Manhole cover assembly

A component and manhole cover technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of large force at the junction, troublesome operation, difficulties, etc., to facilitate manufacturing and on-site installation, avoid well seat displacement, The effect of solving the settlement problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

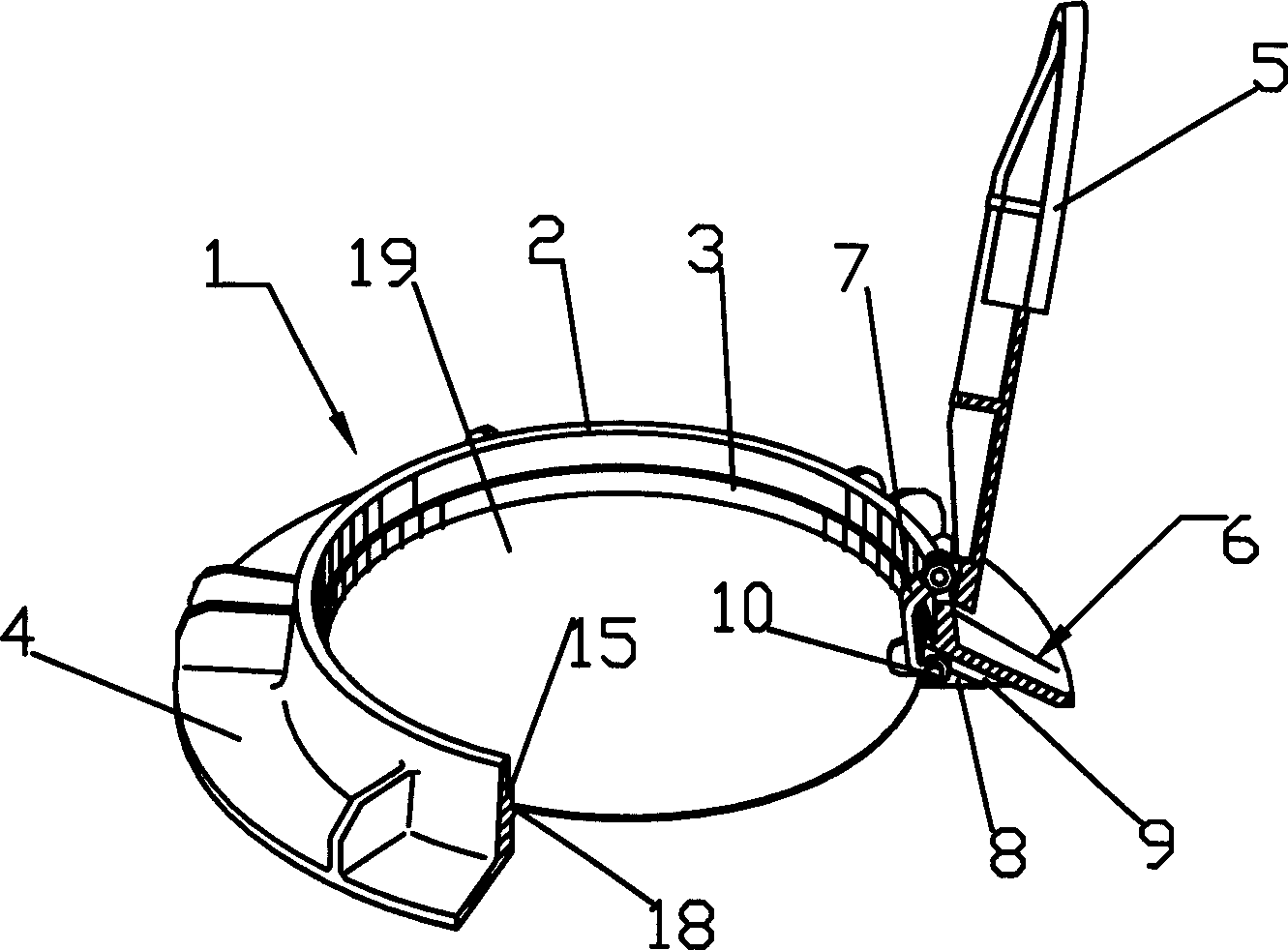

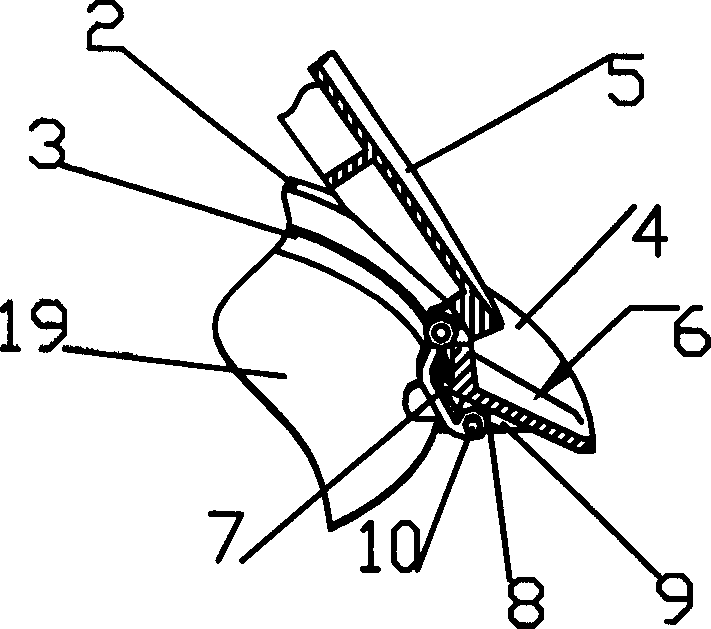

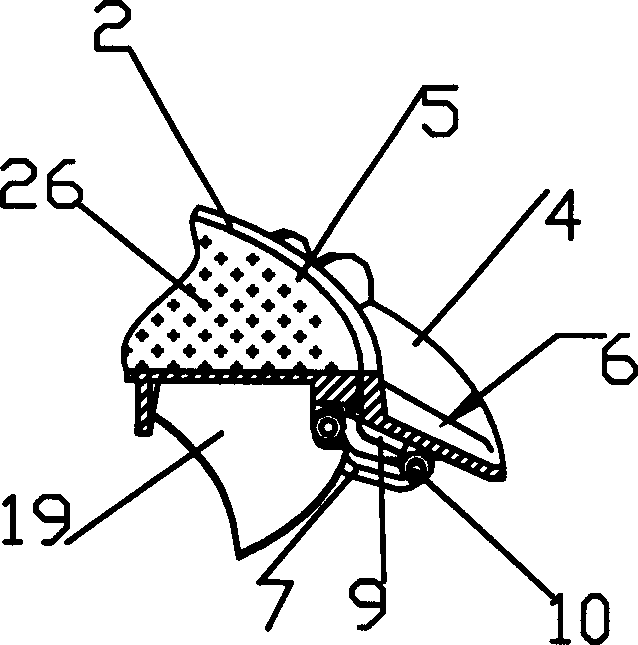

[0032] figure 1 Shown is the first embodiment of the present invention, wherein the manhole cover assembly of the present invention comprises a well circle seat 1, has on said well circle seat 1 an annular well circle seat outer ring opening 2 whose axis is substantially perpendicular to the ground , the manhole cover support platform 3 that protrudes radially inward from the inner wall of the outer ring mouth 2 of the well ring seat substantially perpendicular to its axis and extends radially outward from the lower edge of the outer ring mouth 2 of the well ring seat and a manhole cover 5 matched with the manhole cover support platform 3 and the outer ring mouth of the well ring seat; a slideway structure 6 is set below the manhole cover support platform 3, and a connecting One end of the rod 7 is limited in the slideway structure 6 and can slide therein, and the other end of the connecting rod 7 is hinged to the well cover plate 5 . The connecting rod 7 has an arcuate shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com