Lightweight engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

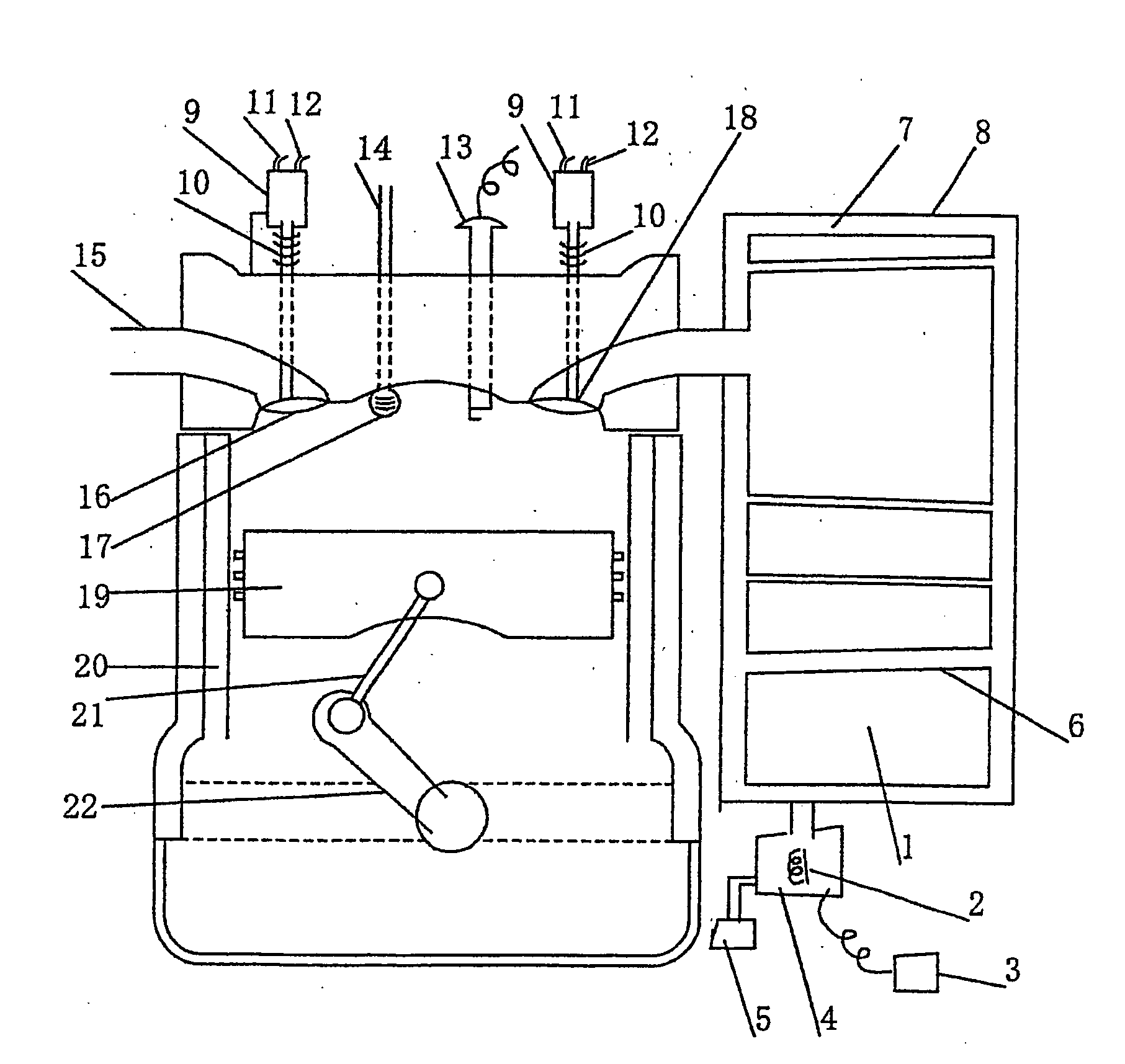

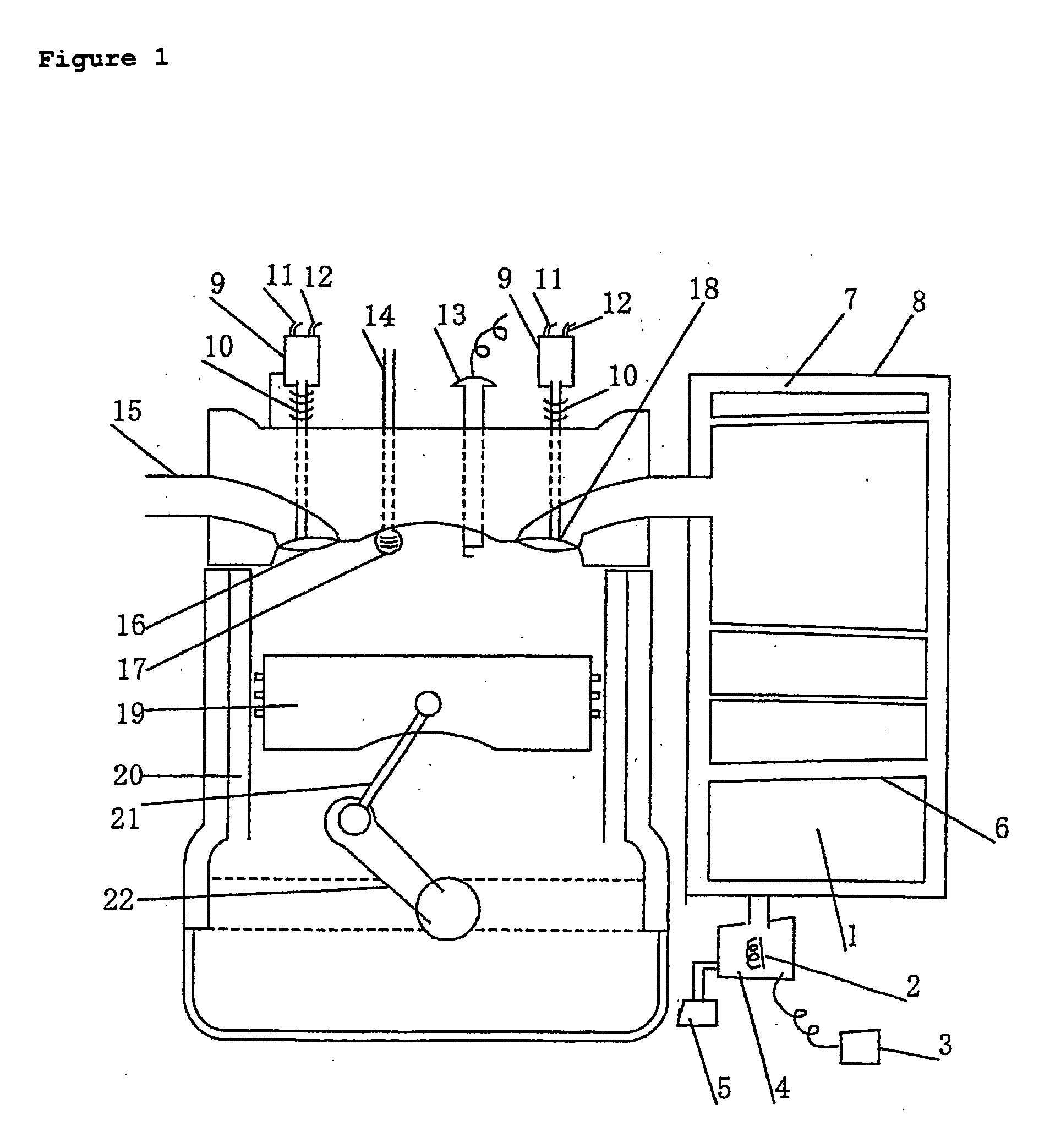

[0029]FIG. 1 is a schematic diagram of the engine. When air is pressurized highly, compression process is decreased. Then total length of the connecting rod (21) and turning radius of the crankshaft (22) is decreased, and the weight is decreased greatly. Additionally, the temperature and the pressure of the air tank (1) can be controlled by the microcomputer reading the numerical value of the sensor located in some areas. Therefore, the burning and the explosion can be controlled stably. And the provision against the exhaust gas, which is nitrogen peroxide gas, carbon monoxide gas, sulfured gas, and unburned fuels, becomes easier. Since the intake gas and the exhaust gas is controlled separately by the motive energy of the oil hydraulics or the electromagnetic force from the microcomputers, operation of the valves can be optimized than ever before and the burning and the explosion can be controlled in line with theoretical figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com