Environment-friendly corrosion-resistant epichlorohydrin rubber

A kind of epichlorohydrin rubber, corrosion-resistant technology, applied in the field of rubber, can solve the problems of cost increase and other problems, and achieve the effect of reduced contact, good flexibility, crystallization and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

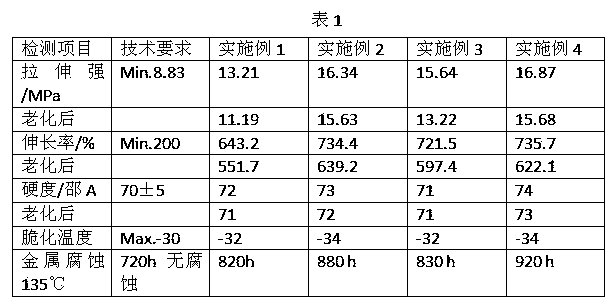

Examples

Embodiment 1

[0047] An environment-friendly and corrosion-resistant epichlorohydrin rubber, consisting of the following components by weight:

[0048] Chlorine ether rubber 50 parts

[0049] Silicon dioxide 10 parts

[0050] Quickly extrude carbon black 20 parts

[0051] 1 part microcrystalline wax

[0052] Vulcanizing agent PDM 0.5 parts

[0053] 0.5 parts of stearic acid

Embodiment 2

[0057] An environment-friendly and corrosion-resistant epichlorohydrin rubber, consisting of the following components by weight:

[0058] Chlorine ether rubber 75 parts

[0059] Silica 12 parts

[0060] Quickly squeeze out 25 parts of carbon black

[0061] Microcrystalline wax 2 parts

[0062] Vulcanizing agent PDM 1.0 parts

[0063] Stearic acid 1.0 parts

Embodiment 3

[0067] An environment-friendly and corrosion-resistant epichlorohydrin rubber, consisting of the following components by weight:

[0068] Chlorine ether rubber 80 parts

[0069] Silicon dioxide 15 parts

[0070] Quickly squeeze out 30 parts of carbon black

[0071] Microcrystalline wax 5 parts

[0072] Vulcanizing agent PDM 1.5 parts

[0073] 1.5 parts of stearic acid

[0074] Magnesium oxide 5 parts

[0075] 3 parts calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com