Part fixed clamping device for mechanical arm production

A technology for fixing clamping and parts, applied in workpiece clamping devices, metal processing machinery parts, positioning devices, etc., which can solve the problems of inability to adjust the height and angle of the clamping device, inconvenience, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

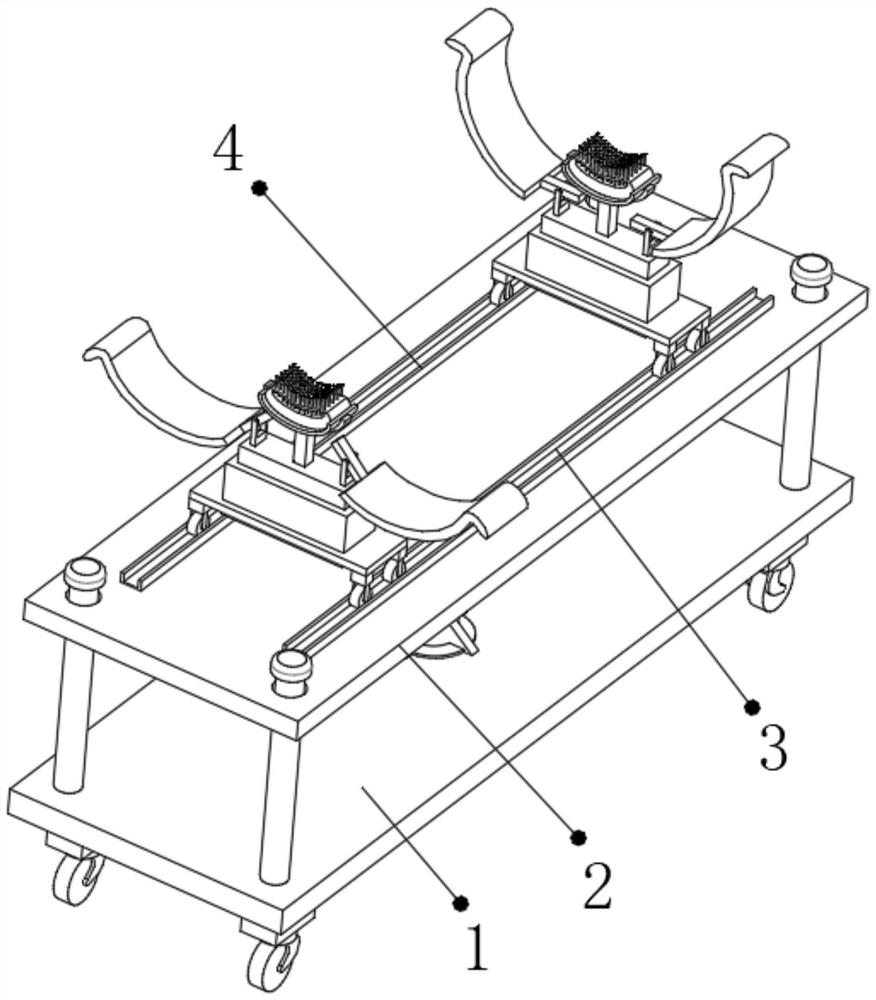

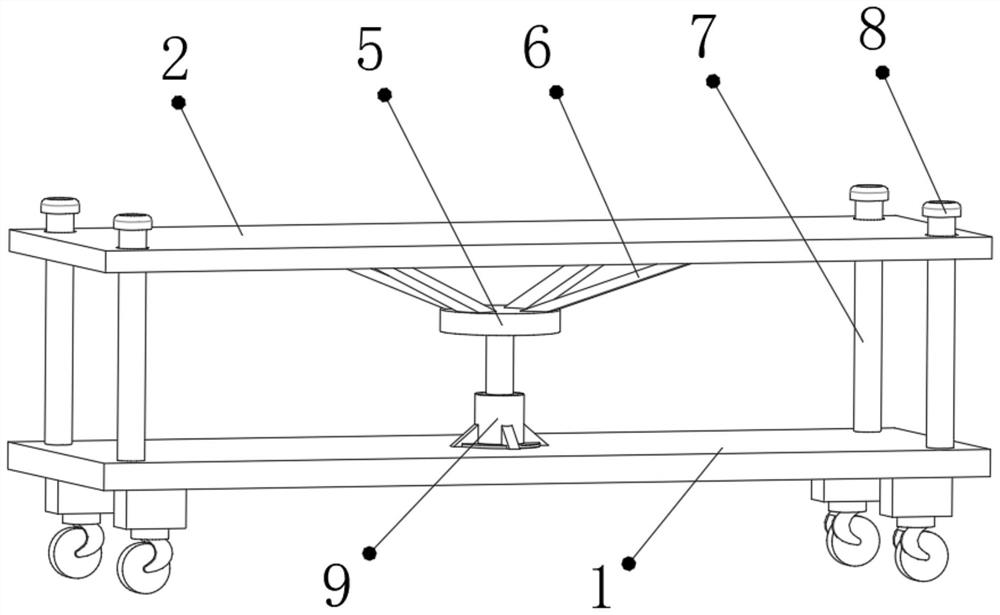

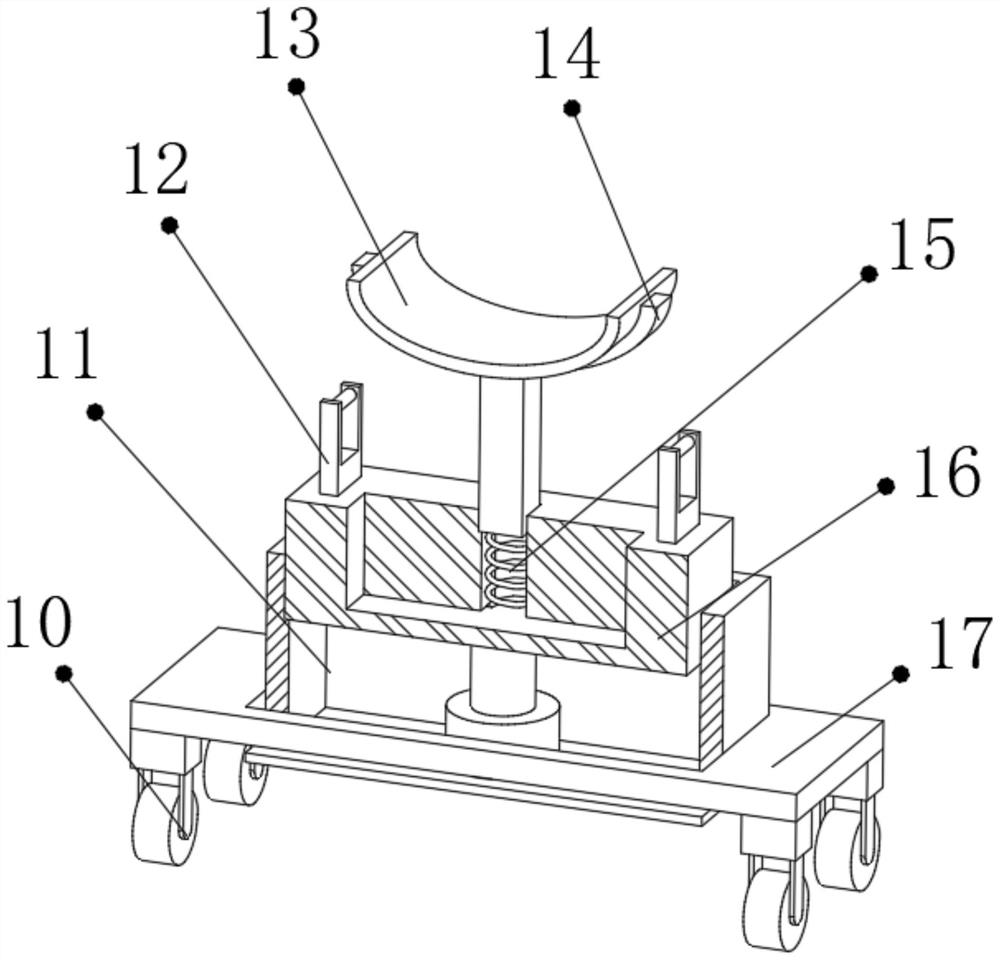

[0029] refer to Figure 1-4 , a kind of fixed and clamping device for mechanical arm production parts, including an operation table 2, the top outer wall of the operation table 2 is connected with a symmetrically distributed first slide rail 3 and a second slide rail 4 by bolts, and the first slide rail 3 Consistent with the size and type of the second slide rail 4, the inner wall of the first slide rail 3 and the second slide rail 4 is rollingly connected to the width adjustment mechanism, and the top outer wall of the width adjustment mechanism is connected with a height adjustment box 11 by bolts, and the height adjustment box 11 There is a cavity on the top outer wall of the cavity, and the inner wall of the cavity is slidably connected with the connection box 16, and the bottom inner wall of the height adjustment box 11 is connected with an electric telescopic rod through bolts, and one end of the output shaft of the electric telescopic rod is connected to the bottom outer...

Embodiment 2

[0033] refer to Figure 5, a kind of mechanical arm production parts fixing and clamping device. Compared with Embodiment 1, the top outer wall of the clamping plate 18 is welded with a bar-shaped magnet block 21 at the corner, and the top outer wall of the clamping plate 18 is welded There are multiple anti-slip protrusions 22.

[0034] Working principle: when in use, start the hydraulic lever 9 according to the actual situation of the use environment, and adjust the height of the console 2. There are a pair of height adjustment boxes 11 and other components on the console 2. When the small parts are placed on the clamping frame 13, the clamping plate 18 cannot be pried up due to the small gravity, and the parts are in contact with the clamping column 20, and are absorbed by the ball spring, elastic The pad 19 is depressed inward under the extrusion of gravity, so that the clamping column 20 can wrap the parts and "hold" the parts like a palm, and the large parts can be lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com