Cooling device for printing head of 3D printing apparatus

A cooling device and 3D printing technology, applied in processing and manufacturing, liquid material additive processing, processing and irradiation arrangement, etc., can solve problems such as nozzle blockage, cooling instability, adhesion, etc., to reduce cooling noise and improve cooling stability , to avoid the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The illustrated embodiments are disclosed with reference to the drawings. It should be understood, however, that the disclosed embodiments are merely embodiments that may be shown in various and alternative forms. The figures are not necessarily to scale and some features may be exaggerated or minimized to show details of particular components. Specific structural and functional details disclosed are not to be interpreted as limiting, but as a representative basis for teaching one skilled in the art how to practice the present disclosure.

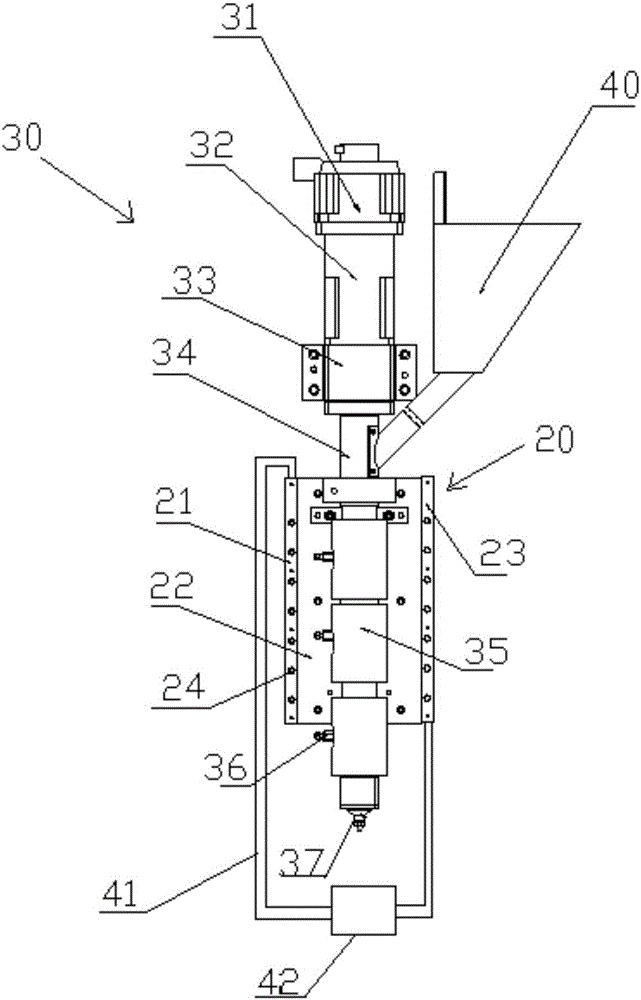

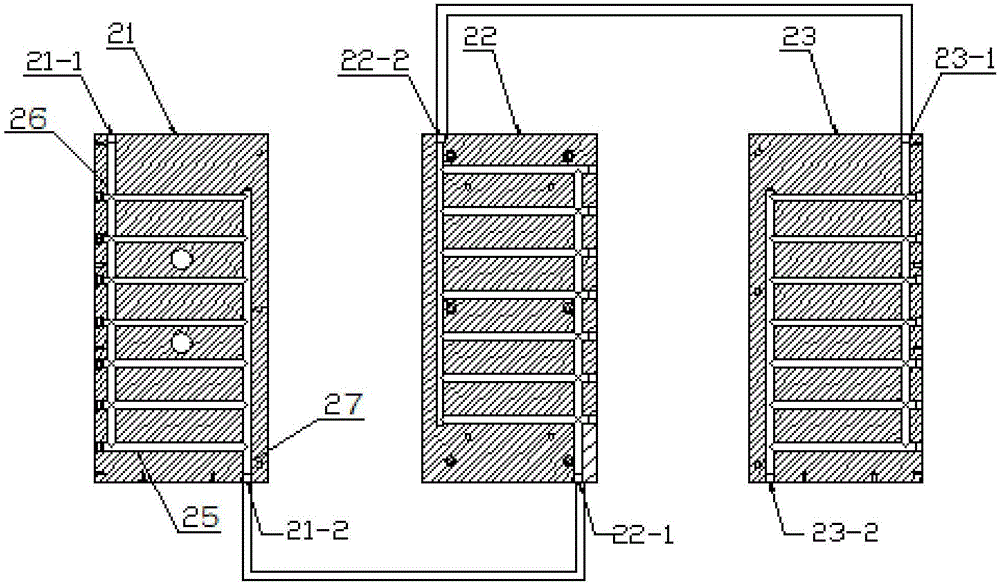

[0017] refer to figure 1 , the present invention provides a cooling device for a print head 30 of a 3D printing device. The print head 30 includes an extrusion screw barrel 34 and a heater 35 arranged on the extrusion screw barrel 34. The cooling device includes: surrounding the heater 35 is provided with a cooling plate 20, and a cooling water channel 24 for cooling water to flow through is arranged inside the cooling plate 20. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com