Novel high-performance high-polymer mixed material for steel-wire-wound hydraulic rubber tubes

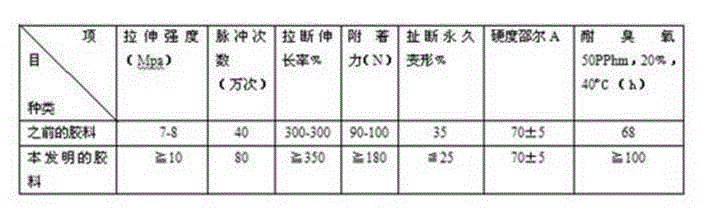

A technology of steel wire winding and mixed materials, applied in the direction of pipes, pipes/pipe joints/fittings, hoses, etc., can solve the problems of non-sticking of the outer glue, bubbling, poor pulse performance of hydraulic hoses, etc., to increase the number of pulses, prolong the Longer service life and improved appearance of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] High-performance steel wire entangled liquid pressure gel tube new type of polymer hybrid material, consists of raw materials of the following weights: Ding Zhe 6420 15-20 copies, alloy PVC 35-40 copies, chlorine polyethylene CM352F 30-40, zinc oxide 1.5-2 parts, 8-10 parts of magnesium oxide, 1-1.5 parts of anti-aging agent, 10-15 parts of silicon dioxide, 50-60 copies of carbon black, 2-4 anti-oxygen agents, 25-35 copies of light calcium, 30-two sink fat 30-40 copies, sulfur 1-1.5 servings, promoter CBS 0.5-1, sulfurizer P1682 2-3 parts; the antioxidant of the oxygen is a microcrystalline wax B10; the carbon black is N330 charcoal;The aging agent is n, n-di-butyl sulfuric amin nickela.

[0011] The present invention presses the steps for preparation: Take the materials according to the weight, put it in a secret refining machine, 100OC-110 OC temperature conditions, mix 8min-12min, mixed with sulfur and mixedEssenceThen refine and press it, and formed in 150 OC's vulcaniz...

Embodiment 2

[0013] In this embodiment, the following raw materials are called: Dingya 642015kg, alloy PVC 35kg, chlorine polyethylene CM352F 30 kg, zinc oxide 1.5 kg, magnesium oxide 8kg, n-d-d-d-d-d-d-d-d -l nickel nickel nickel nickel 1KG, Silicon 10 KG, N330 charcoal black 50 kg, microcrystalline wax B102 KG, light calcium 25 kg, two sulfur 1 kg, sulfur 1 kg, promoter CBS 0.5 kg, sulfur P1682 2 kg.

[0014] Place the good materials in the secret refinery, under the temperature conditions of 100OC, mix 8min for 8 minutes, mix the mixed sulfur and mix, park and park for more than 12h.Then refine and press it, and formed in 150 OC's vulcanization for 40 minutes, that is, the steel wire hydraulic gum pipe is used for a new type of polymer mixed material for the outer gum.

Embodiment 3

[0016] In this embodiment, the following raw materials are called: Ding Zhe 642017.5kg, alloy PVC 37.5kg, chlorine polyethylene CM352F 35 kg, zinc oxide 1.75 kg, magnesium oxide 9kg, n-dicotyl aminosulfenate aminicate acid acidNickel 1.25 kg, silicon 12.5 kg, N330 charcoal black 55 kg, microcrystalline wax B103 kg, light calcium 30 kg, two sulfur 35kg, sulfur 1.25 kg, promoter CBS 0.75 kg, sulfur P1682 2.5 kg.

[0017] Place the good materials in the secret refinery, under 101OC temperature conditions, mix 9 minutes, mix the mixed sulfur and park, park and park more than 12h.Then refine and press it, and formed in 150 OC's vulcanization for 40 minutes, that is, the steel wire hydraulic gum pipe is used for a new type of polymer mixed material for the outer gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com