Shaft-like workpiece storing and feeding device

A shaft workpiece and feeding device technology, applied in the field of automatic processing, can solve the problems of difficult control of feeding accuracy, complex feeding structure, and low feeding efficiency, and achieve short moving time and stroke, simple device structure, and high feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0039] The present invention improves the existing material storage and feeding equipment, aiming at simplifying the structure of the traditional equipment, reducing its occupied space, shortening the moving stroke of the workpiece, and improving the feeding efficiency and accuracy of the workpiece.

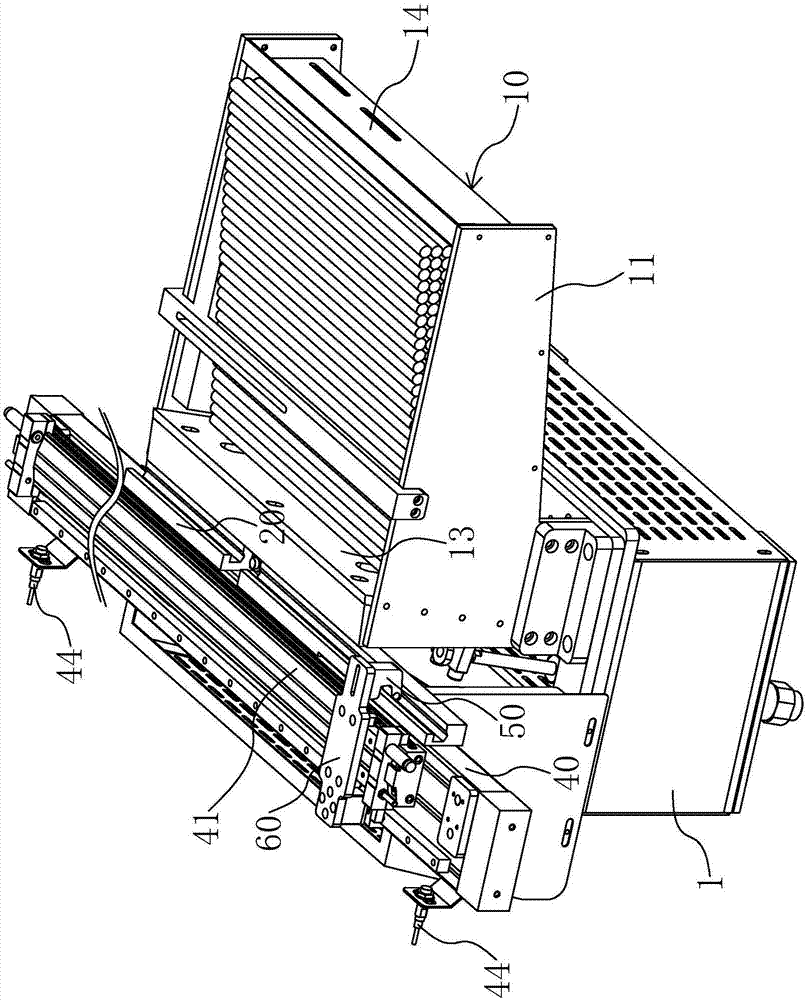

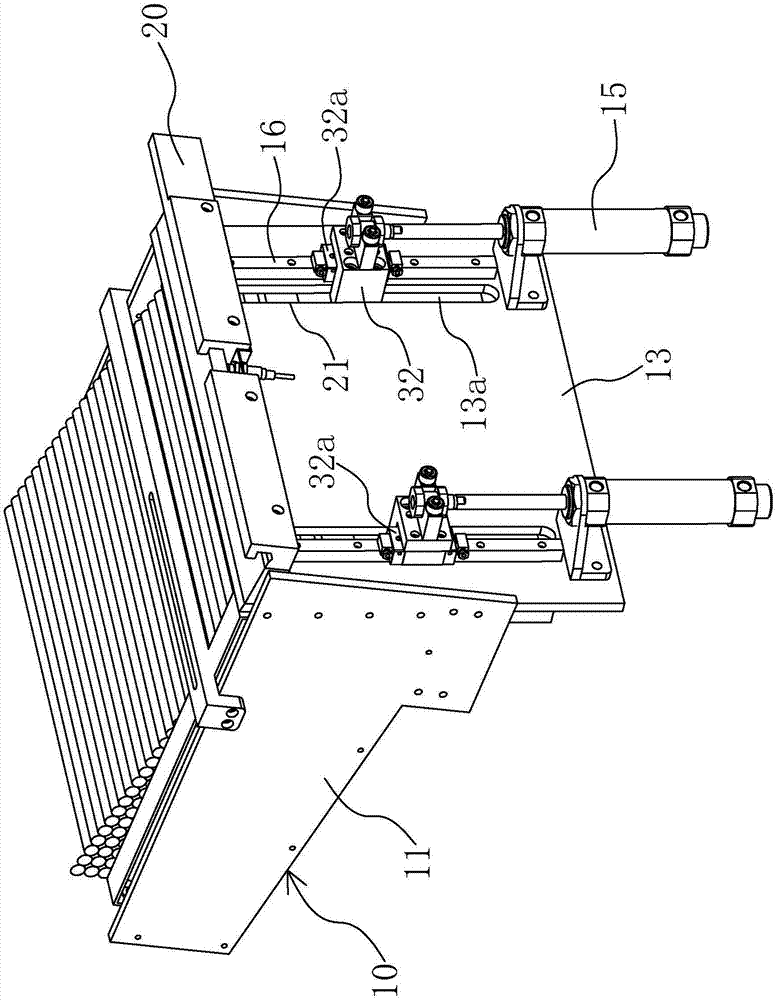

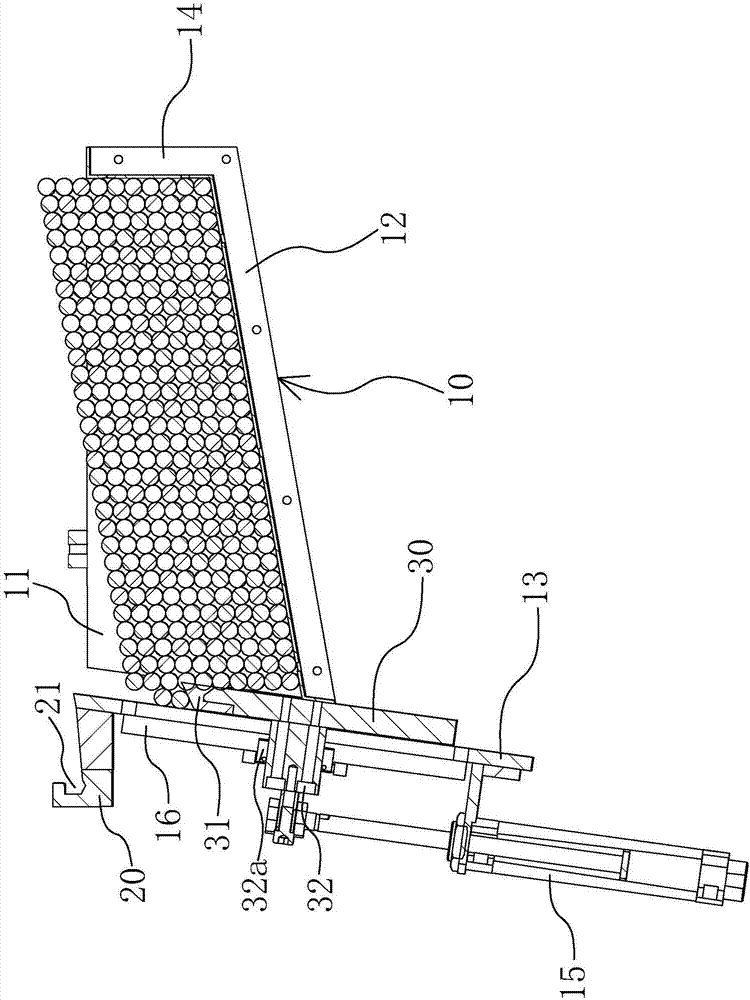

[0040] Such as Figure 1 to Figure 4 As shown, a shaft workpiece storage and feeding device of the present invention is installed on the feed end side of the processing equipment during its work, and it includes a storage rack 10, a stock stand 20, a pushing plate 30, a mounting table 40 and Push block 50.

[0041] The material storage rack 10 is horizontally arranged, and it is fixed on a frame 1, and its interior is hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com