Delivery and clearance device of circular bin

A silo and clearing technology, applied in the field of warehousing and discharging facilities, can solve the problems of investment cost, high power consumption, unavailability of the clearing machine for liquidity, and high operating costs, and achieves the effect of avoiding poor revolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

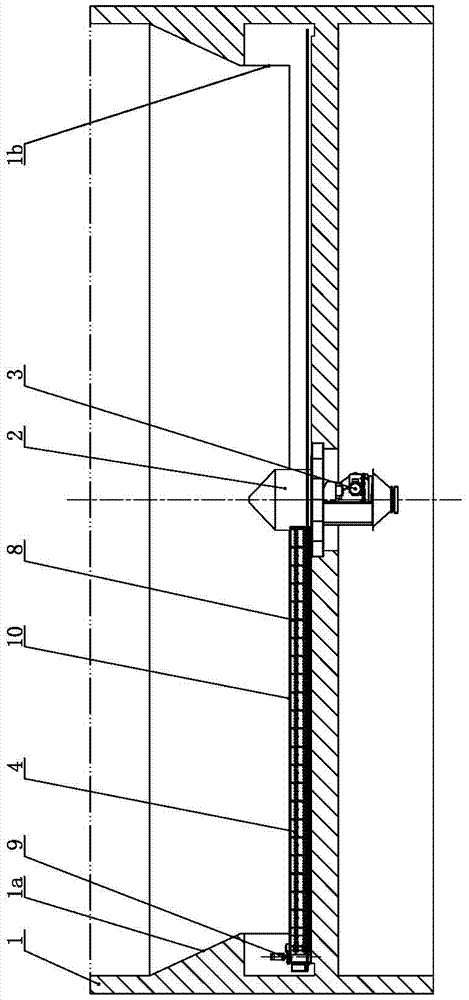

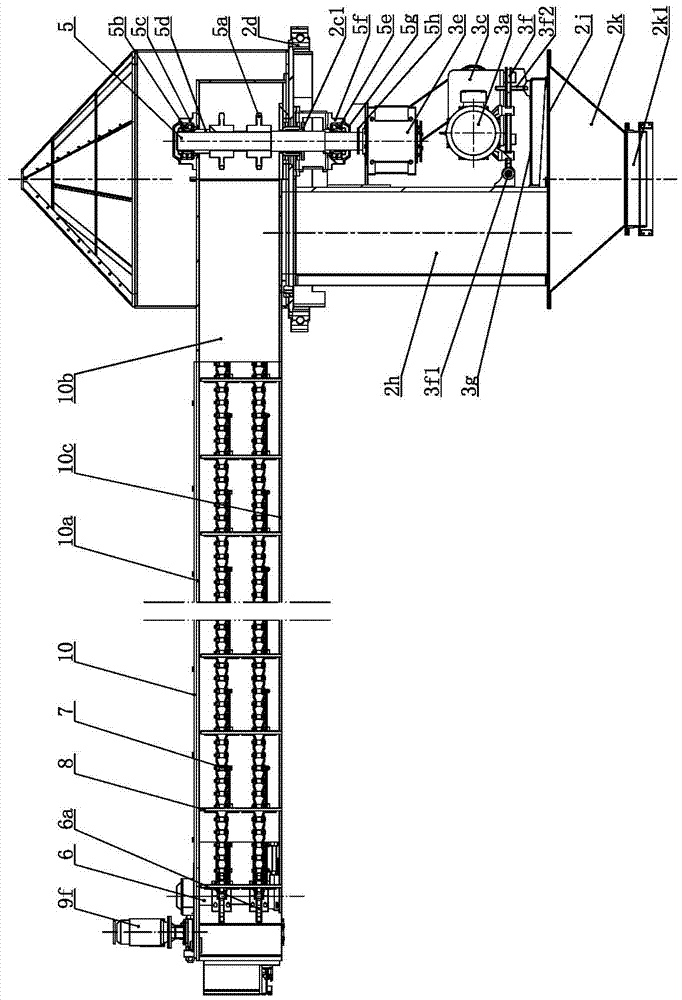

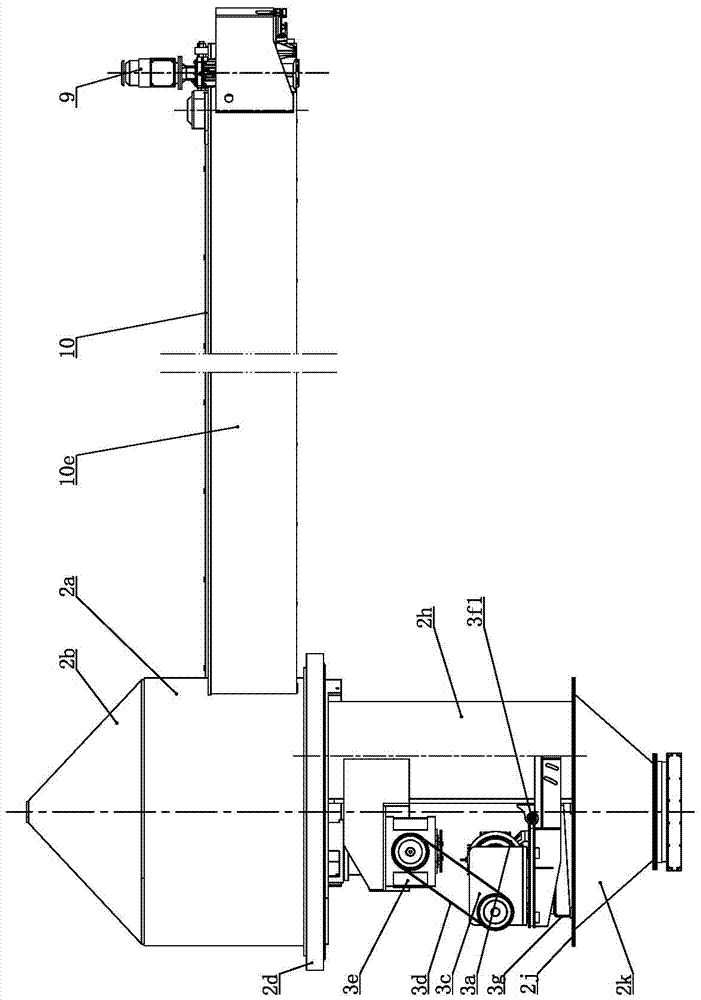

[0036] like Figure 1 to Figure 8As shown, the discharge and clearing device of the circular silo of the present invention includes a central rotation mechanism 2, a main drive mechanism 3, a scraper discharge mechanism 4, a girder mechanism 10 and a revolution walking mechanism 9, and the central rotation mechanism 2 is located at the bottom of the silo 1. Bottom center, the central rotating mechanism 2 includes a rotating cylinder 2a coaxial with the silo 1, the top of the rotating cylinder 2a is provided with a rotating top cap 2b, and the bottom of the rotating cylinder 2a is provided with a rotating bottom plate 2c; the scraper discharge mechanism 4 includes a vertically extending head shaft 5 and a tail shaft 6. The head shaft 5 is installed on the head of the beam mechanism 10 and driven by the main drive mechanism 3. The head shaft 5 is equipped with a driving sprocket 5a; the tail shaft 6 is installed on the beam mechanism At the tail of the mechanism 10, a driven spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com