Patents

Literature

76results about How to "Short travel distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

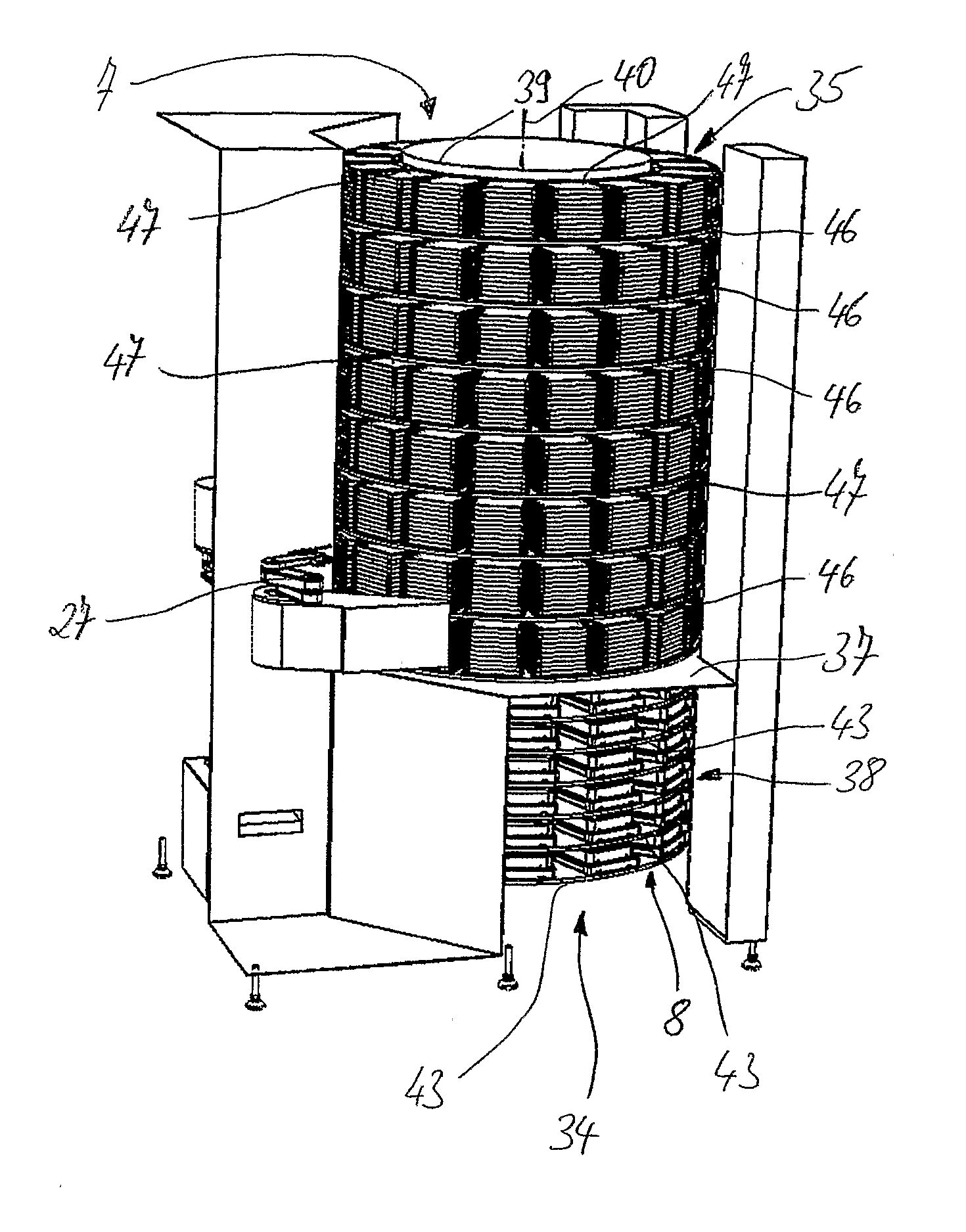

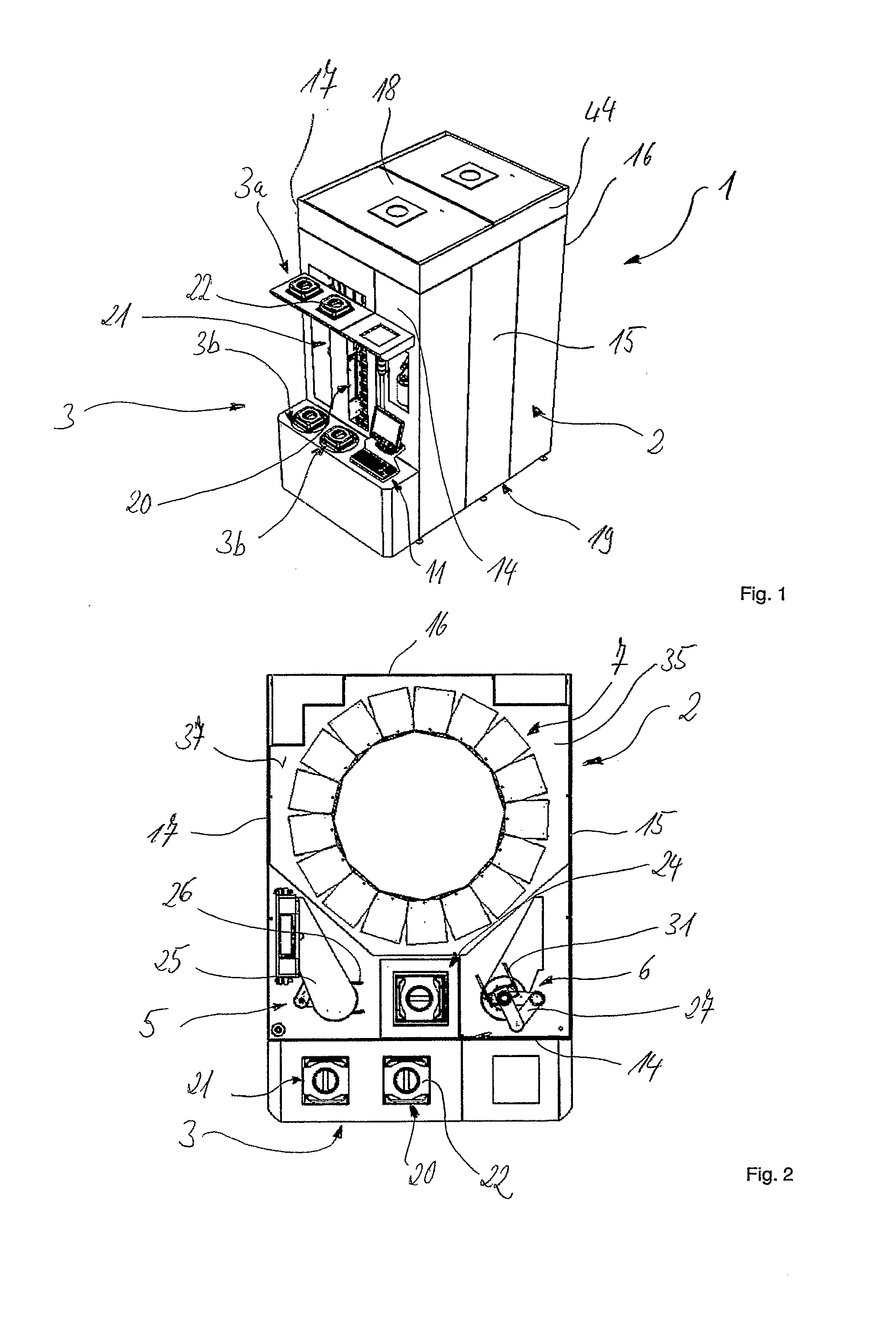

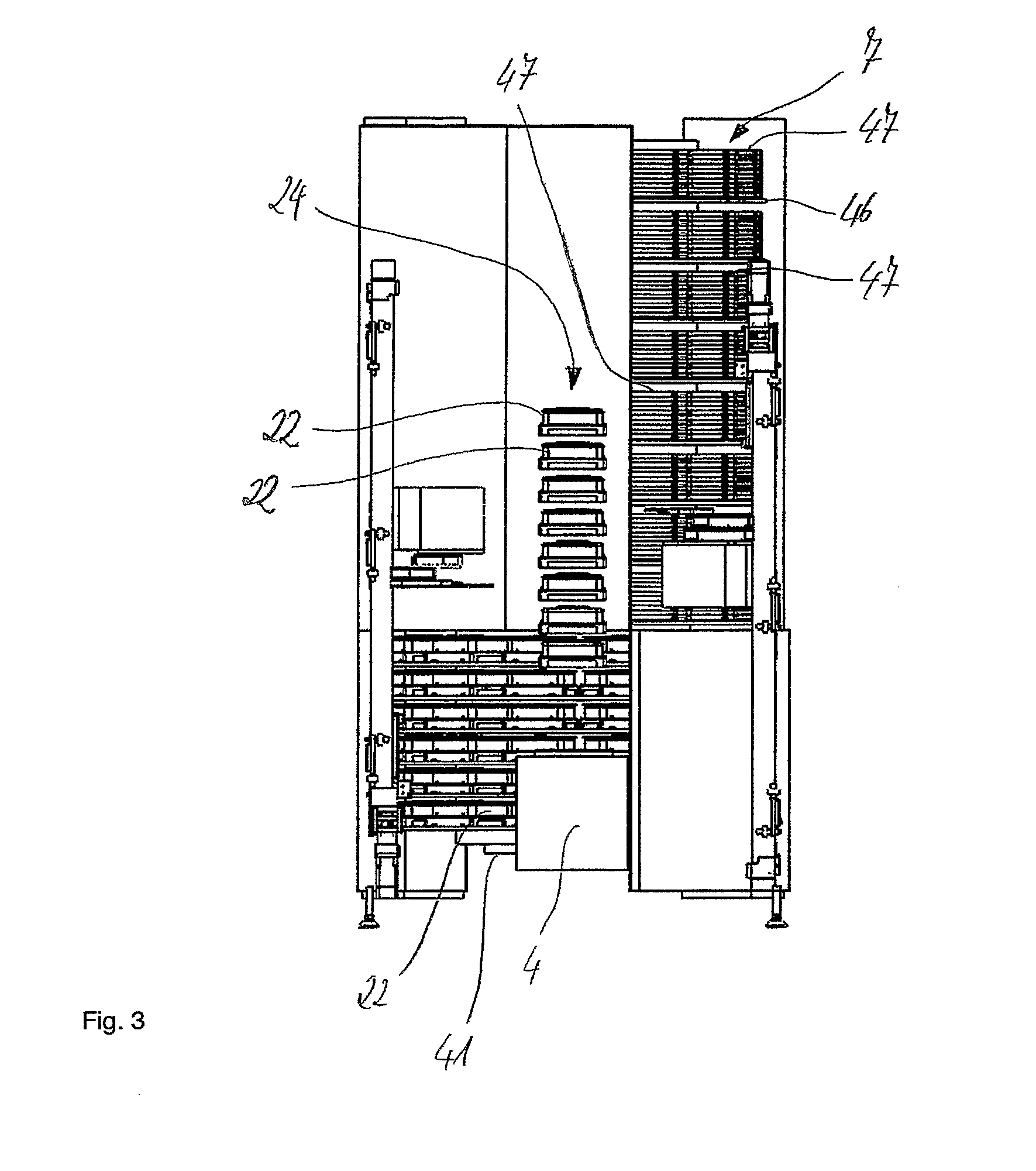

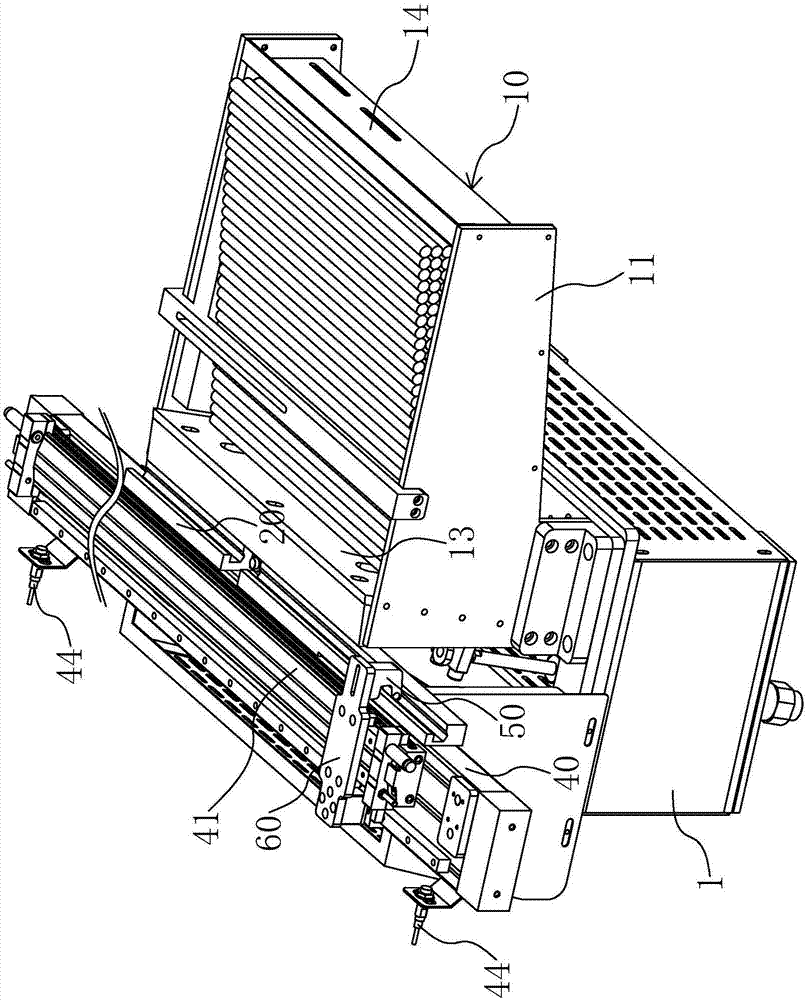

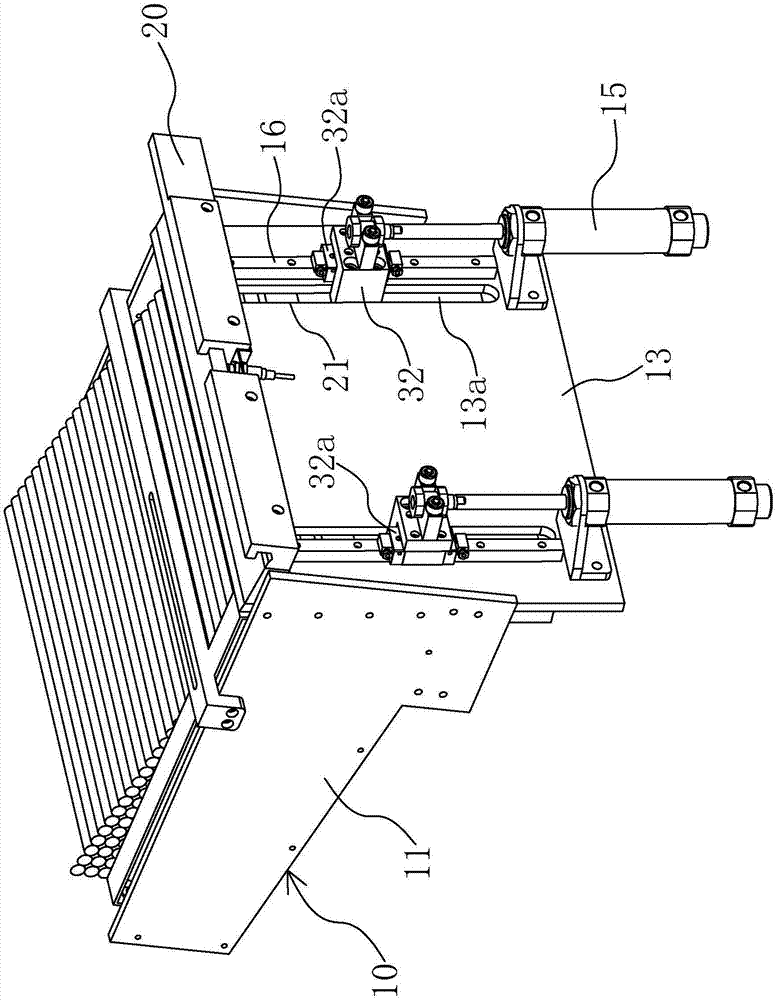

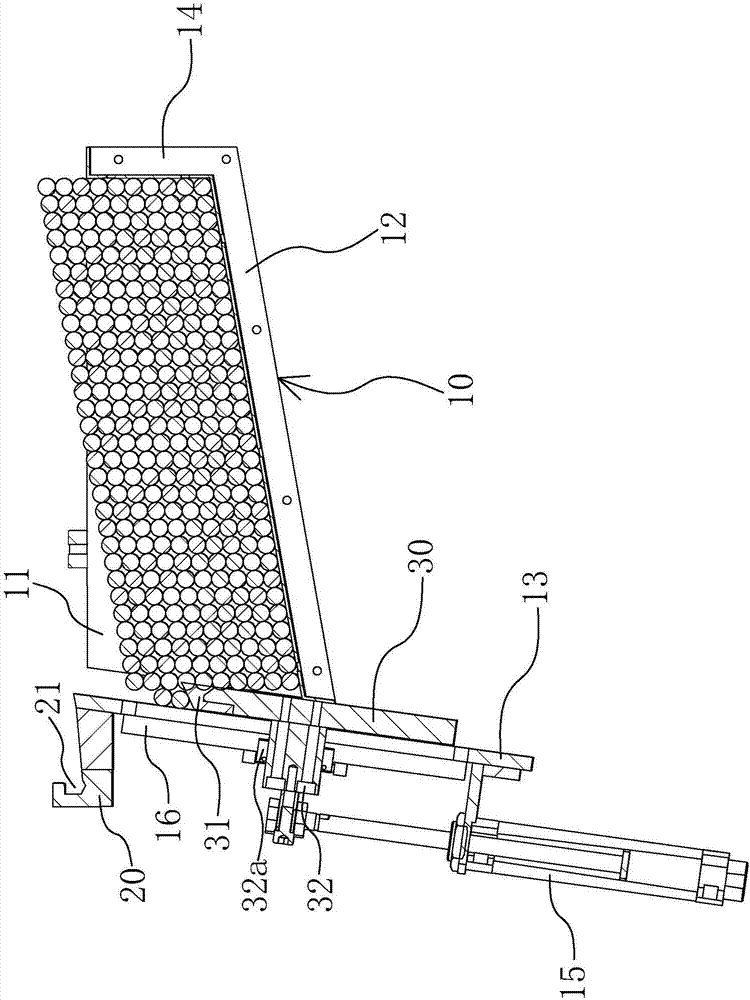

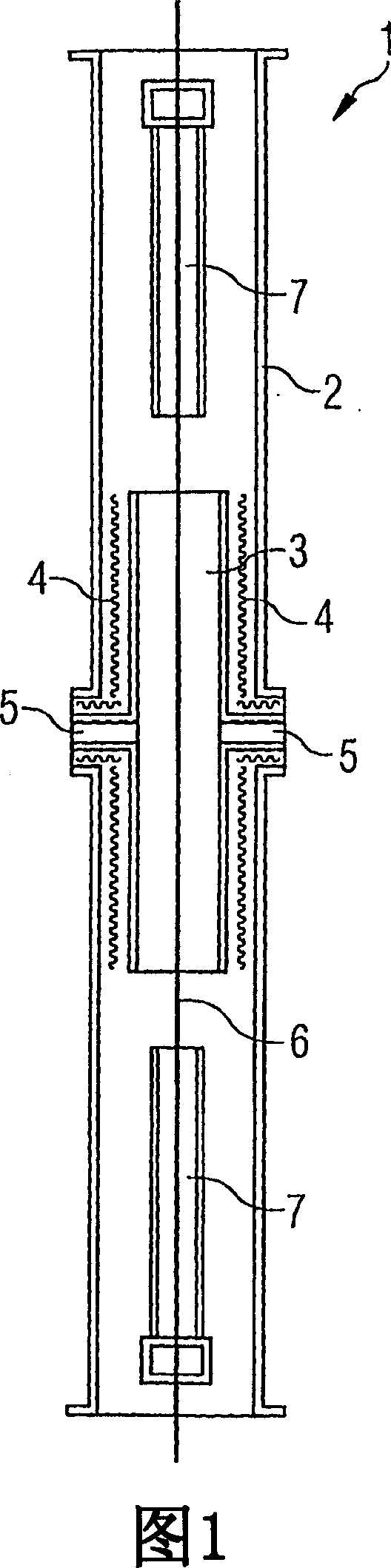

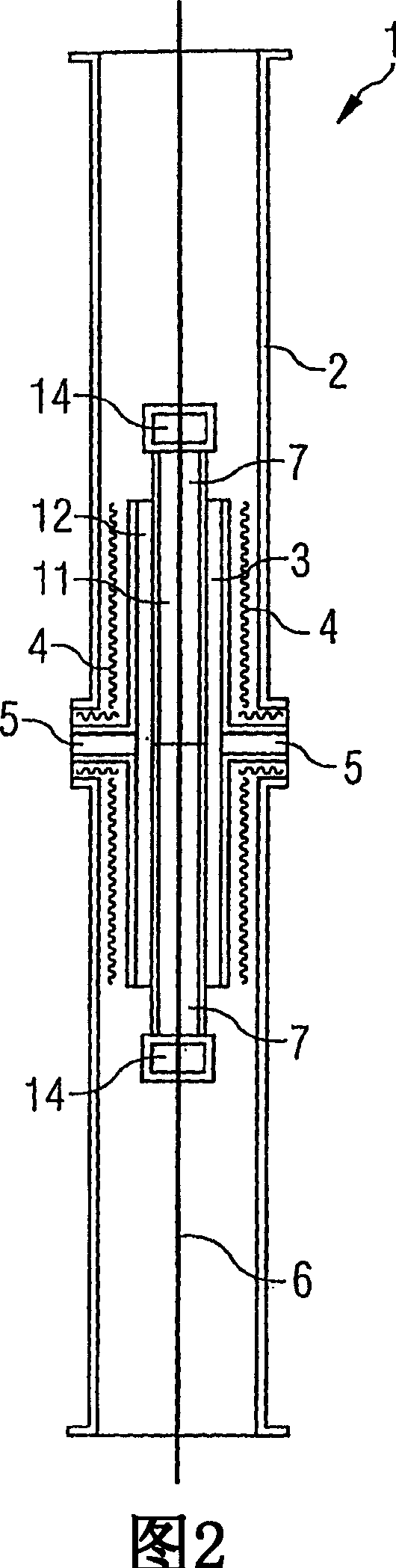

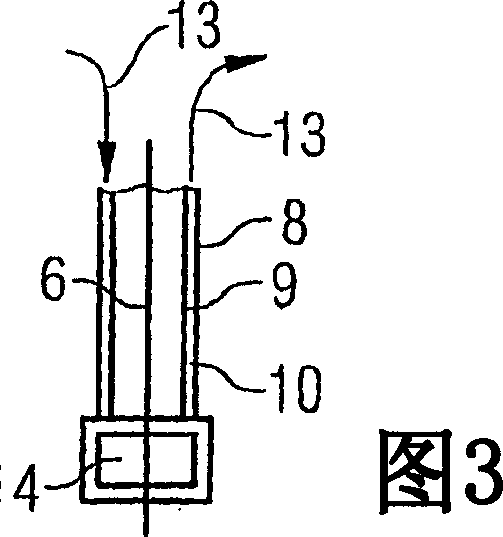

Apparatus for storage of objects from the field of manufacture of electronic components

ActiveUS20120027547A1Avoid pollutionFew stepsSemiconductor/solid-state device manufacturingLoading/unloadingAir atmosphereEngineering

A storage apparatus for objects in the manufacture of substrates, in particular of substrates for electronic components, is provided with a housing which forms at least one closed area for storage of the objects. The storage apparatus also has a pure air device by which a pure air atmosphere can be produced at least within a section of the housing. Using at least one input / output device for the storage apparatus, objects can be passed into the interior of the housing or removed from the interior, in which case the objects can be handled by at least one handling device in the interior of the housing, and object receptacles are provided within the housing, in which objects can be temporarily stored outside transport containers. In order to require a position area which is as small as possible for a storage apparatus such as this, despite it having a high storage capacity, the invention provides that two areas which are arranged at least partially one above the other are formed in the same housing of the storage apparatus, with a first area for an object storage device, and a second area for a transport container storage device.

Owner:BOOKS AUTOMATION US LLC +2

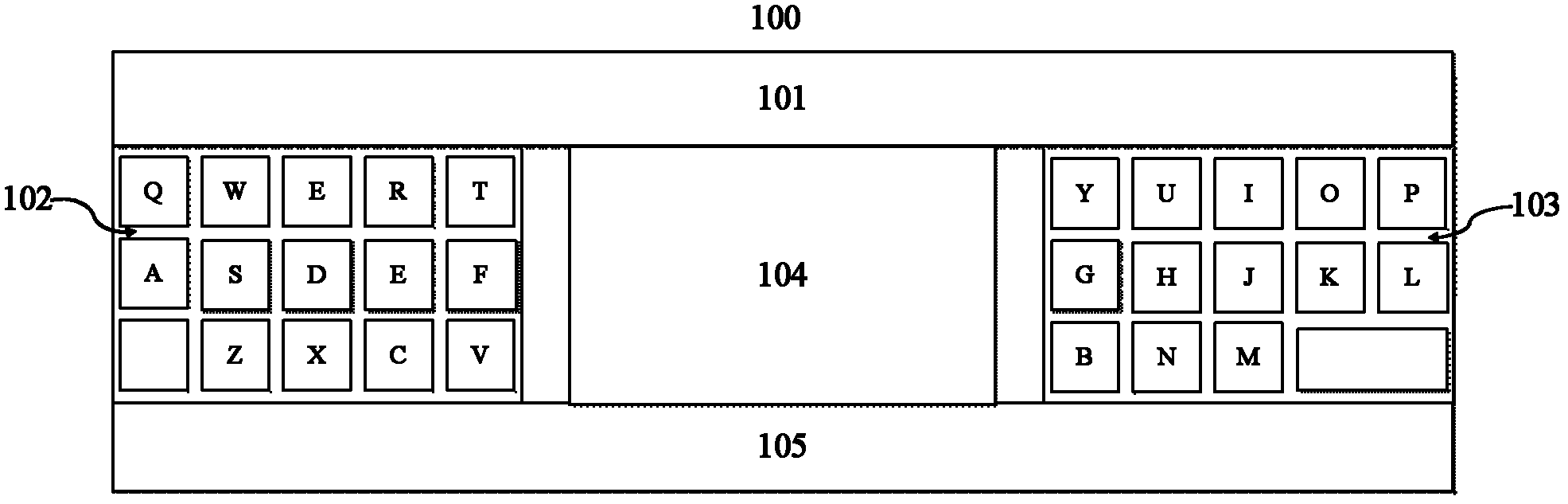

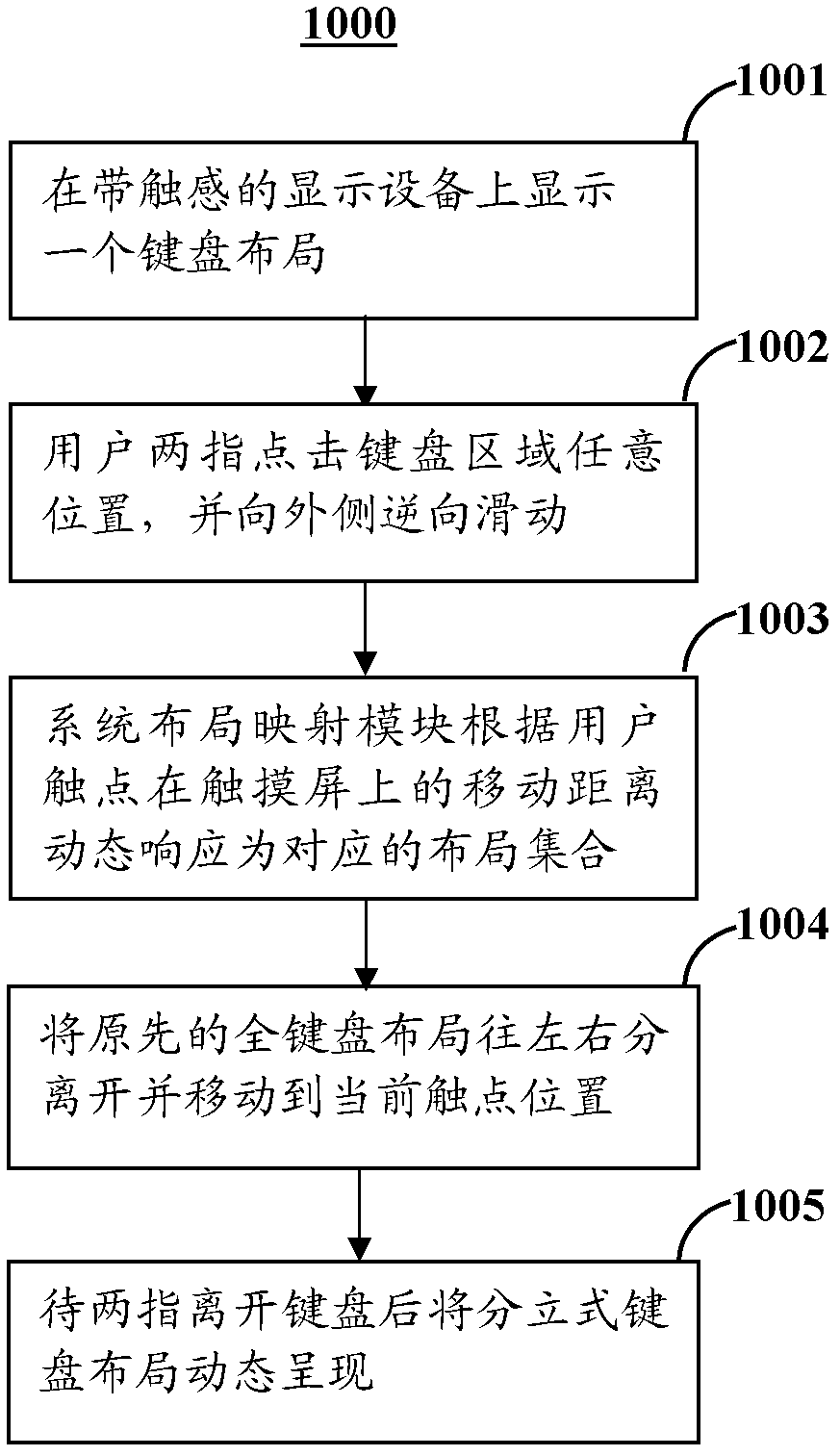

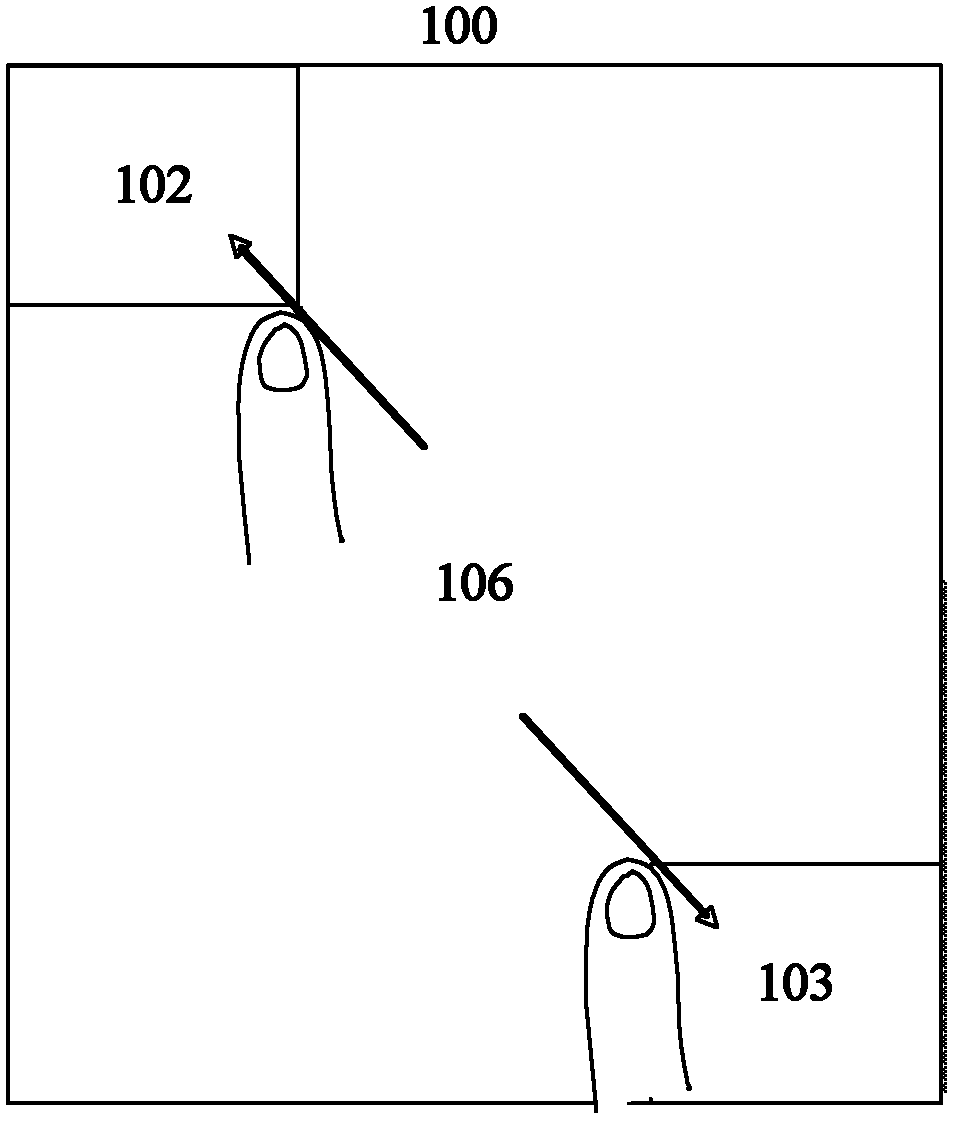

Discrete keyboard layout system and setting method, corresponding portable electronic device and control method

ActiveCN102360249AReduce operational complexityFriendly interfaceInput/output for user-computer interactionEmbedded systemHuman engineering

The invention relates to a discrete keyboard layout system used in a touch screen of a portable electronic device. The system comprises a left master keyboard area, a right master keyboard area and an additional function area, wherein the additional function area is arranged between the left master keyboard area and the right master keyboard area. The invention also relates to a method for carrying out keyboard layout switching setting and dynamic zooming on the discrete keyboard layout system, an electronic device system for implementing the discrete keyboard layout system, and a method for implementing the setting control of discrete keyboard layout switching based on the electronic device system. By using the discrete keyboard layout system and setting method, corresponding portable electronic device and control method disclosed by the invention, the keyboard position layout function can be changed flexibly so as to accord with the human engineering, thereby obviously reducing the operating complexity of a user and solving the continuity problem of overall error correction of an area of a keyboard; meanwhile, an interface is friendly, the implementation procedure is simple, the application is flexible and efficient, the performance is stable and reliable, and the application range is wide.

Owner:SHANGHAI CHULE (COOTEK) INFORMATION TECH CO LTD

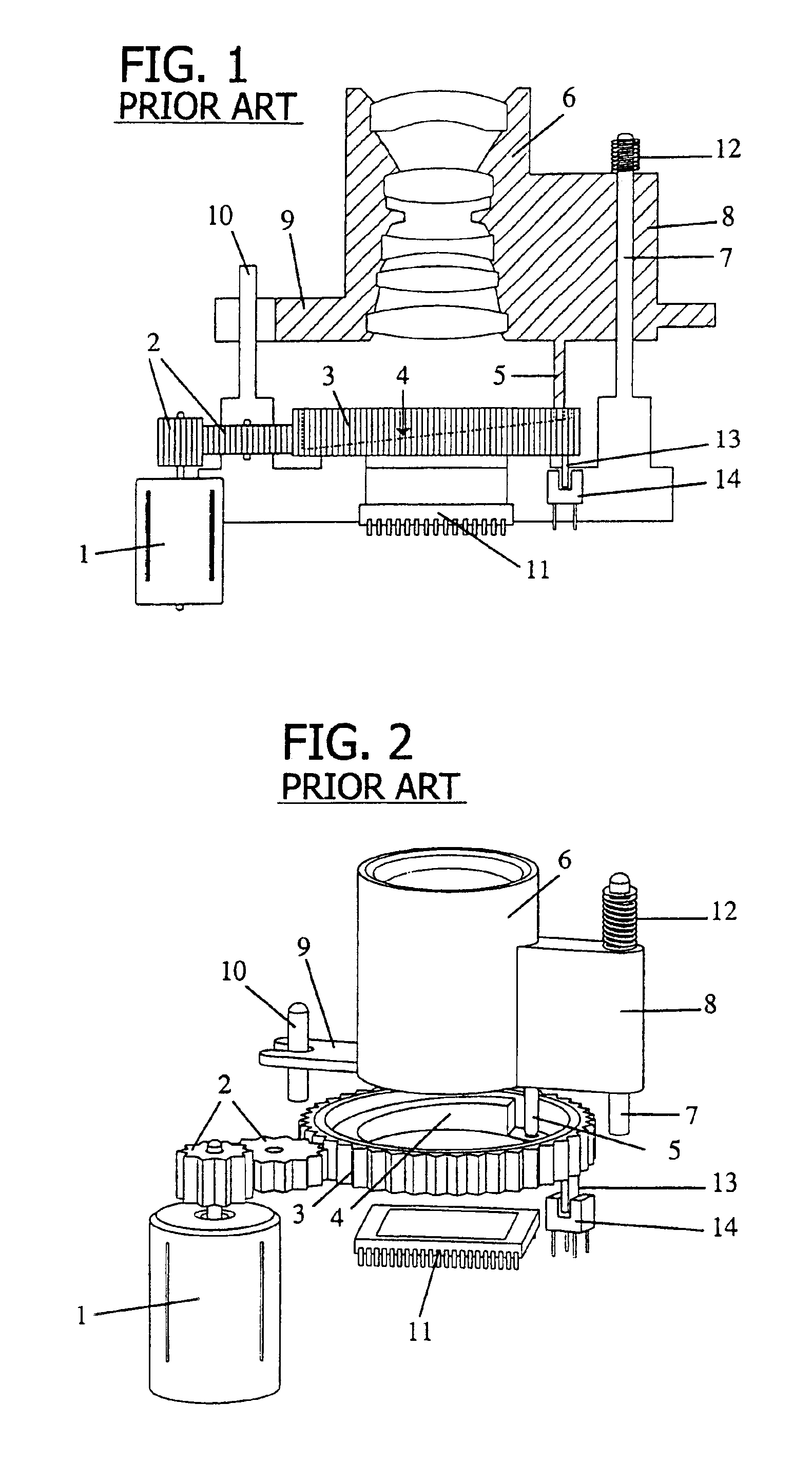

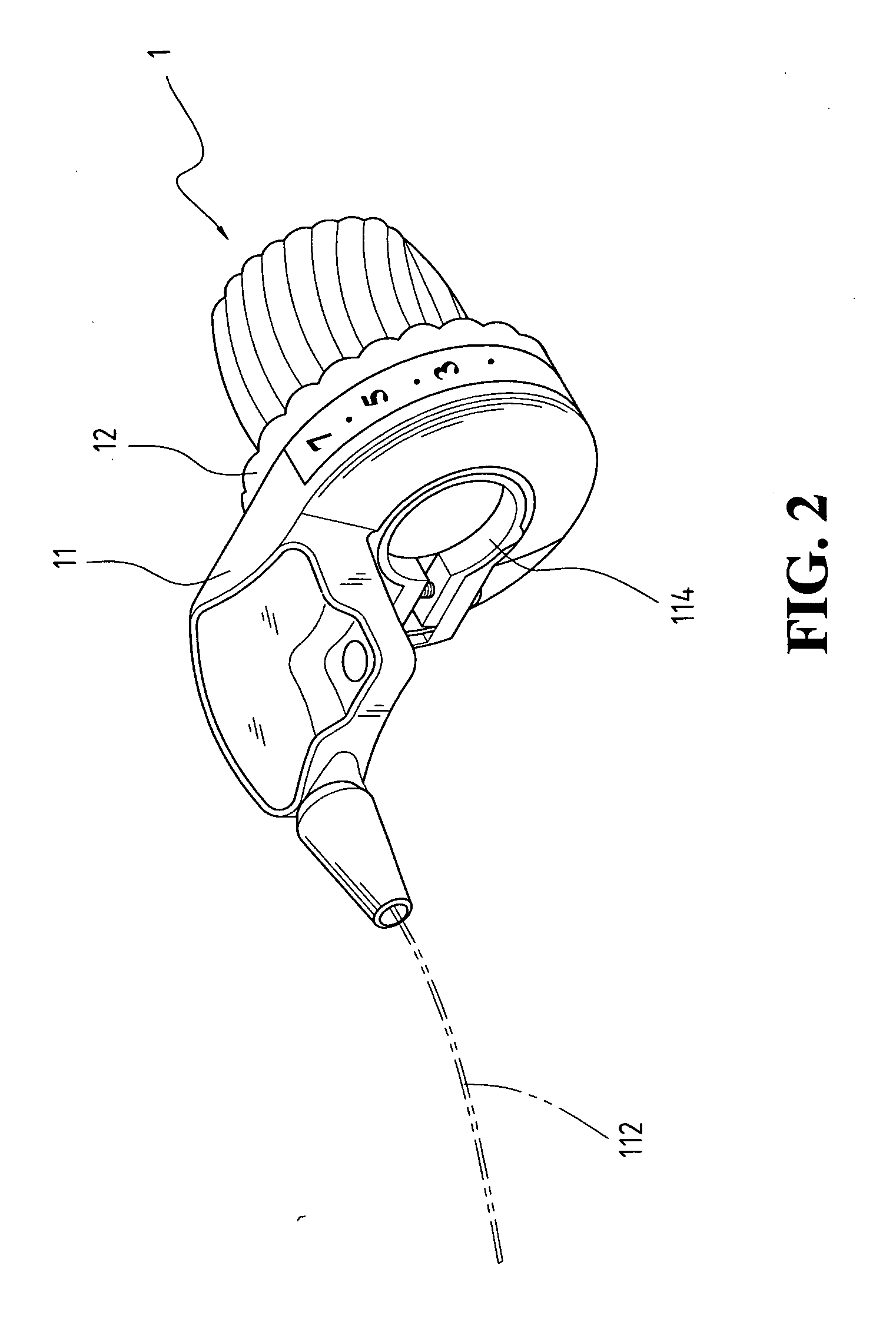

Two zone automatic lens focusing system for digital still cameras

InactiveUS6961090B2Reduce processing timeLess expensiveTelevision system detailsProjector focusing arrangementFar distanceCamera lens

A two zone lens auto-focusing system to be used in a digital still camera includes a picture taking lens, a solenoid to switch the lens focus point between near distance point and far distance point. The CPU or the electronically controlled distance measuring system of the camera having detected the position of the object, it excites the solenoid, and the head of the solenoid is pulled into the solenoid body with a very short stroke, and the arm that is provided on the lens barrel and coupled with the solenoid head is also pulled toward the solenoid body to transfer the movement of solenoid head to the lens barrel, so that the lens focus may be set at either of far position or near position automatically. These members are assembled and form a simple two zone auto-focusing system of digital still cameras.

Owner:ARC DESIGN

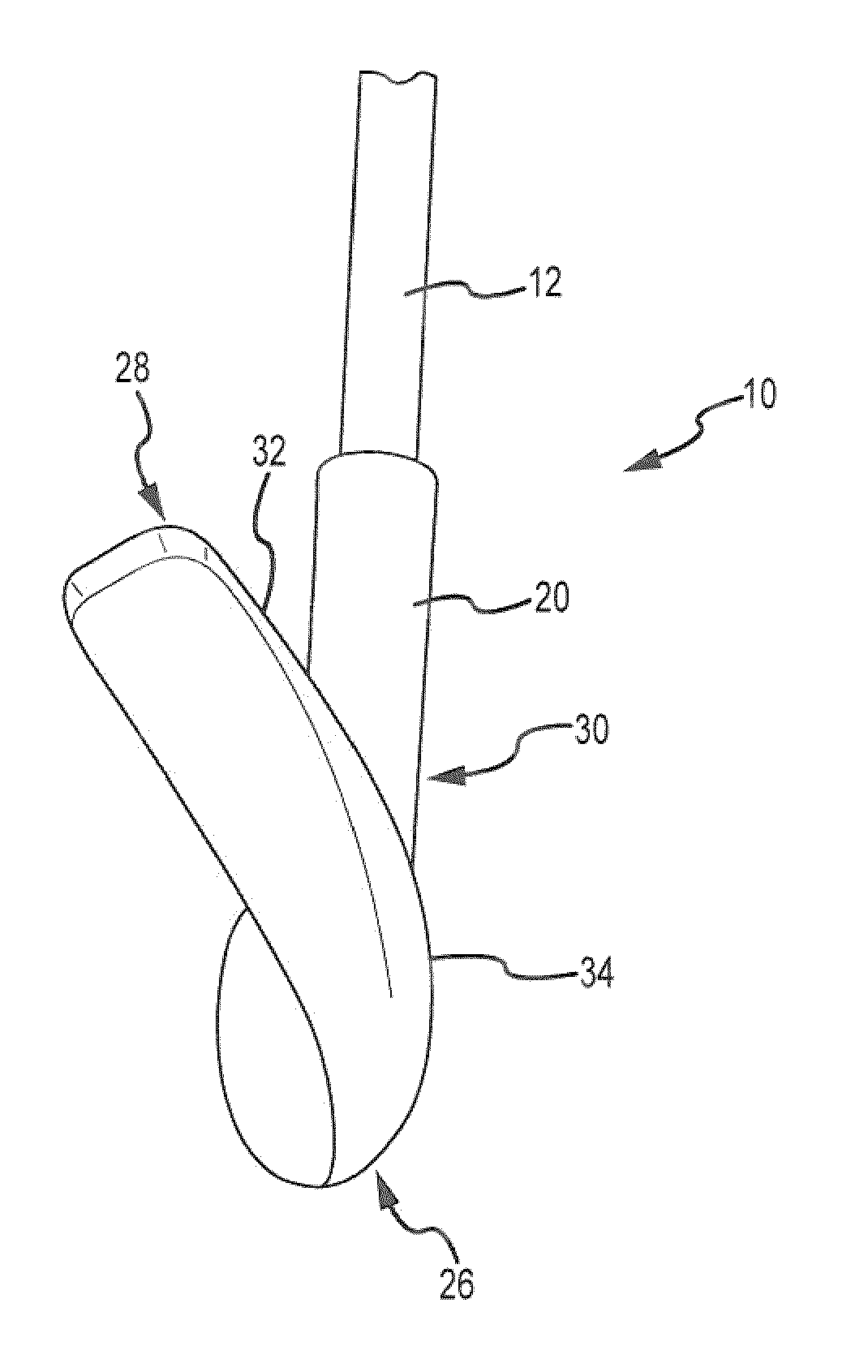

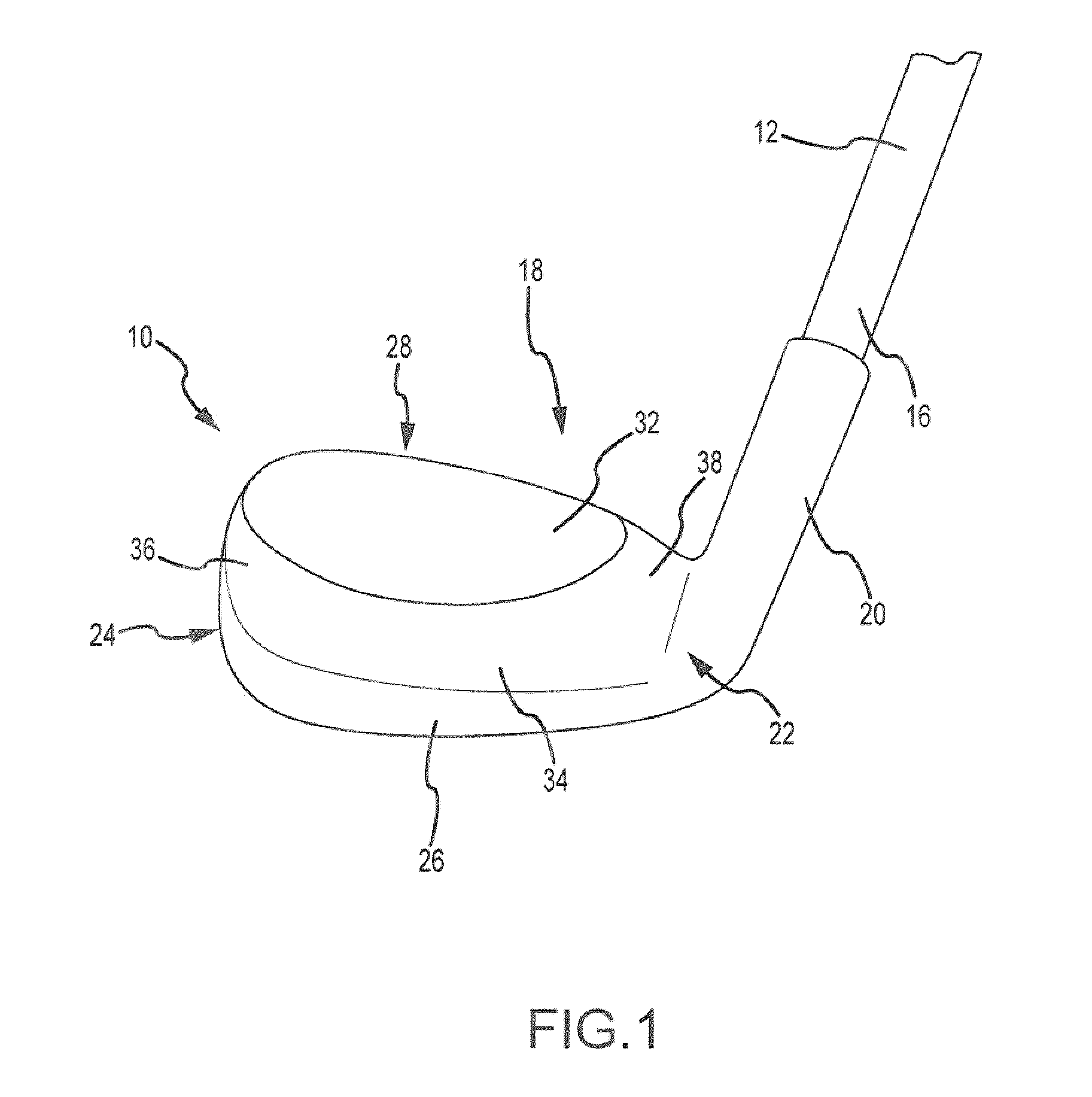

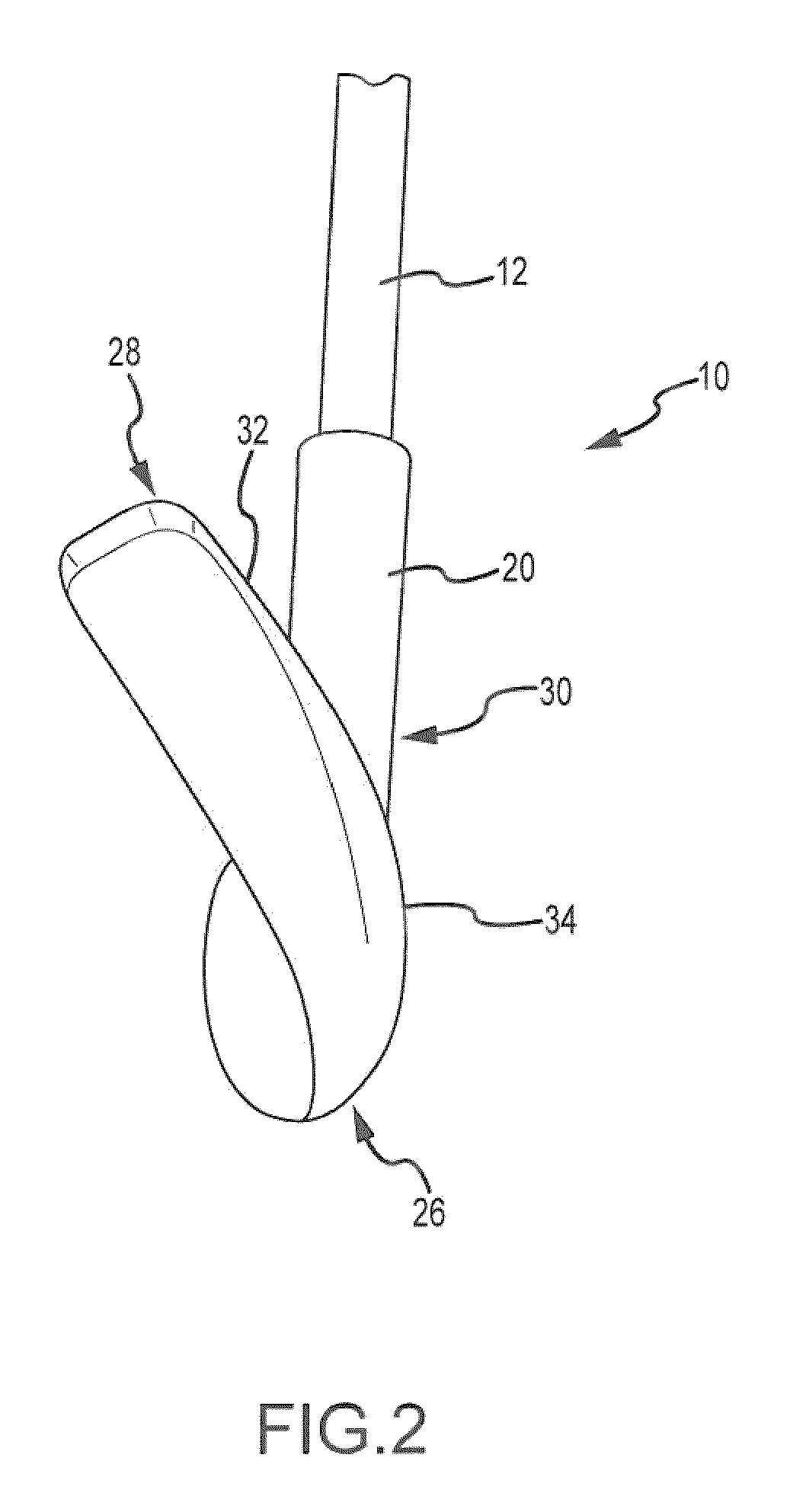

Golf swing training device and method of use

ActiveUS8388459B2Better engagementShort travel distanceMetal rolling stand detailsMetal working apparatusGolf BallLower face

A training golf club includes a shaft having a gripping end and an opposite end coupled with a club head. A club head face includes a planar striking face that is spaced from a club head sole. A lower face of the club head extends between a lower edge of the striking face to the sole of the club head, downwardly and rearwardly from the plane of the striking face. Striking a ball below a mid-plane of the ball with the striking face produces a desirable shot, whereas striking the ball above the mid-plane produces an undesirable shot. Repeated use of the club teaches a user to consistently swing a club with a forward shaft lean for optimal impact with a ball.

Owner:CHUCK MARTIN

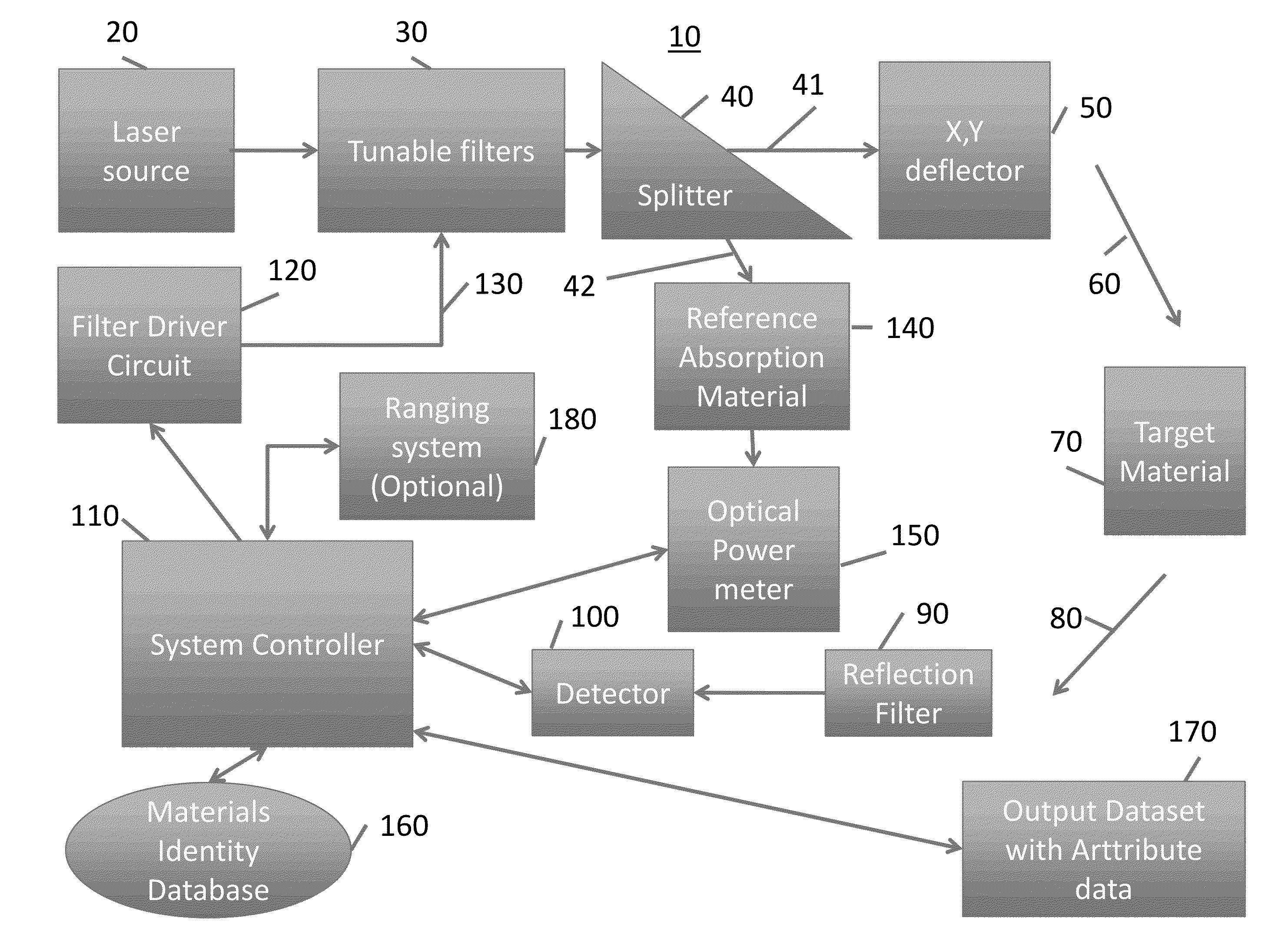

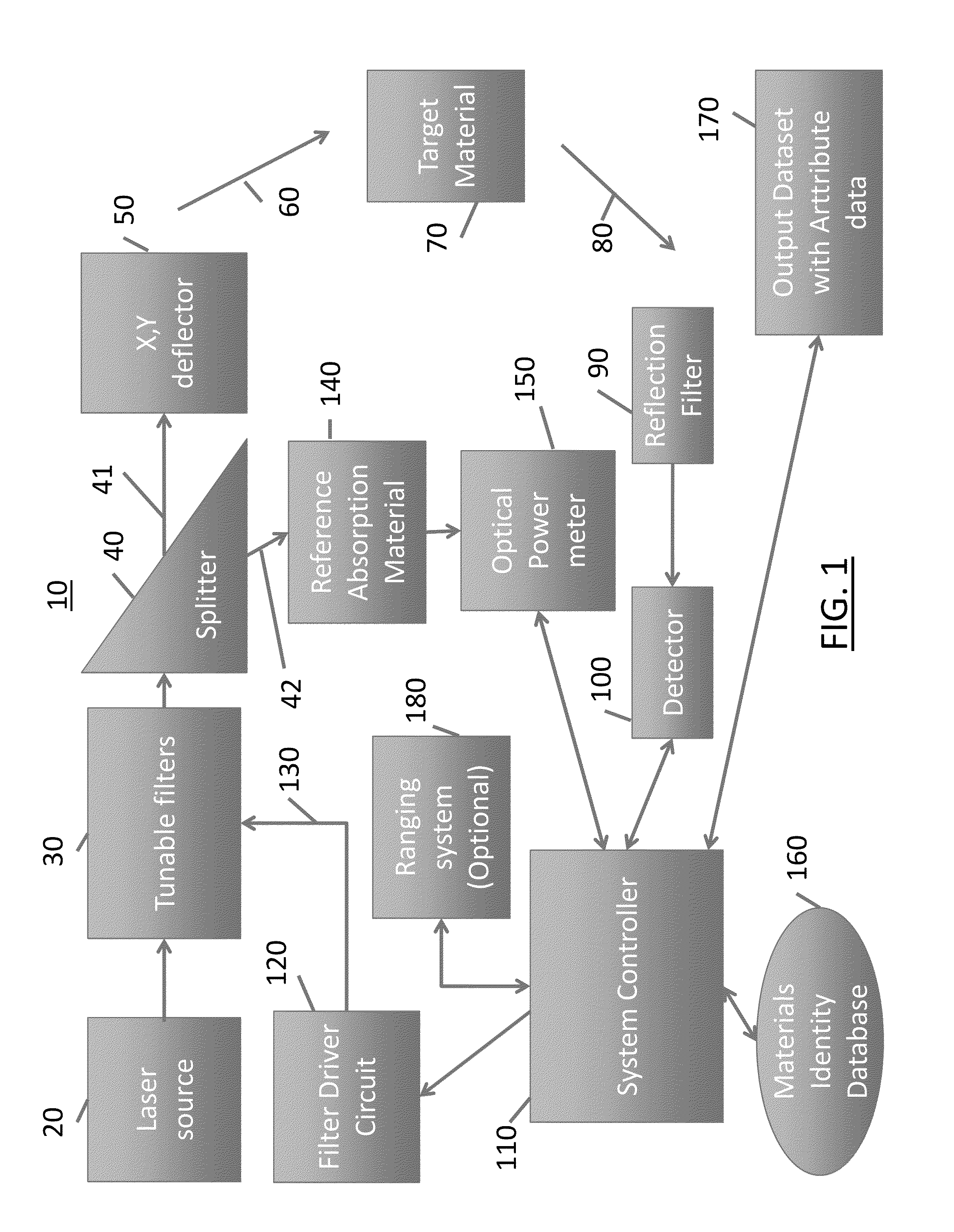

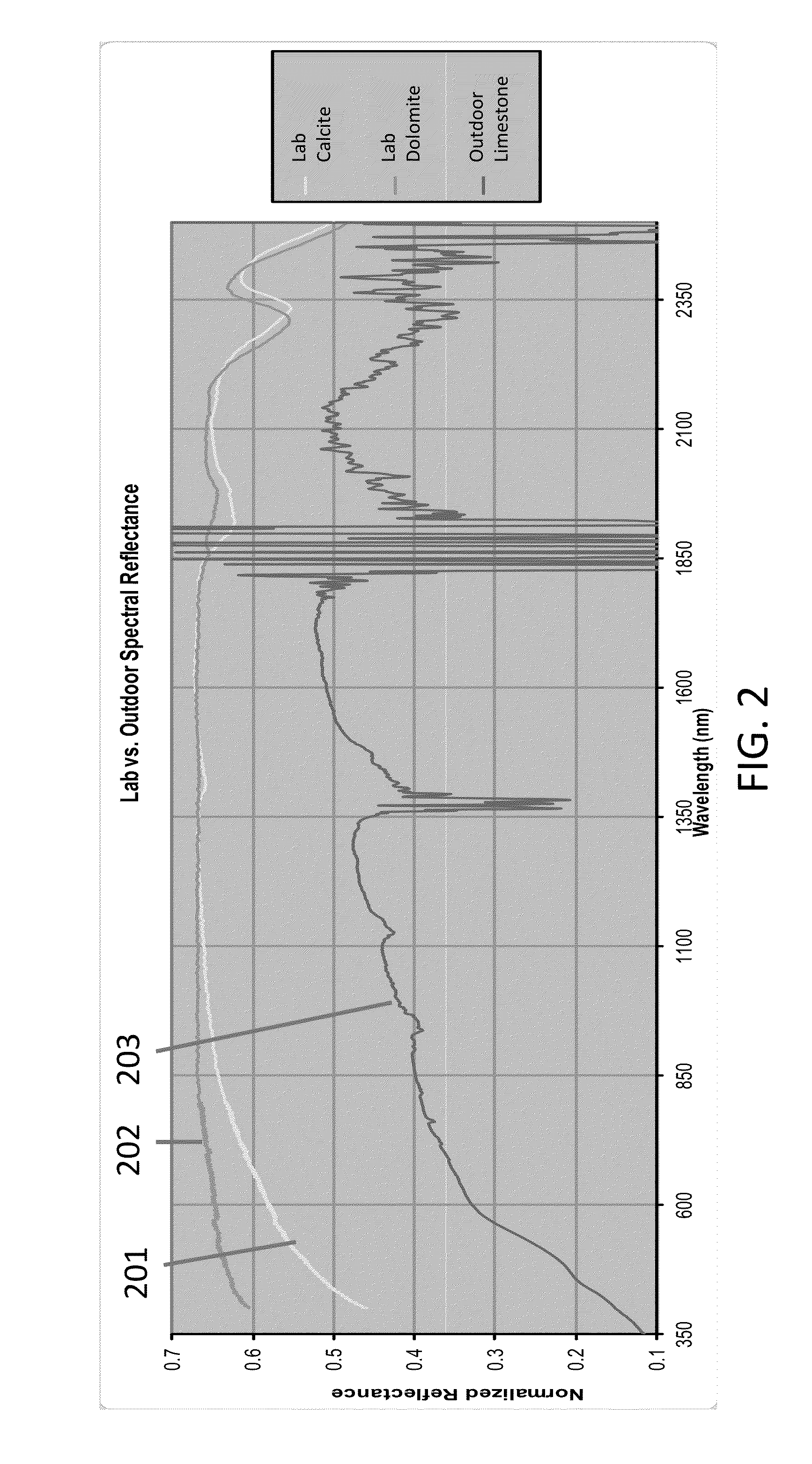

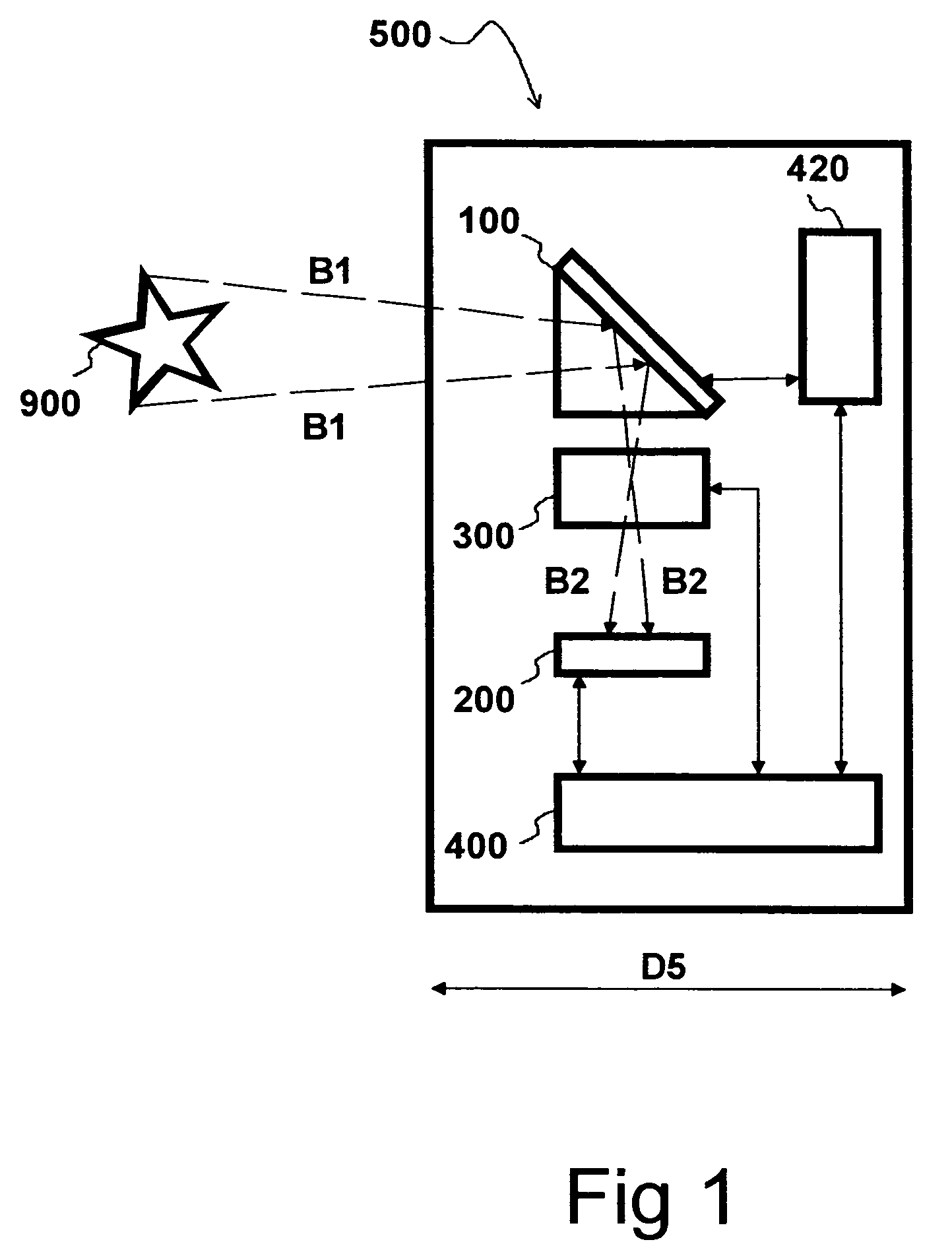

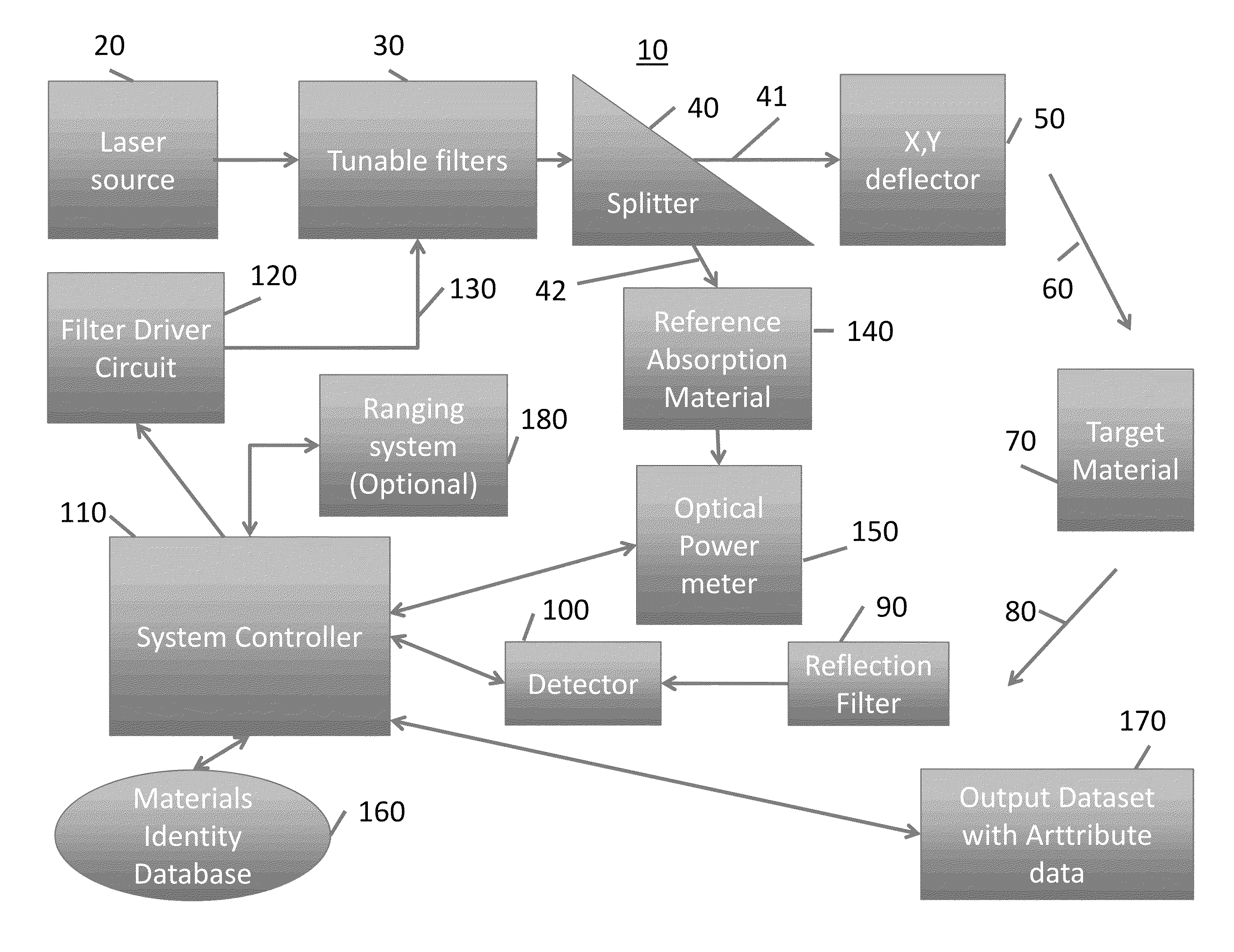

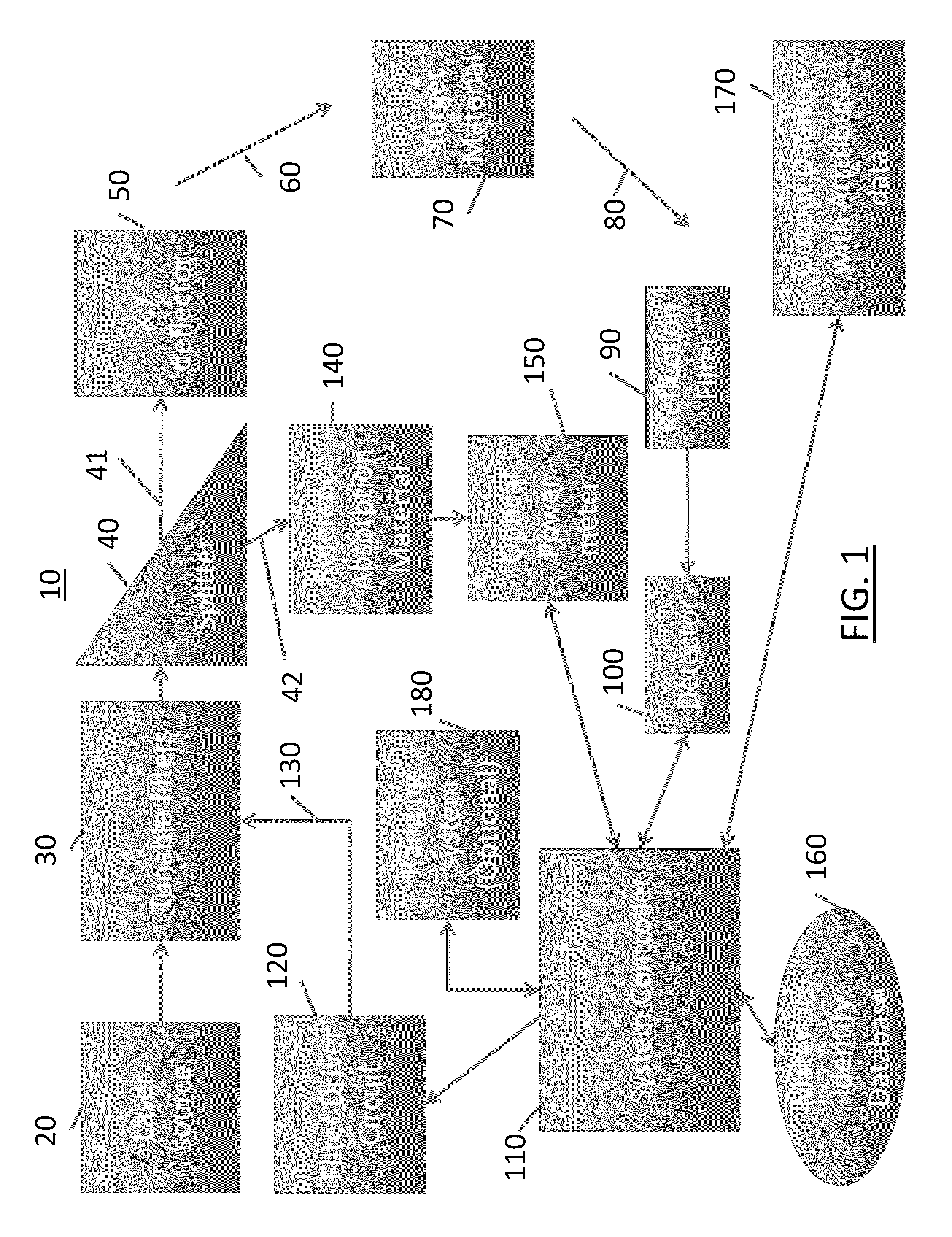

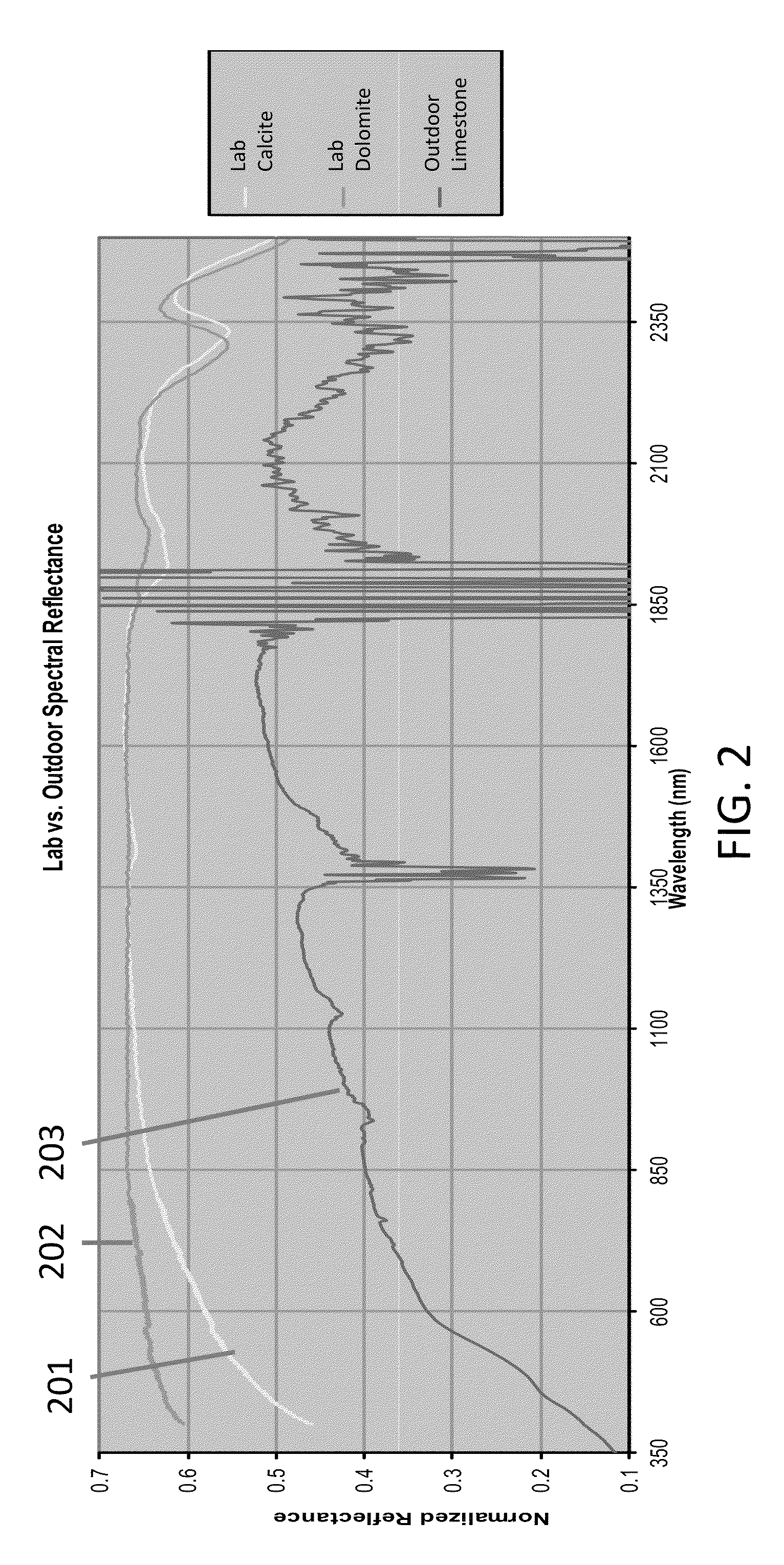

System and method for interrogation of target material in situ

ActiveUS20130271752A1Adapt quicklyReduced post-processing timeOptical prospectingScattering properties measurementsOptical pathImage resolution

A system for remotely sensing a target material in situ include a broad-band laser source, at least one tunable filter coupled to the source laser for generating a swept-frequency signal an optical device for splitting the swept-frequency signal into a first illumination signal and second illumination signal, a first optical path for directing the first illumination signal unto the target material and receiving a reflected signal from the target material, a second optical path for receiving the second illumination signal and generating a spectral reference signal, and a controller coupled to the first optical path and the second optical path for adjusting the frequency and spatial resolution of the laser source based at least in part on a comparison of the spectral reference signal and the reflected signal.

Owner:CHEVROU USA INC

Handlebar gear shifter for bicycle

InactiveUS20050081672A1Avoid interferenceEasy to operateControlling membersCycle control systemsMechanical engineering

A handlebar gear shifter for a bicycle includes a tabular handlebar having a support plate extending from an end of the handlebar at the top of the peripheral thereof. A sleeve is rotatably mounted to the handlebar. A fan-shaped mediate member has an end pivotally connected onto the support plate. A first cable has one end thereof engaged with a recess in the sleeve and the other end of the first cable is engaged with the mediate member. A second cable connects between the mediate member and a derailleur mechanism. A C-shaped member having notches is connected to the handlebar. A spring member is engaged with the sleeve. An index member is biased by the spring member and removably engaged with one of the notches. The improvement is that the distance between the pivot end of the fan-shaped mediate member and one distal end thereof connected to the first cable is approximately equal to or slightly less than that between the pivot end and the other distal end thereof connected to the second cable, so that the traveling distance of the first cable is less than that of the second cable. Therefore, the traveling distance of the first cable and thus the rotated angle of the sleeve can be shorted for each gearshift that is more convenient for operation.

Owner:CHEN PO CHENG

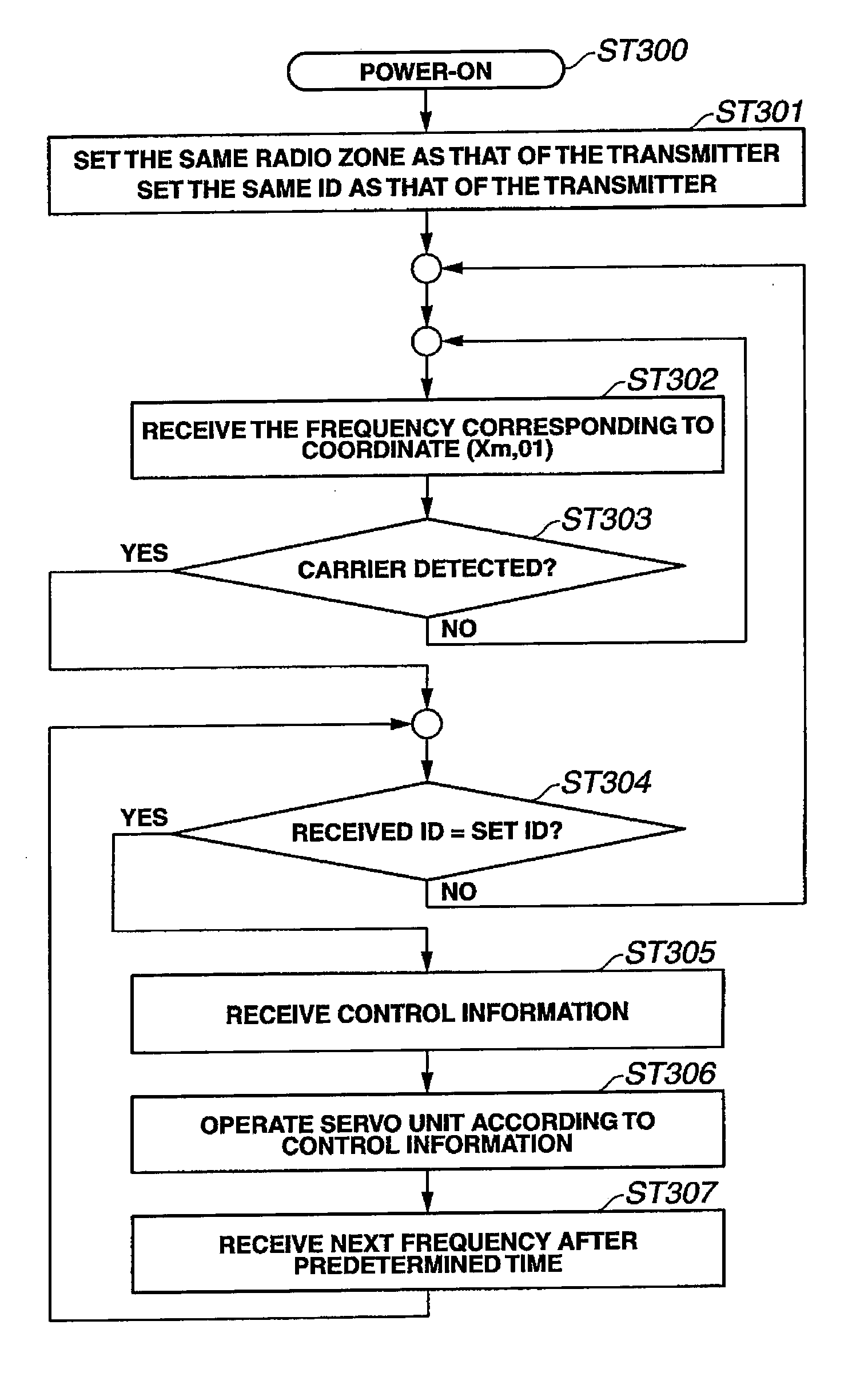

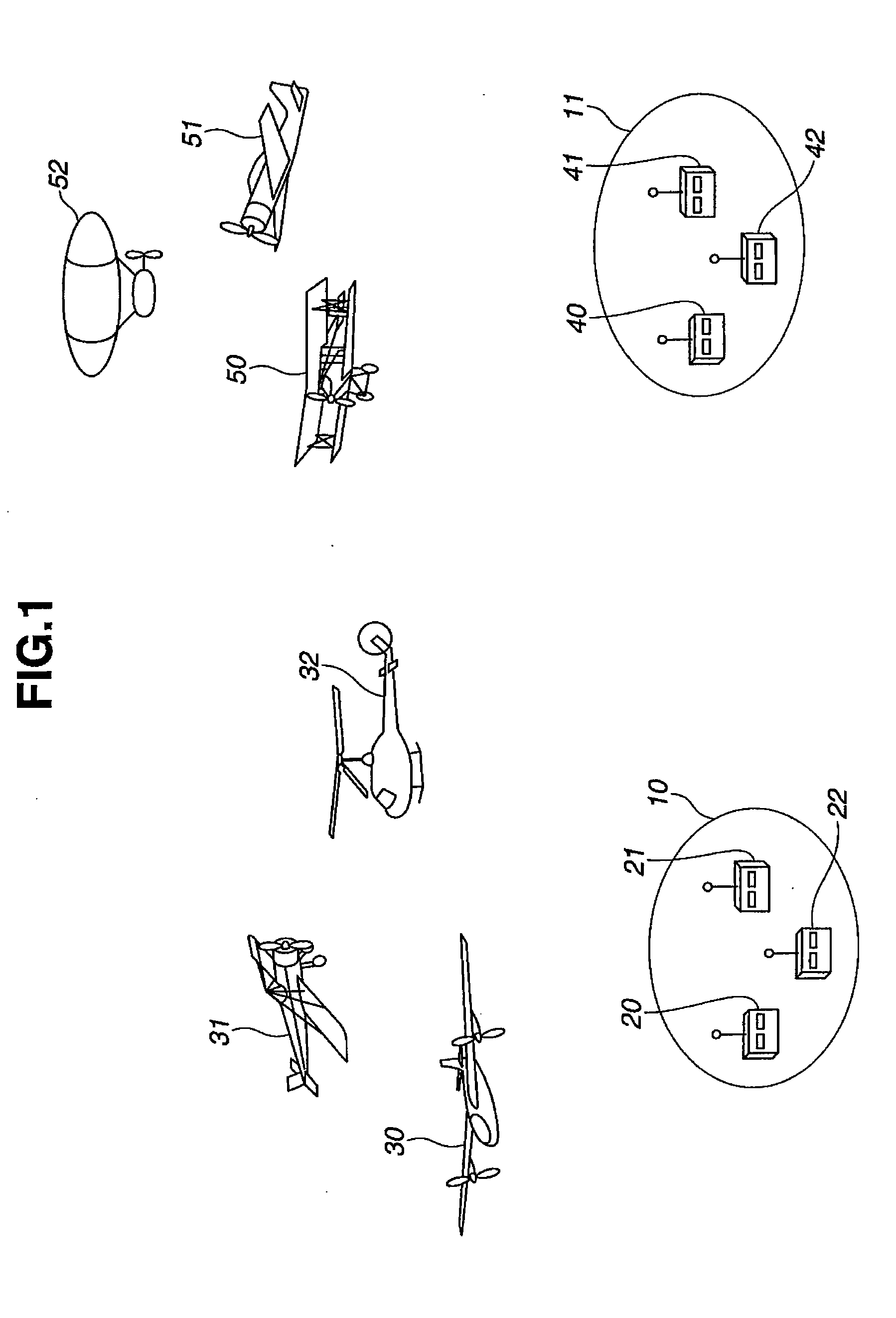

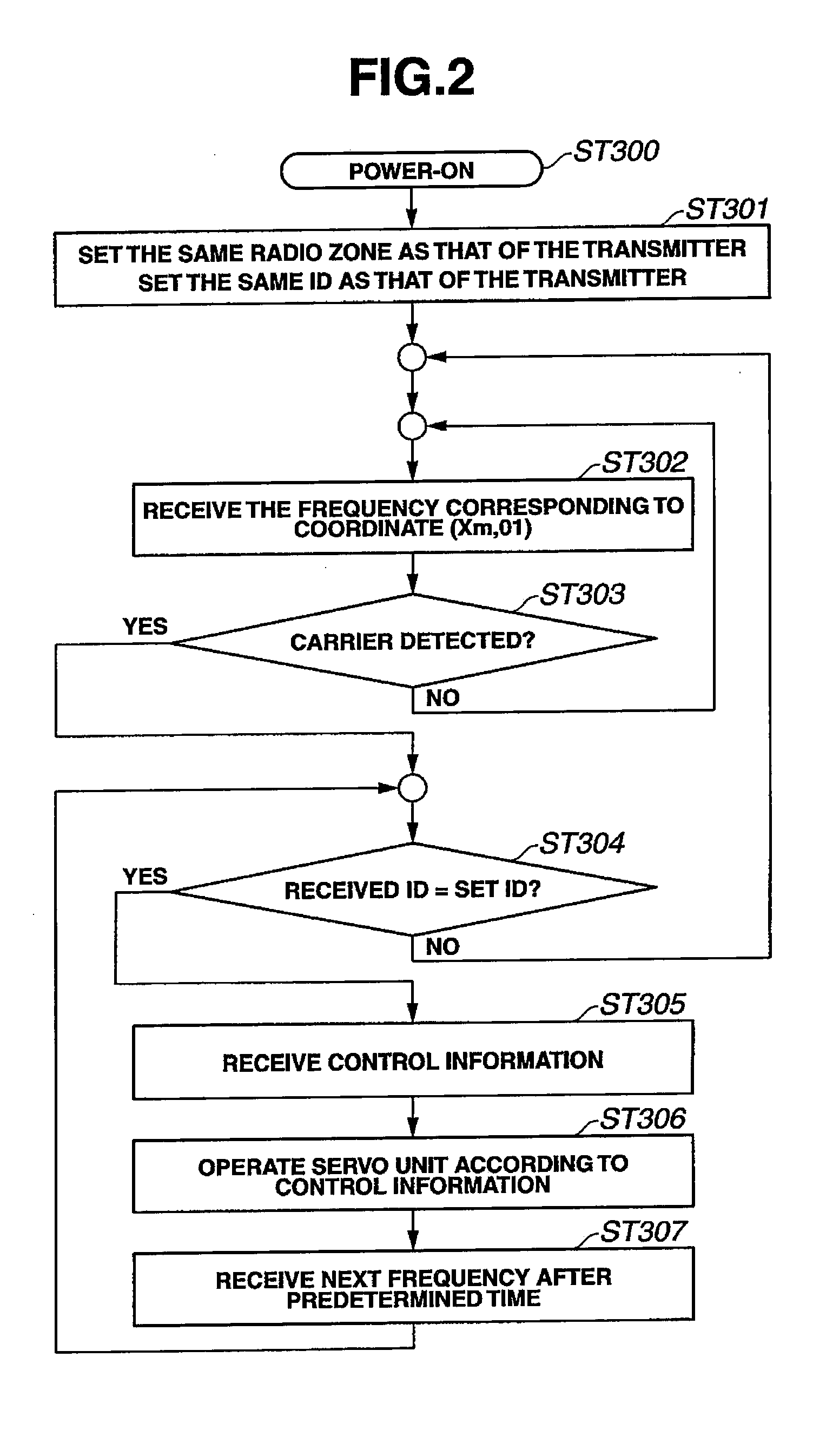

Radio controlled model apparatus, controller for radio controlled model apparatus, and frequency hopping pattern selection method

ActiveUS20090086792A1Avoid interferenceReduce probabilityTransmission systemsSecret communicationAirplaneRadio-controlled model

A technique is provided that can avoid radio zone interference in a radio controlled model apparatus, which employs the frequency hopping system in the spread spectrum radio techniques. In the controller for maneuvering, for example, model airplanes, a process for detecting whether or not a radio zone is in an occupied state is initiated, with an initial radio zone represented by information (M) stored in a nonvolatile memory, acting as a starting point. Until an unoccupied radio zone is detected, the process of detecting occupation of radio zones continues, according to a predetermine sequence. Thus, an available radio zone can be detected. Moreover, information (M) representing an initial radio zone, stored in a nonvolatile memory, is updated immediately after power-on of the controller.

Owner:FUTABA CORPORATION

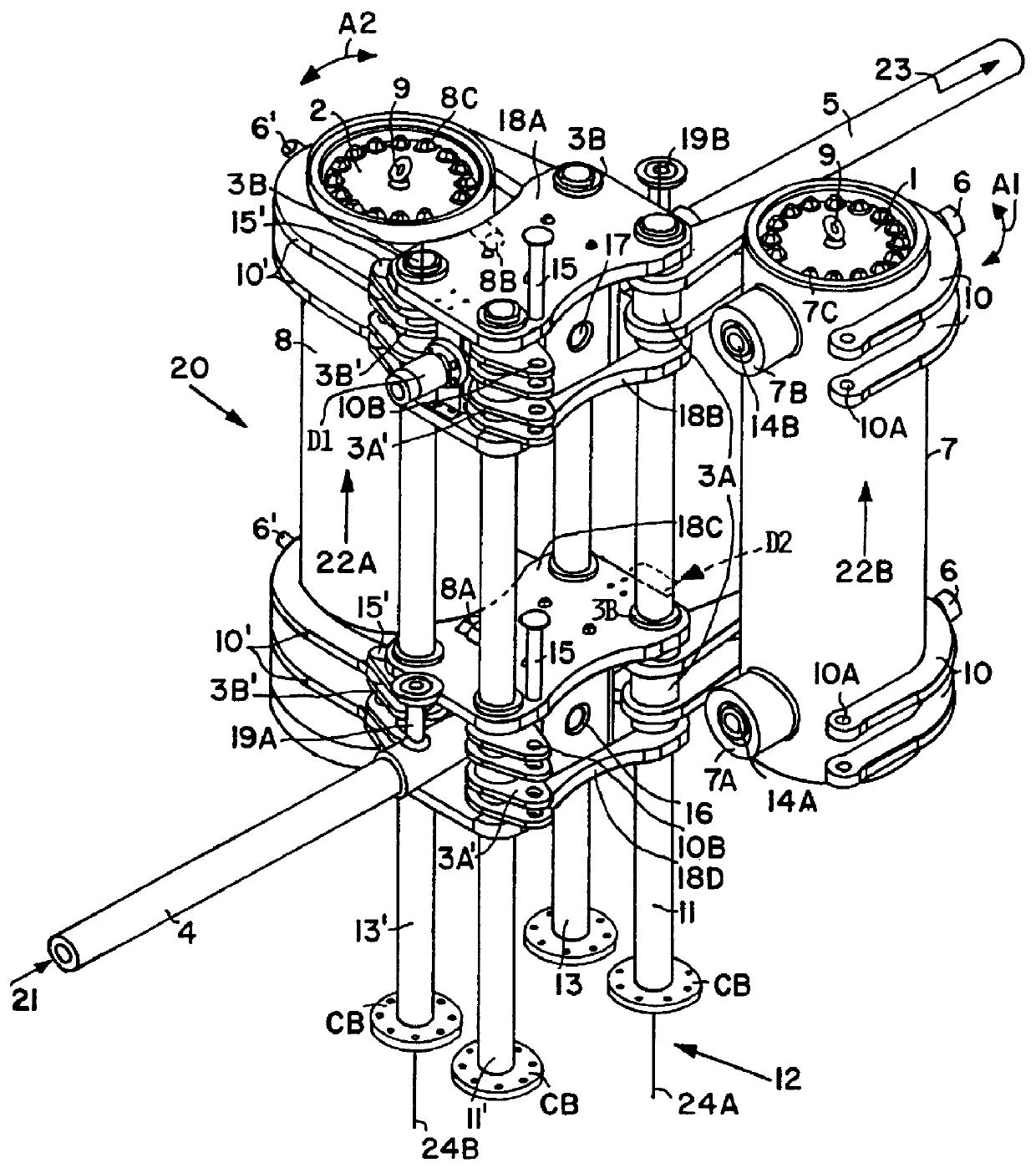

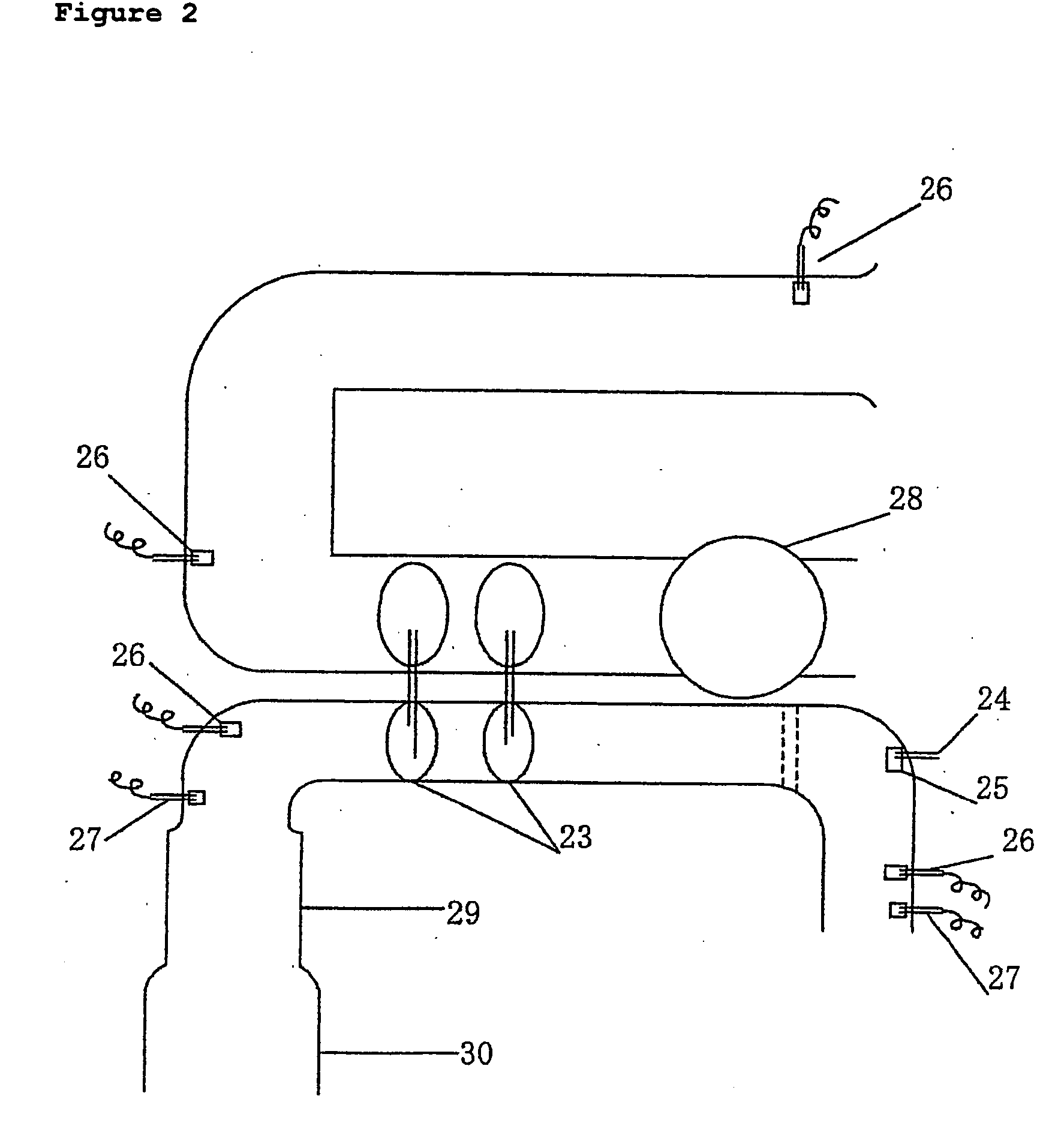

Parallel filters for plastic melts

InactiveUS6117320AEasy accessAvoid insufficient lengthSettling tanks feed/dischargeLoose filtering material filtersWaste managementHinge angle

A filter for filtering plastic melt prior to feeding the melt into an extruder nozzle, for example a thermoplastic film extruder nozzle, has preferably two filter housings for holding respective exchangeable filter cartridges. Both filter housings are articulated by hinges to a column mounting so that one filter housing can be serviced while the other filter housing with its filter cartridge is in a filtering position and vice versa. A single filter may be used alternatively. In both instances the column mounting may include at least one, preferably two, mounting columns.

Owner:LINDAUER DORNIER GMBH

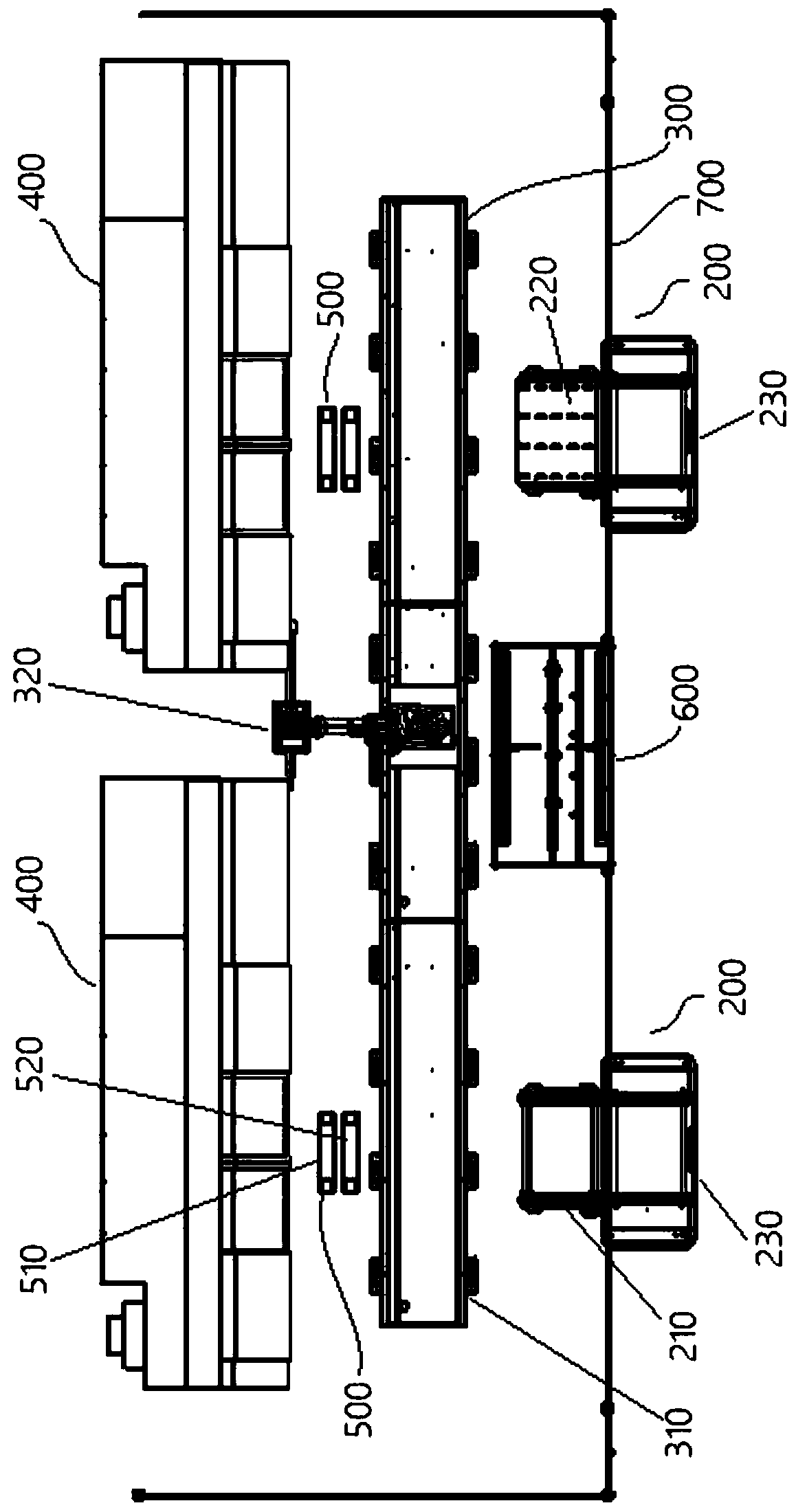

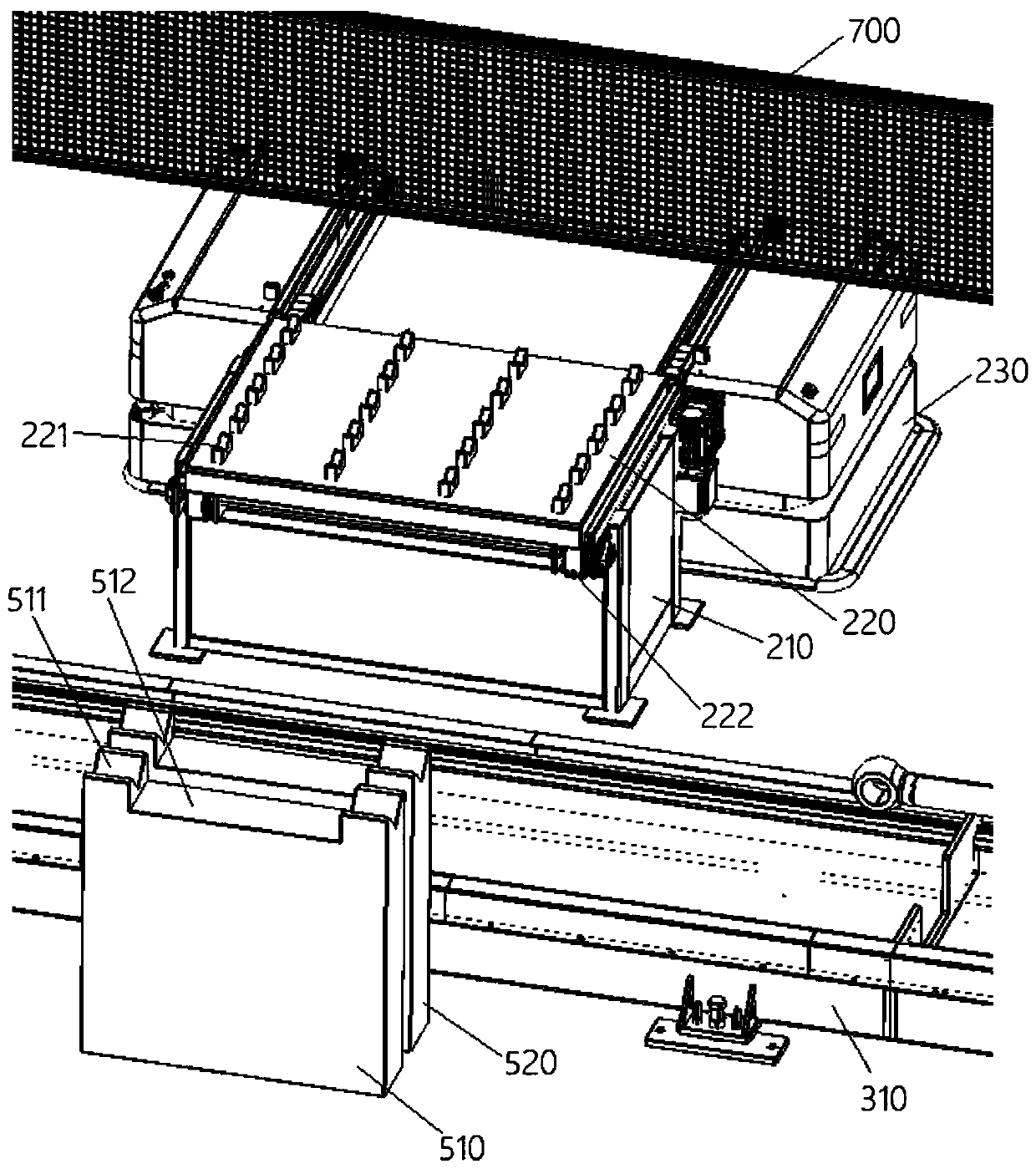

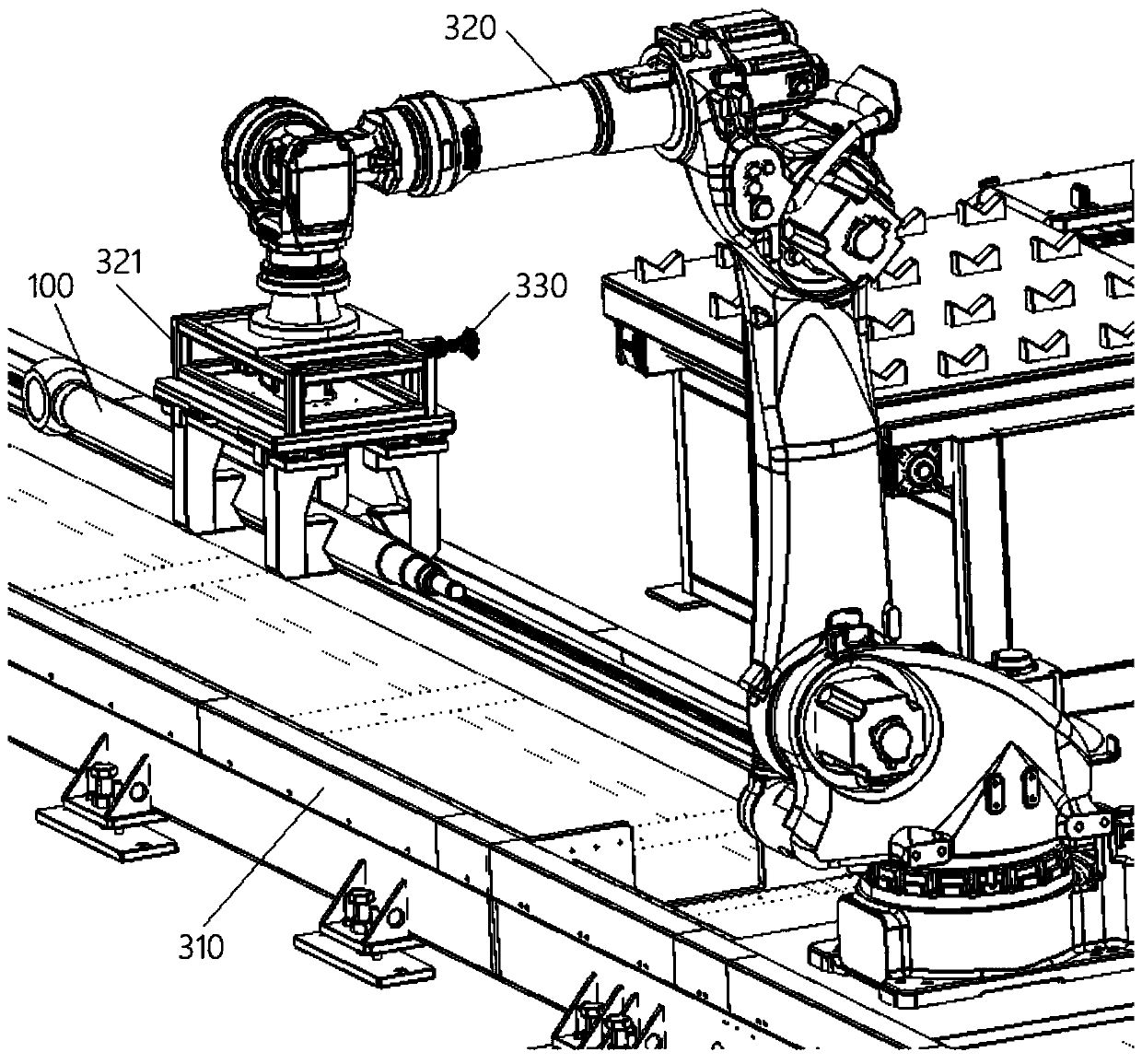

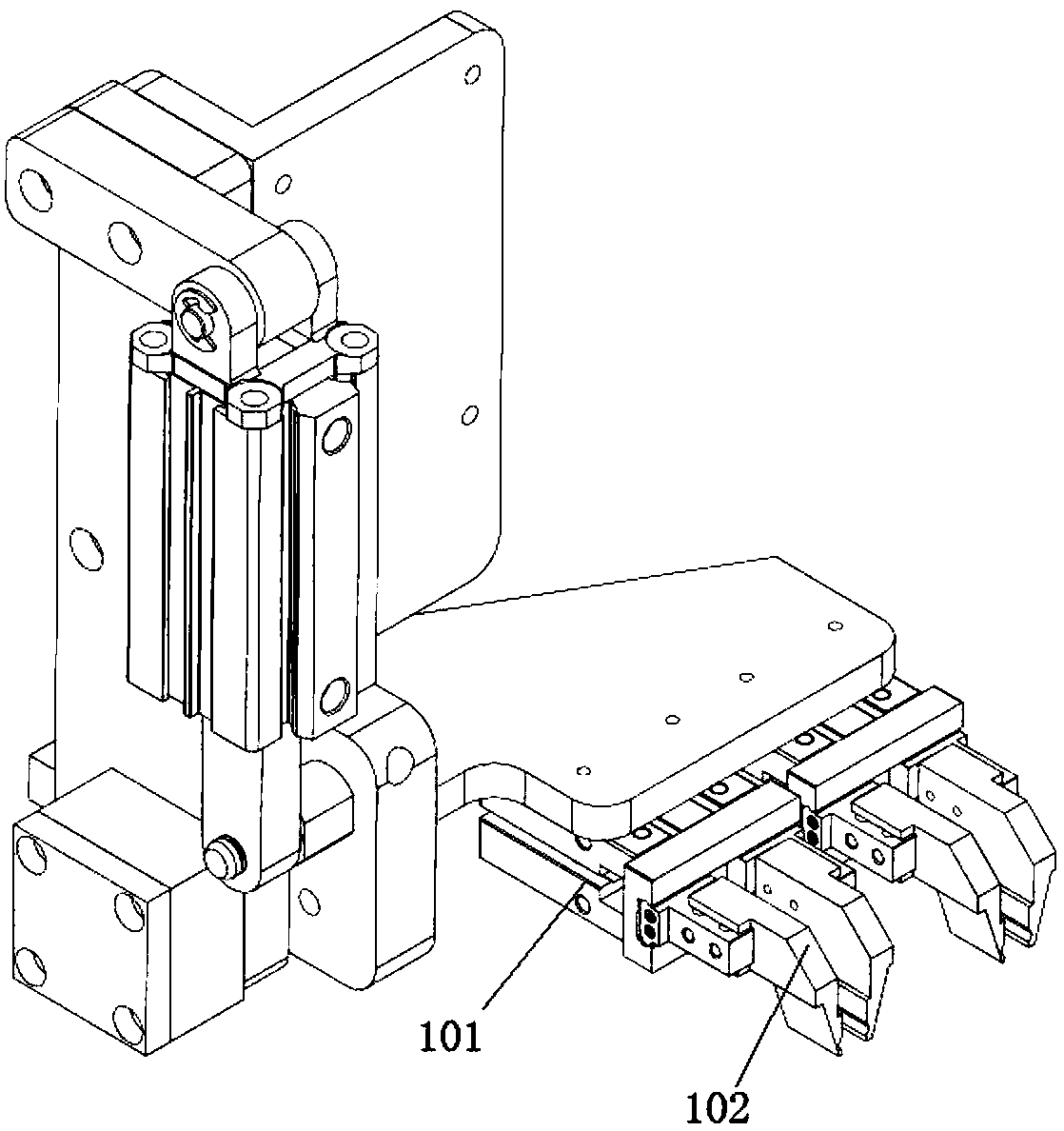

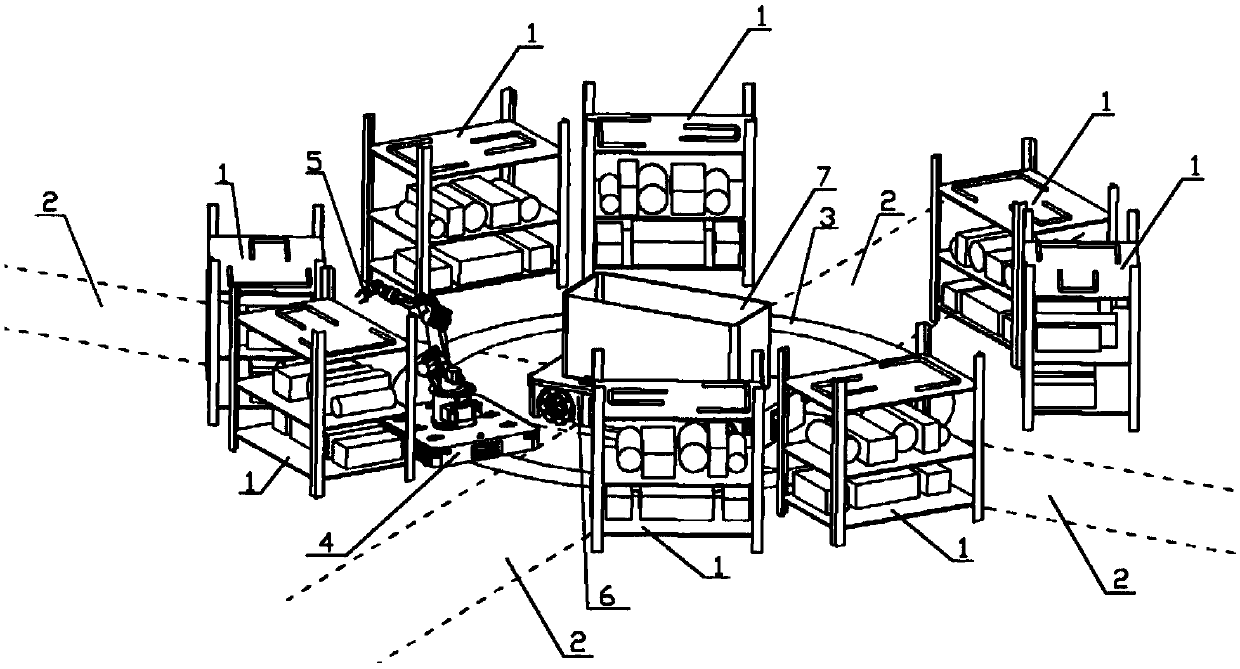

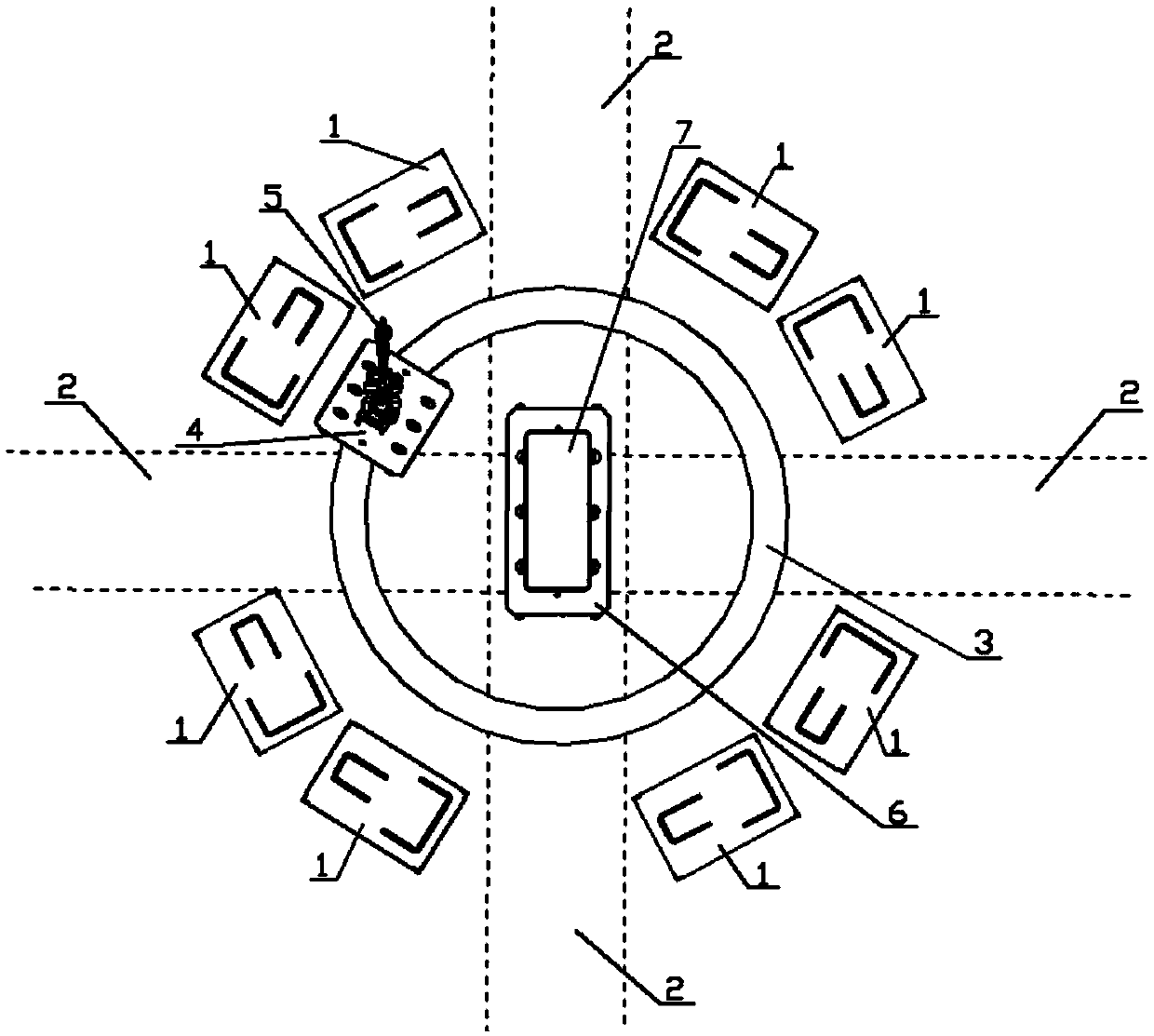

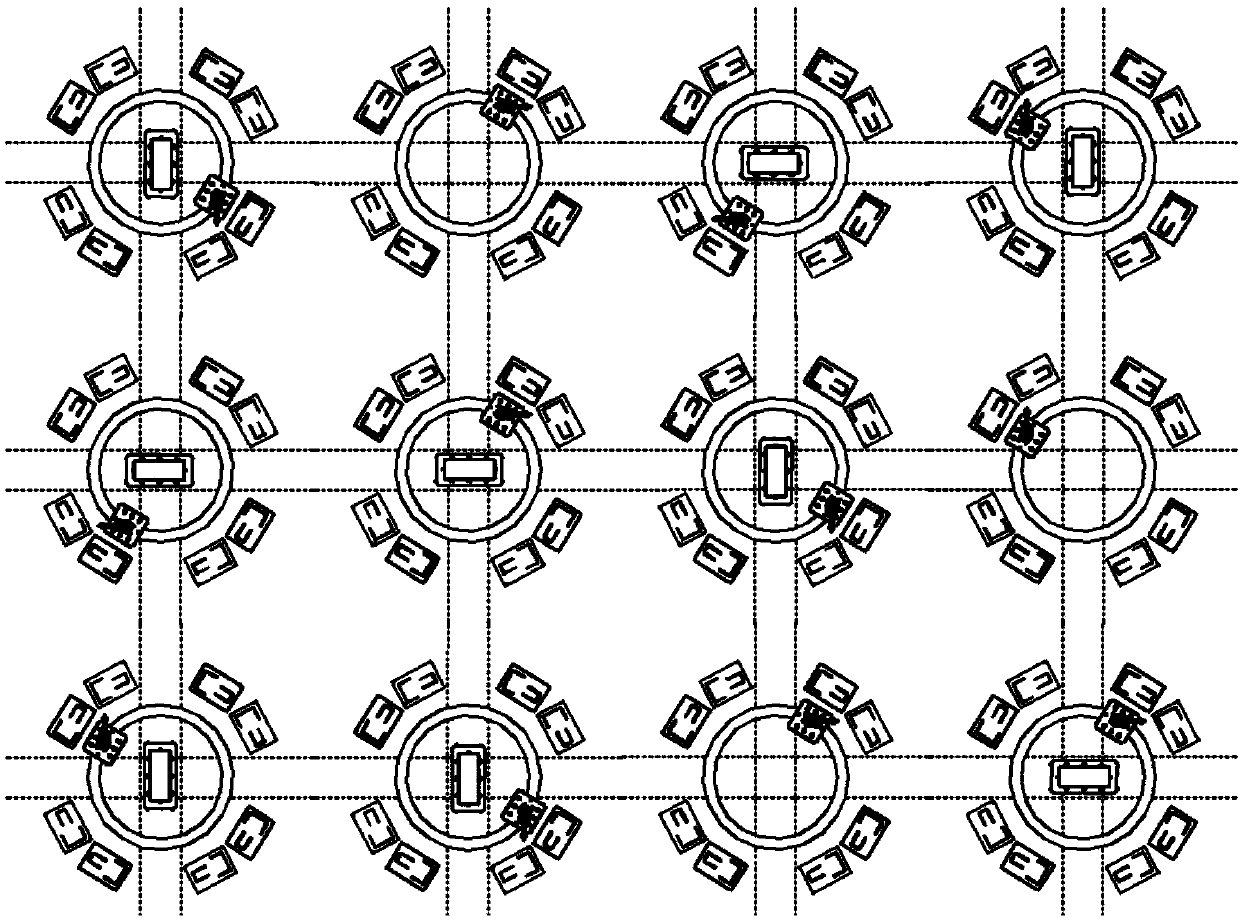

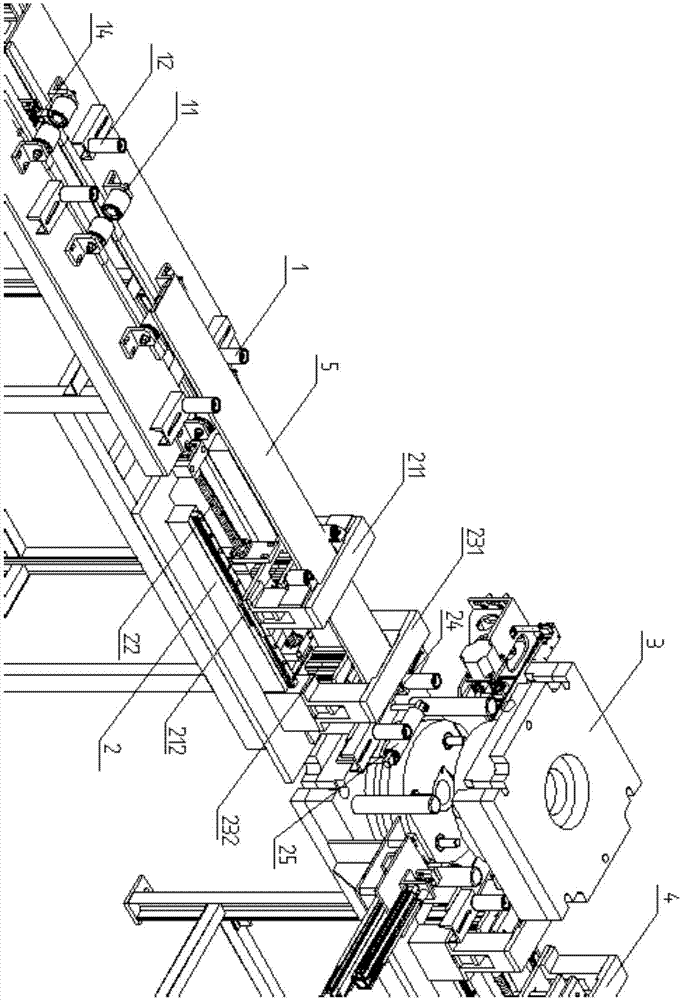

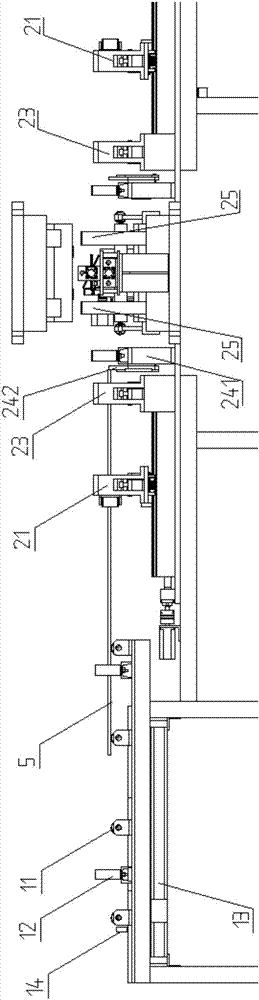

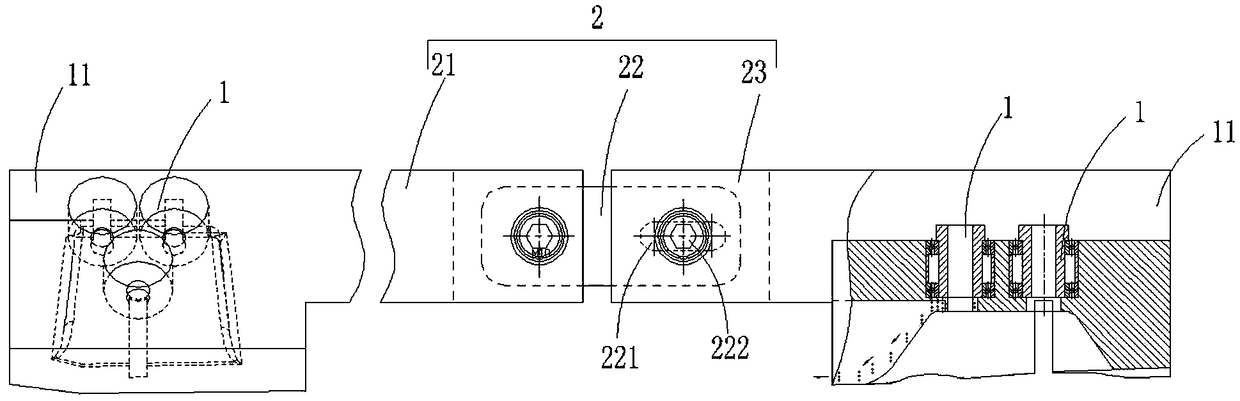

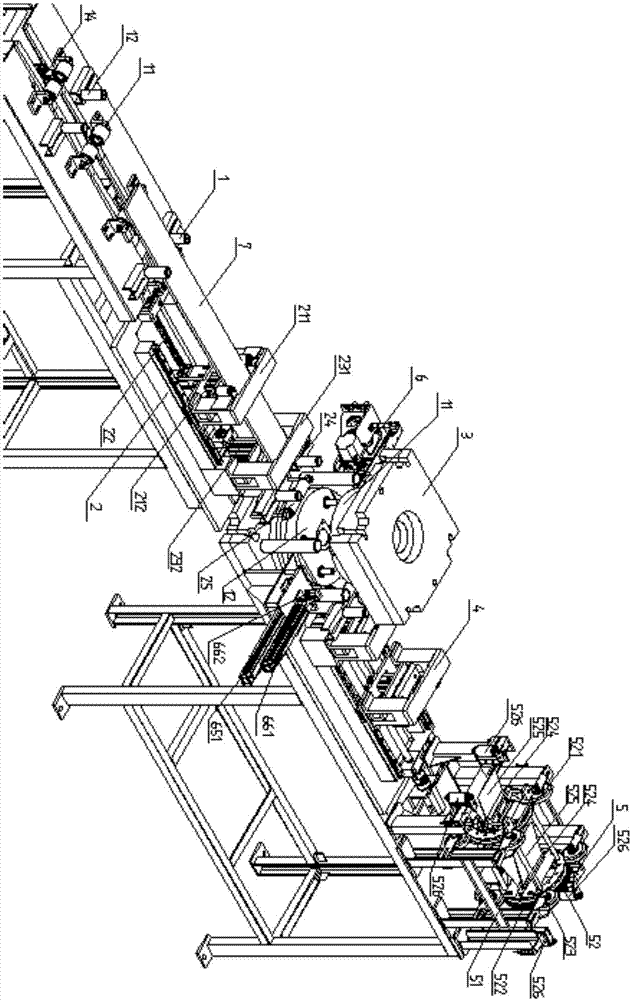

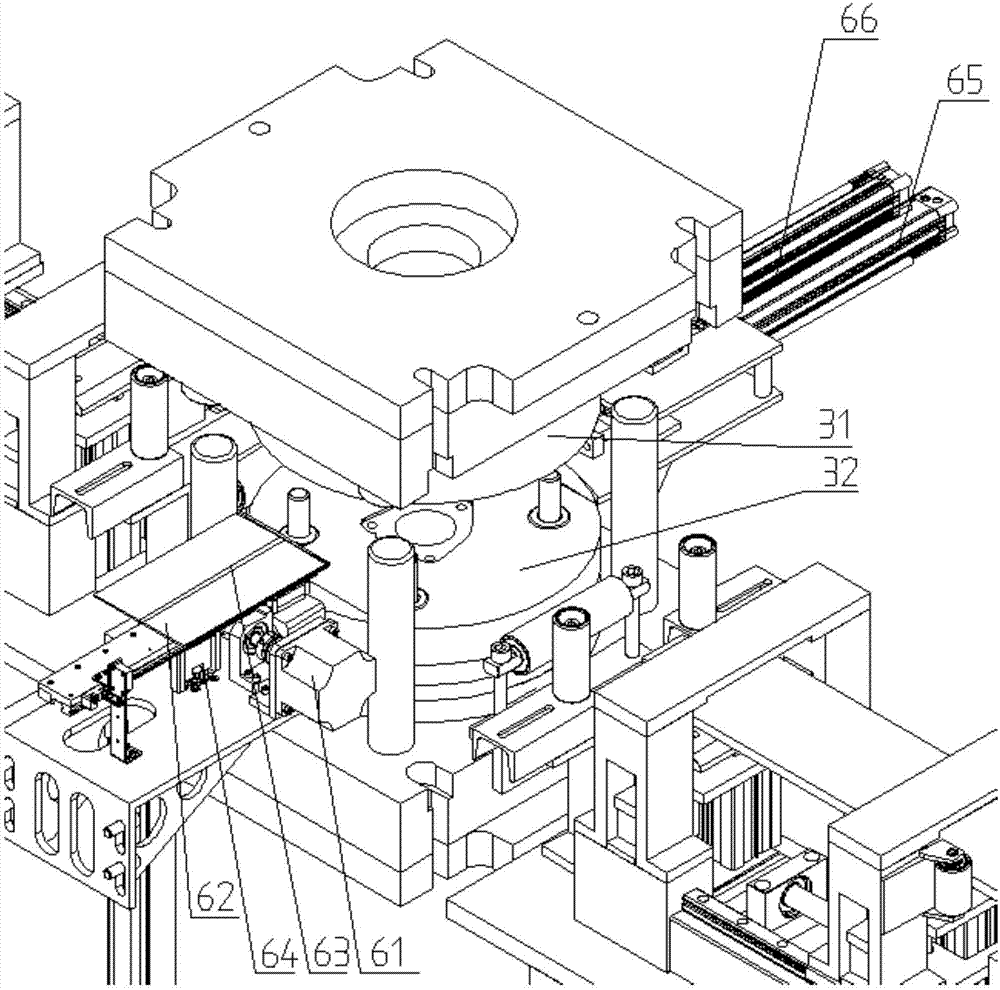

Plated piston rod assembly polishing processing device and processing method thereof

PendingCN110682169AQuick actionSmall range of motionRevolution surface grinding machinesGrinding feed controlRobot handControl engineering

The inventin provides a plated piston rod assembly polishing processing device which comprises loading and unloading caching stations, a ground track robot, cylindrical grinding machines, grinding machine caching stations and a detection platform. The two loading and unloading caching stations are distributed on the front side of the ground track robot; workpiece trays are arranged on the loadingand unloading caching stations; multiple V-shaped support blocks are arranged on the workpiece trays and can position piston rod assemblies; a ground track of the ground track robot is arranged alongthe left-and-right direction; a manipulator can move along the ground track; the two cylindrical grinding machines are located on the back side of the ground track robot; the two grinding machine caching stations are located on the front sides of the two cylindrical grinding machines; a first workpiece support frame and a second workpiece support frame are arranged on the grinding machine cachingstations; the detection platform is located between the two loading and unloading caching stations; a detection scanner is arranged on the detection platform and can be used for detecting faults of the surfaces of the piston rod assemblies; the detection scanner is connected with a controller; and the controller is connected with the ground track robot. The plated piston rod assembly polishing processing device provided by the invention has high processing efficiency.

Owner:苏州迅益科系统科技有限公司

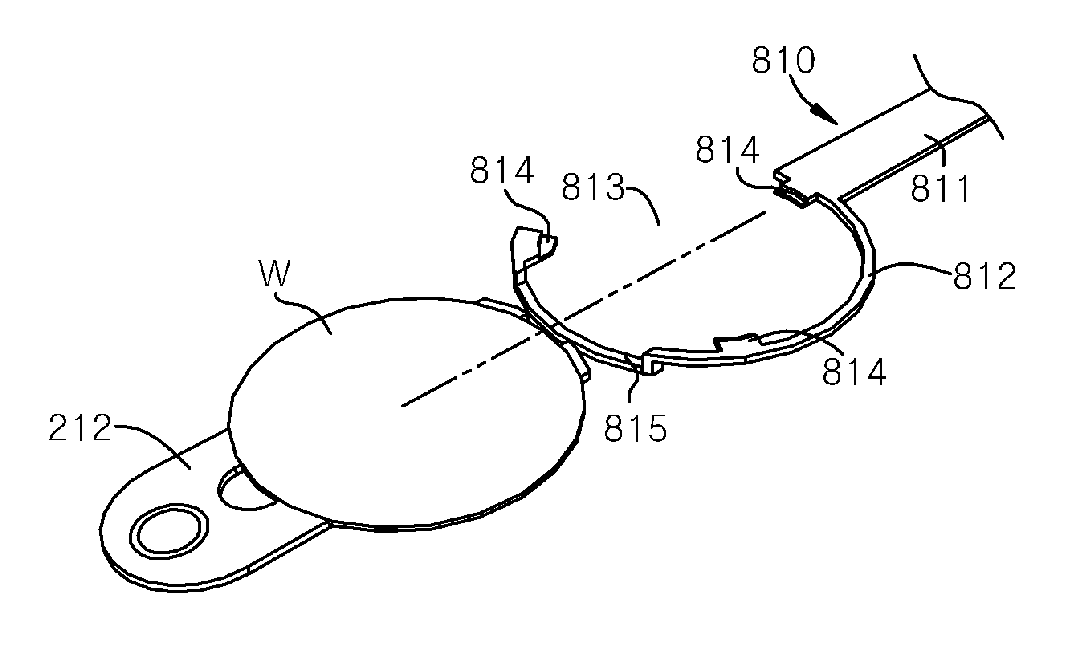

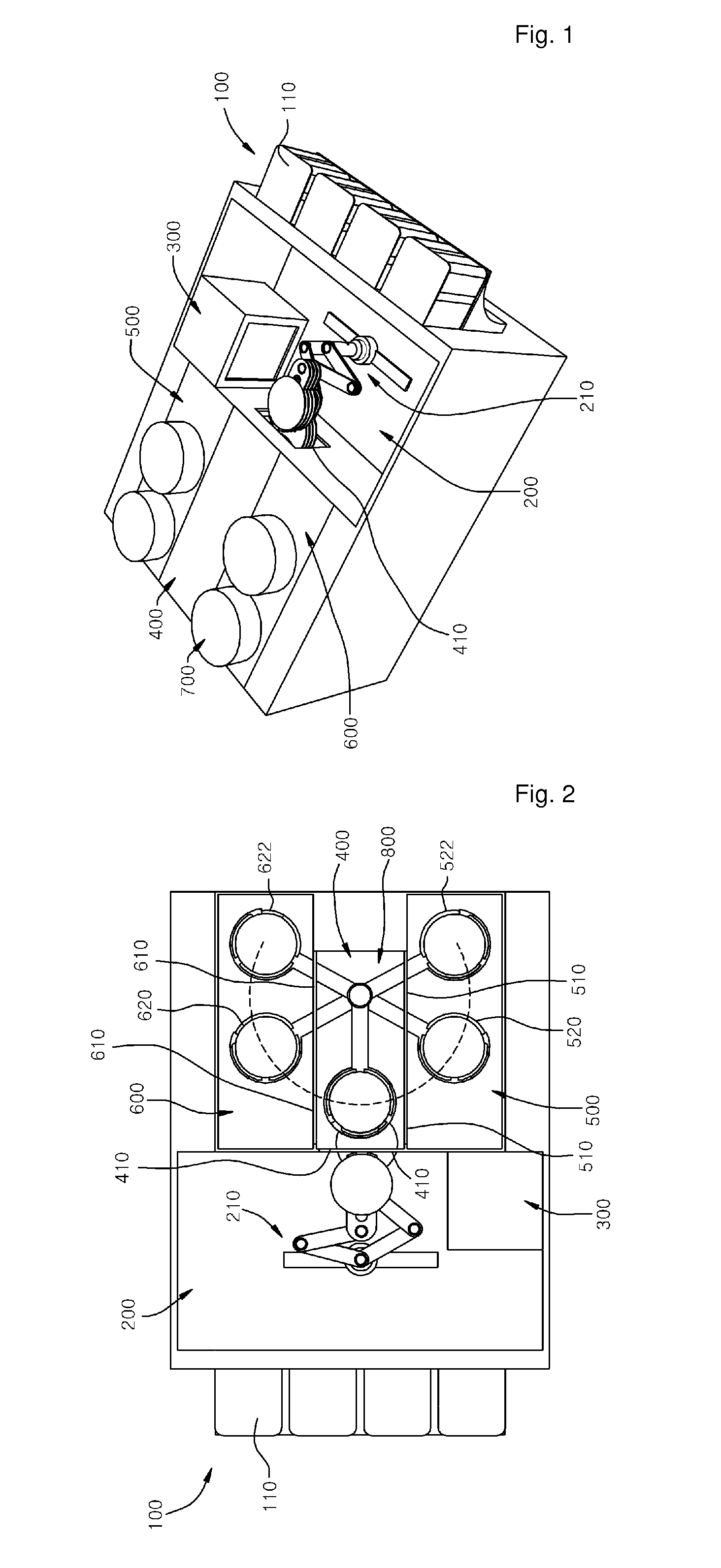

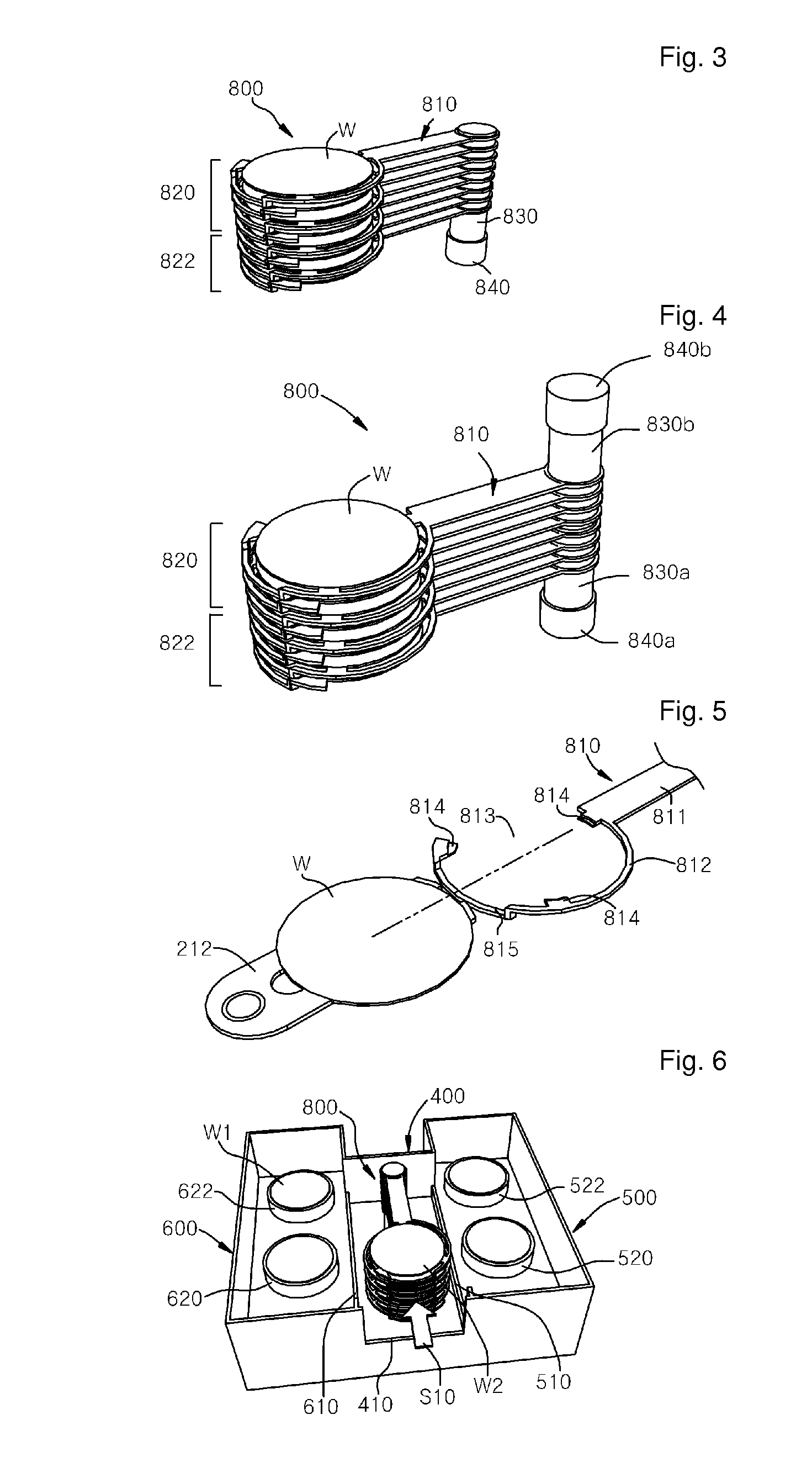

Substrate transfer equipment and high speed substrate processing system using the same

InactiveUS9054146B2Easy to implementImprove processing speedSemiconductor/solid-state device manufacturingRobotProduction rateEngineering

There are provided a substrate transferring apparatus for continuously loading / unloading a plurality of substrates in and from a process chamber to reduce time spent on transferring the substrates and to improve productivity and a substrate processing system using the same. The substrate transfer apparatus is installed in the transfer chamber and transfers substrates between first and second process chambers which is positioned lateral sides of the transfer chamber and a load rock chamber. The substrate transfer apparatus includes a driving unit to supply a rotational force, a spindle connected to the driving unit, first swivel plate arms to load / unload substrate to / from first process chamber, and second swivel plate arms to load / unload substrate to / from second process chamber. Since substrates before and after being processed are rapidly exchanged during the simultaneous or continuous process of plural substrates, processing rate increases and overall productivity can be increased.

Owner:NEW POWER PLASMA CO LTD

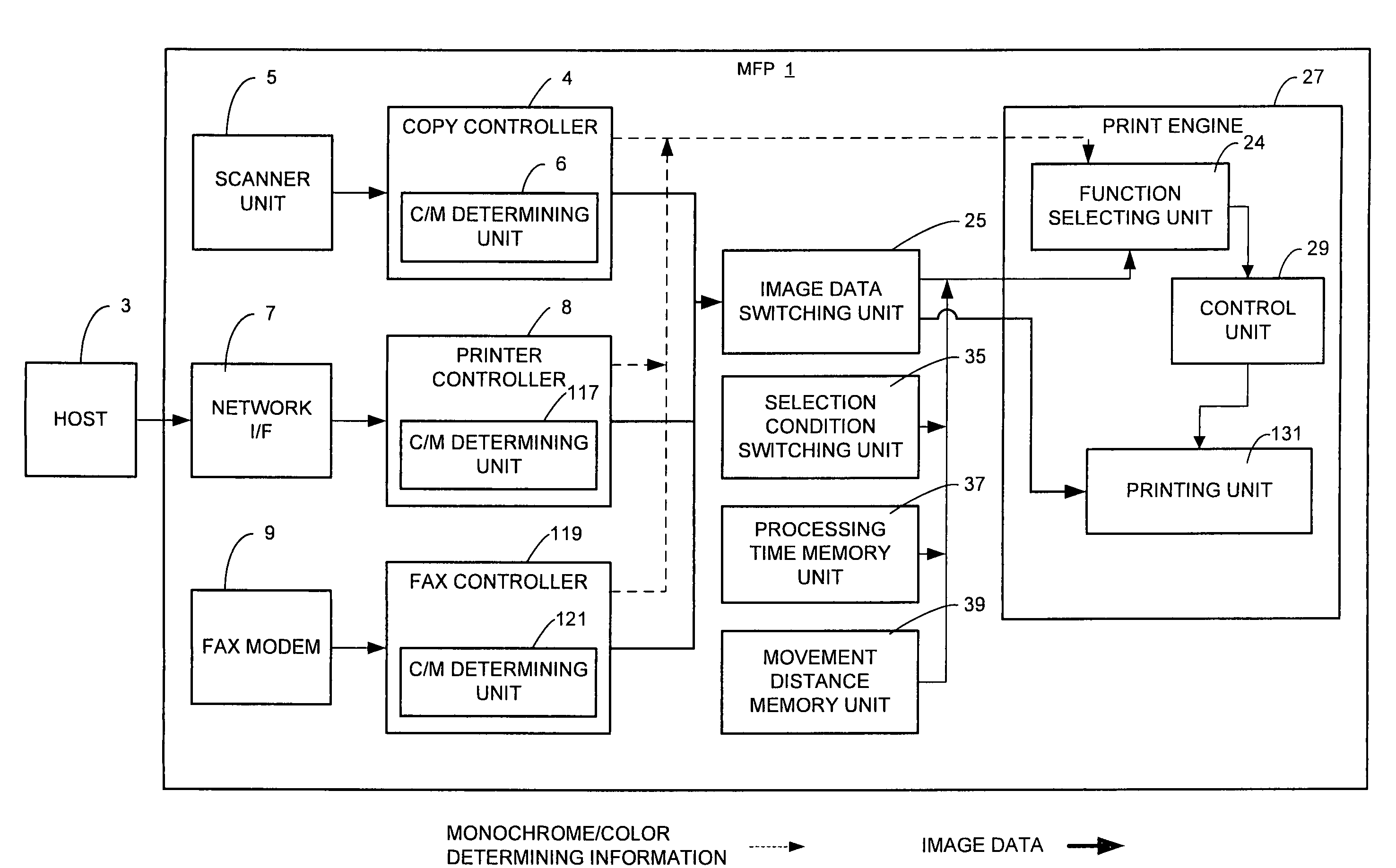

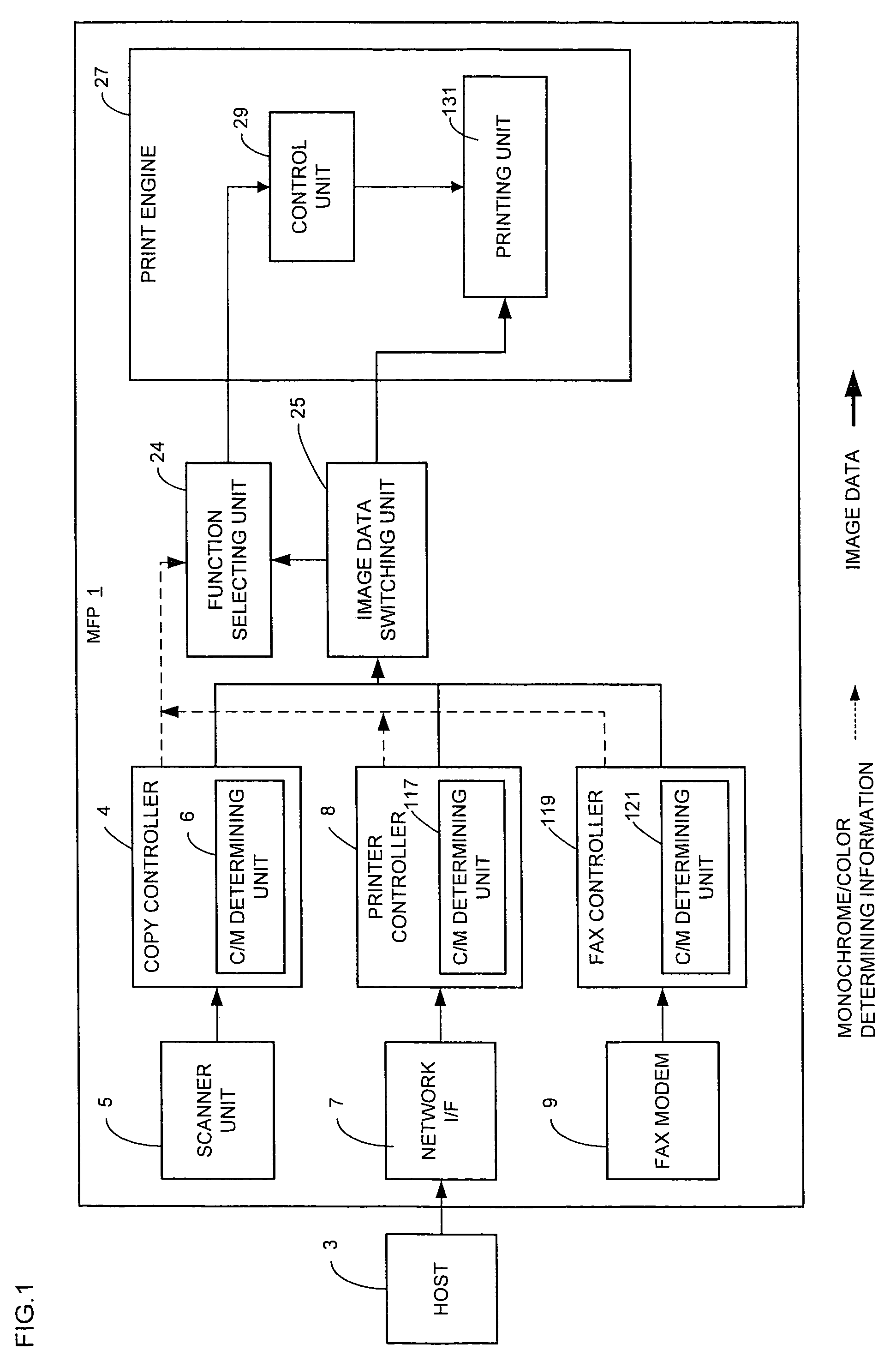

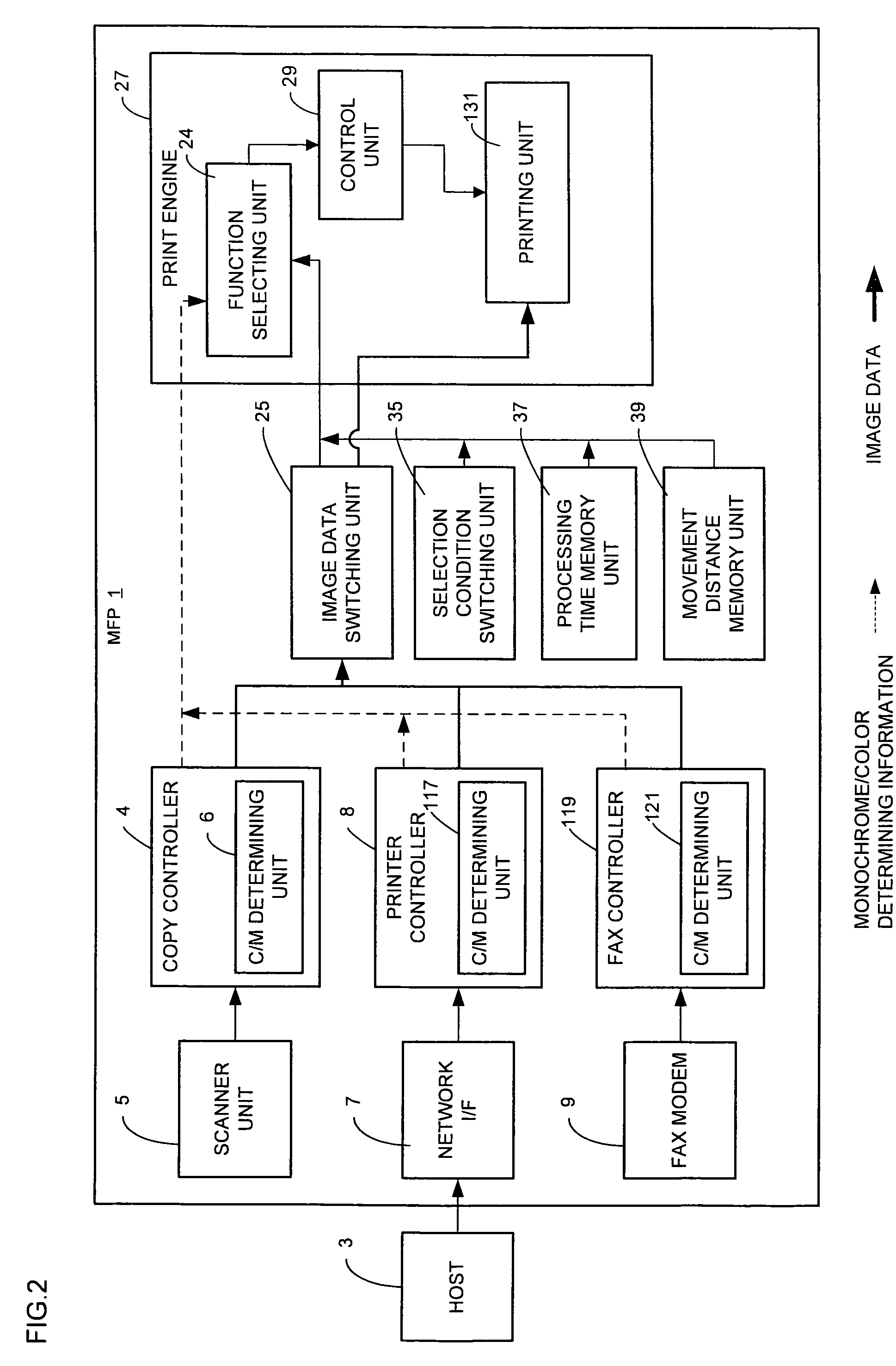

Image forming apparatus

InactiveUS7667861B2Shorten the timeCurb consumptionRecording apparatusElectrographic processes using photoelectrophoresisData acquisitionImage formation

An image forming apparatus including: a plurality of image data acquisition units for respectively acquiring one or more page(s) of image data; a color or monochrome determining unit for determining whether each of the acquired pages is in color or in monochrome; an image forming unit for performing image formation of each page switchably using a monochrome-only image forming function for a monochrome page or a color and monochrome image forming function for a color page and a monochrome page; an image data switching unit for sequentially selecting and arranging the acquired pages of image data one by one so that the image formation of each page is performed in the order of selection; a function selecting unit for selecting either one of the monochrome-only and color and monochrome image forming functions for each of the arranged pages on the basis of the determination result made by the color or monochrome determining unit; and a control unit for controlling the image forming unit so that image formation of each page is performed using the selected image forming function.

Owner:SHARP KK

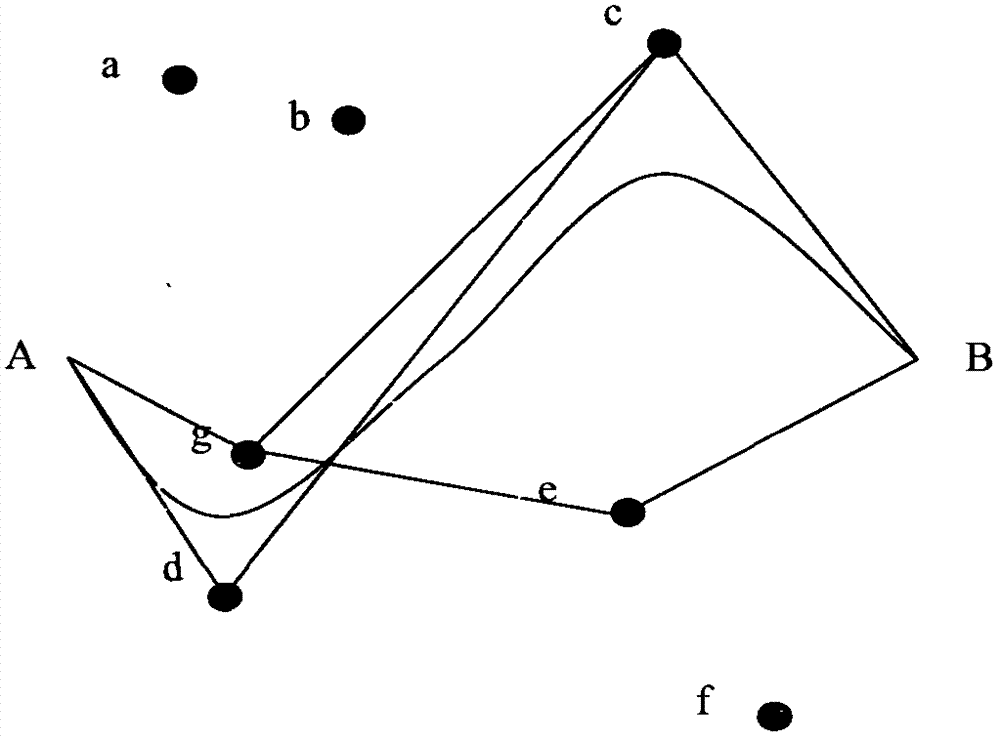

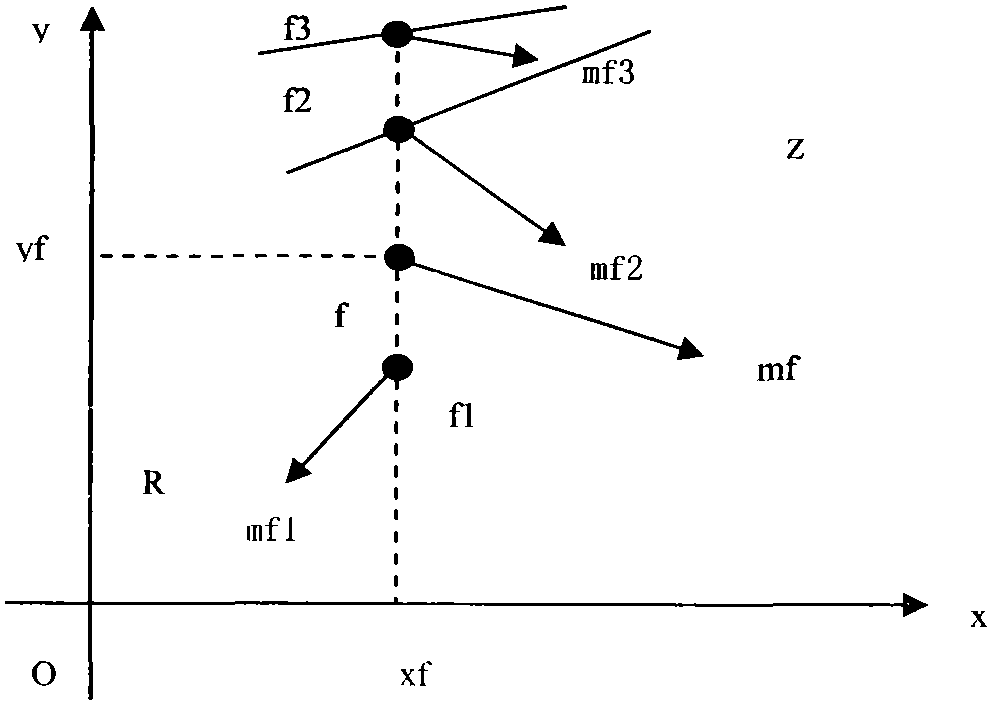

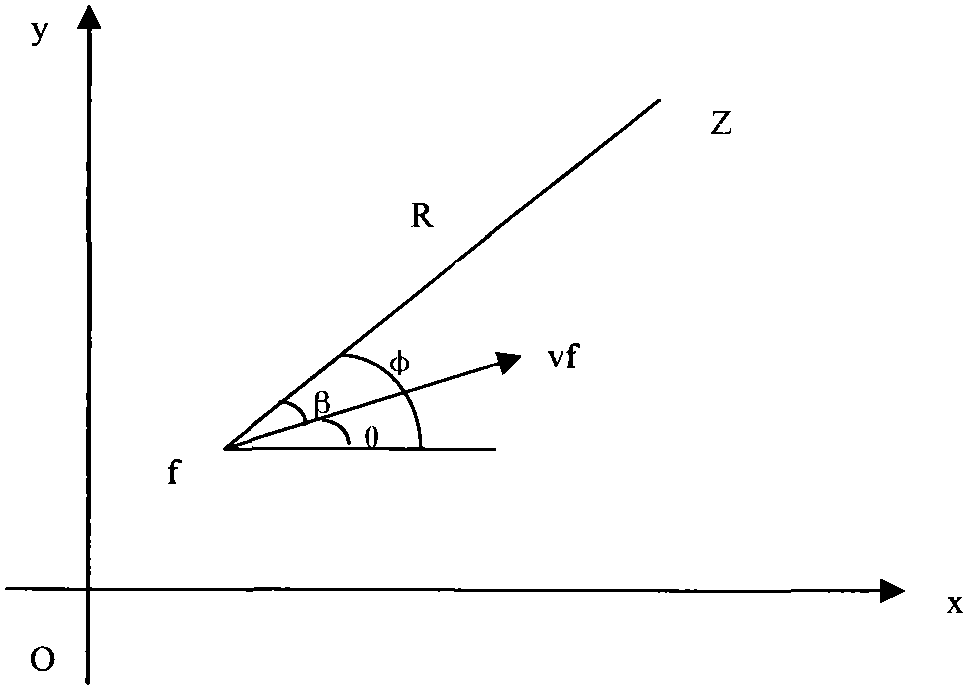

Vehicle routing method for simulating missile guidance

InactiveCN102768807ASave travel timeOptimize allocationRoad vehicles traffic controlForecastingAerodynamic dragSingle vehicle

The invention discloses a vehicle routing method for simulating missile guidance. The principle and the method are used for simulating missile guidance so that a missile needs to overcome earth gravity, air resistance and the like, and a vehicle can avoid congested road sections (save travel time) in running so that vehicle routing is realized. The method includes a global mode and a stepping mode, and the two modes respectively have advantages. The stepping mode places particular emphasis on achieving a single-vehicle routing goal, and the global mode simultaneously achieves the single-vehicle routing goal and a system optimization goal. By being improved, the vehicle routing method for simulating missile guidance can also be used for realizing routing to avoid the congested road sections (save travel time) and shorten travel distance. The method is a dynamic routing method, and the single-vehicle routing goal can be changed when the vehicle runs. Compared with other methods, the method is suitable for routing of urban intelligent transportation, so that the vehicle using the method avoids the congested road sections.

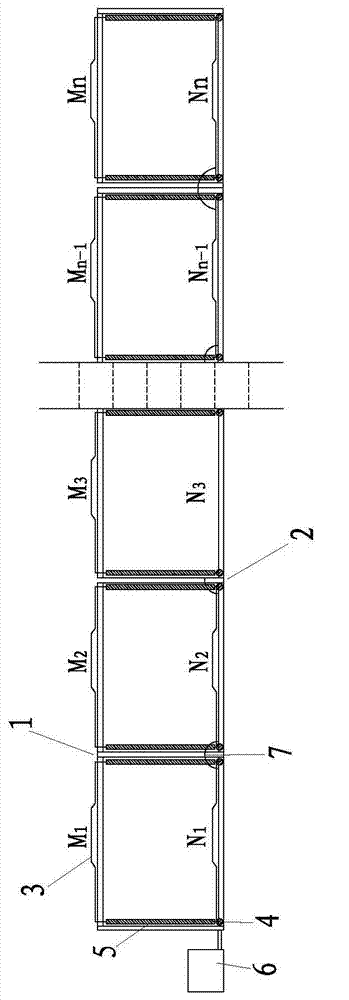

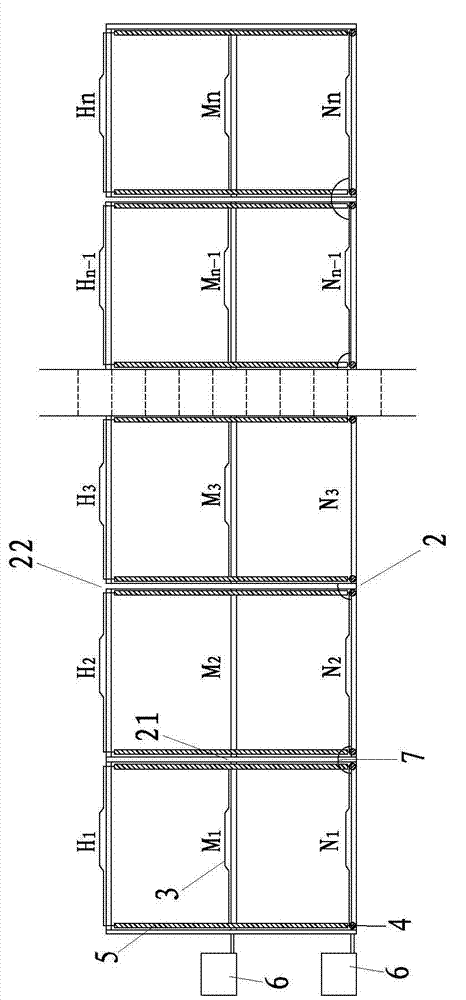

Three-dimensional parking garage and method for storing and taking car by applying same

The invention relates to the field of parking garages, and particularly to a three-dimensional parking garage and a method for storing and taking a car by applying the same. The invention is realized through the following technical scheme that: the three-dimensional parking garage comprises a ground layer garage and a non-ground layer garage which are distributed at the upper side and the lower side; the parking garage has empty carports; and other carports except for the empty carport are provided with car carrying platforms; the parking garage further comprises a transverse moving mechanism used for moving a corresponding car carrying platform at the ground layer out of the carport at the ground layer, a ground-layer lengthways moving mechanism used for moving a corresponding car carrying platform at the ground layer to a current empty carport at the ground layer, and a lifting mechanism used for moving each car carrying platform upwards and downwards. The three-dimensional parking garage can ease the parking difficulty efficiently, and is particularly suitable for simple parking garages at roadsides.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD

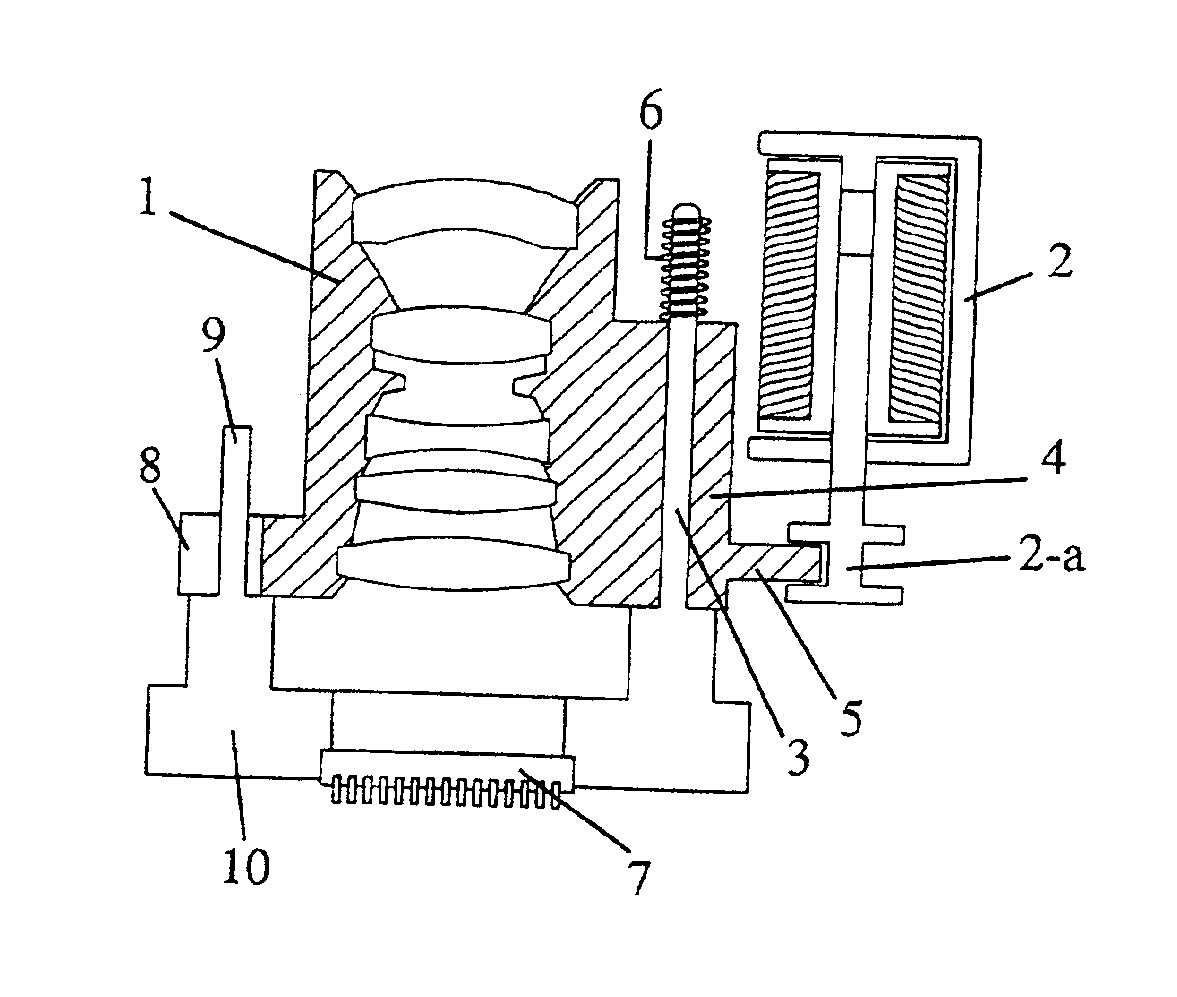

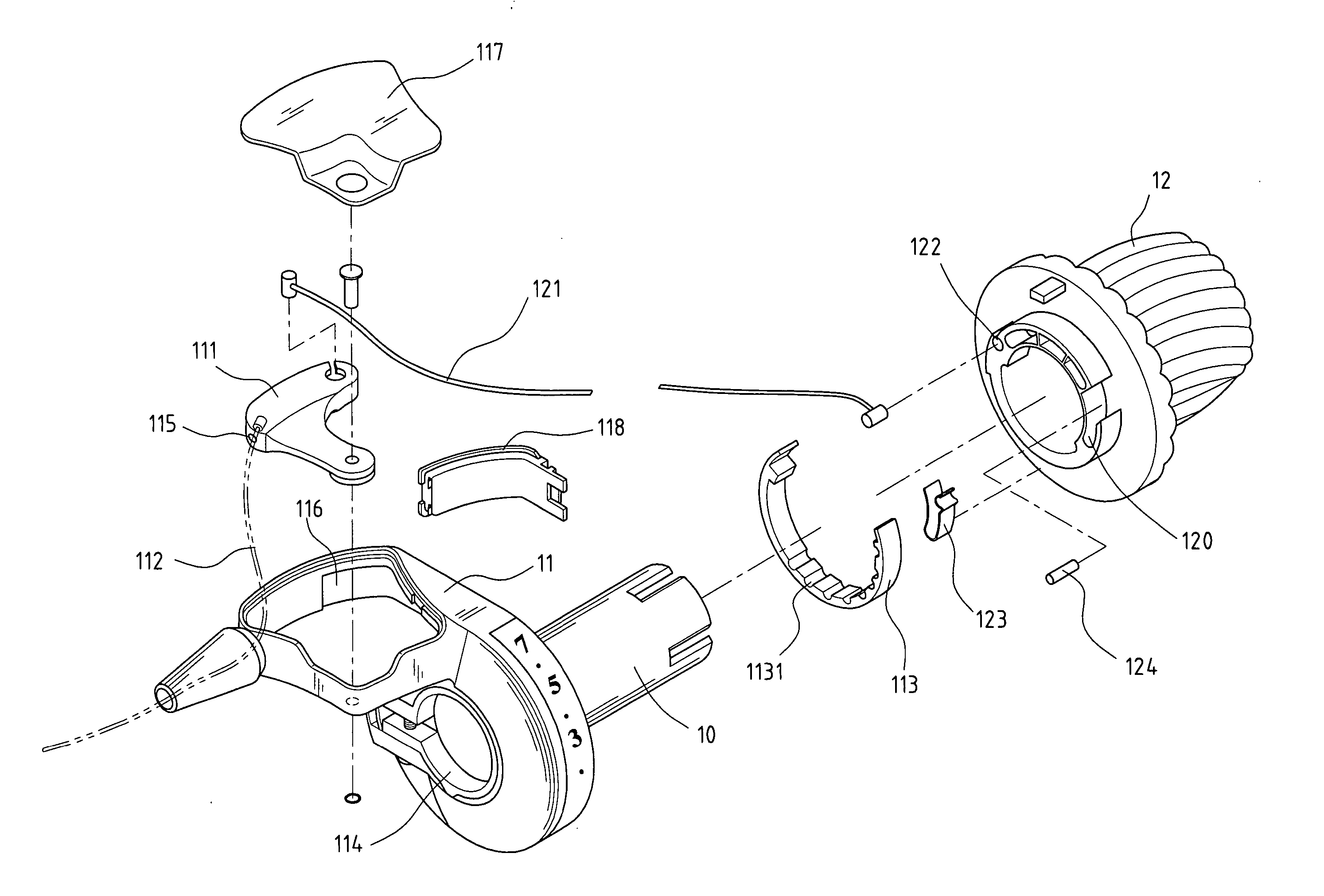

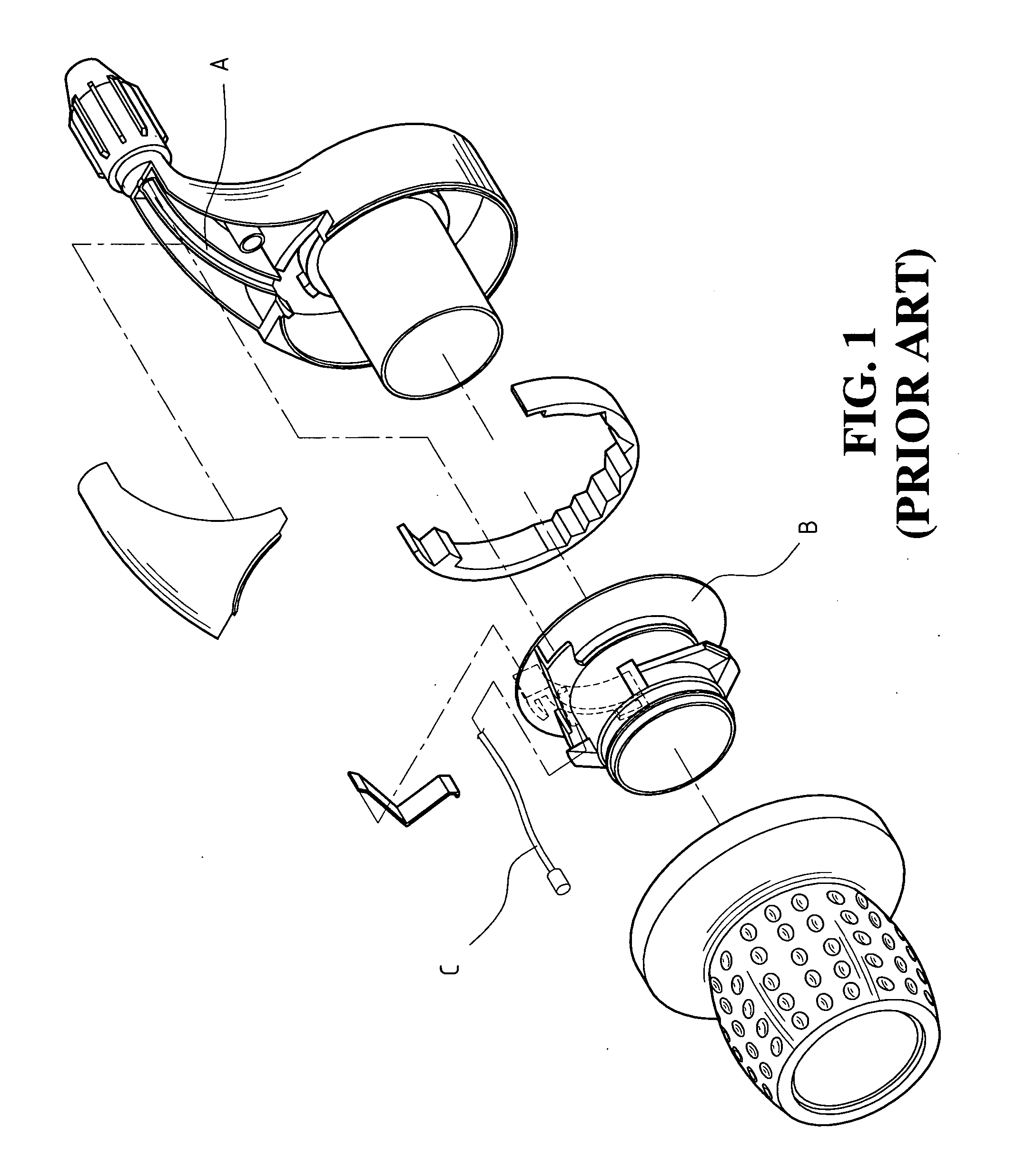

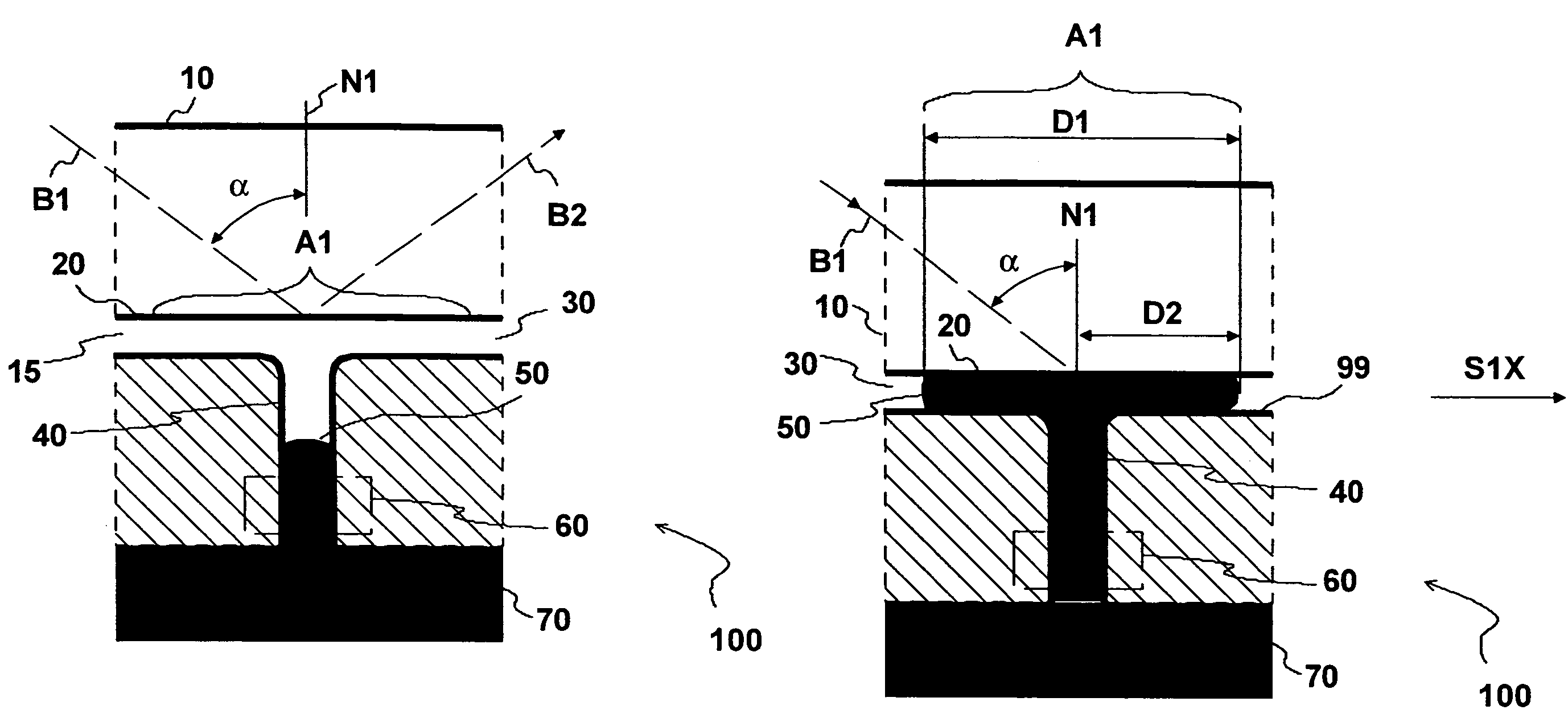

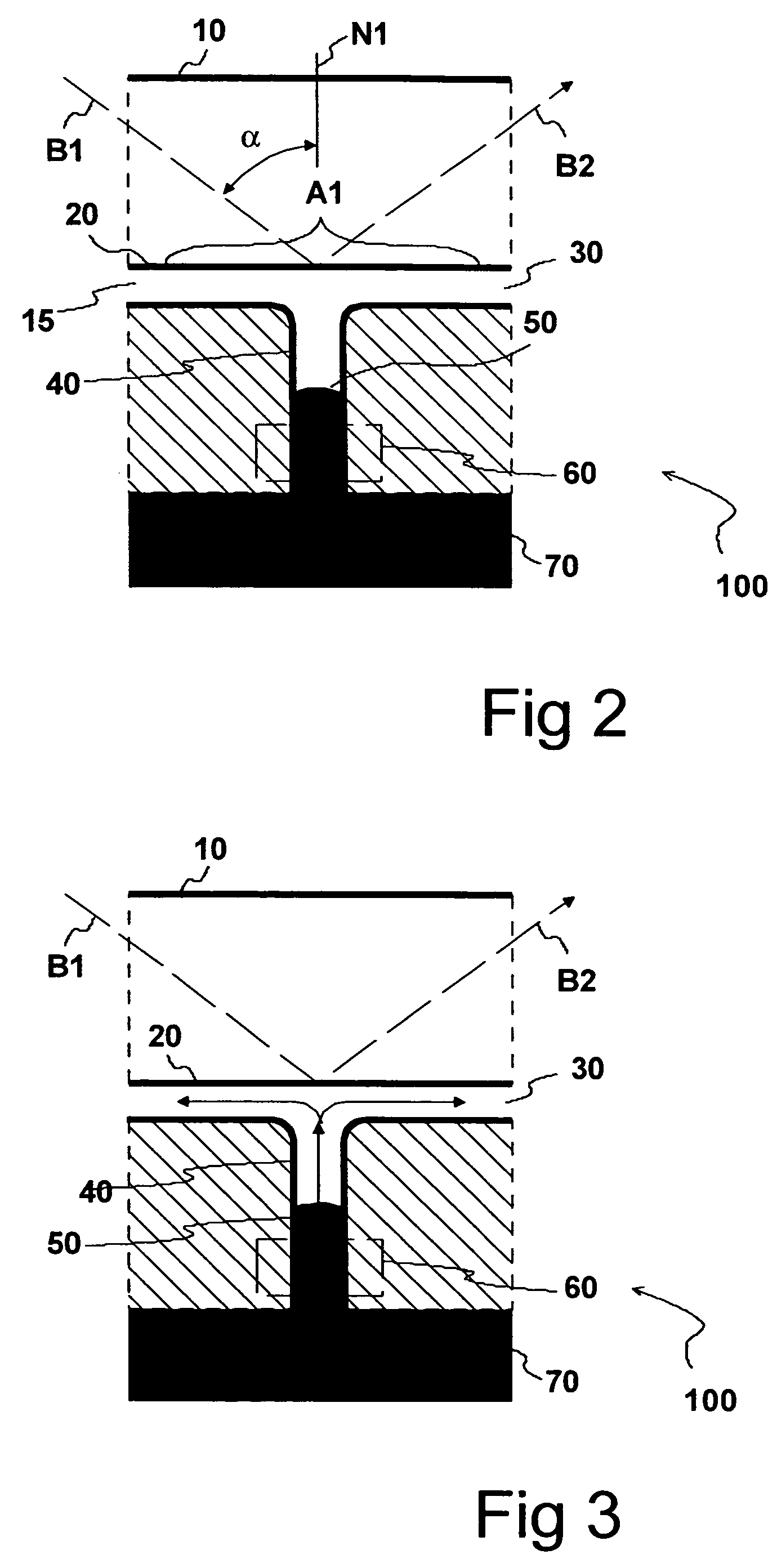

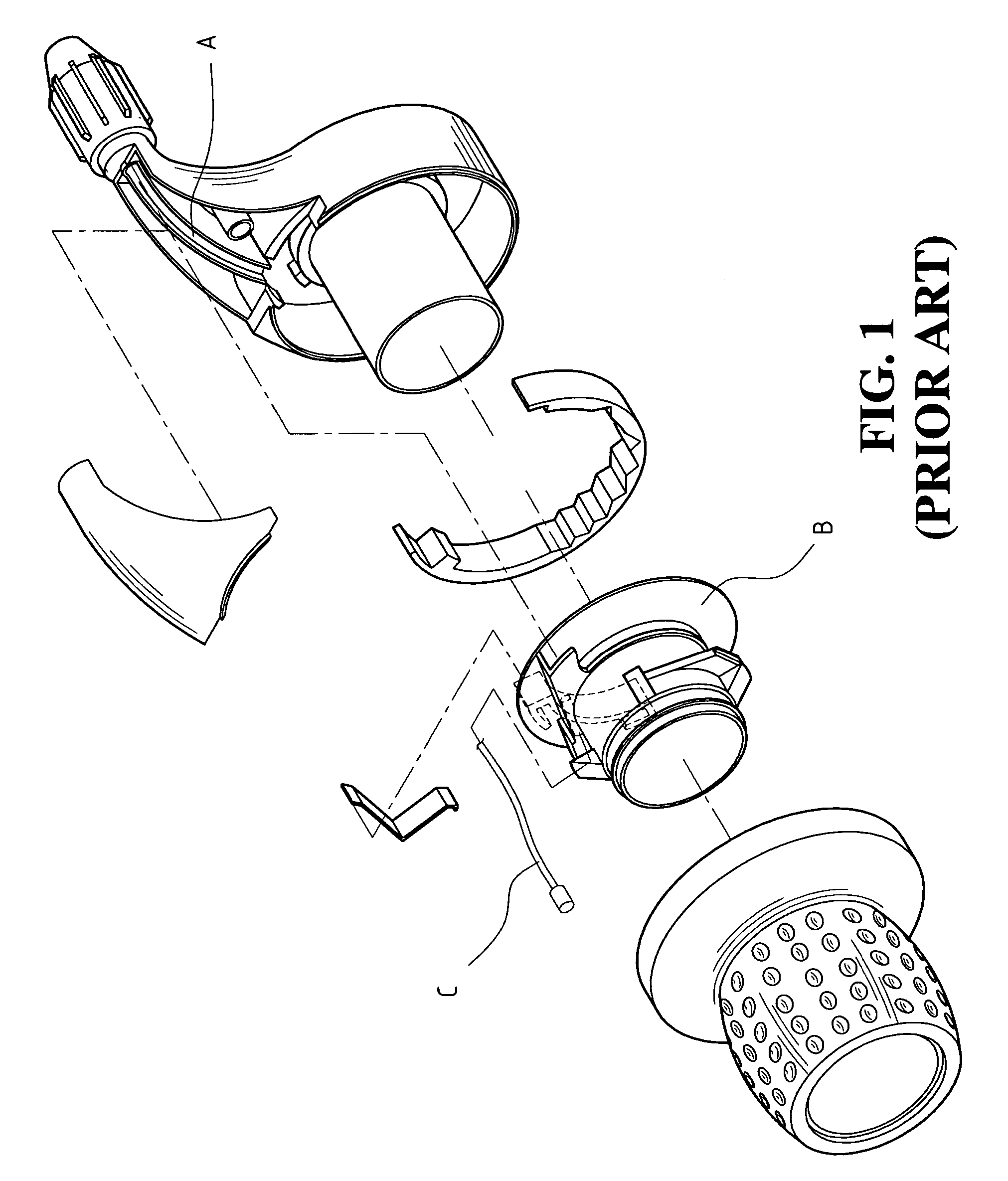

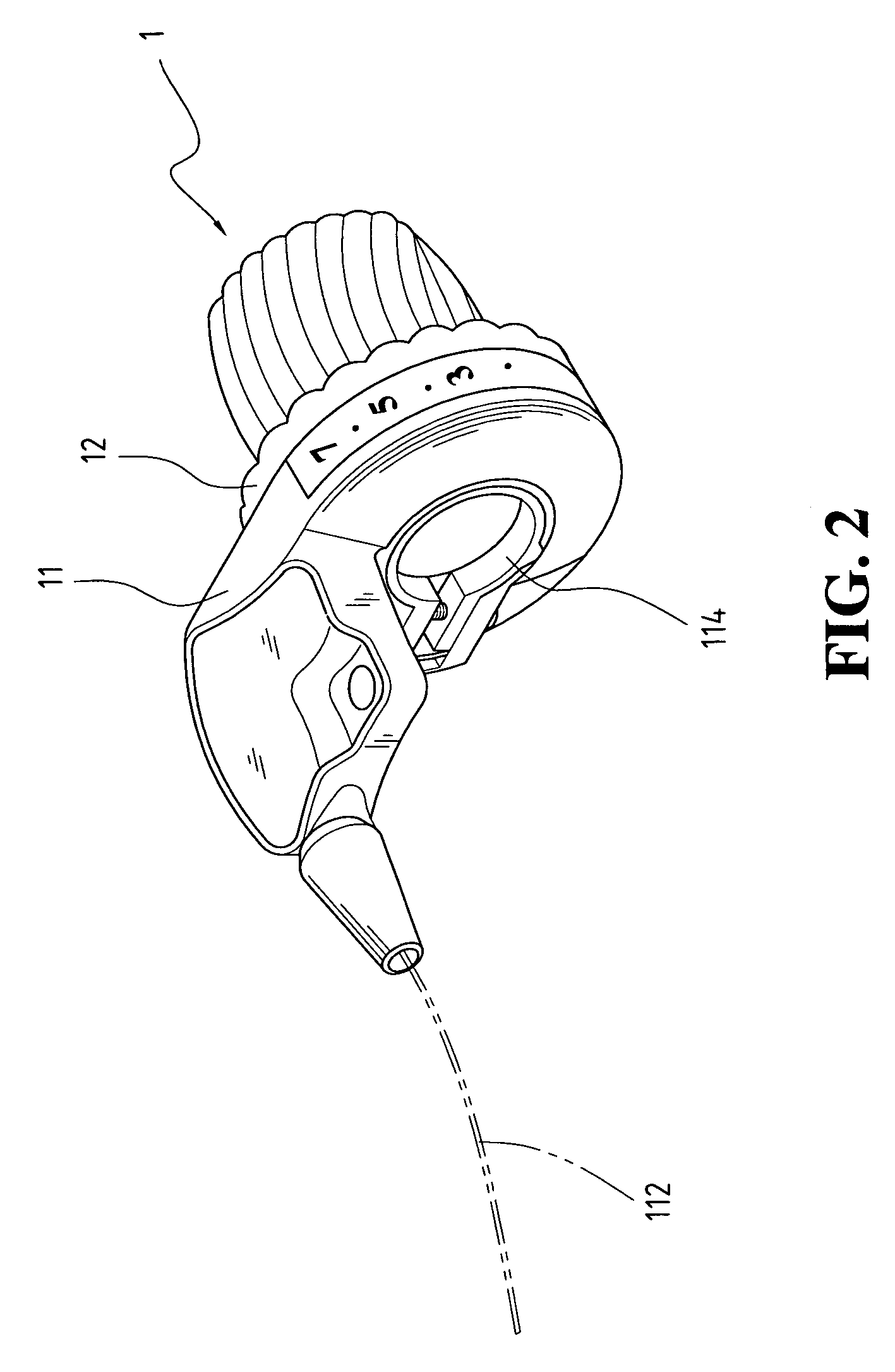

Optical shutter for miniature cameras

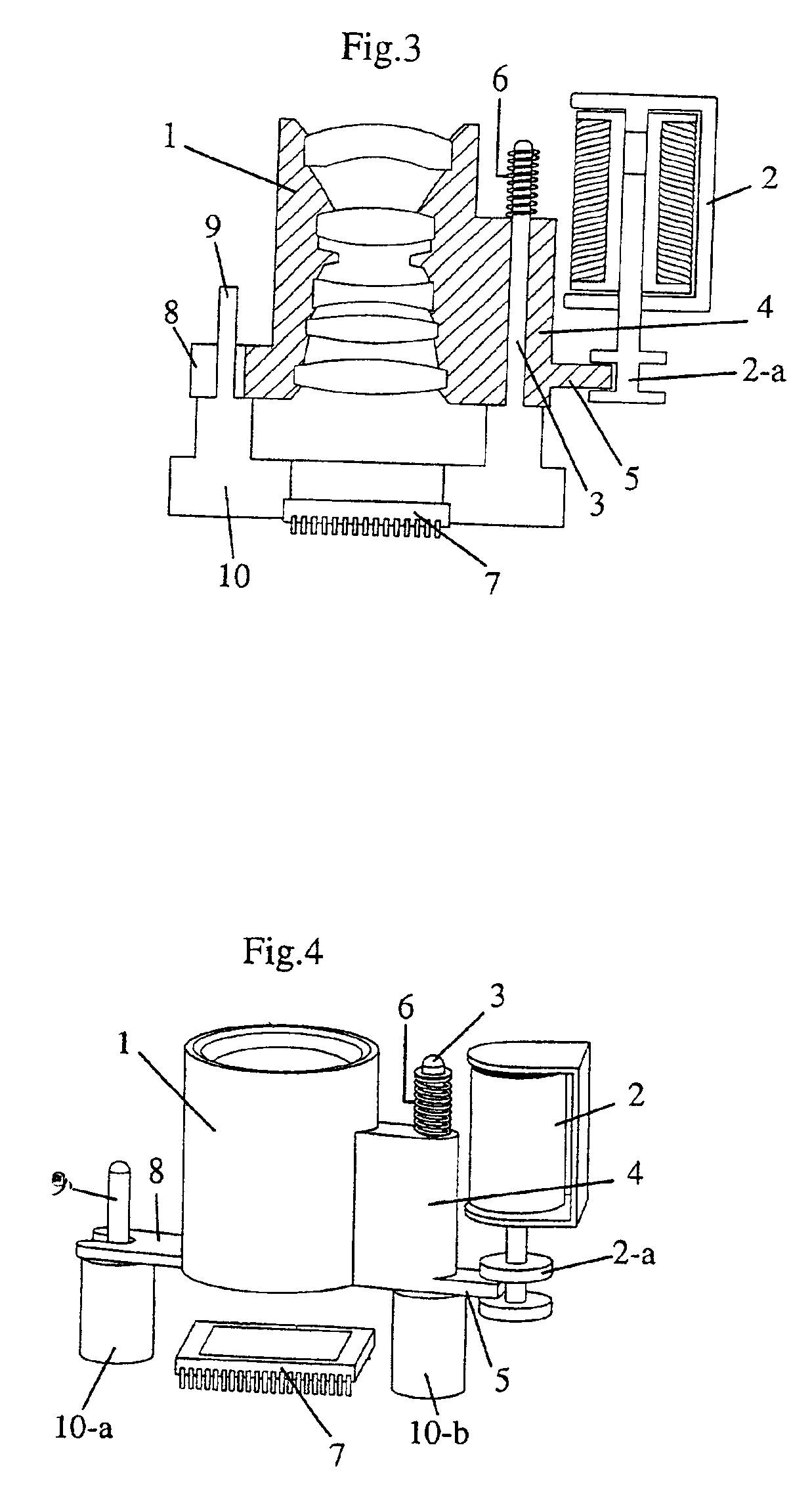

ActiveUS7427745B2Increase shutter speedShort travel distanceTelevision system detailsDischarge tube screensTotal internal reflectionDigital camera

The invention relates to a shutter for an optical imaging system, e.g. a digital camera. The shutter comprises an interface between a transparent body and a capillary space. Light rays introduced to the active area of the interface are reflected by total internal reflection when the capillary space is filled with a gas. The light rays are transmitted through the interface when the capillary space is rapidly filled with a liquid. Thus, the light rays are either absorbed or reflected towards an image sensor, depending on the state of the shutter. The liquid is delivered to the capillary space through at least one duct which is positioned opposite the active area.

Owner:CORE WIRELESS LICENSING R L

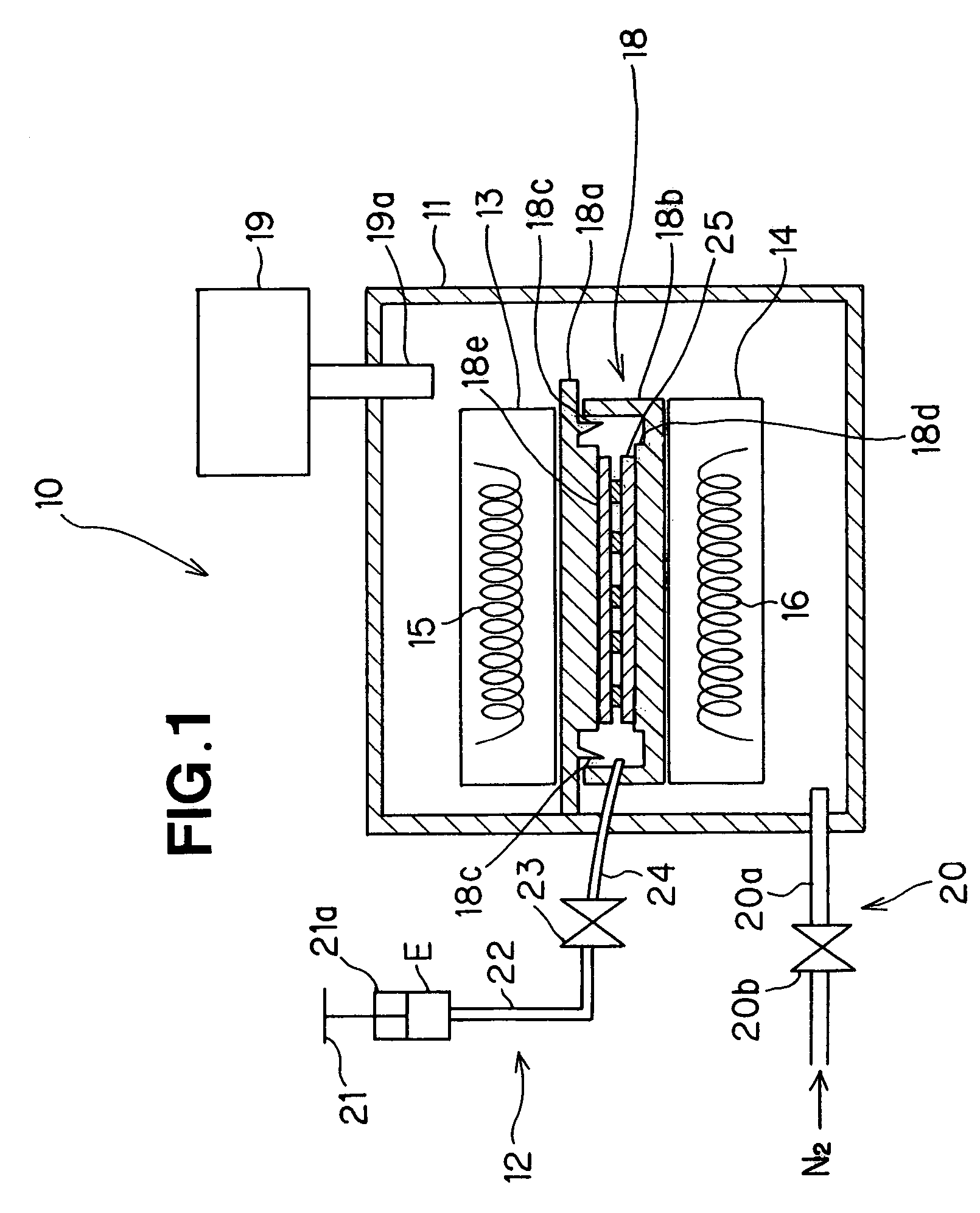

Adhesive injection apparatus

InactiveUS7594805B2Easy to unifyShort travel distanceTailstocks/centresConfectioneryAdhesivePressure difference

Adhesive injection apparatus, designed to inject an adhesive into gaps between a plurality of layers of flat plate members, includes: a receptacle for holding therein the flat plate members; an evacuation section for evacuating the interior of the receptacle and the gaps between the flat plate members; an adhesive supply section for supplying the adhesive into the receptacle; and a gas introduction section for introducing a gas into the receptacle to produce a pressure difference between the interior of the receptacle and the gaps between the flat plate members, so as to allow the adhesive to be injected from all around the flat plate members into the gaps.

Owner:HONDA MOTOR CO LTD

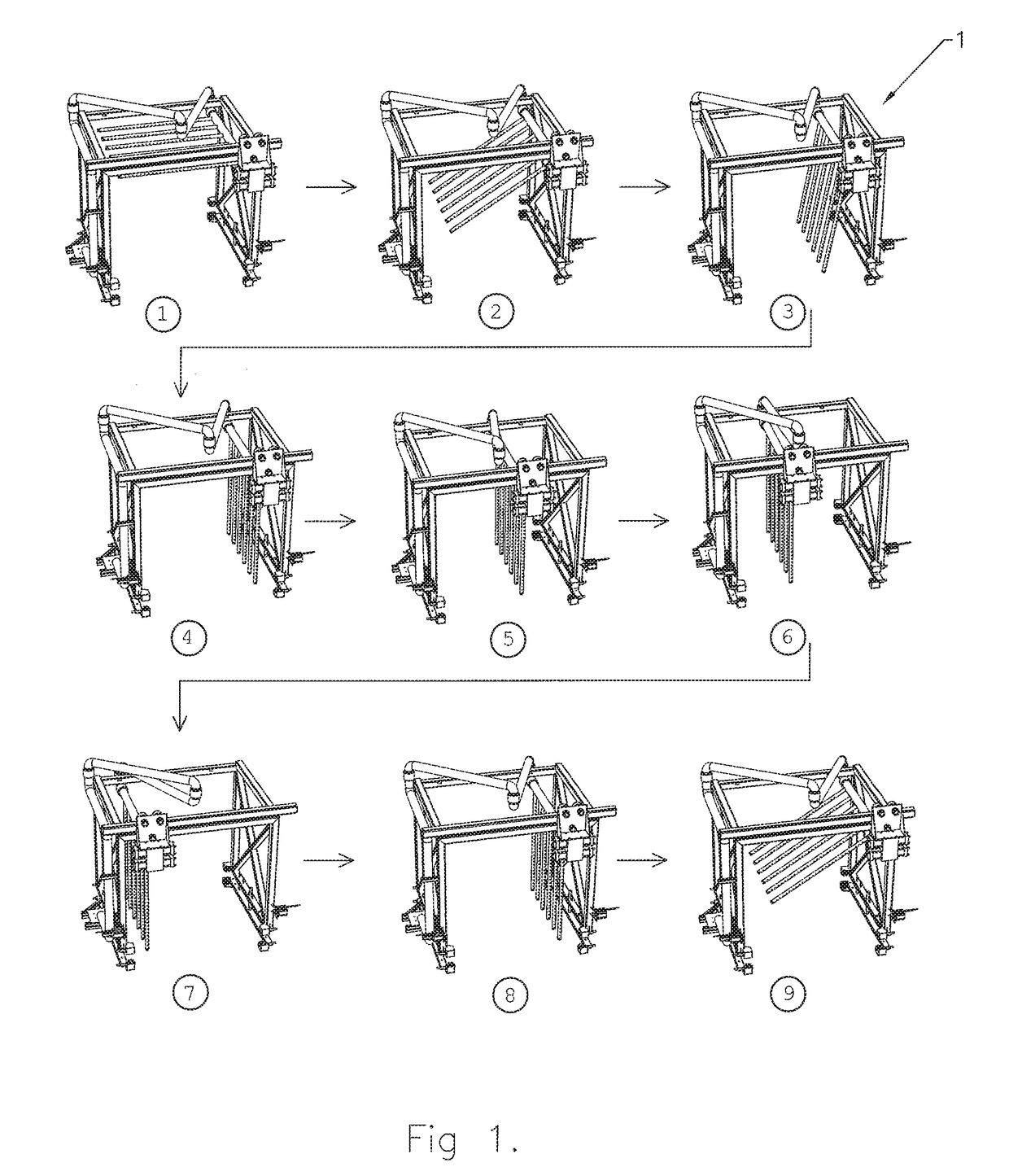

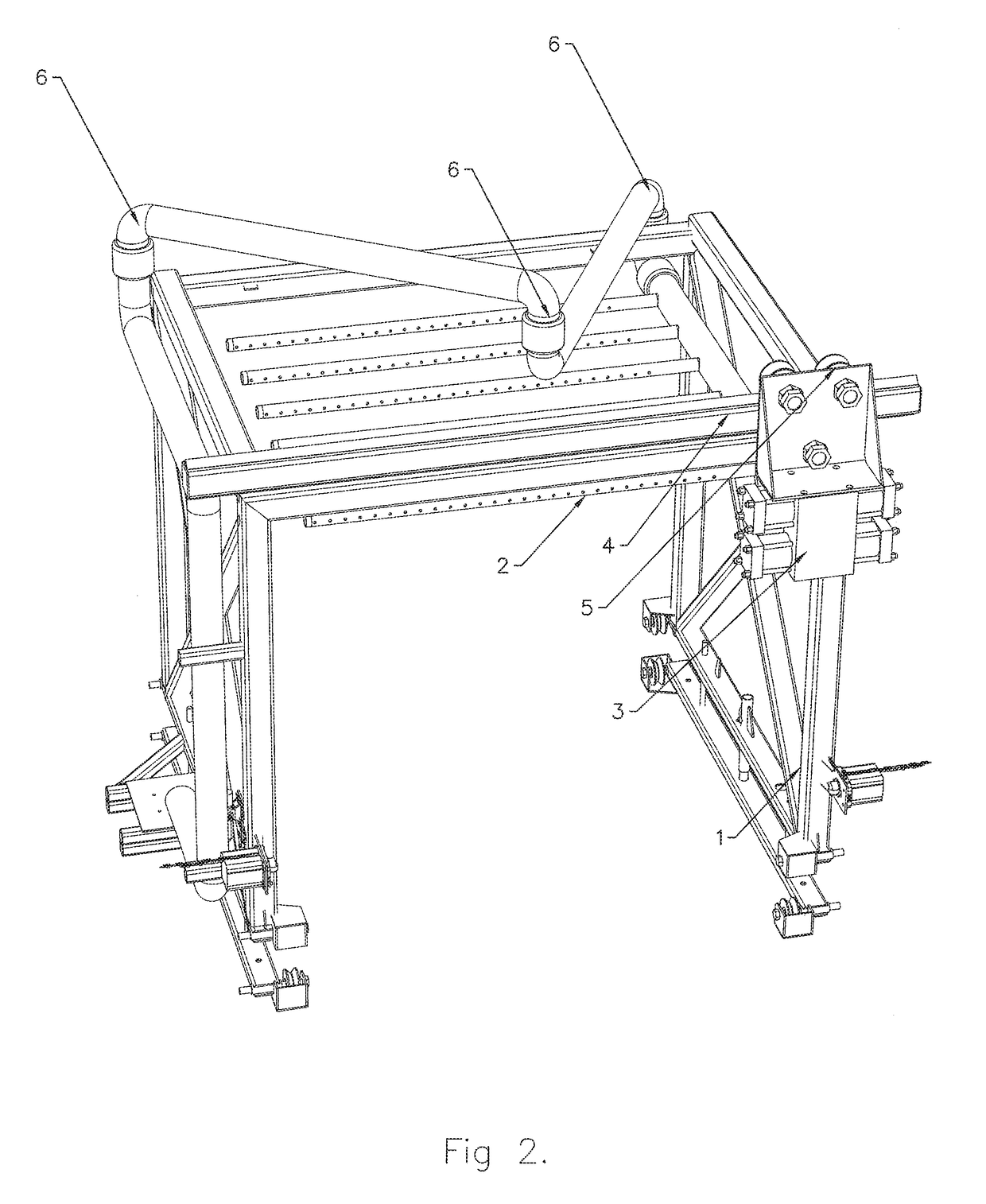

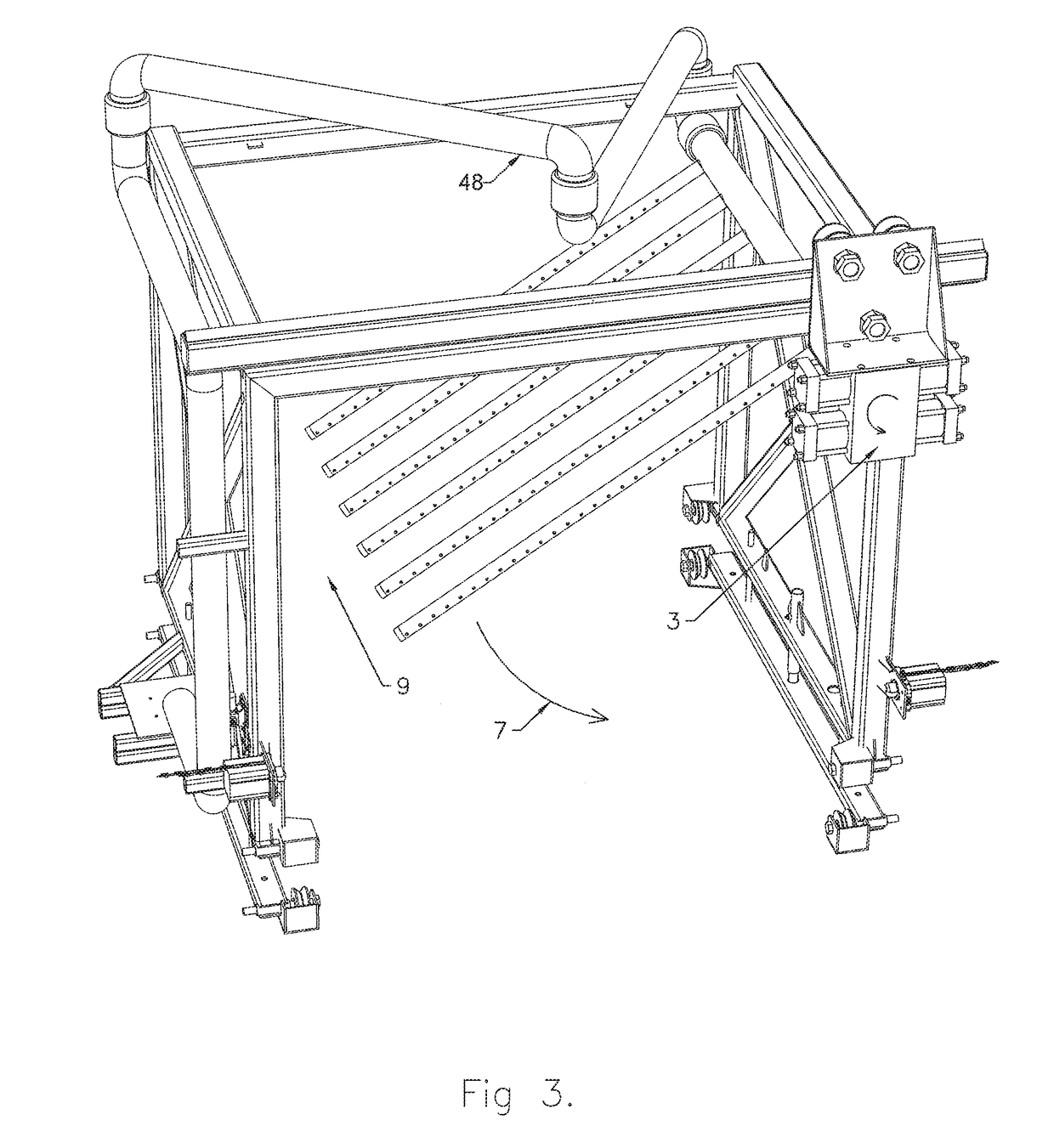

Rotary and laterally translating washer for filter presses and methods thereof

InactiveUS20180345178A1Lower cost of capitalReduce manufacturing costFiltration separationWash waterEngineering

Various embodiments of a filter (31 38, 42) are disclosed. According to some embodiments, filter (31, 38, 42) may have a frame (34) and washing means operatively coupled to the frame (34) which is configured to wash one or more filter cloths simultaneously, the filter cloths being attached to a respective number of filter plate assemblies (13) which are supported by the frame (34). The washing means may comprise a laterally traversing washer mechanism, the laterally traversing washer mechanism being configured to move (8) along a lateral axis (35) of the filter (31, 38, 42) from a first side of the one or more filter cloths to a second side of the one or more filter cloths. In some embodiments, the washing means may be operatively coupled to the frame (34) via a track (3) and a washer carriage (1) on the track (3). In some embodiments, the washer carriage may be further provided with means, for example, to simultaneously shake one or more filter plate assemblies (13), without limitation. Methods of filtering slurry comprising the steps of moving (8) a laterally traversing washer mechanism in a direction along a lateral axis (35) of a filter (31, 38, 42); rotating at least one spray bar (2); and providing wash water to the at least one spray bar (2) are further disclosed.

Owner:F L SMIDTH & CO AS

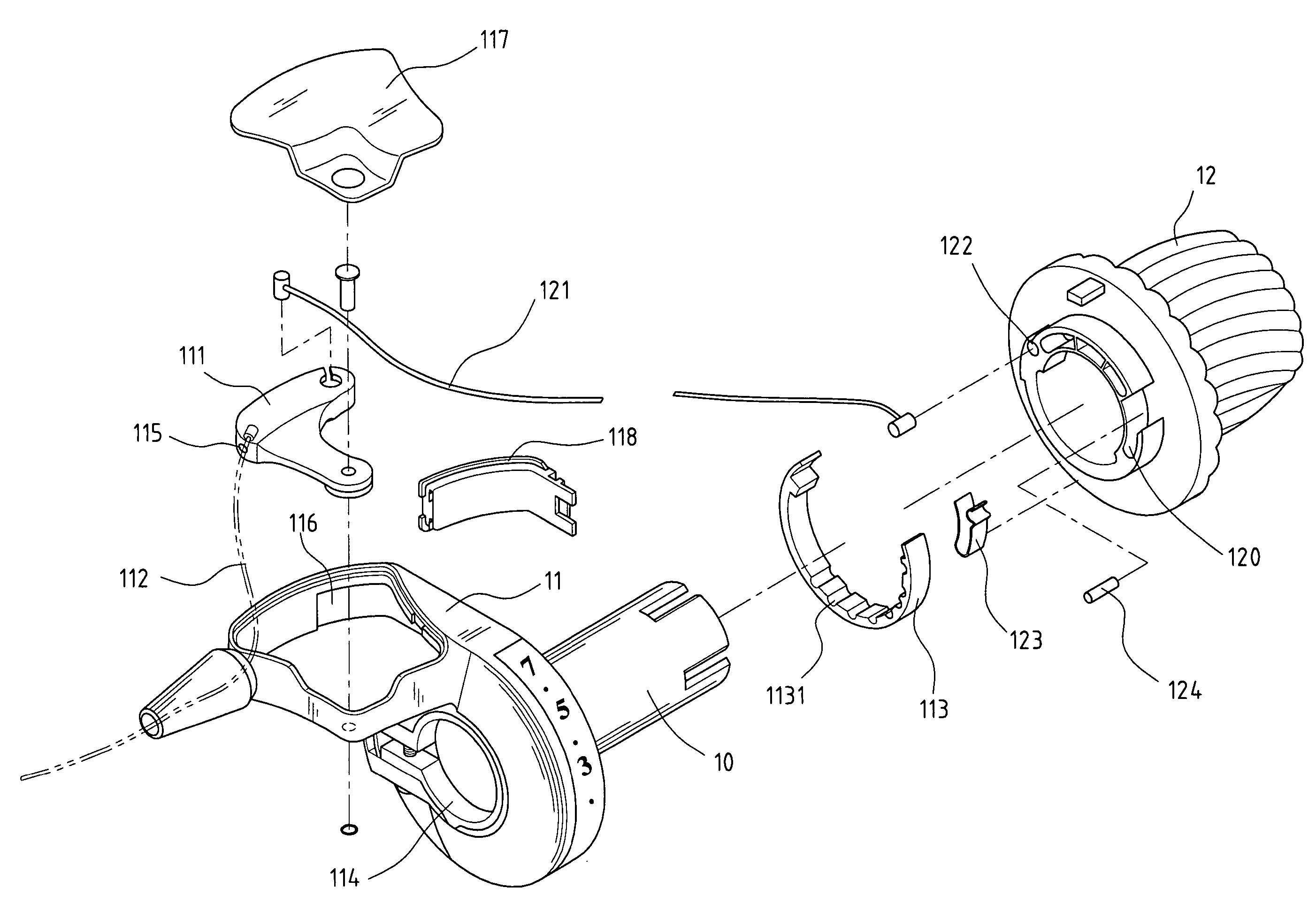

Handlebar gear shifter for bicycle

InactiveUS7302874B2Easy to operateShort travel distanceControlling membersCycle control systemsEngineeringMechanical engineering

A handlebar gear shifter for a bicycle includes a tabular handlebar having a support plate extending from an end of the handlebar at the top of the peripheral thereof. A sleeve is rotatably mounted to the handlebar. A fan-shaped mediate member has an end pivotally connected onto the support plate. A first cable has one end thereof engaged with a recess in the sleeve and the other end of the first cable is engaged with the mediate member. A second cable connects between the mediate member and a derailleur mechanism. A C-shaped member having notches is connected to the handlebar. A spring member is engaged with the sleeve. An index member is biased by the spring member and removably engaged with one of the notches. The improvement is that the distance between the pivot end of the fan-shaped mediate member and one distal end thereof connected to the first cable is approximately equal to or slightly less than that between the pivot end and the other distal end thereof connected to the second cable, so that the traveling distance of the first cable is less than that of the second cable. Therefore, the traveling distance of the first cable and thus the rotated angle of the sleeve can be shorted for each gearshift that is more convenient for operation.

Owner:CHEN PO CHENG

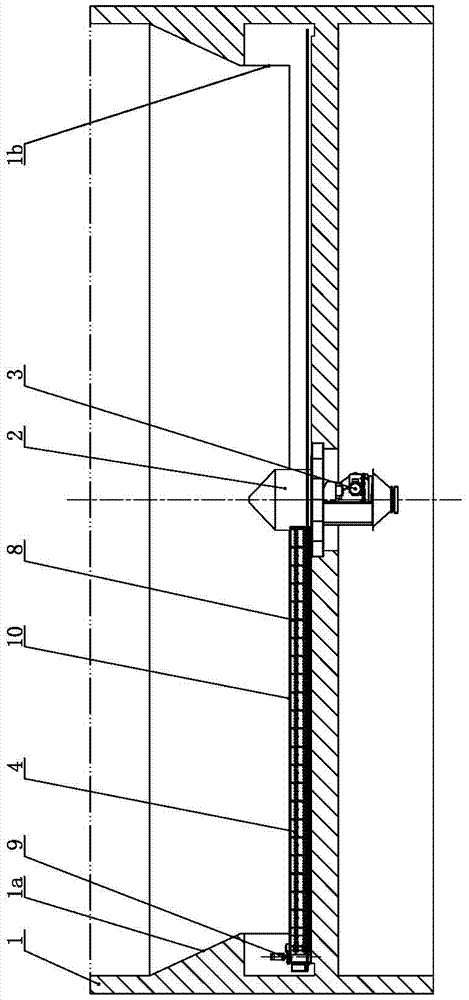

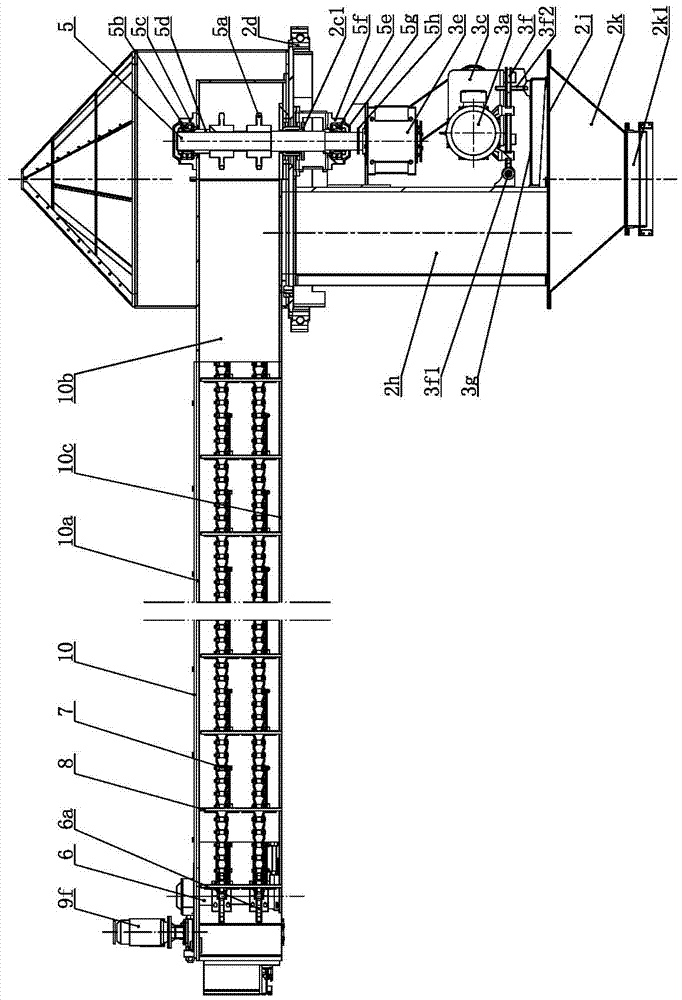

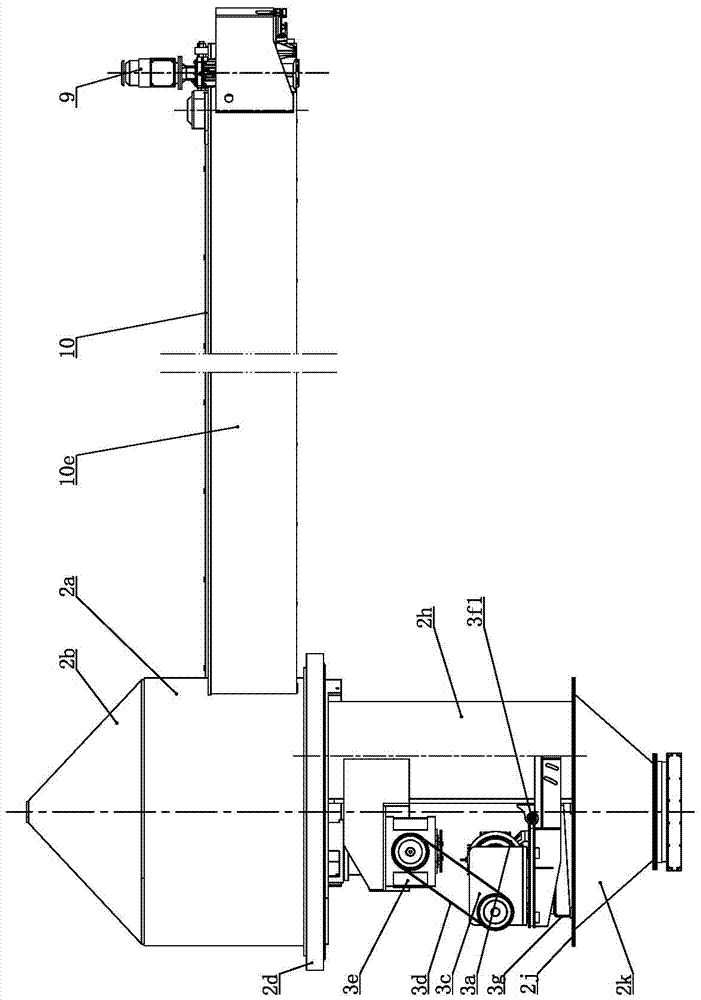

Delivery and clearance device of circular bin

The invention relates to a delivery and clearance device of a circular bin. The device comprises a center rotating mechanism, a main driving mechanism, a scraper discharge mechanism, a large beam mechanism and a revolution walking mechanism; the center rotating mechanism comprises a rotating cylinder coaxial with the bin; a rotating baseplate is arranged at the bottom of the rotating cylinder; the scraper discharge mechanism comprises a head shaft and a tail shaft; the head shaft is mounted at the head part of the large beam mechanism, and is driven by the main driving mechanism; the tail shaft is mounted at the tail part of the large beam mechanism; chain is wound between a driving chain wheel on the head shaft and a driven chain wheel on the tail shaft; scrapers are uniformly arranged on the chain; the revolution walking mechanism is positioned in annular space at the lower part of the bin; the tail part of the large beam mechanism is supported on the revolution walking mechanism; the head part of the large beam mechanism is inserted in the rotating cylinder; and a scraper mechanism discharge port for penetrating through the rotating baseplate to position between the rotating cylinder and the head shaft is arranged at the head part of the large beam mechanism. The delivery and clearance device of the circular bin can adapt to a cake bin or a grain bin, is low in operation energy consumption, and can greatly save the bin construction cost.

Owner:MYANDE GRP CO LTD

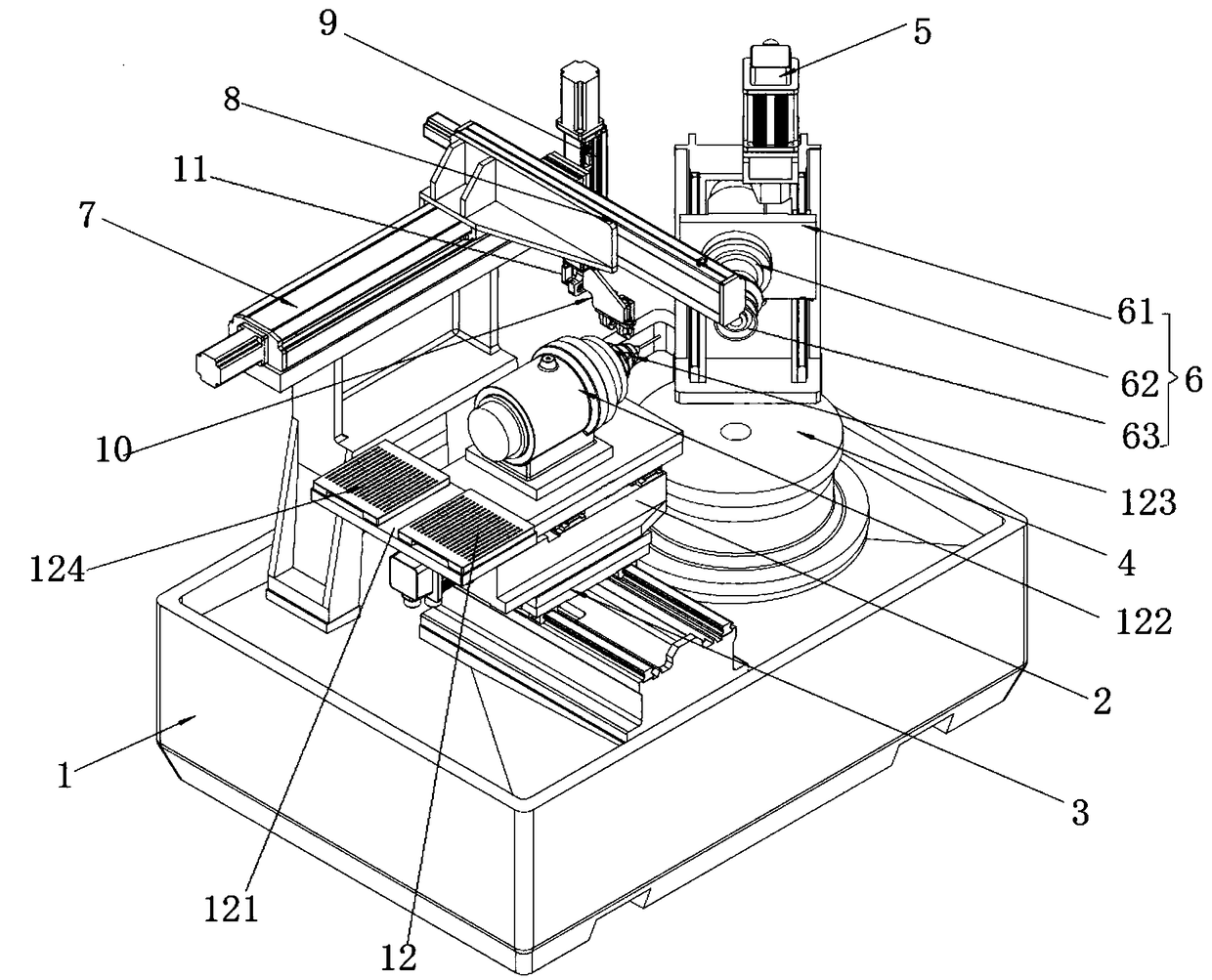

Single-head full-automatic numerical control tool grinding machine

InactiveCN108890466AHigh degree of automationEasy to operateGrinding carriagesGrinding machinesNumerical controlMachine tool

The invention relates to a single-head full-automatic numerical control tool grinding machine. The grinding machine comprises a base. The base is provided with a machine tool X axis, a machine tool Yaxis and a machine tool C axis. The machine tool X axis is provided with a clamping mechanism, the machine tool C axis is provided with a machine tool Z axis, and the machine tool Z axis is connectedwith a grinding mechanism. The base is provided with a machine tool V axis, a machine tool W axis and a machine tool U axis sequentially connected. The lower end of the machine tool U axis is providedwith a mechanical claw. The machine tool U axis is connected with a flip mechanism for adjusting the mechanical claw from the vertical state to the horizontal state. The tool grinding machine can solve the problem of interference between the a gripper and a grinding head, does not need to adjust tools, effectively improves the production efficiency, and has higher machining precision.

Owner:WUHU HONGJIN MACHINE TOOL

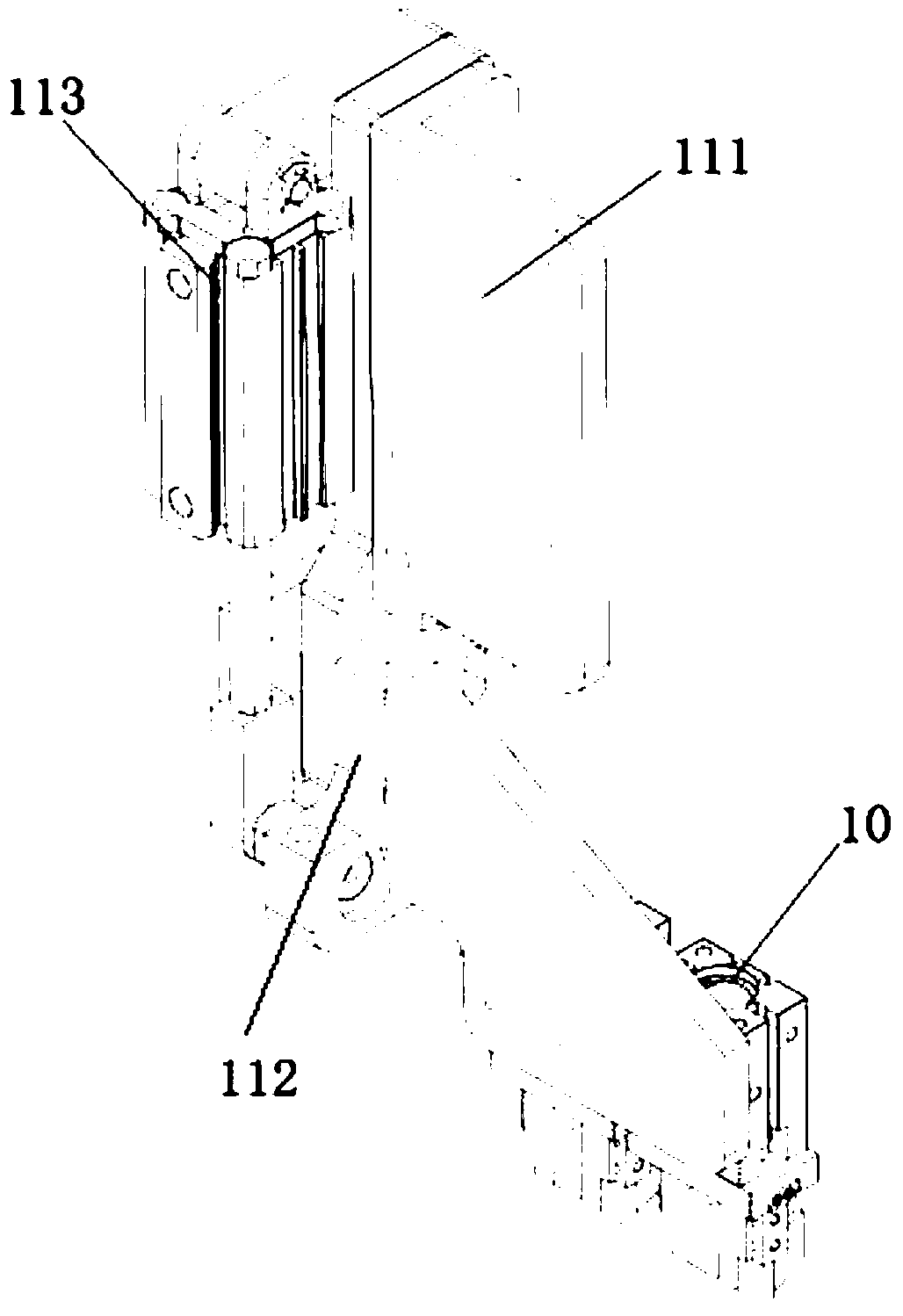

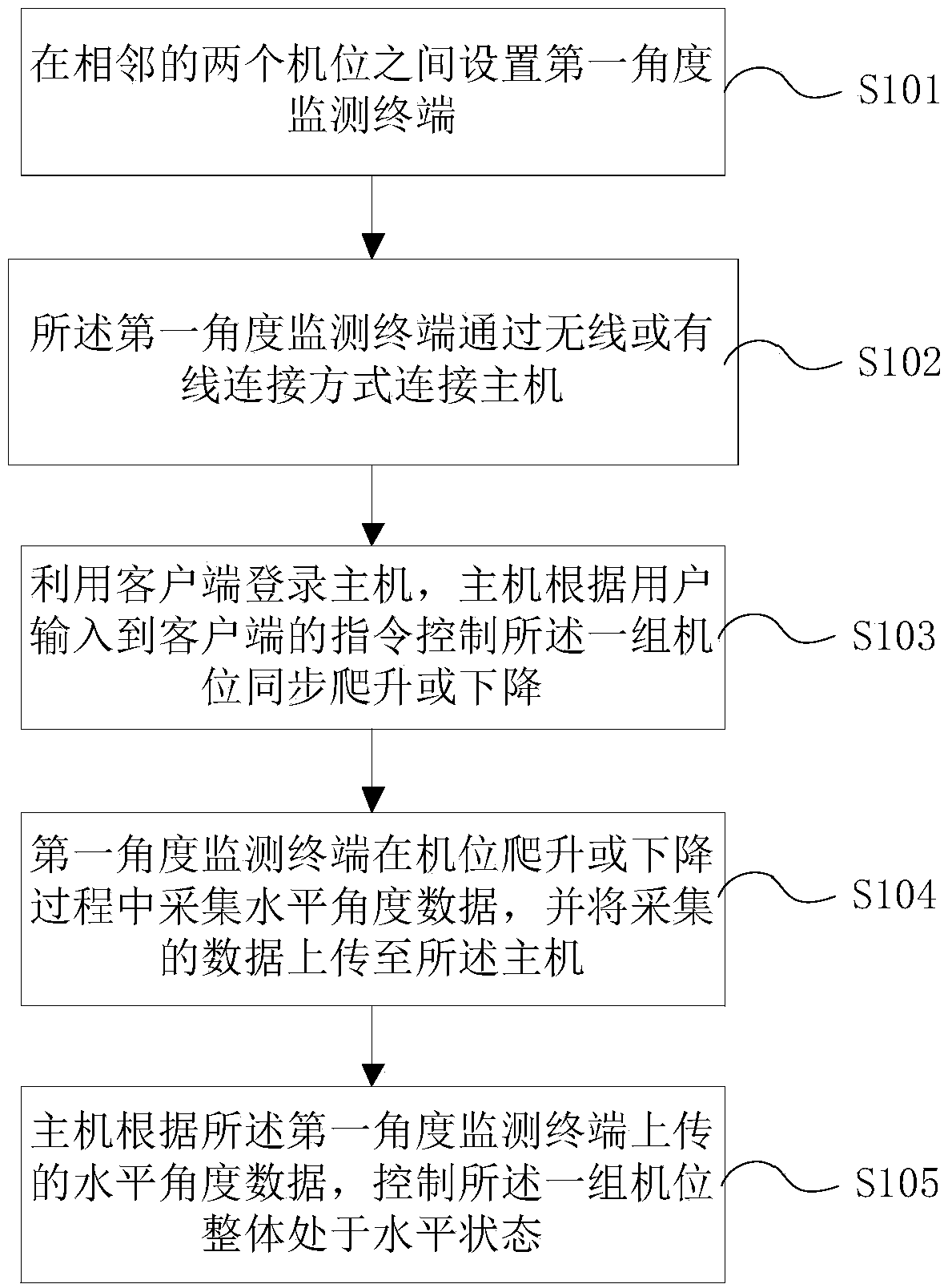

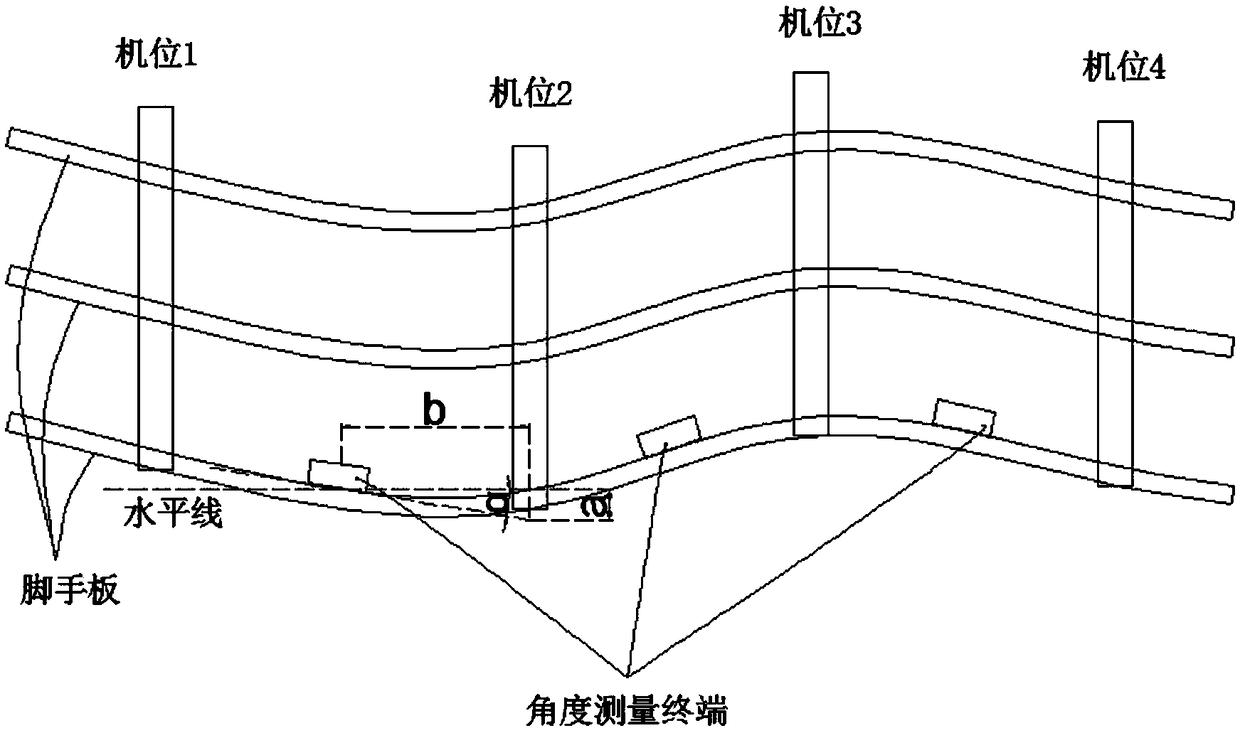

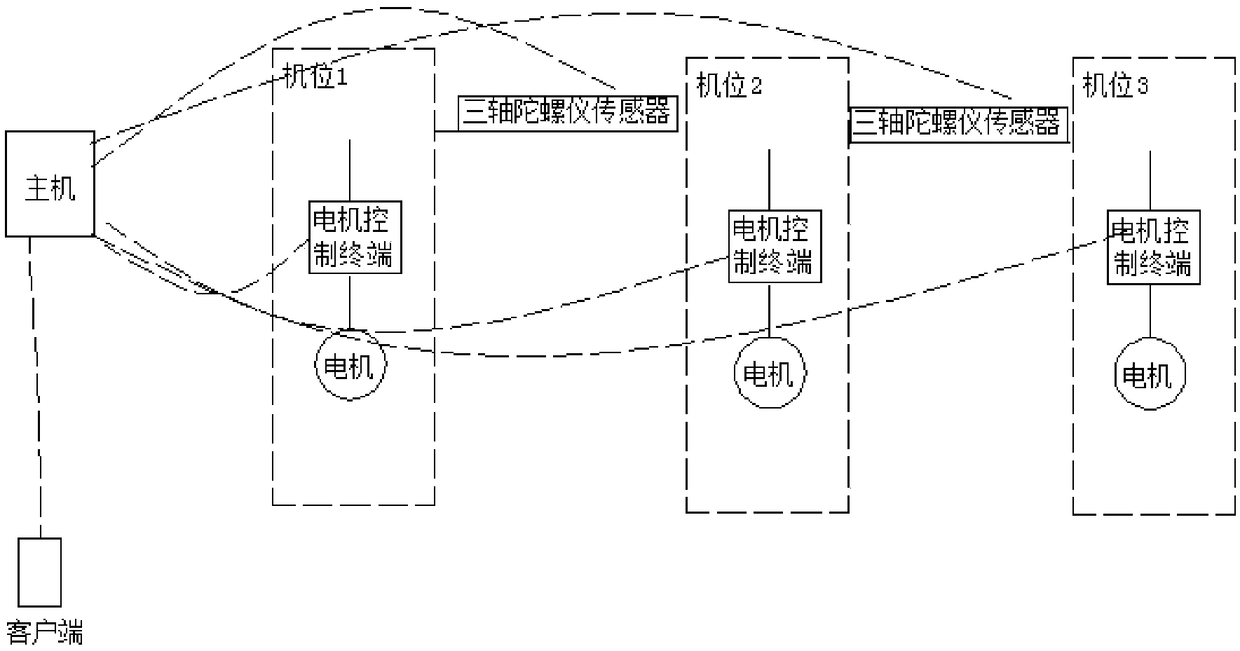

Climbing frame angle monitoring method and system, and angle monitoring terminals

InactiveCN108756218AIncrease travel distanceShort travel distanceForms/shuttering/falseworksIncline measurementEngineeringComputer terminal

The invention discloses a climbing frame angle monitoring method and system, and angle monitoring terminals. A climbing frame comprises a set of machine positions constituted by two or more machine positions. The climbing frame angle monitoring method comprises the steps that the first angle monitoring terminal is arranged between every two adjacent machine positions; the first angle monitoring terminals are connected with a main machine in a wireless or wired connection mode; the set of machine positions is controlled to synchronously climb or descend; the first angle monitoring terminals collect horizontal angle data in the climbing or descending process of the machine positions, and upload the collected data to the main machine; and the main machine adjusts the climbing / descending stateof the set of machine positions according to the horizontal angle data uploaded by the first angle monitoring terminals, so that the set of machine positions is overall located in the horizontal state. According to the climbing frame angle monitoring method and system, and the angle monitoring terminals, the problems that some of machine positions are long in stroke distance and some of machine positions are short in stroke distance due to the fact that the lifting distances of the machine positions are inconsistent can be avoided, so that the set of machine positions is overall located in the horizontal state, and safety accidents caused by the large horizontal altitude difference are avoided.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

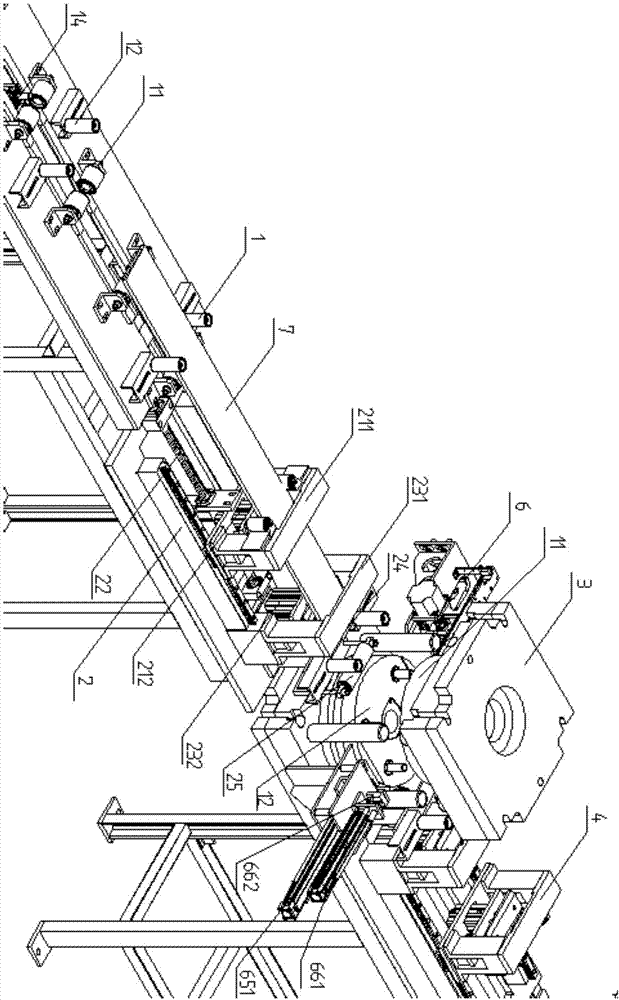

Shaft-like workpiece storing and feeding device

The invention provides a shaft-like workpiece storing and feeding device, and belongs to the technical field of automatic machining. The technical problems of large size, low feeding efficiency and low feeding precision of existing storing and feeding equipment are solved. The shaft-like workpiece storing and feeding device comprises a storing frame, a material preparing base, a material pushing plate, an installing table and a pushing block, wherein the storing frame is used for storing workpieces; the material preparing base is fixedly connected with one end of the storing frame, and a material trough is formed in the material preparing base; the material pushing plate is arranged in the storing frame and movably connected with the storing frame; the installing table is arranged horizontally and adjacent to one end of the storing frame; and the pushing block is movably arranged on one side of the installing block and adjacent to the material preparing base, and the pushing block extends into the material trough. The pushing plate can move in the storing frame and can push the workpieces in the storing frame into the material trough. The pushing block can move on the installing table and can push the workpieces out of the material trough. Through moving of the material pushing plate, the workpieces in the storing frame can be pushed into the material trough in the material preparing base in sequence, the workpieces are conveniently conveyed into machining equipment, and the shaft-like workpiece storing and feeding device is simple in structure, small in occupied area and flexible in using.

Owner:宁波宫铁智能科技有限公司

Automatic warehouse

Owner:XIAN AIRCRAFT IND GROUP

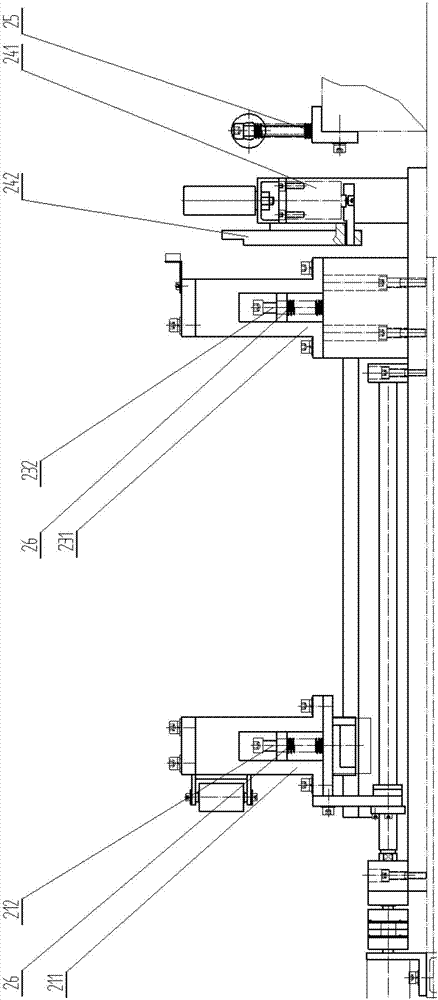

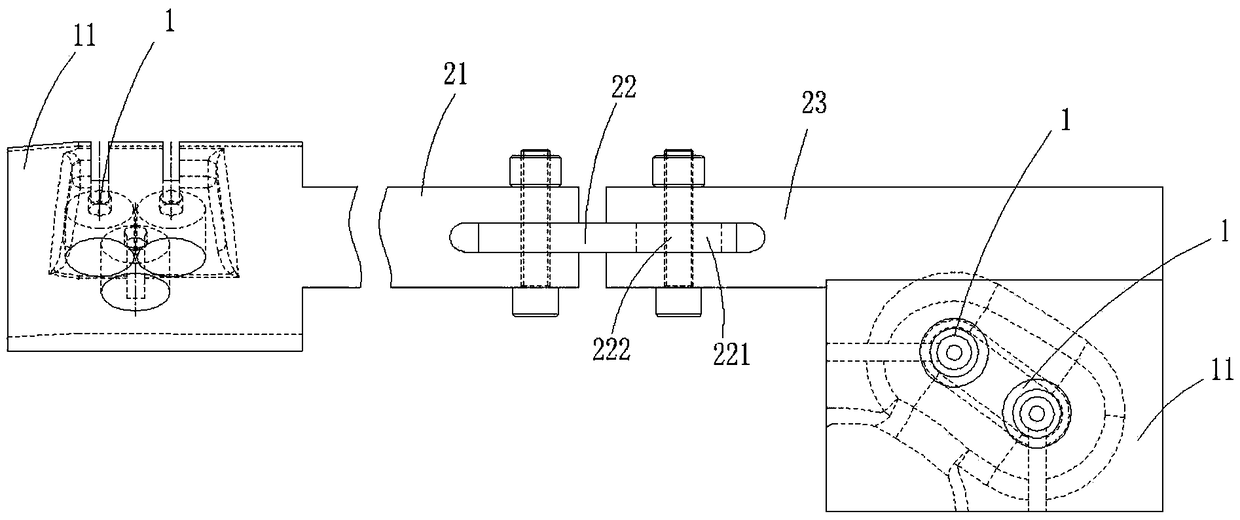

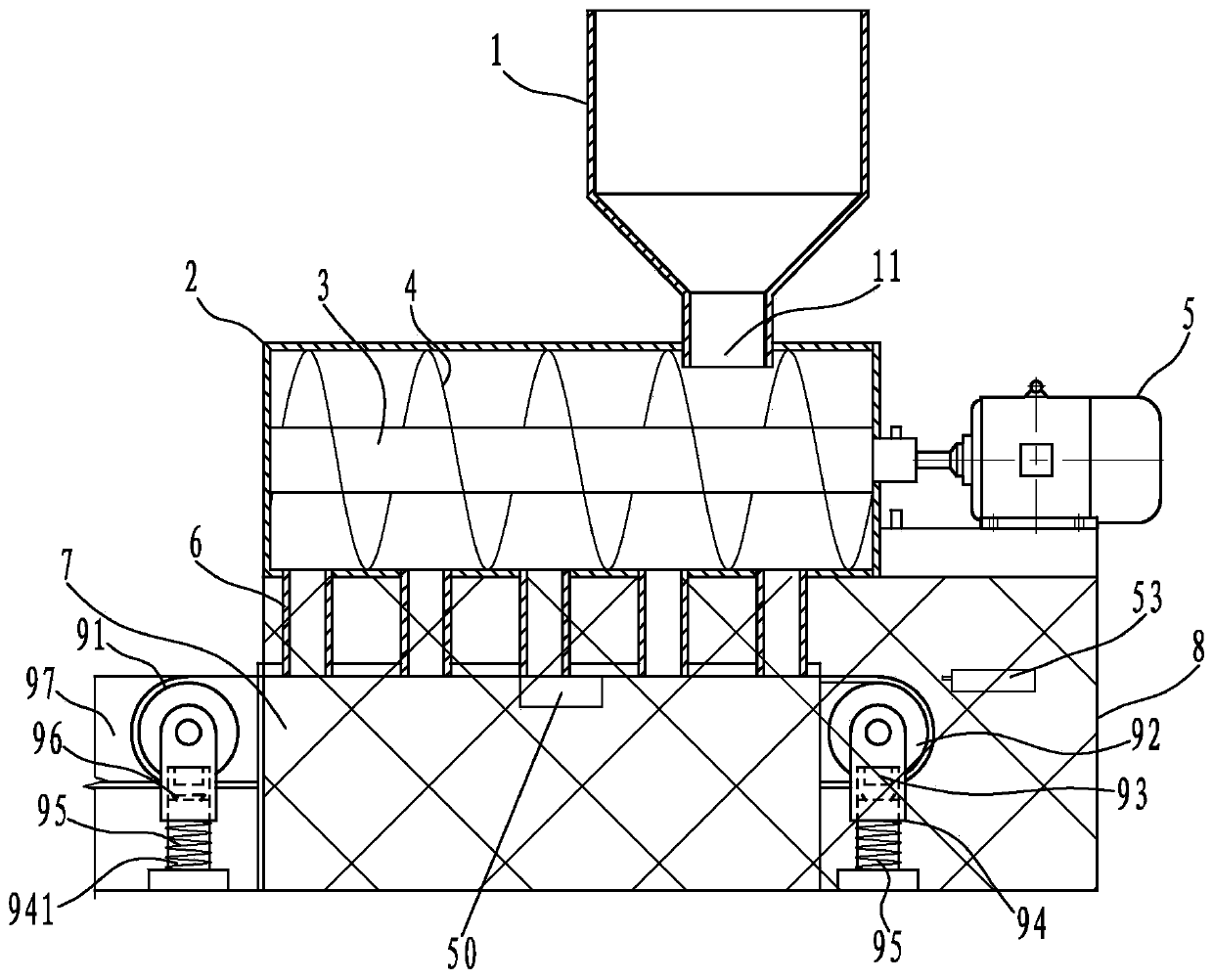

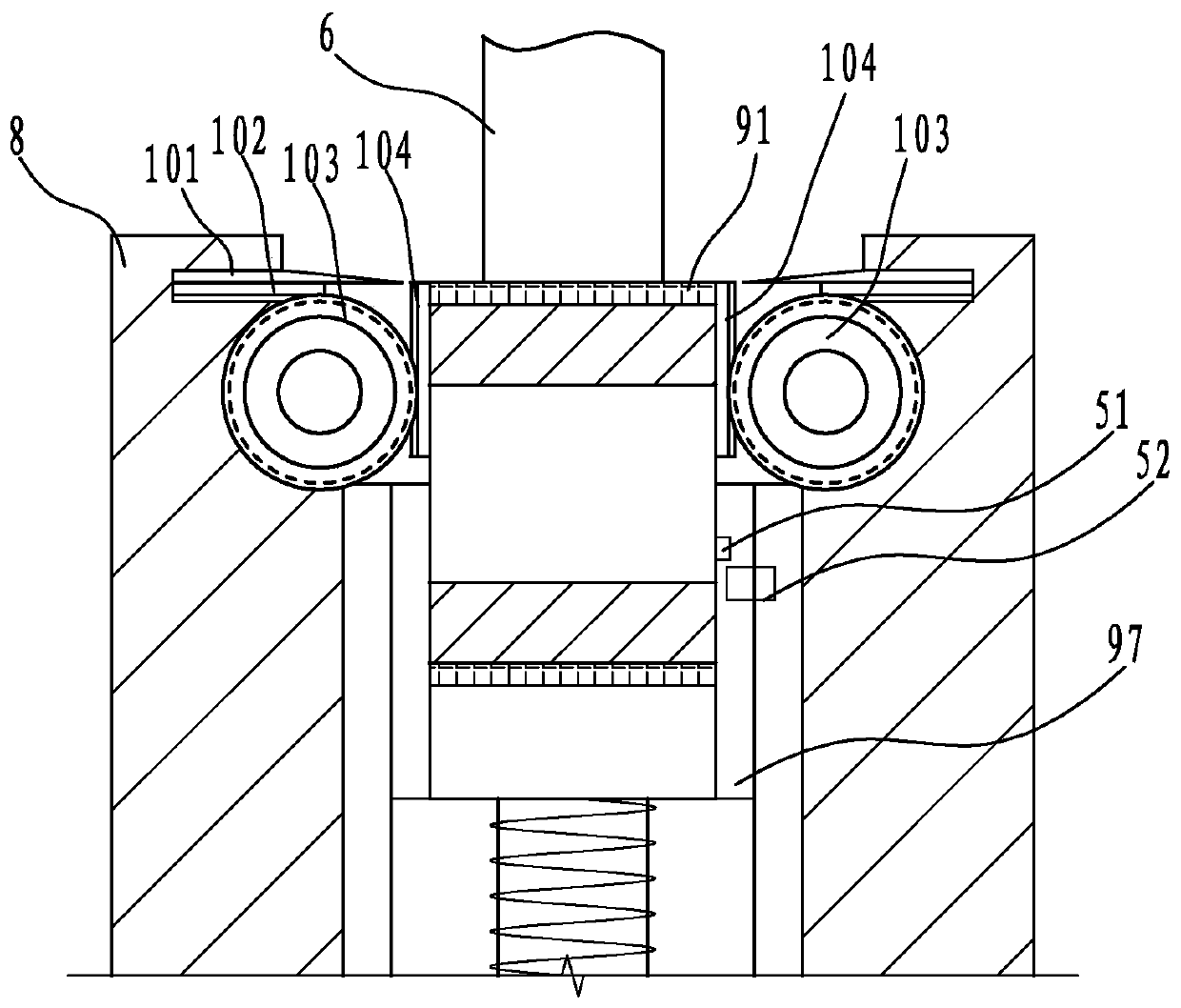

Feeding device with precise step pitch for fine stamping of thick plates

ActiveCN107442677AShort travel distanceSave spaceMetal-working feeding devicesPositioning devicesThick plateEngineering

The invention relates to a feeding device with precise step pitch for fine stamping of thick plates. The feeding device with the precise step pitch for fine stamping of the thick plates comprises a conveying device, a front-mounted feeding device and a rear-mounted feeding device, the front-mounted feeding device and the rear-mounted feeding device are symmetrically arranged on the two sides of a stamping device, and the conveying device is arranged at the front end of the front-mounted feeding device and used for conveying the thick plates to the front-mounted feeding device; each of the front-mounted feeding device and the rear-mounted feeding device comprises a movable clamping device and a fixed clamping device, the moving directions of the movable clamping devices are parallel to the conveying direction of the conveying device, and the movable clamping devices can get close to the stamping device or keep away from the stamping device oppositely and are used for conveying the thick plates to the stamping device and the fixed clamping devices are used for clamping the thick plates when the movable clamping devices loosen the thick plates. The feeding device with the precise step pitch can achieve automatic feeding of the thick plates, each feeding length is equal to the distance between the trip destinations of the movable clamping devices and the trip starting points, feeding with the precise step pitch can be achieved, and automatic floating of the clamping devices can further be achieved so as to prevent the thick plates from deforming in the machining process.

Owner:武汉思凯精冲模具有限责任公司

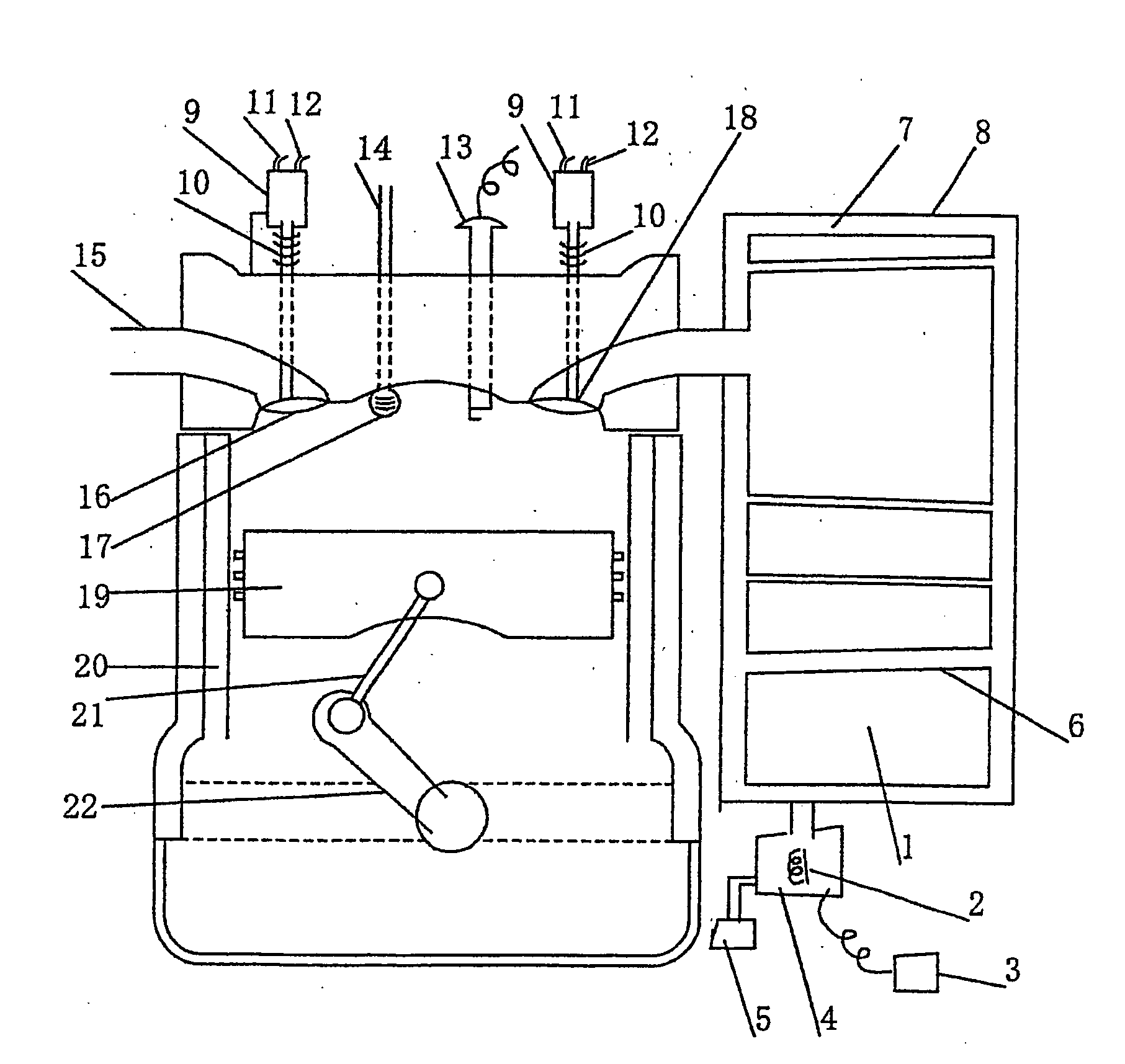

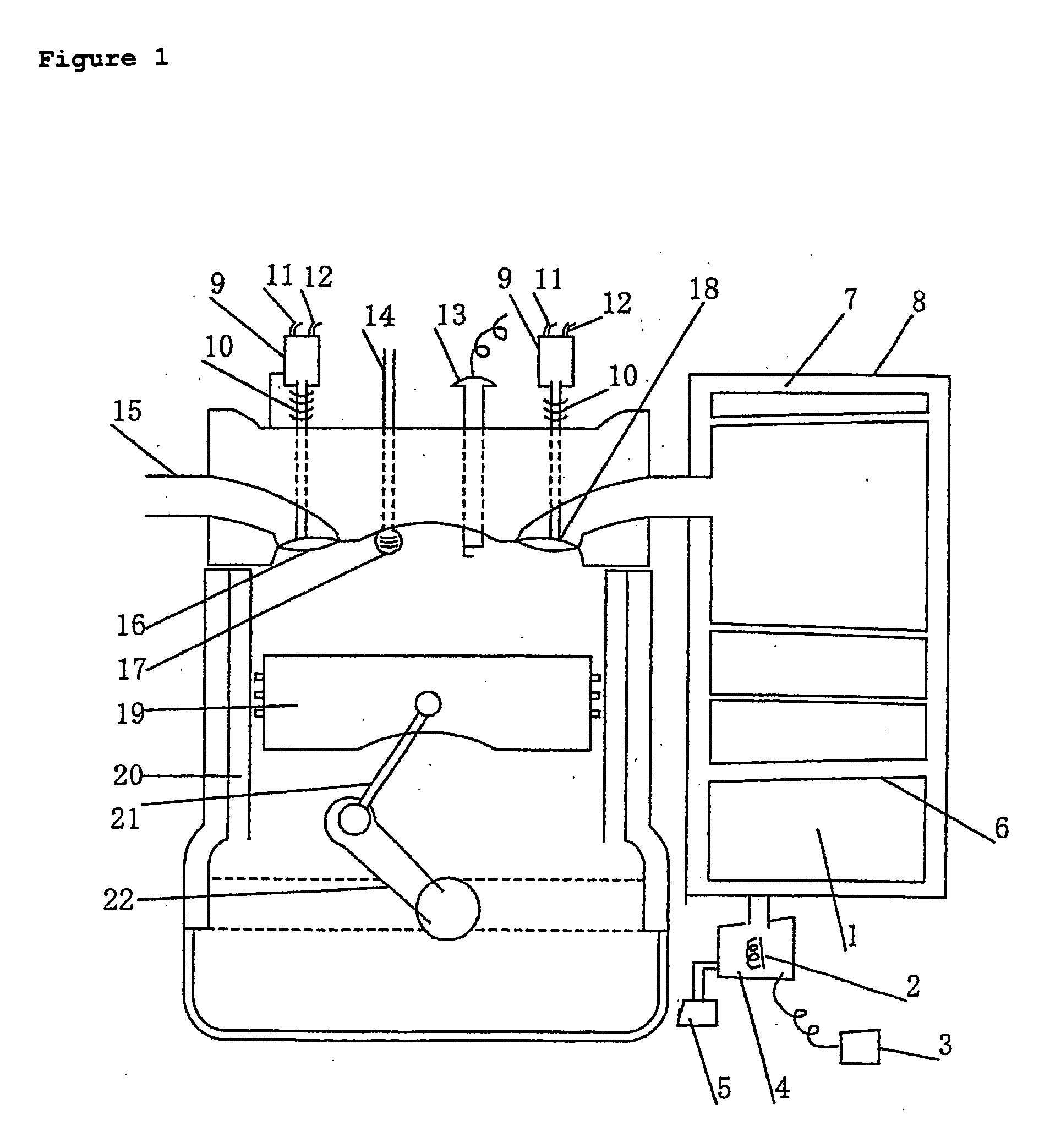

Lightweight engine

InactiveUS20060207242A1Improve thermal efficiencyStroke distance of shortInternal combustion piston enginesExhaust apparatusAutomotive engineeringLean combustion

Weight saving of industrial engines. Making pollution-causing material harmless. Improvement in thermal efficiency and reduction of operating cost. Arrangement To produce compressed air, air is pressurized by a turbo charger or a super turbo charger and stored in an air tank. The air is fed, at an optimum temperature and a given pressure, to a cylinder liner shortened according to the pressure. Valves for taking in and out air are hydraulically driven for individual opening and closing according to a computer-aided optimum valve timing diagram. The engine is controlled under high-oxygen high-temperature lean burn condition, and a hydrocarbon is injected into an exhaust manifold to reduce peroxides, thus making pollution-causing material harmless. Effects Reduction of operating cost. Increase in carrying capacity due to the weight reduction of the vehicle body in the case of a vehicle-mounted engine.

Owner:FUKUMOTO TOSHIHIRO +2

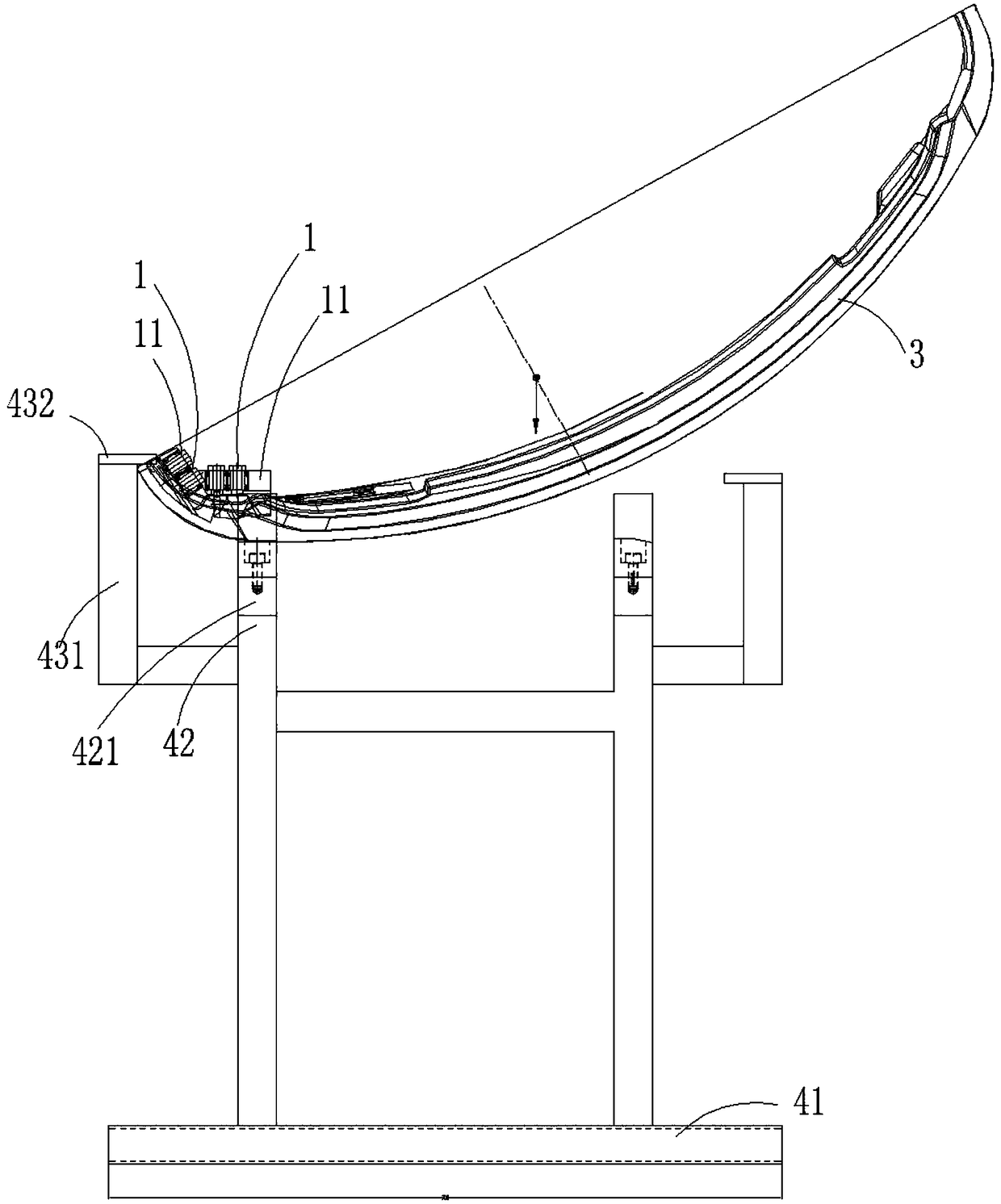

Tool system of arc-shaped plate-shaped part,

PendingCN108637736ANot easy to shakeImprove processing qualityDrilling/boring measurement devicesThread cutting machinesEngineeringDrill bit

The invention provides a tool system of an arc-shaped plate-shaped part. The system aims to solve the problem that the machining quality of the hole of the arc-shaped plate-shaped part is not high inthe prior art. The tool system of the arc-shaped plate-shaped part comprises a workpiece self-tight-clamping fast mounting and dismounting support and a combined drilling and tapping tool, wherein theworkpiece self-tight-clamping fast mounting and dismounting support is used for clamping a workpiece, and the workpiece is of an arc-shaped plate-shaped structure; the combined drilling and tapping tool comprises at least two supporting bodies and guide assemblies, wherein the supporting bodies and the workpiece cooperate with a sunken structure through a protruding structure, and the guide assemblies are installed on the supporting bodies and are used for guiding drill bits; and each supporting body is connected through a middle connecting mechanism, and the middle connecting mechanisms areused for limiting the relative positions of the supporting bodies. During drilling, the supporting bodies are not prone to shake, so that the machining quality is improved.

Owner:QINGLING MOTORS GRP +1

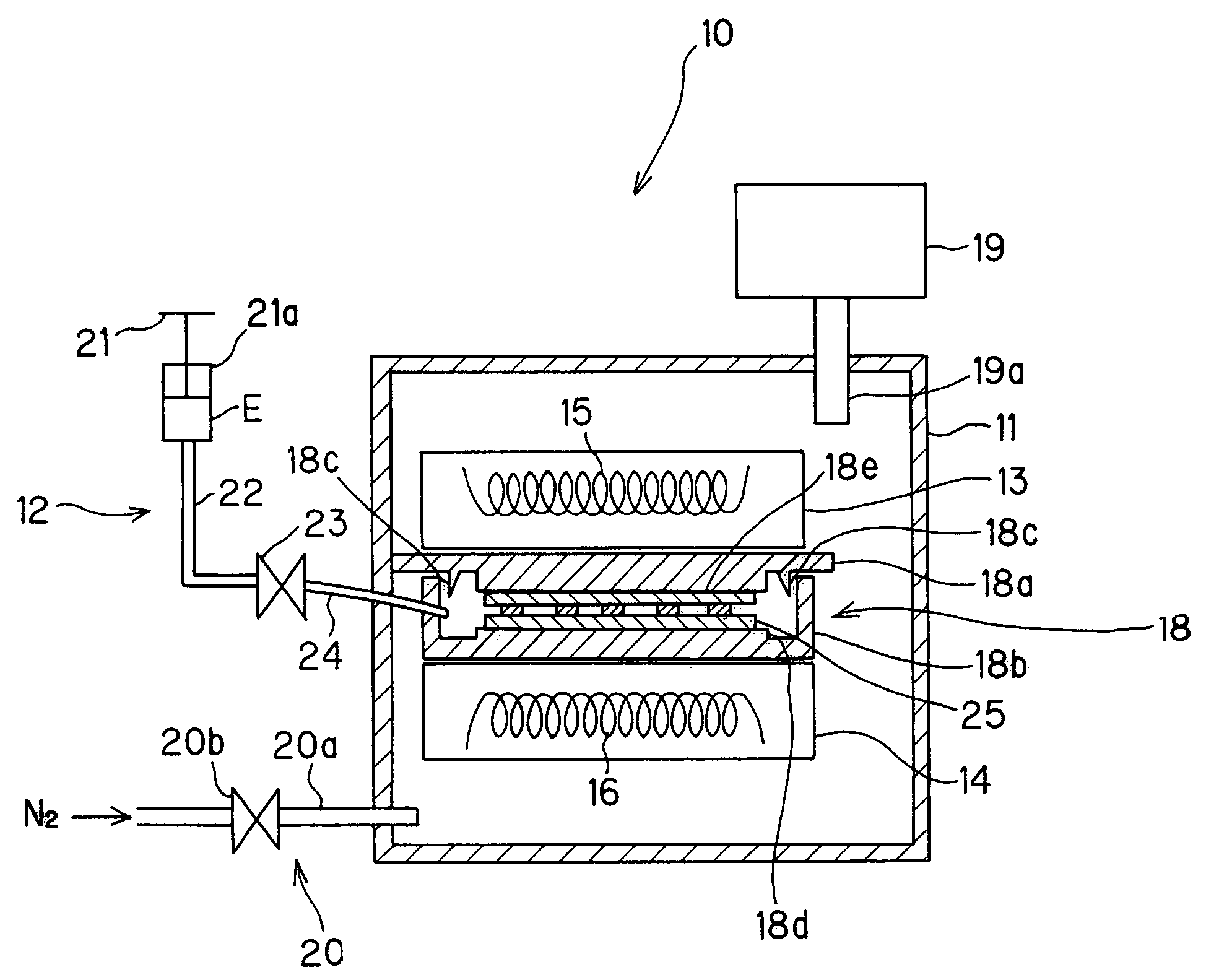

Thermal vacuum deposition method and device

InactiveCN1950535APrevents uncontrolled depositionAvoid pollutionVacuum evaporation coatingSputtering coatingInterior spaceVaporization

The present invention relates to a thermal vacuum deposition apparatus and method in which a strip-shaped substrate is continuously conveyed in a vaporization channel supplied with a gaseous coating material. The object of the present invention is to allow rapid protection of the substrate from damage during the coating process in known deposition methods and devices. This object is achieved in an inventive method, characterized in that when the minimum conveying speed is not reached or when the substrate is stopped so that the substrate is located in the interior space, by inserting at least one position-adjustable hollow element into the vaporization channel The vaporization channel is sealed in the external space of the vaporization channel and the internal space of the vaporization channel.

Owner:冯·阿德纳设备有限公司

System and method for interrogation of target material in situ

ActiveUS9140643B2Adapt quicklyMaximize resolutionRadiation pyrometrySpectrum investigationImage resolutionLaser source

A system for remotely sensing a target material in situ include a broad-band laser source, at least one tunable filter coupled to the source laser for generating a swept-frequency signal an optical device for splitting the swept-frequency signal into a first illumination signal and second illumination signal, a first optical path for directing the first illumination signal unto the target material and receiving a reflected signal from the target material, a second optical path for receiving the second illumination signal and generating a spectral reference signal, and a controller coupled to the first optical path and the second optical path for adjusting the frequency and spatial resolution of the laser source based at least in part on a comparison of the spectral reference signal and the reflected signal.

Owner:CHEVROU USA INC

Machine head of cookie blank forming machine

ActiveCN111436472AEasy to replaceEasy to adjustDough shaping and cutting apparatusDough extruding machinesSpiral bladeMolding machine

The invention discloses a machine head of a cookie blank forming machine. A plurality of discharging openings are formed in the bottom of an extruding roller along an axial direction, each dischargingopening is detachably connected with a die, a conveying combination comprises a conveying belt, a conveying wheel, a miniature motor and a mounting rack, an outer belt surface of a belt body of an upper half part of the conveying belt is in fit with an outlet of a lower end of each die and closes the corresponding outlet in an initial state; and the conveying belt sleeves the conveying wheel, andthe miniature motor is used for driving the conveying wheel to rotate. The machine head of the cookie blank forming machine, disclosed by the invention, comprises a machine body, wherein a hopper, aspiral type extruding mechanism and a continuous type forming mechanism are fixedly mounted on the machine body sequentially from top to bottom. The hopper is used for loading a raw-material mixture and conveying the raw-material mixture into the extruding roller of the spiral type extruding mechanism through a discharging opening in the lower end of the hopper. The spiral type extruding mechanismis used for conveying and extruding the raw-material mixture through spiral blades until the raw-material mixture is extruded into cookie blanks through dies.

Owner:涿州北方绿色巨人农业发展有限公司

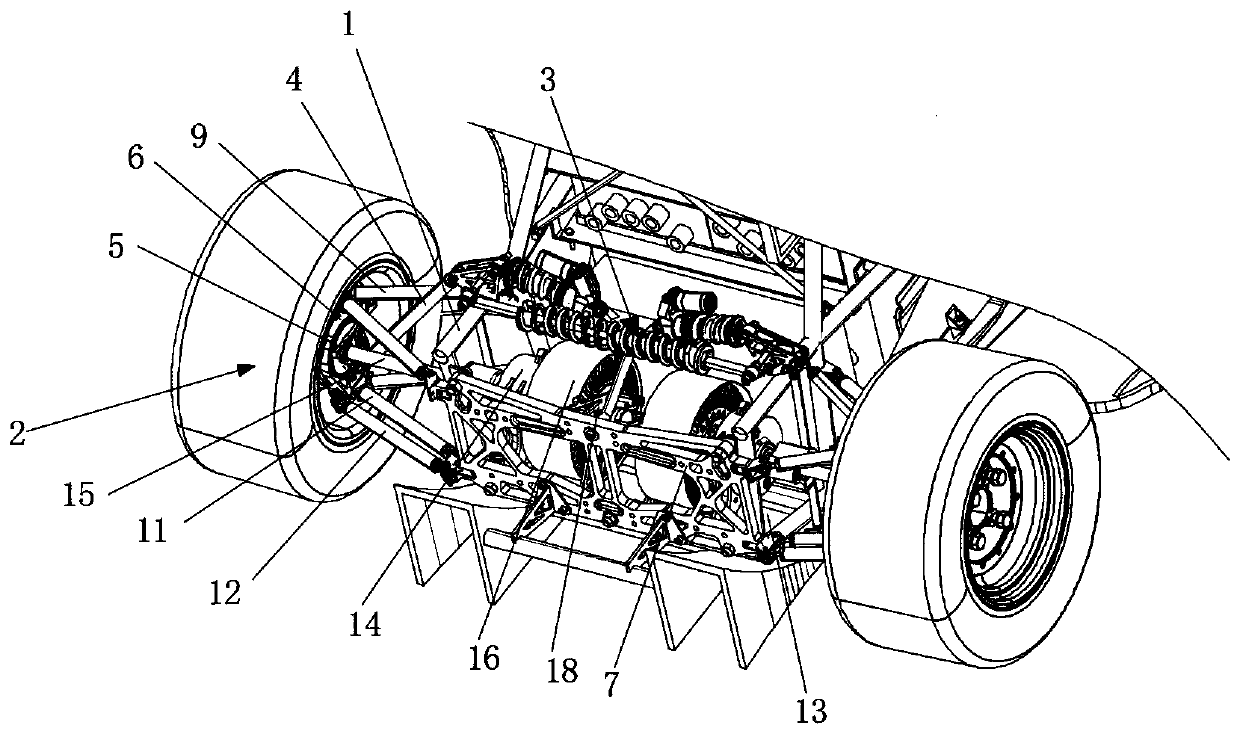

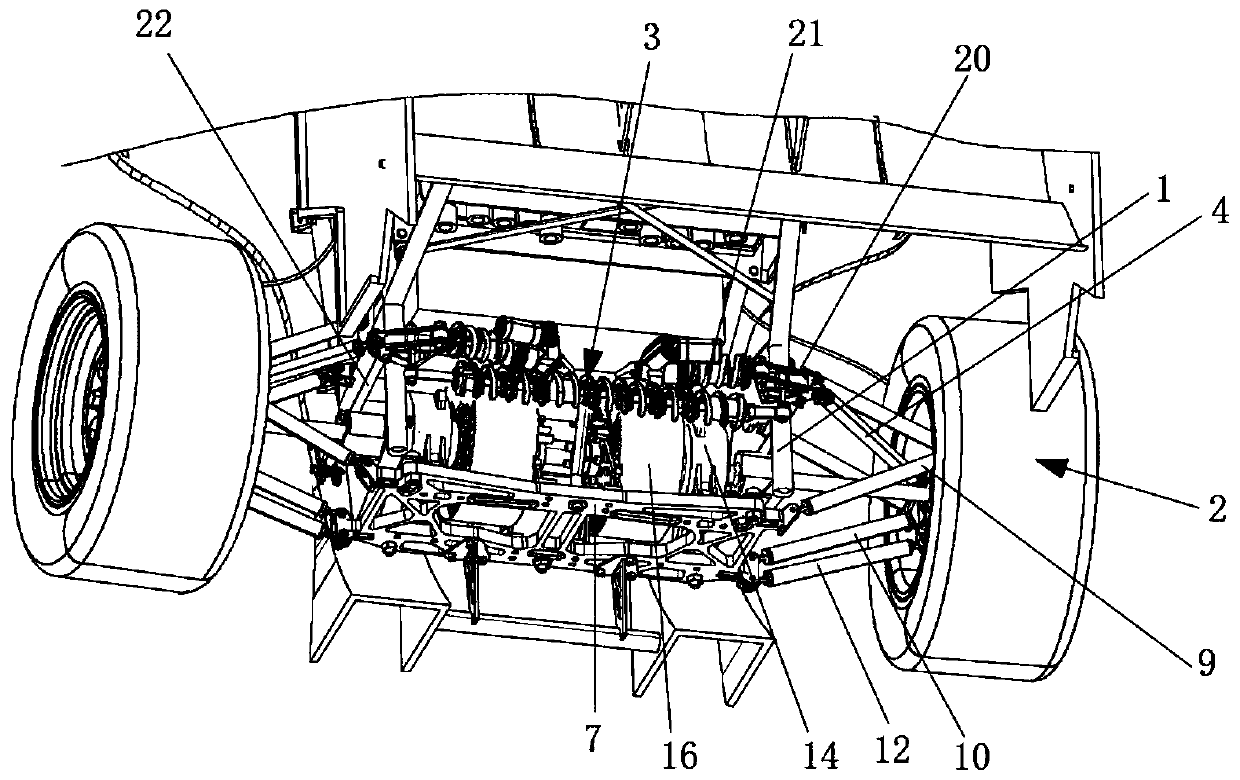

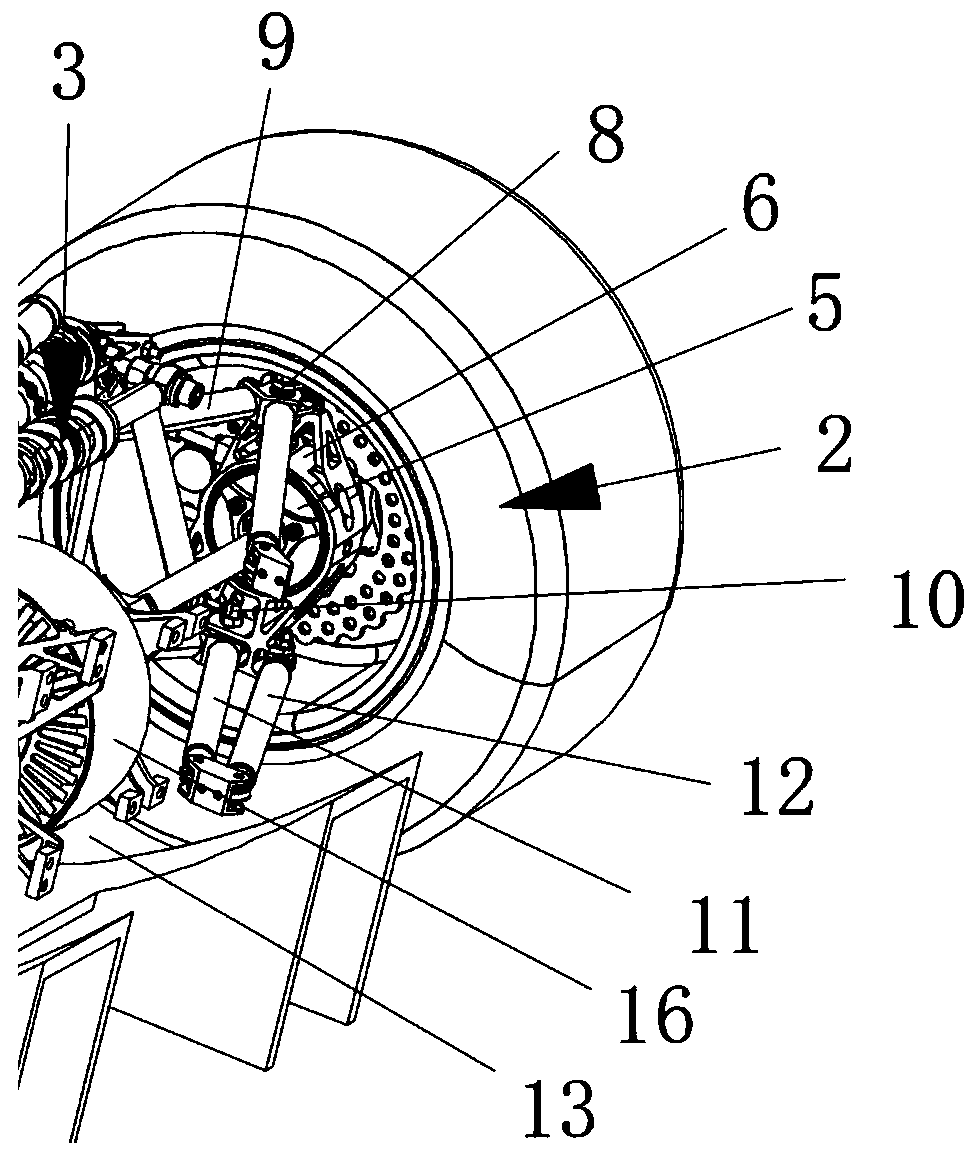

Integrated sub-frame for formula racing car

ActiveCN110803221AEasy to transformAvoid deformationUnderstructuresResilient suspensionsVehicle frameControl theory

The invention discloses an integrated sub-frame for a formula racing car. The integrated sub-frame includes a car body main frame, independent suspension assemblies are arranged on the both sides of the rear portion of the car body main frame, each independent suspension assembly includes a rear pillar connected to a rear suspension core through a bearing, a sub-frame body is also arranged on therear position of the car body main frame, the upper portion of each rear pillar is provided with an upper V-shaped fork arm through a first pin joint in a hinged manner, one top end, far away from thecorresponding first pin joint, of each upper V-shaped fork arm is hinged to the sub-frame body, and the other top end, far away from the first pin joint, of each upper V-shaped fork arm is hinged tothe car body main frame; and the lower portion of each rear pillar is provided with a lower V-shaped fork arm through a second pin joint in a hinged manner, one top end, far away from the second pin joint, of each lower V-shaped fork arm is hinged to the sub-frame body. The sub-frame body is arranged, the sub-frame body and the car body main frame are used for sharing action force on the independent suspension assemblies, the strength and the bearing force of the whole car frame are effectively improved, the racing car frame is not prone to deformation, and the good operation stability is achieved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Automatic thick plate fine stamping system with two-face sample arranging and feeding functions

ActiveCN107457294ASave raw materialsEasy to operateMetal-working feeding devicesStripping-off devicesThick plateEngineering

The invention relates to an automatic thick plate fine stamping system with two-face sample arranging and feeding functions. The system comprises a conveying device, a front feeding device, a stamping device, a rear feeding device and an overturning device which are arranged in sequence, and further comprises a taking device arranged on the stamping device. The conveying device is used for conveying a thick plate to the front feeding device, the front feeding device is used for driving the thick plate to be close to or away from the stamping device, the stamping device is used for stamping parts on the thick plate, the taking device is used for collecting finished parts, the rear feeding device is used for driving the thick plate to be close to or away from the stamping device, and the overturning device is used for overturning the thick plate. The full-automatic feeding, front-face stamping, taking, overturning, back-face stamping and taking process for the thick plate can be achieved, the system is applicable to stamping of thick plates with different lengths and parts with different shapes and sizes, raw materials are saved, time and labor are saved, operation is easy, a clamping device can automatically float along with pressing and ascending of a stamping head, and the thick plate is prevented from being deformed in the machining process.

Owner:武汉思凯精冲模具有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com