Non-magnetic temperature control system of solid-state atomic spin sensor

A technology of atomic spin and temperature control system, applied in the field of quantum sensing, can solve the problems of atomic coherence fluctuation and test sensitivity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

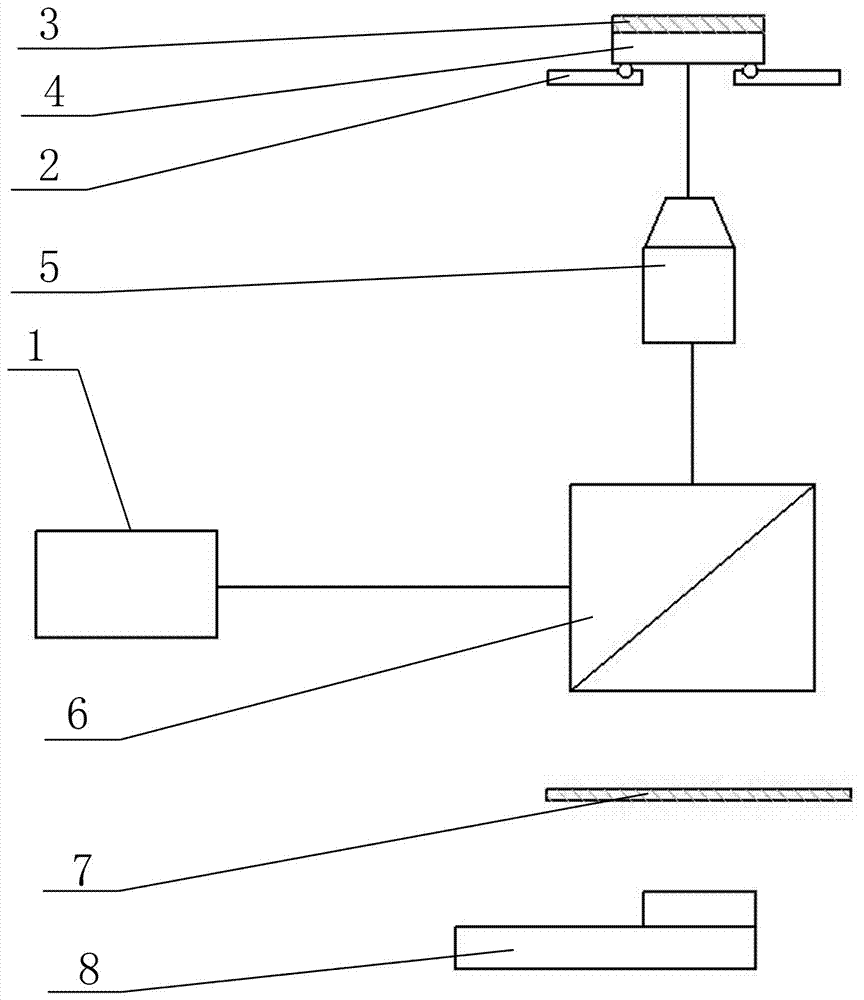

[0014] A non-magnetic temperature control system for a solid-state atomic spin sensor, comprising a diamond substrate on which a diamond NV color center waveguide 4 is processed, and the diamond substrate is provided with a porous hole covering the diamond NV color center waveguide 4 Magnetic PDMS film 3, microstrip antenna array 2 is processed on both sides of the lower surface of the diamond substrate, and the microstrip antenna array 2 is connected to a microwave source; an objective lens 5 is arranged below the diamond substrate, and an objective lens 5 is arranged below the objective lens 5 There is a beam splitter 6, a long-wave pass filter 7 is arranged below the beam splitter 6, and a photodiode 8 is arranged below the long-wave pass filter 7; the beam splitter 6 receives pulsed laser light from the laser 1 and passes through the object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com