Flame-retardant composite rubber material capable of resisting high-concentration ozone and preparation method thereof

A flame-retardant composite and rubber material technology, applied in the field of rubber materials, can solve the problems of high-concentration ozone resistance and poor flame-retardant performance, improve process performance and mechanical properties, improve heat aging resistance and flame-retardant performance , the effect of weak elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 provides a flame-retardant composite rubber material resistant to high-concentration ozone, which is prepared by the following method:

[0050] (1) Weigh 65 parts of EPDM rubber, 35 parts of chlorosulfonated polyethylene, 50 parts of reinforcing agent, 35 parts of flame retardant material, 10 parts of paraffin oil, 8 parts of antiozonant, 5 parts of zinc oxide in proportion by weight parts, 3 parts of magnesium oxide, 0.5 parts of stearic acid, 2.5 parts of processing aids, 3.2 parts of vulcanizing agents, 2 parts of pigments, and 1.2 parts of crosslinking additives; among them, the antiozonant is antiaging agent AFS and microcrystalline wax by mass A mixture with a ratio of 1:9, the reinforcing agent is a mixture of white carbon black and barium sulfate in a mass ratio of 4:1, and the flame retardant material is a mixture of antimony trioxide and decabromodiphenylethane in a mass ratio of 1:3 Composite flame retardant, the processing aid is WB42, the vulca...

Embodiment 2-6

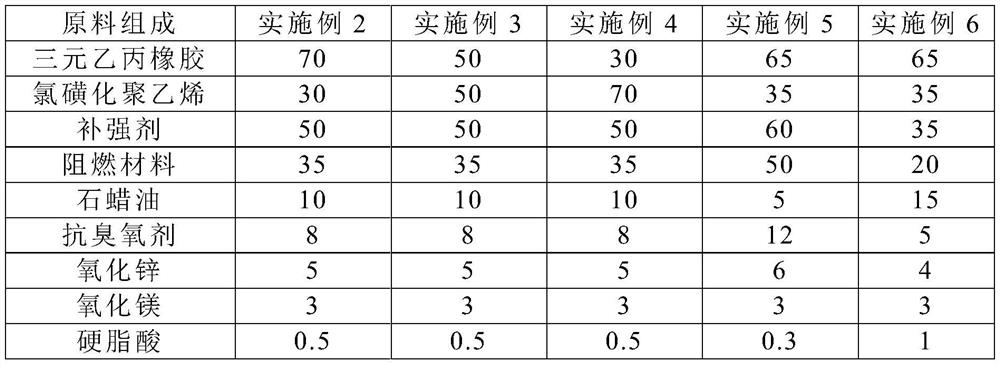

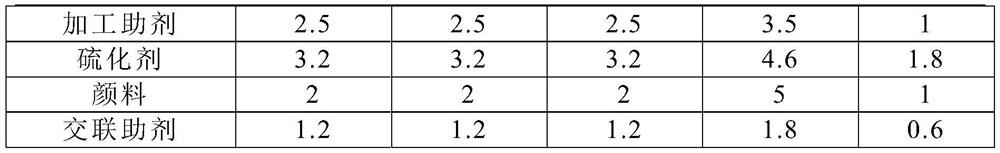

[0057] The difference between the flame-retardant composite rubber material against high-concentration ozone provided by Examples 2-6 and Example 1 is only that the proportioning of raw material components is different, and the preparation method is the same as that of Example 1, and the proportioning of raw materials in Examples 2-6 is as follows: Shown in table 1; Wherein, reinforcing agent, antiozonant, flame retardant material, processing aid, vulcanizing agent, pigment, crosslinking auxiliary agent are all identical with embodiment 1.

[0058] Raw material composition and parts by weight of flame-retardant composite rubber material in Table 1 embodiment 2-6

[0059]

[0060]

Embodiment 7

[0062] The high-concentration ozone-resistant flame-retardant composite rubber material provided in Example 7 differs from Example 1 only in that the reinforcing agent in the raw material is a single reinforcing agent of white carbon black, and the other components and preparation methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com