Electron beam metal 3D printing device and printing method

A 3D printing and electron beam technology, which is applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problem of reducing the processing effect and safety of electron beam 3D printing, reducing the energy of electron beam sintering, and the yield of fine powder. It can improve the real burning power, evenly distribute the metal mass, and enhance the melting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

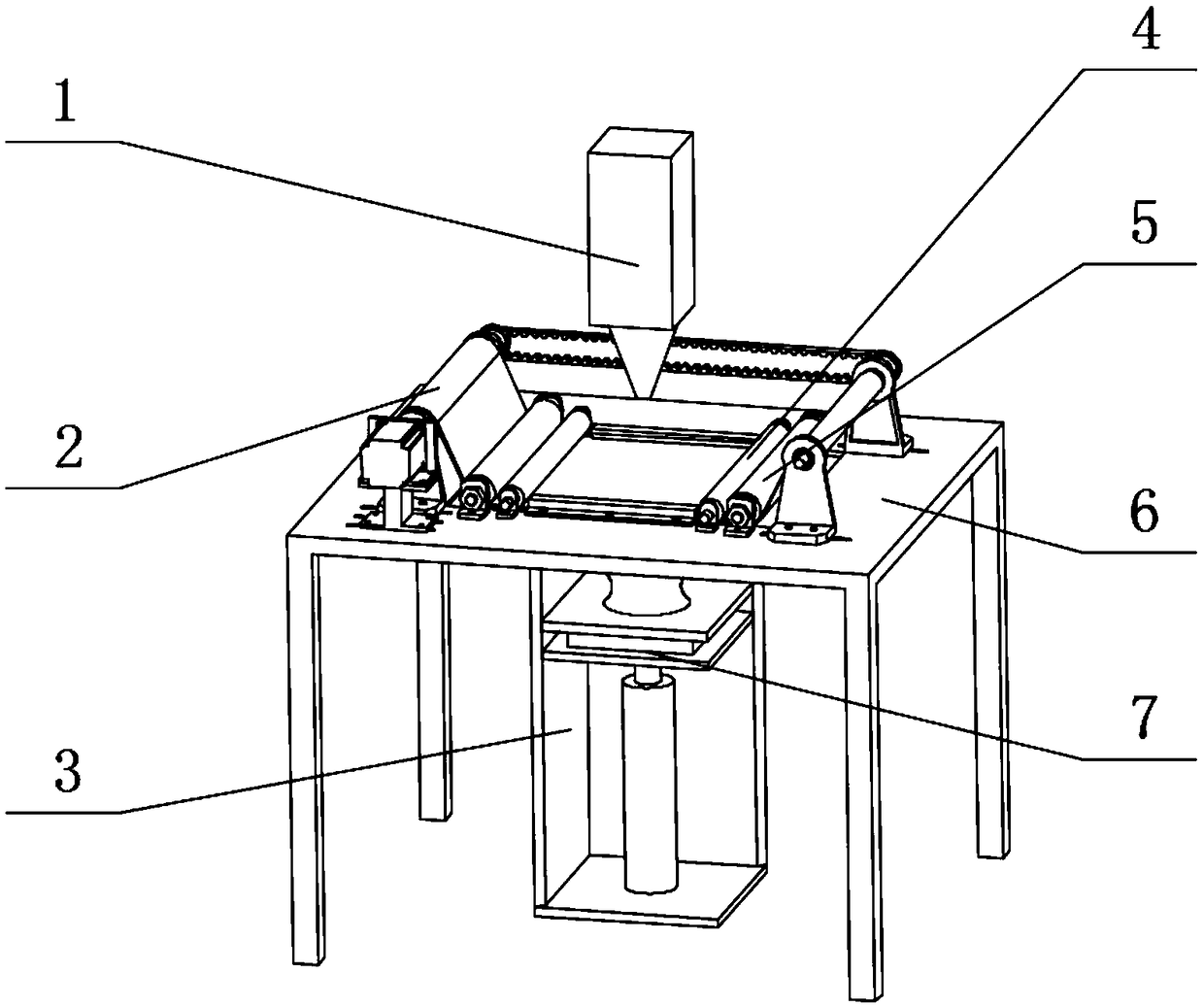

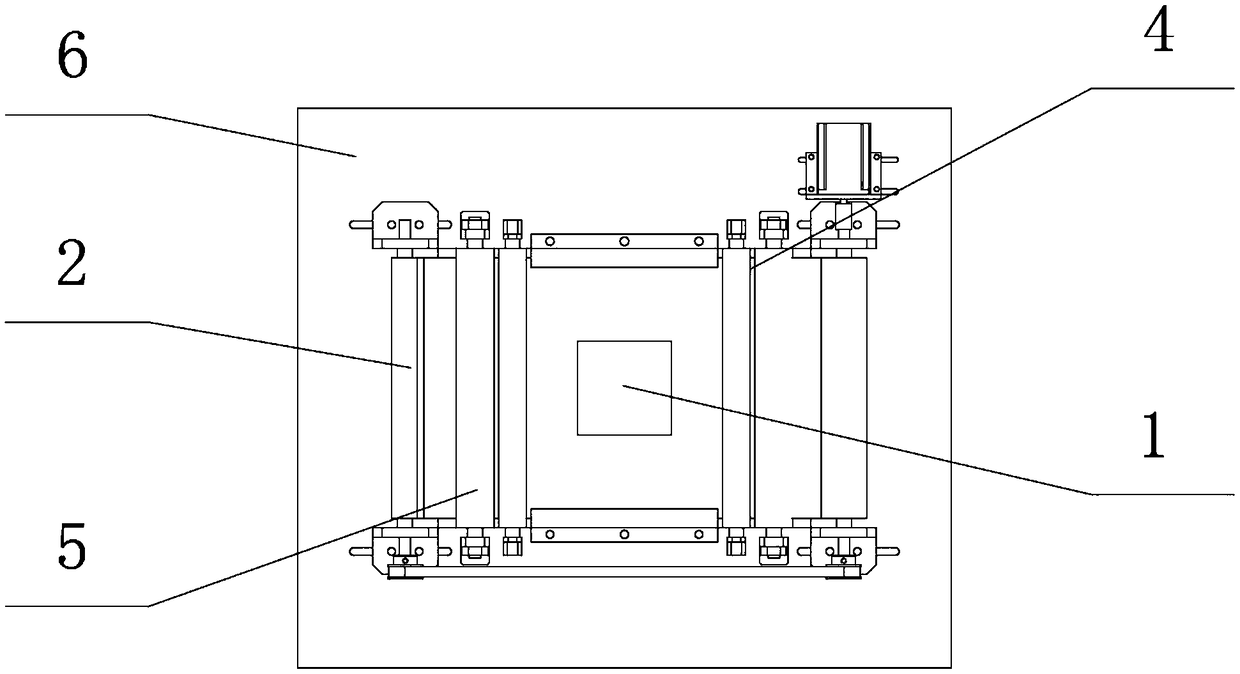

[0036] Such as figure 1 , 2 As shown, it includes the forming chamber 3, the lifting table 7, the working table 6, the electron gun 1, the feeding module 2, the tensioning module 5, and the preheating module 4. The electron gun 1 is located directly above the forming chamber 3 and is kept properly above the working table 6. Distance, the forming room 3 is located under the workbench 6, its square mouth is connected with the workbench square mouth 6-3, the lifting platform 7 that can move up and down is located inside the forming room 3, the feeding module 2 and the tensioning module 5 are respectively connected to the workbench 6 The upper surface is fixedly connected and distributed symmetrically on both sides of the workbench square mouth 6-3. The preheating module 4 is fixedly connected with the upper surface of the workbench 6, which is distributed around the workbench square mouth 6-3.

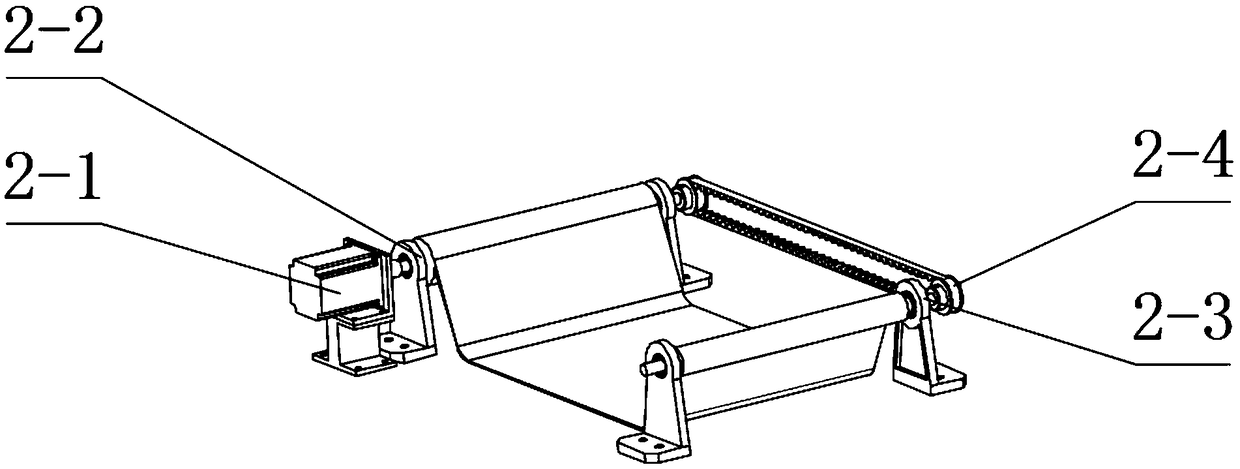

[0037] Such as image 3 As shown, the feeding module 2 is used to realize the transportat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com