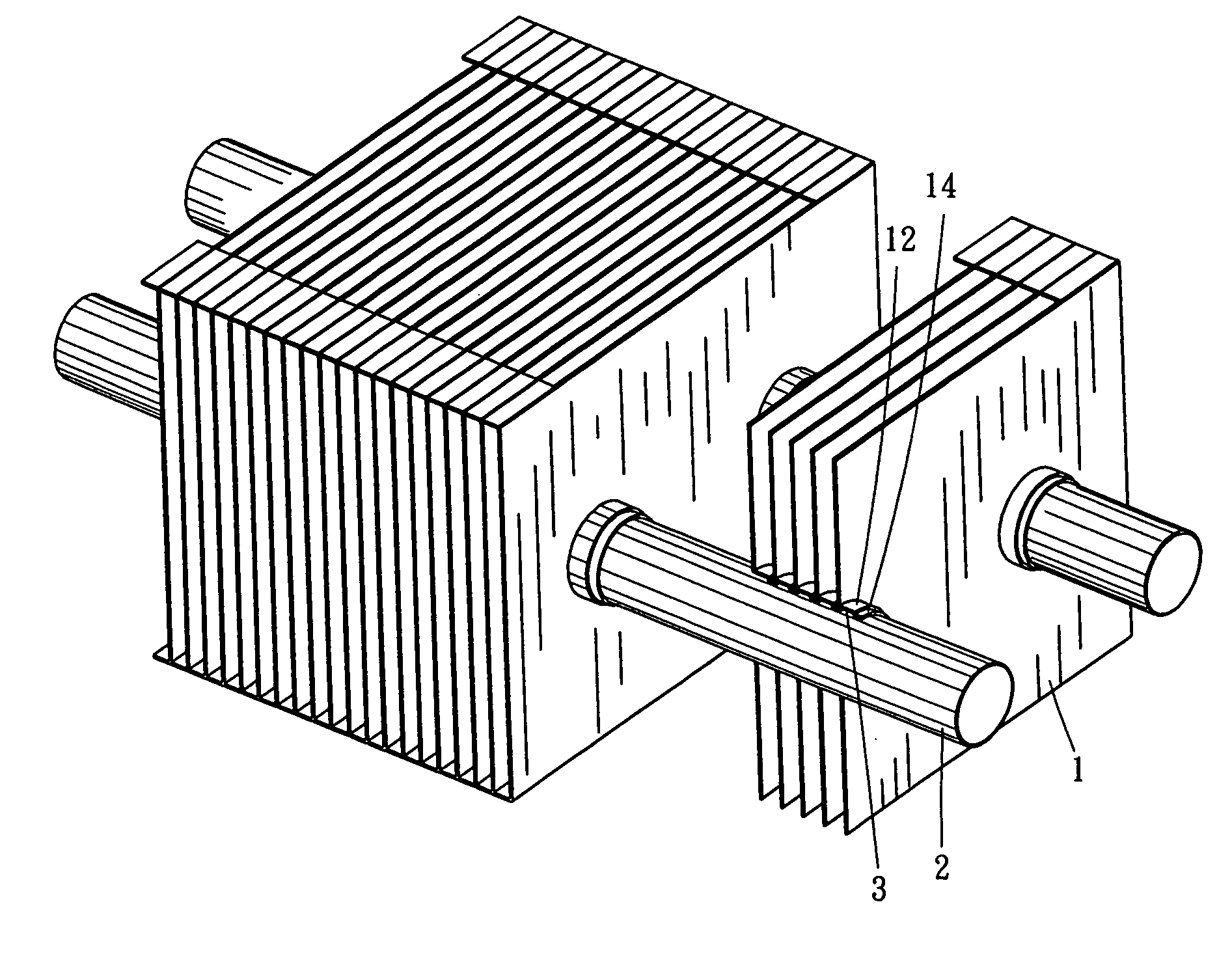

Assembled configuration of cooling fins and heat pipes

a technology of cooling fins and heat pipes, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, tubular elements, etc., can solve the problems of uneven distribution or leakage of thermal interface materials, and achieve enhanced stability of cooling fins, facilitate filling of thermal interface materials, and facilitate the effect of cooling fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

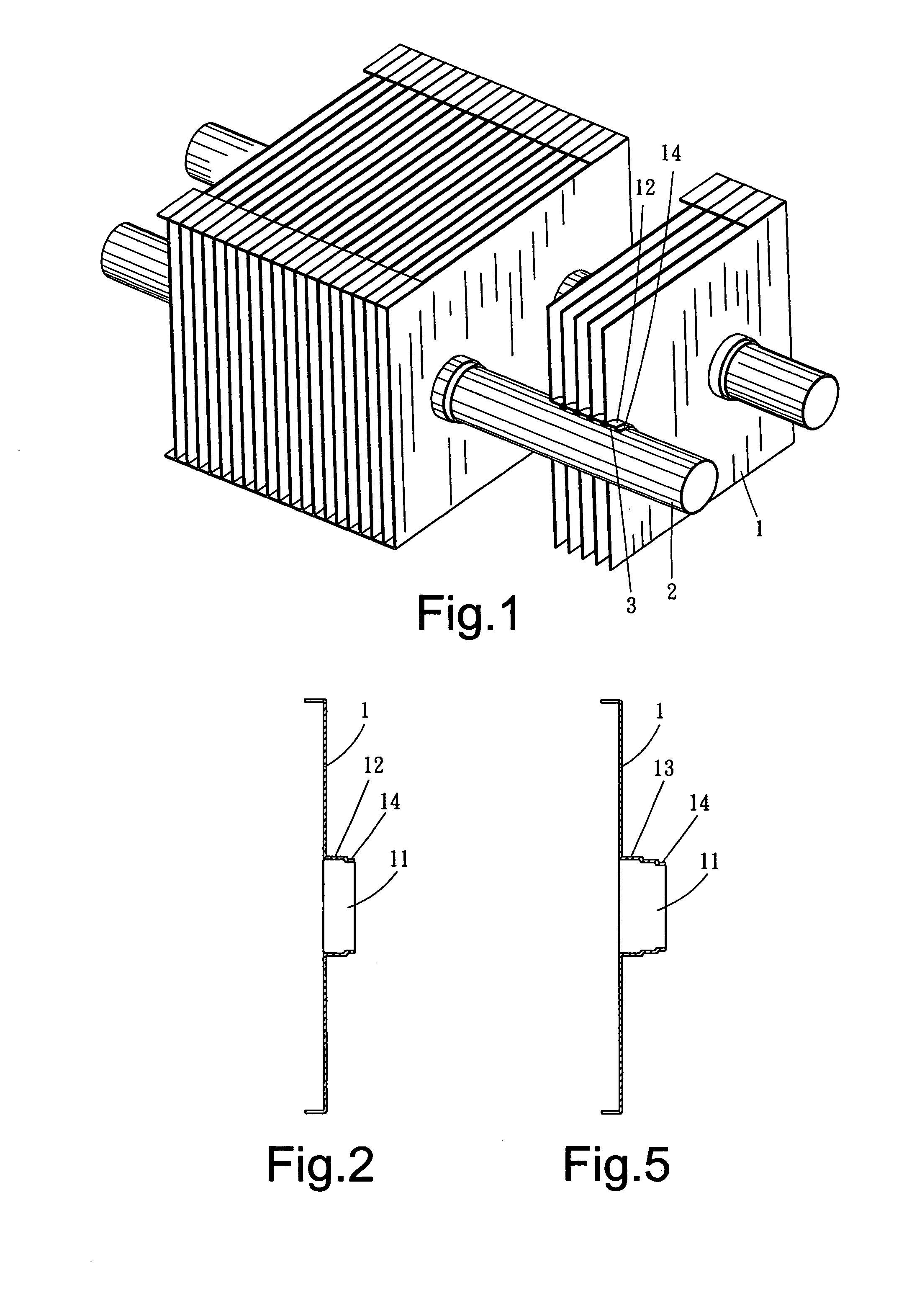

[0015]As shown in FIGS. 1 and 2, an assembled configuration of cooling fins and heat pipes according to the present invention is characterized in that each of the cooling fins 1 has through holes 11 for heat pipes 2 to pass through, and each said through hole 11 is formed with a stair-shaped bent portion 12 at a periphery thereof having an extending section 14 formed at an distal end of said stair-shaped bent portion 12, wherein the extending section 14 has an outer diameter approximately equal to an inner diameter of the stair-shaped bent portion 12.

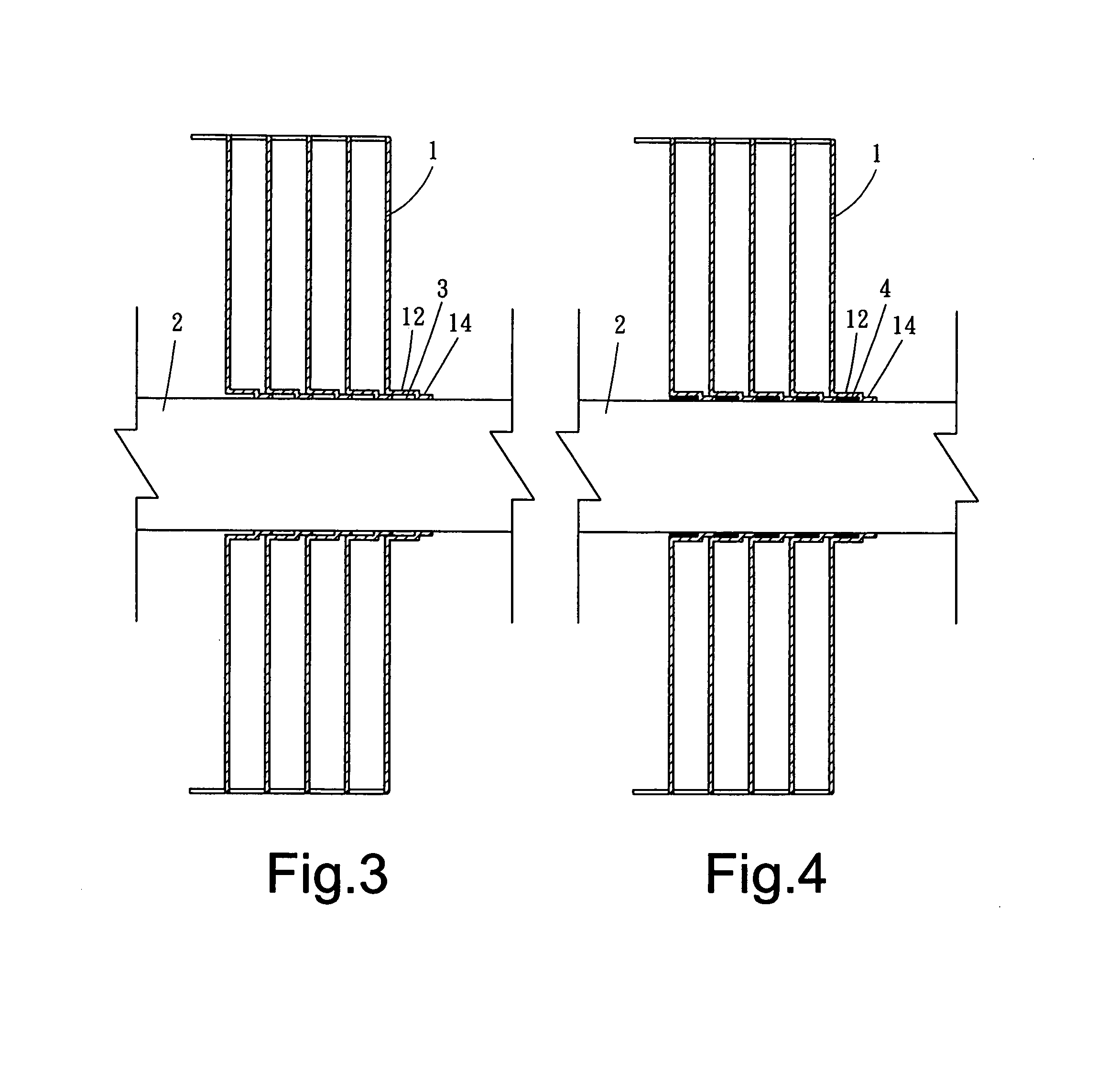

[0016]Referring to FIGS. 3 and 4, when the plural cooling fins 1 are successively penetrated by the heat pipes 2 at the through holes 11 and arranged in juxtaposition, a small part of the stair-shaped bent portion 12 of one said cooling fin 1 is nestingly placed over the extending section 14 of an underlying said cooling fin 1.

[0017]Thereby, a closed accommodating space 3 is defined between the stair-shaped bent portion 12 and the exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com