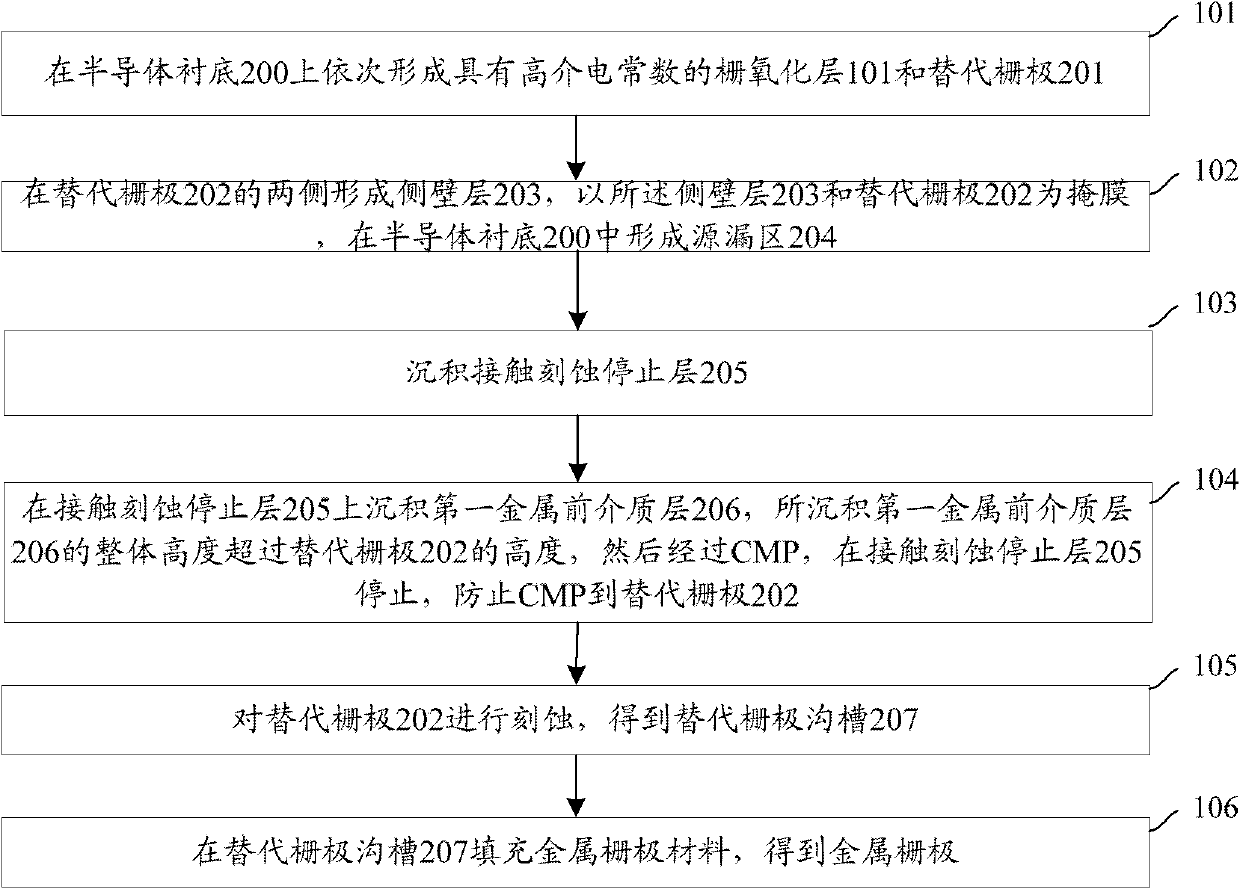

Manufacture method of metal grid electrode

A technology of metal gate and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems affecting and affecting the performance of semiconductor devices, and achieve the effect of eliminating the step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

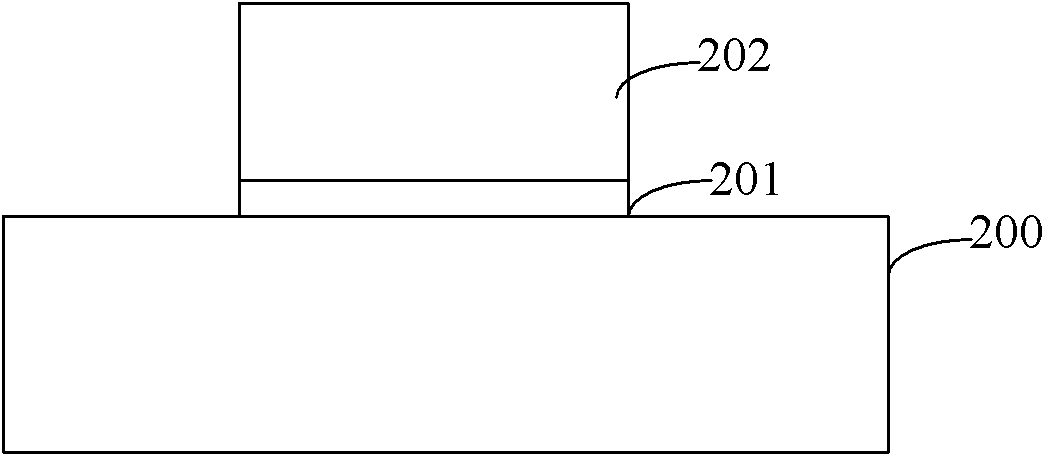

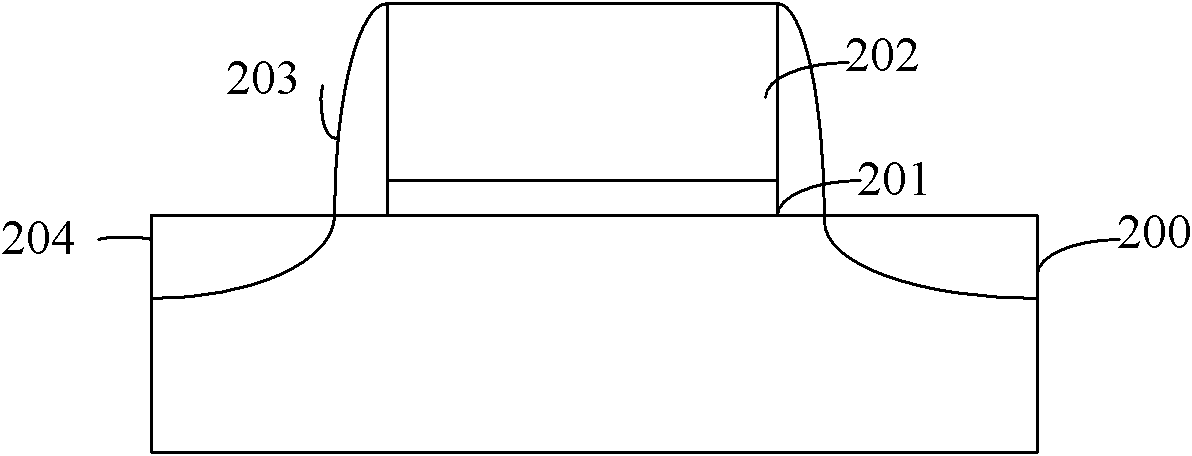

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0044] In the process of making the metal gate, in order to overcome the step effect on the semiconductor device when the first pre-metal dielectric layer is polished, the present invention, before etching the replacement gate, after polishing the first pre-metal dielectric layer, It also includes depositing a second pre-metal dielectric layer to cover the steps produced by polishing the first pre-metal dielectric, and then polishing the second pre-metal dielectric layer to the surface of the replacement gate. In this way, during subsequent etching of the replacement gate and filling of the metal gate, there will be no steps on the semiconductor device.

[0045] In the present invention, the second pre-metal dielectric may be a silicon oxide layer, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com