Formula for temperature-sensing rubber sneaker sole and manufacturing method thereof

A manufacturing method and technology of sports shoes, applied in the direction of soles, footwear, footwear, etc., can solve problems such as failure of anti-slip performance, and achieve the effects of outstanding anti-slip performance, better anti-slip effect, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of oil-resistant rubber outsole of the present invention comprises the following steps:

[0029] 1) Material weighing

[0030] Weigh accurately according to the mass percentage of the formula in Table 1. Weigh BR01, BX2G66, S2250 and RH-100AN together; weigh ZC-185, ST, ZnO, CPL, G-34, PEG4000, P-10, 669, SKA pounds are easy to put together; sulfur and accelerators will be weighed later when dosing.

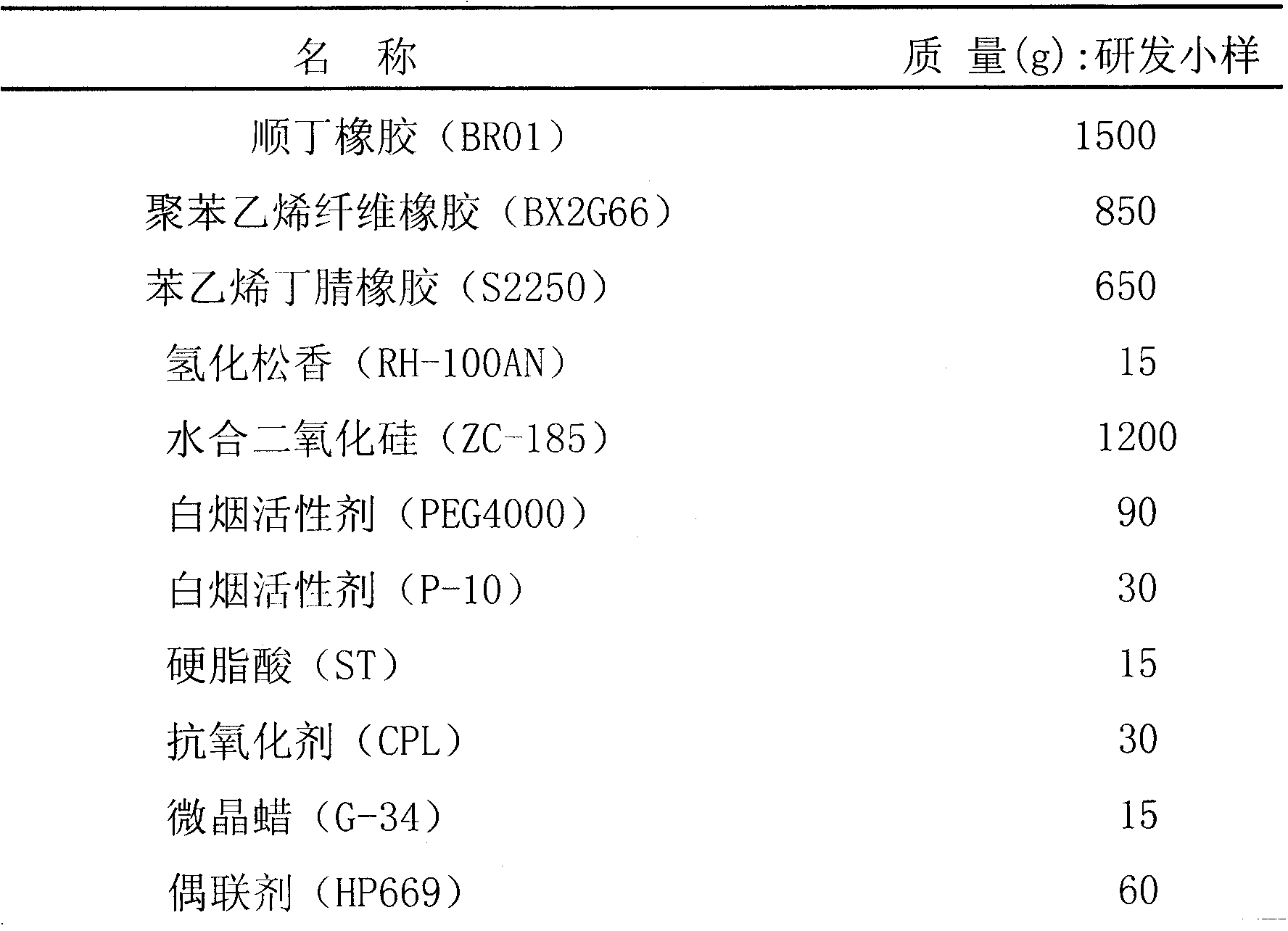

[0031] Table 1

[0032]

[0033]

[0034] 2) Banbury

[0035] Mix the rubber main ingredients and tackifier raw materials together, put them into the internal mixer for internal mixing, start the internal mixing and mix evenly, after 2 minutes, add 1 / 3 of the precipitated hydrated silica, and continue the internal mixing, the rubber and precipitation Mix the hydrated silica and re-agglomerate. When the temperature reaches 100°C, add the remaining 2 / 3 precipitated hydrated silica, wear-resistant agent and all additives until the...

Embodiment 2

[0043] Embodiment 2: On the basis of Embodiment 1, the wear resistance is adjusted, and its raw material composition is shown in Table 2.

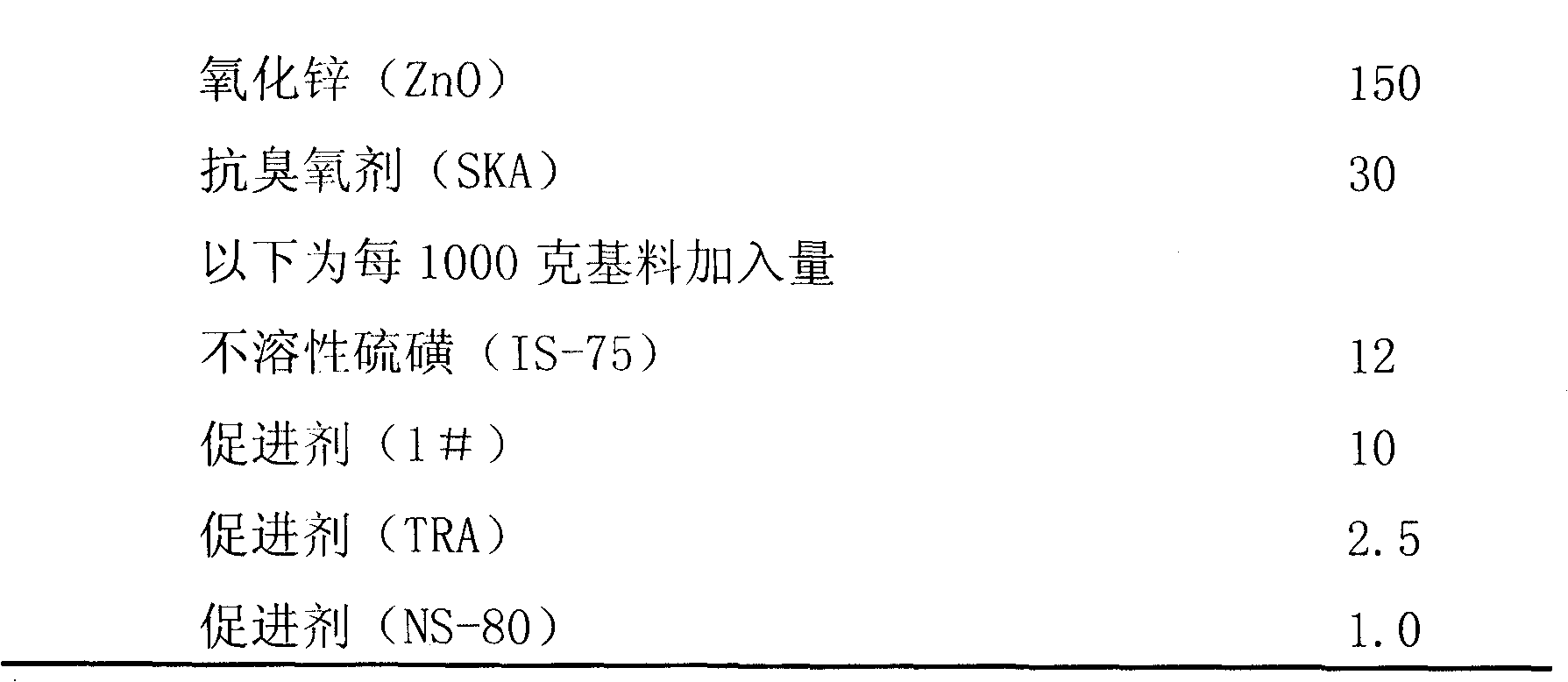

[0044] Table 2

[0045]

[0046]

Embodiment 3

[0047] Embodiment 3: The wear resistance of Embodiment 2 is better than that of Embodiment 1, but it is still unqualified, and the adjusted formula is shown in Table 3.

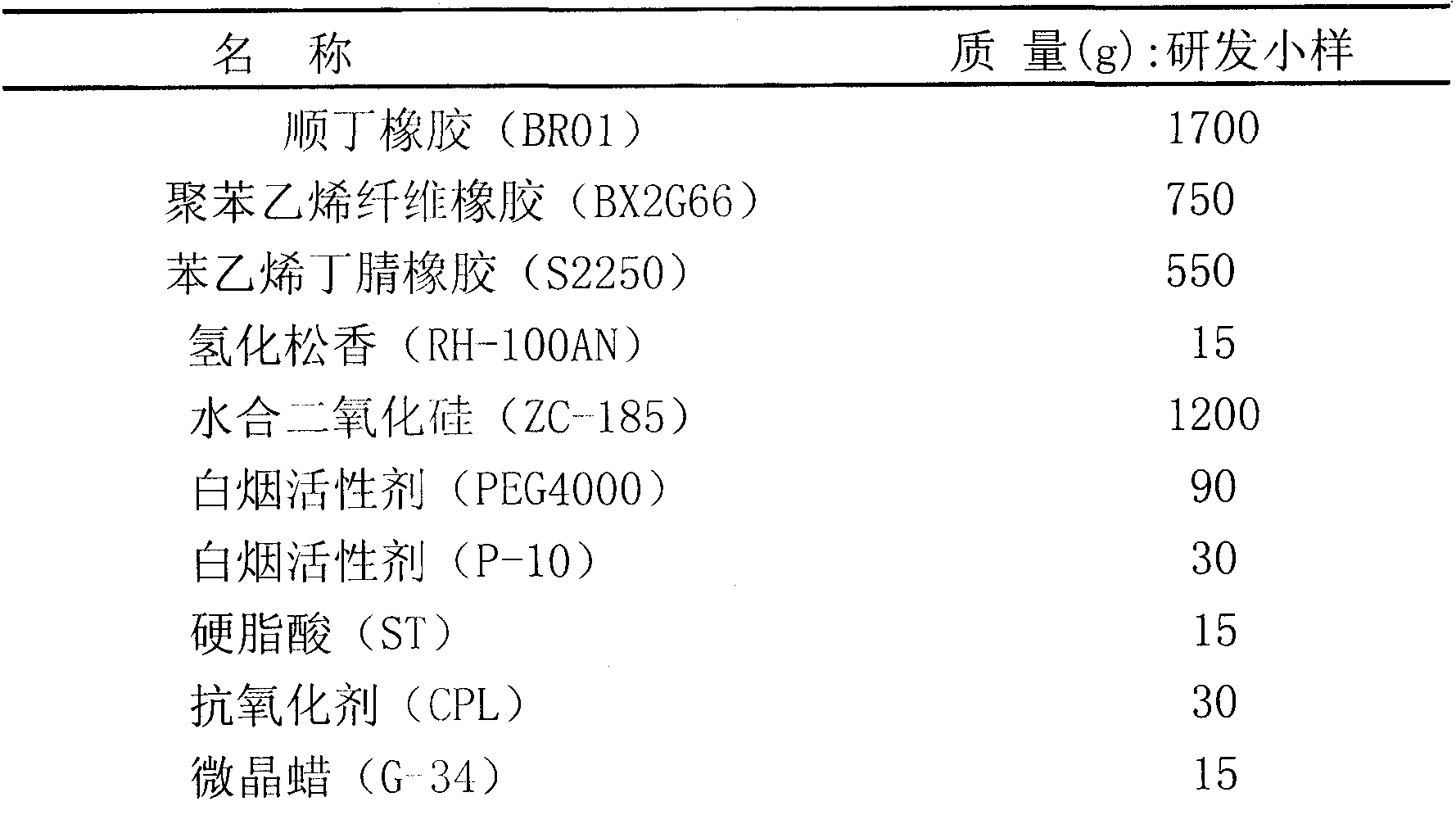

[0048] table 3

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com