Side rubber of aircraft tire

A technology for aviation tires and sidewall rubber, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of carcass elongation performance decline, etc., achieve good heat resistance, high tear performance, and good processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

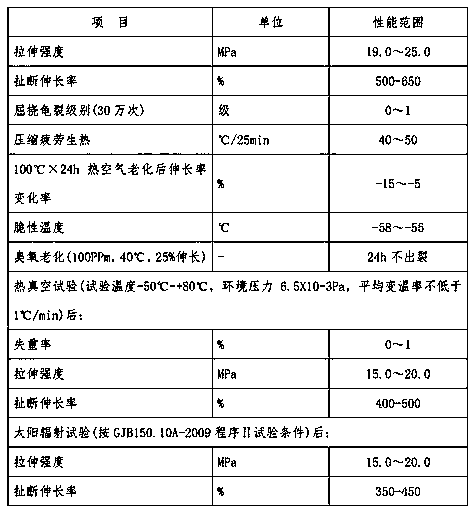

[0040] The present invention will be described in detail below with three examples of aircraft tire sidewall rubber prepared in different proportions. The ratio of raw materials in each embodiment is shown in the table below. The modified N330 carbon black in the list is a modified N330 carbon black sold by Xinjiang Junxin Chemical Co., Ltd.

[0041] .

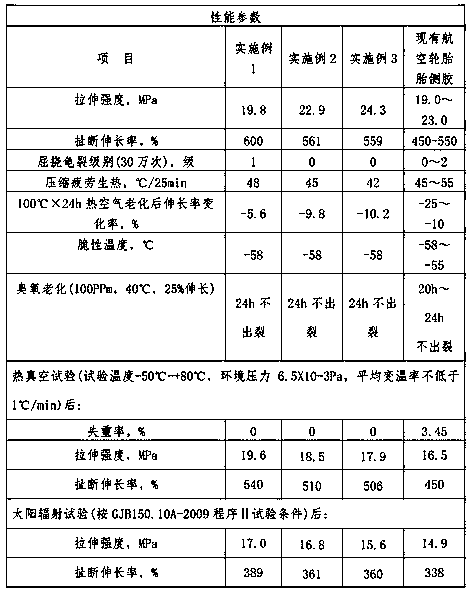

[0042] The performance parameters of the aviation tire sidewall rubber obtained in the above embodiments are compared with the aviation tire sidewall rubber of the prior art through testing. , has the advantages of small weight loss rate in thermal vacuum environment, good heat resistance and radiation resistance, and at the same time has good flex cracking resistance, low heat generation, high elongation at break and tensile strength, brittleness Low temperature performance characteristics. See table below.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com