Graphene composite damping rubber material and preparation method thereof

A graphene composite and shock-absorbing rubber technology, which is applied in the field of rubber materials, can solve problems such as shortened service life of shock-absorbing parts, and achieve good elasticity, good fatigue resistance, and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

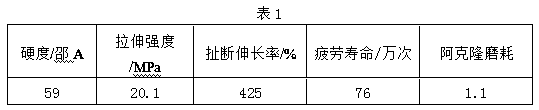

Embodiment 1

[0036] The formula selects 75g natural rubber, 15g high vinyl polybutadiene rubber, 10g neoprene rubber, 5g nano-zinc oxide, 15g N990 carbon black, 20g DZ-13 carbon black, 10g N220 carbon black, 1 part stearic acid, anti-aging Agent MB 1.5g, antioxidant 4020 1.5g, coupling agent 2 parts, graphene 0.4g, insoluble sulfur 0.8g, accelerator BZ 1g, accelerator DTDM 1.5g, accelerator TRA 0.5g, accelerator DM 0.8g.

[0037] a. Preparation of graphene premix: After nano-zinc oxide 5g and graphene 0.4g are treated with coupling agent according to the same mass fraction, add 10g chloroprene rubber on the open mill, keep the roller distance 0.1mm, and the roller temperature Keep at 25~40℃, thin pass 6-8 times;

[0038] b. Internal mixing and blending of natural rubber and high vinyl polybutadiene rubber: Mix natural rubber and high vinyl polybutadiene in an internal mixer according to the formula ratio, and control the mixing temperature at 110~120°C. The time is 5~6 minutes; then thin ...

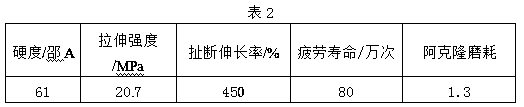

Embodiment 2

[0044] The formula selects 80g natural rubber, 12.5g high vinyl polybutadiene rubber, 7.5g neoprene, 6.5g nano-zinc oxide, 25g N990 carbon black, 15g DZ-13 carbon black, 15g N220 carbon black, 1.2 stearic acid parts, antioxidant MB 1.5g, antioxidant 4020 1.5g, coupling agent 2.5 parts, graphene 0.6g, insoluble sulfur 1.2g, accelerator BZ 0.8g, accelerator DTDM 1.3g, accelerator TRA 0.4g, accelerator DM 0.9g.

[0045] a. The preparation of graphene premix: nano-zinc oxide 6.5g and graphene 0.6g are treated with coupling agent according to the same mass fraction, and then added to 7.5g chloroprene rubber on the open mill, keeping the roll distance 0.1mm, The temperature of the roller is kept at 25~40℃, thin pass 6-8 times;

[0046] b. Internal mixing and blending of natural rubber and high vinyl polybutadiene rubber: Mix natural rubber and high vinyl polybutadiene in an internal mixer according to the formula ratio, and control the mixing temperature at 110~120°C. The time is ...

Embodiment 3

[0052] The formula selects 85g natural rubber, 10g high vinyl polybutadiene rubber, 5g neoprene rubber, 8g nano-zinc oxide, 30g N990 carbon black, 10g DZ-13 carbon black, 20g N220 carbon black, 1.5 parts of stearic acid, anti-aging Agent MB 1.5g, antioxidant 4020 2g, coupling agent 3 parts, graphene 0.75g, insoluble sulfur 1.5g, accelerator BZ 0.5g, accelerator DTDM 1.2g, accelerator TRA0.3g, accelerator DM 1g.

[0053] a. Preparation of graphene premix: After nano-zinc oxide 8g and graphene 0.75g are treated with coupling agent according to the same mass fraction, add 5g chloroprene rubber on the open mill, keep the roller distance 0.1mm, and the roller temperature Keep at 25~40℃, thin pass 6-8 times;

[0054] b. Internal mixing and blending of natural rubber and high vinyl polybutadiene rubber: Mix natural rubber and high vinyl polybutadiene in an internal mixer according to the formula ratio, and control the mixing temperature at 110~120°C. The time is 5~6 minutes; then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com