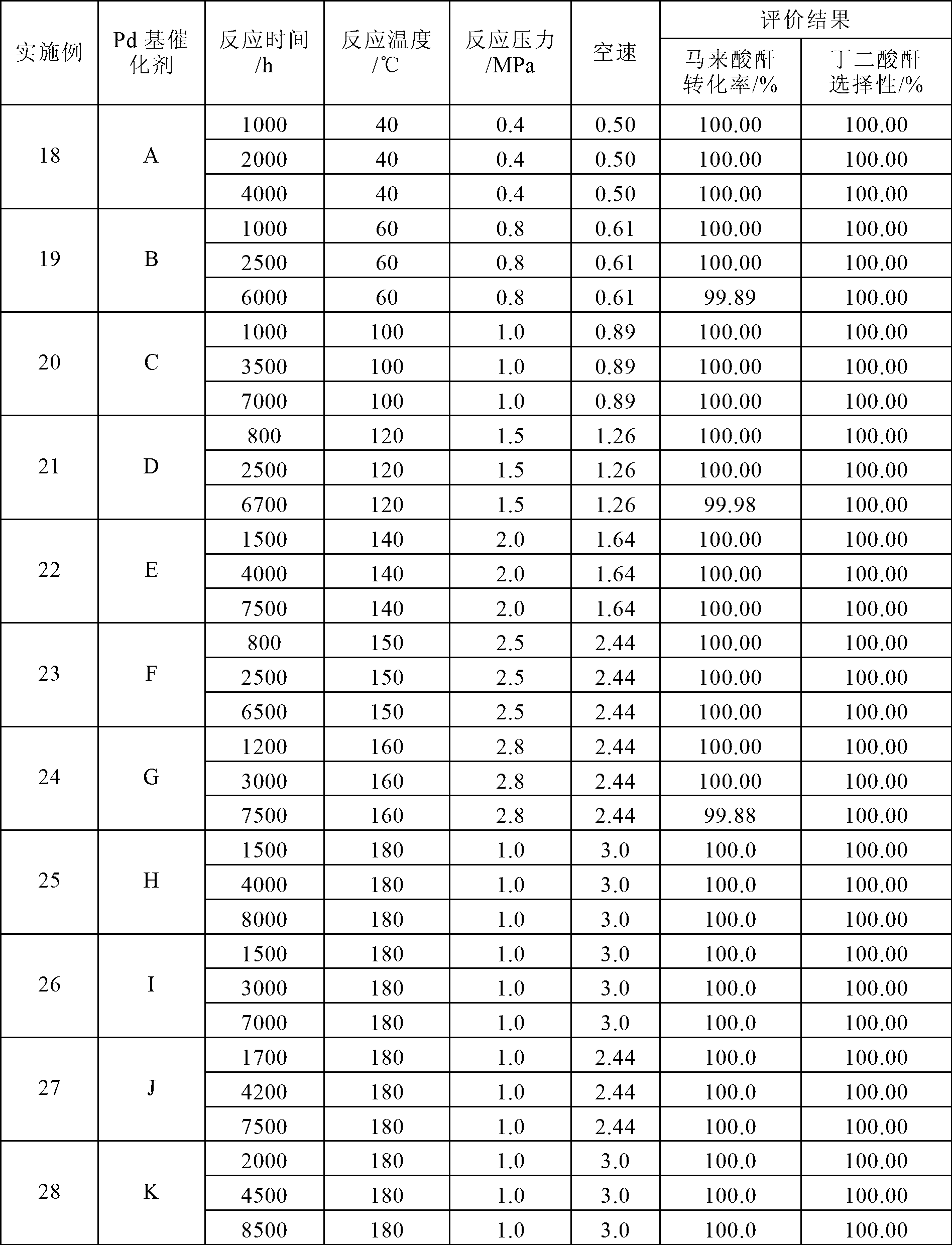

Examples

Embodiment 1

[0034] Weigh 0.3366g PdCl 2 And 0.5547g NaCl solid is dissolved in the ethylene glycol solution of 1155.17ml, prepares Pd salt solution. Add 2.8485g PVP to the Pd salt solution to obtain a mixed solution, which is stirred for 2h.

[0035] Prepare fresh 0.5M NaOH / ethylene glycol solution, pipette an accurate amount of 7.6ml into the above mixture, and immediately obtain a black colloidal solution, stir for 3 hours.

[0036]Add 20g Al to the above black colloidal solution 2 o 3 Carrier and 1780ml distilled water, stirred for 3h. Then put it in a water bath for 12 hours. After the water bath, the mixture was suction filtered and washed with distilled water until no Cl was detected. - until. The washed catalysts were dried at 100°C for 2h and then dried at 300°C 2 / Ar roasting 2h, 300℃H 2 / Ar mixed gas reduction for 2h, down to room temperature, that is, Pd-based catalyst A.

Embodiment 2

[0038] Weigh 0.3366g PdCl 2 And 0.5547g NaCl solid is dissolved in the ethylene glycol solution of 1155.17ml, prepares Pd salt solution. Weigh 0.1355g of copper chloride and 0.2045g of nickel chloride and dissolve them in the Pd salt solution, then add 2.8485g of PVP to obtain a mixed solution, and stir for 2h.

[0039] Prepare fresh 0.5M NaOH / ethylene glycol solution, pipette an accurate 7.6ml of fresh 0.5M NaOH / ethylene glycol solution dropwise into the above mixture, and immediately obtain a black colloidal solution, stir for 3 hours.

[0040] Add 9.7983g Al to the above black colloidal solution 2 o 3 Carrier and 1780ml distilled water, stirred for 3h. Then put it in a water bath for 12 hours. After the water bath, the mixture was suction filtered and washed with distilled water until no Cl was detected. - until. The washed catalysts were dried at 100°C for 2h and then dried at 300°C 2 / Ar roasting 2h, 300℃H 2 / Ar mixed gas reduction for 2h, down to room temperature...

Embodiment 3

[0042] Weigh 0.3366g PdCl 2 And 0.5547g NaCl solid is dissolved in the ethylene glycol solution of 1155.17ml, prepares Pd salt solution. Weigh 0.1056g of chloroauric acid and dissolve it in the Pd salt solution. Then 2.8485g of PVP was added to obtain a mixed liquid, which was stirred for 2h.

[0043] Prepare fresh 0.5M NaOH / ethylene glycol solution, pipette an accurate amount of 7.6ml into the above mixture, and immediately obtain a black colloidal solution, stir for 3 hours.

[0044] Add 9.8488g apricot kernel charcoal carrier and 1780ml distilled water to the above black colloidal solution, and stir for 3h. Then put it in a water bath for 12 hours. After the water bath, the mixture was suction filtered and washed with distilled water until no Cl was detected. - until. The washed catalysts were dried at 100°C for 2h and then dried at 300°C 2 / Ar roasting 2h, 300℃H 2 / Ar mixed gas for 2h, then lowered to room temperature to obtain Pd-based catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com