Automatic warehouse

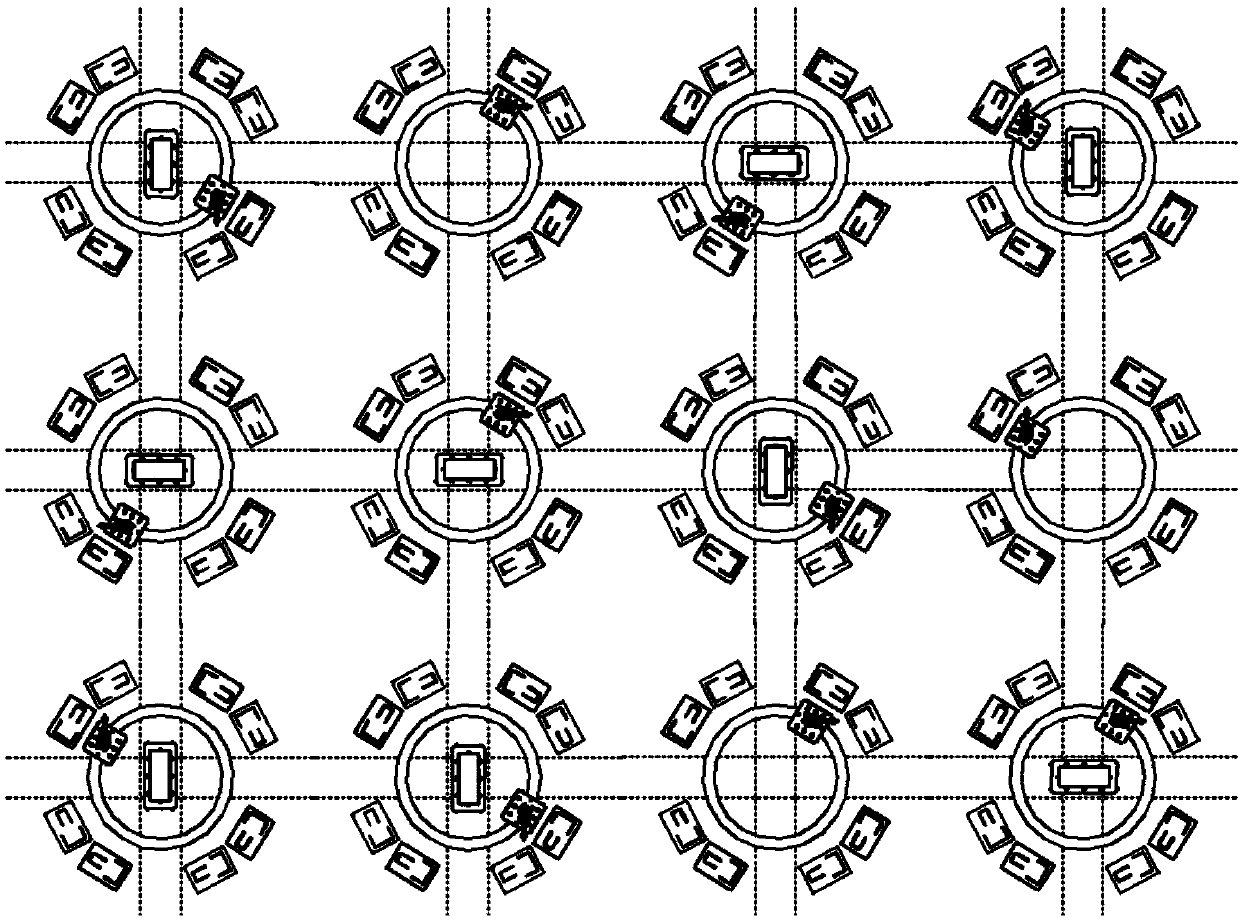

A technology for automated warehouses and warehousing, applied in the field of automated warehouses, can solve problems such as difficulty in adapting to production line upgrades, transformation requirements, increased travel of reciprocating motion, affecting material access efficiency, etc. , the effect of flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

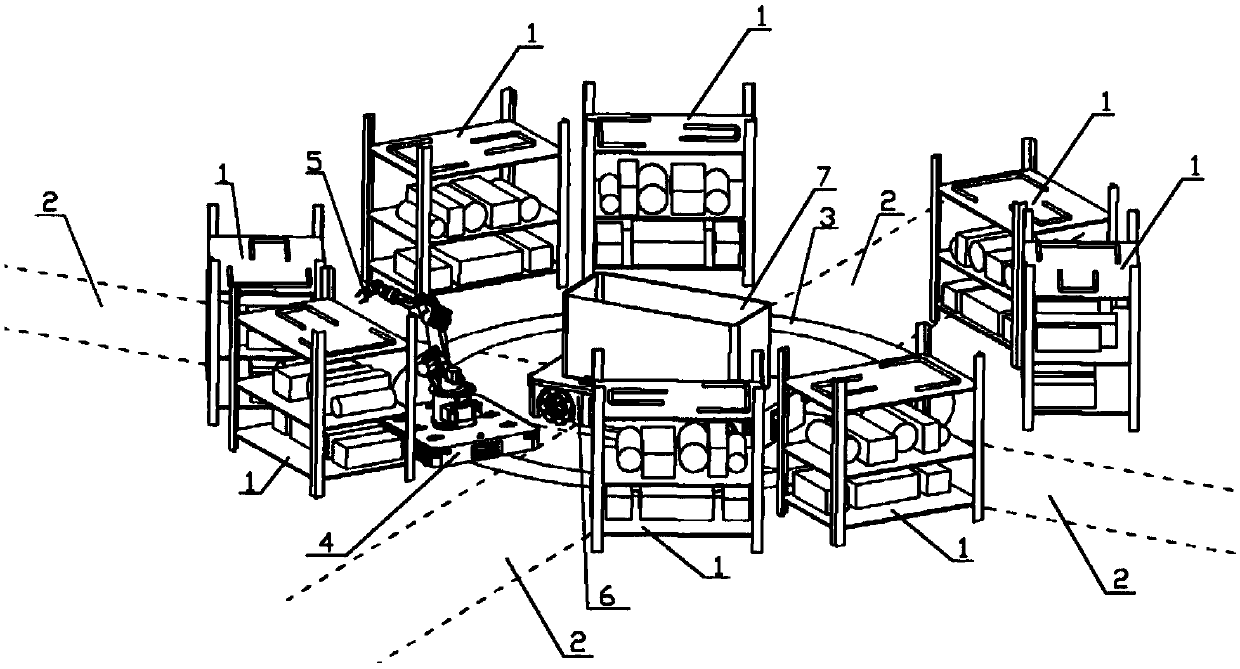

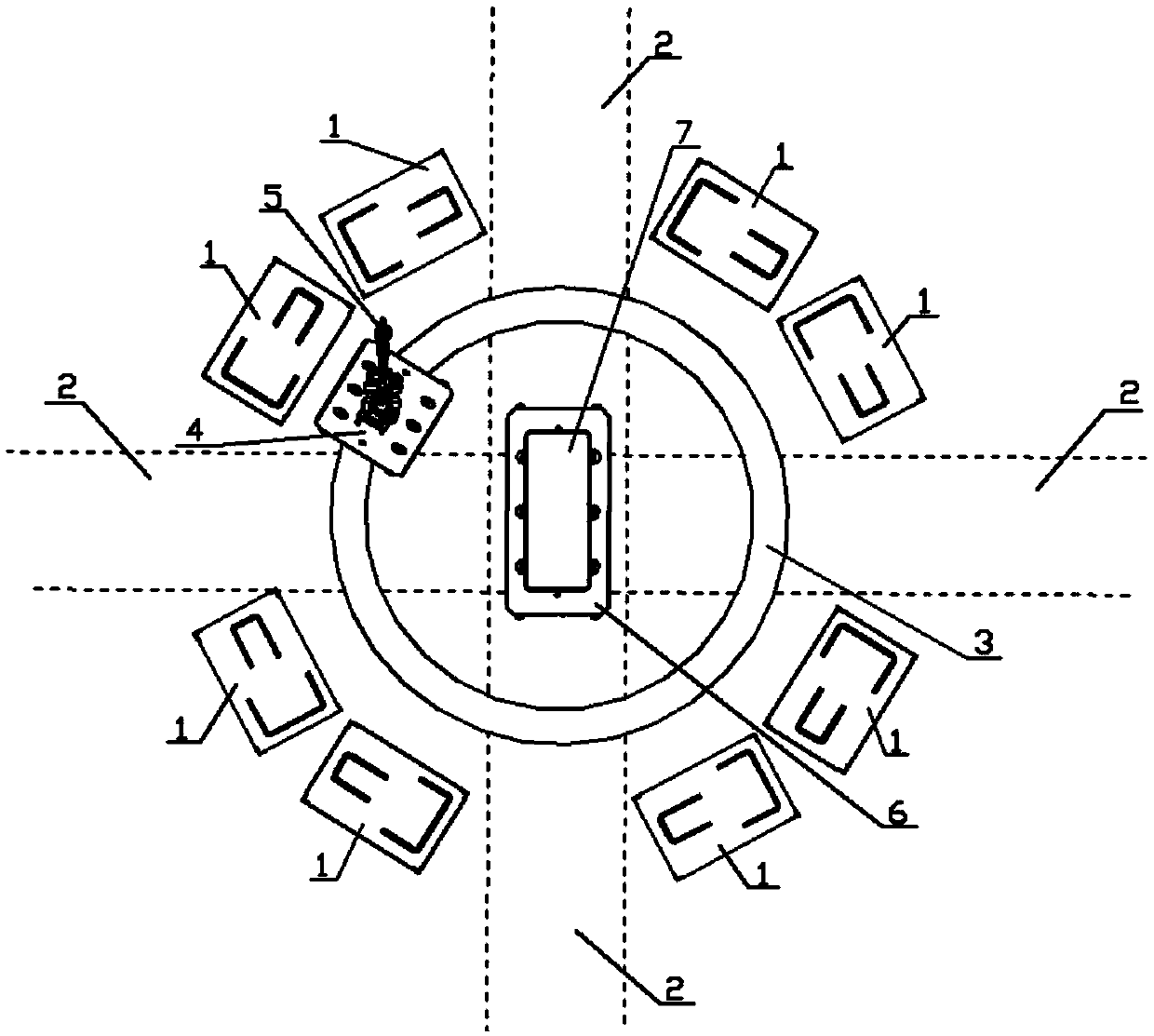

[0013] Such as figure 1 , figure 2 As shown, a storage unit is composed of a shelf 1, a circular guide rail 3, a manipulator transport vehicle 4, and a manipulator 5. The shelves 1 are arranged in a ring shape to form a ring-shaped shelf group. The east, south, west, and north directions of the ring-shaped shelf group No shelf is placed to form a cross-shaped passage 2, and the material box 7 enters and exits the storage unit through the cross-shaped passage 2; a circular guide rail 3 is provided on the inner side of the ring-shaped shelf group, and the manipulator transport vehicle 4 carries the manipulator 5 and will move along the circular guide rail 3 to reach At the specified location, the manipulator 5 grabs the material on the shelf and places it in the material box 7.

[0014] Taking the reclaiming process as an example, by figure 1 , figure 2 It can be seen that the storage unit includes 8 shelves 1, forming a ring-shaped shelf group. The AGV car 6 carries the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com