Climbing frame angle monitoring method and system, and angle monitoring terminals

A technology of angle monitoring and monitoring system, applied in the field of climbing frame angle monitoring and angle monitoring terminals, can solve the problems of uneven construction platform, short stand travel, inconsistent stand lift distance, etc., and achieve the effect of avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

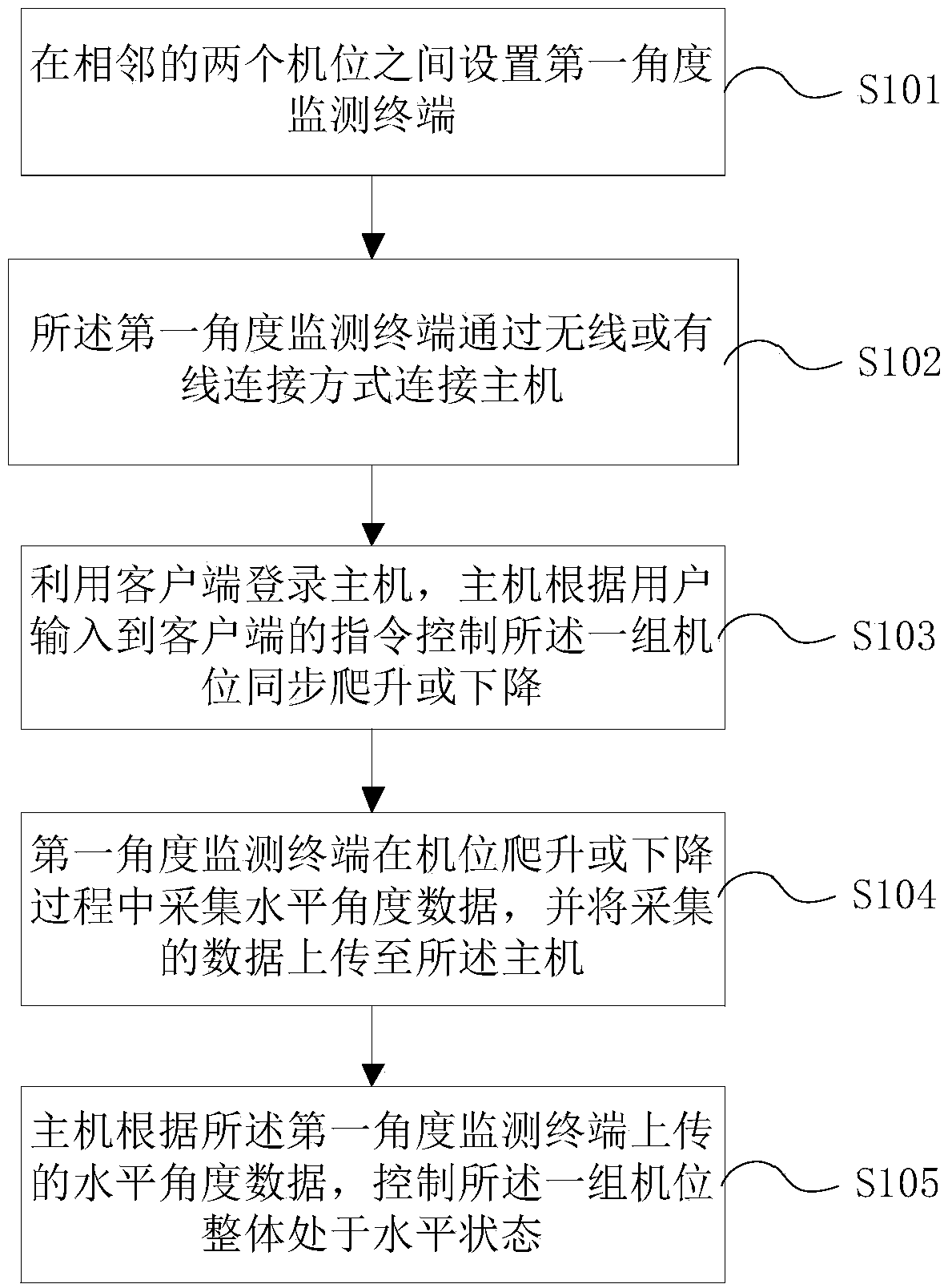

[0043] refer to figure 1 , Embodiment 1 discloses a climbing frame angle monitoring method, the climbing frame includes a group of positions consisting of at least two positions, the method includes:

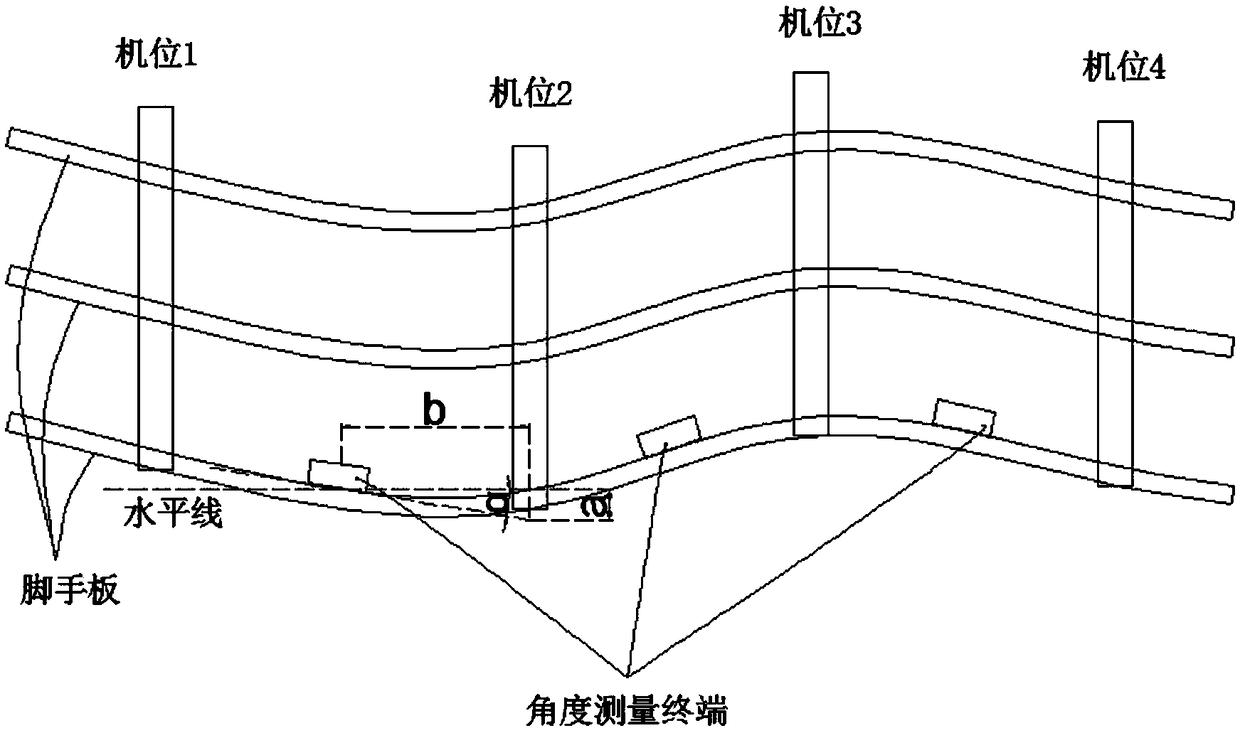

[0044] S101. Install a first-angle monitoring terminal between two adjacent machine positions; specifically, the first-angle monitoring terminal is set on a rigid connection between the two machine positions, such as a scaffolding board. Wherein, the first angle monitoring terminal may use a three-axis gyroscope sensor, or other types of angle measurement sensors.

[0045] S102. The first angle monitoring terminal is connected to a host through a wireless or wired connection, and the host manages the first angle monitoring terminal;

[0046] S103. Use the client to log in to the host, and the host controls the group of camera positions to climb or descend synchronously according to the instructions input by the user to the client;

[0047] S104. The first angle monitoring termin...

Embodiment 2

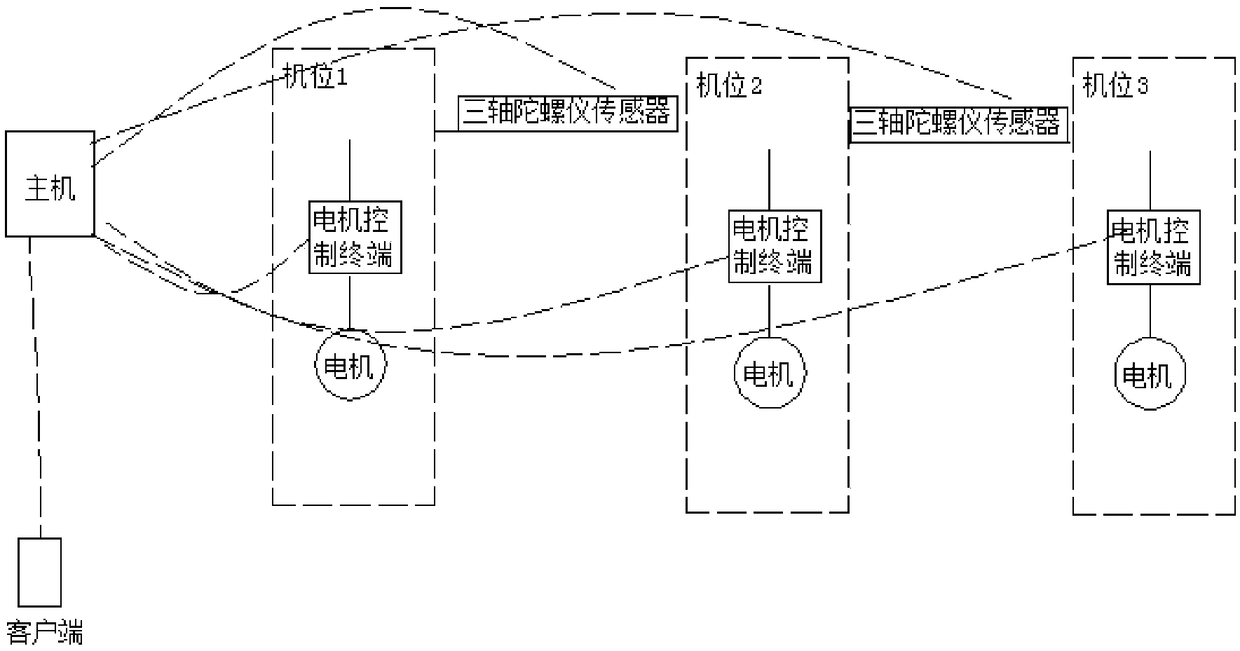

[0059] refer to image 3 , Embodiment 2 discloses a climbing frame angle monitoring system, the climbing frame includes a group of positions consisting of at least two positions, the monitoring system includes a host, a client, and a first angle monitoring terminal, the The first angle monitoring terminal is connected to the host through a wireless or wired connection, and the first angle monitoring terminal is set between any two adjacent positions. Specifically, the first angle monitoring terminal is set on a rigid connection between two machine positions, such as a scaffolding board. Wherein, in this implementation, the first angle monitoring terminal uses a three-axis gyroscope sensor, and of course other types of angle measurement sensors may also be used.

[0060] Wherein, the client is used to log in to the host computer to provide human-computer interaction functions; the first angle monitoring terminal is used to collect horizontal angle data during the climbing or d...

Embodiment 3

[0065] Embodiment 3 discloses an angle monitoring terminal, which is used in the climbing frame angle control system of the present invention. The angle monitoring terminal is set between two adjacent machine positions, and is connected to the host through a wireless or wired connection. Preferably, the angle monitoring terminal includes a three-axis gyro sensor. For other details, reference may be made to Embodiment 1 and Embodiment 2, which will not be repeated here.

[0066] The above description refers to various units. These units typically comprise hardware and / or a combination of hardware and software (eg firmware). These units may also include computer-readable media (eg, non-transitory media) containing instructions (eg, software instructions) that, when executed by a processor, perform various functional features of the present invention. It should be pointed out that, in the above description of various units, the division into these units is for the sake of clari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com