Spinning equipment for producing porous fine denier polyester POY

A fine denier and spinning technology, which is applied in the field of equipment for producing porous fine denier POY yarns, can solve problems such as unsatisfactory production costs, frequent equipment failures, etc., and achieve sufficient and uniform cooling, improved cooling stability, and improved The effect of production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

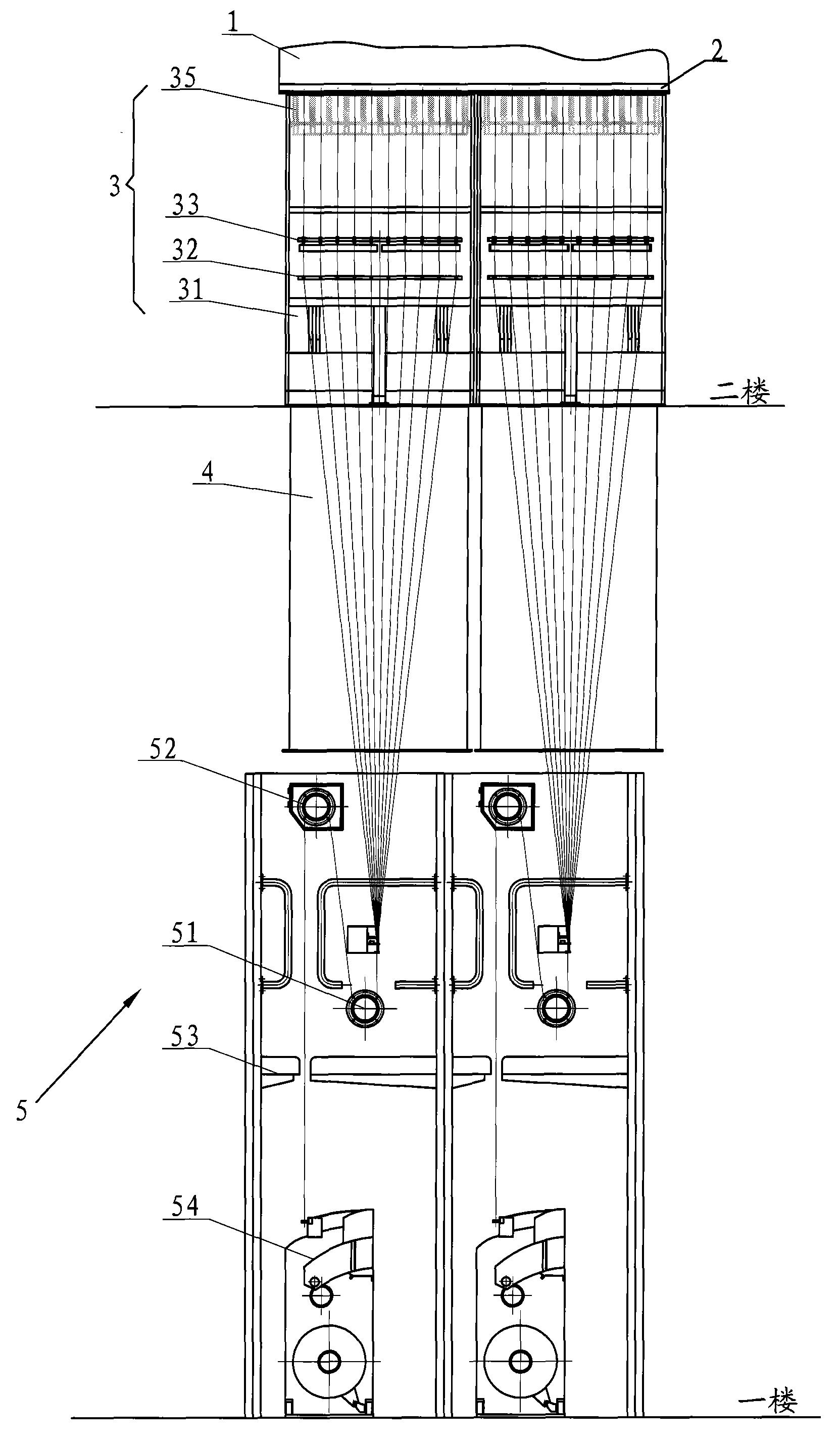

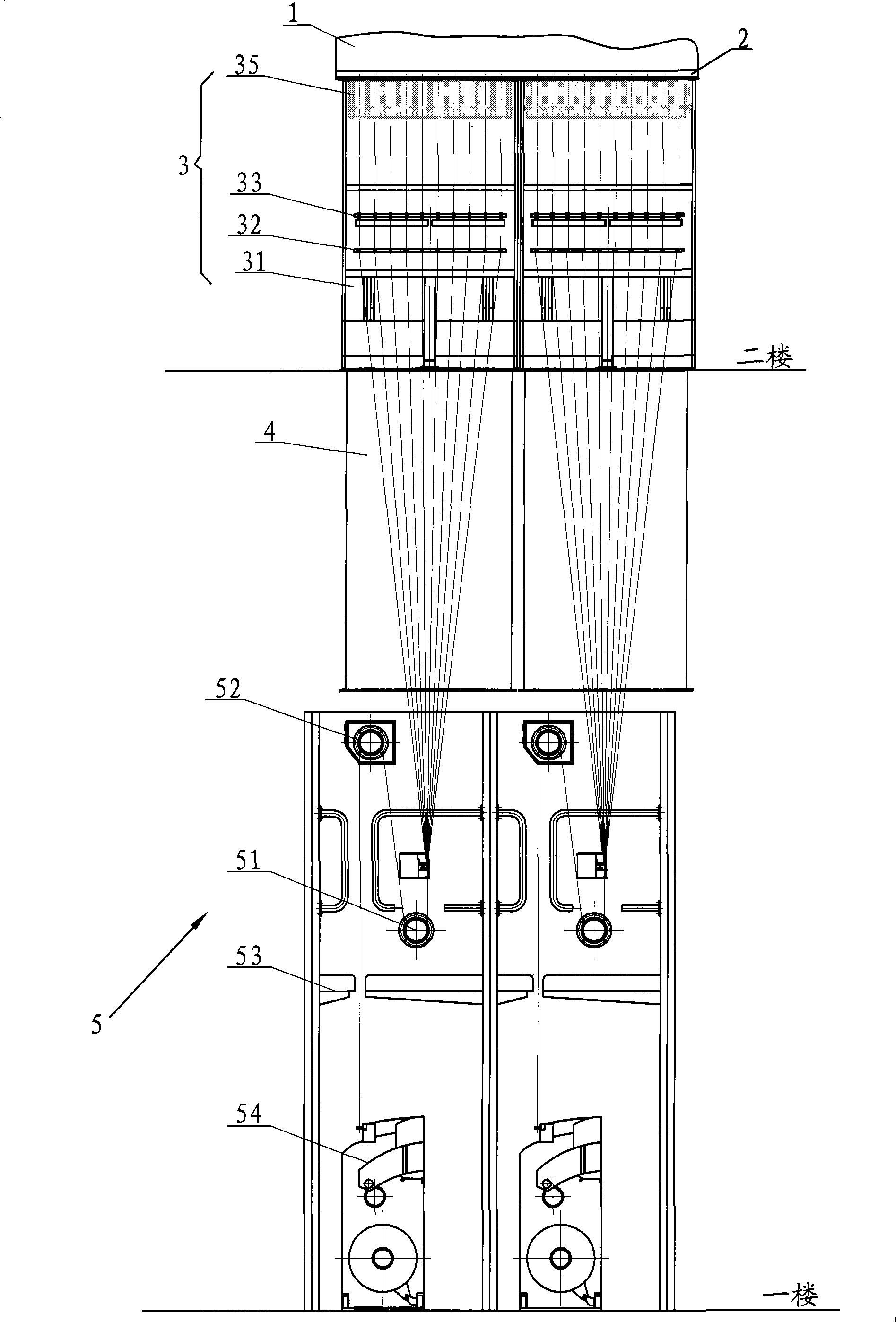

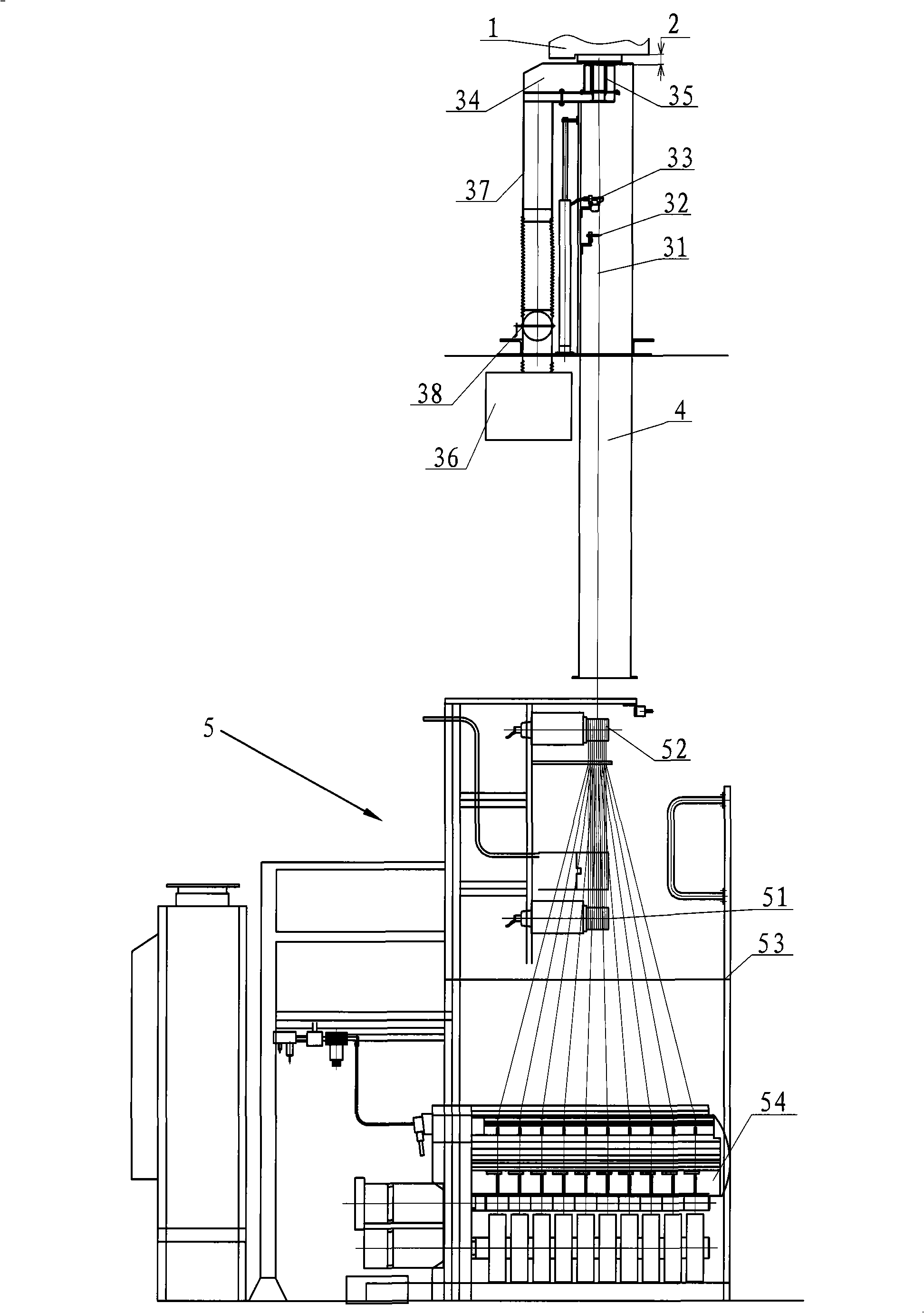

[0014] Spinning equipment as shown in Figure 1 and Figure 2, it comprises spinning box 1, windless area 2, blowing device 3, tunnel 4 and winding machine 5 from top to bottom, wherein, spinning box 1 mainly consists of box Body, metering pump, spinneret assembly (not shown in the figure), etc., the spinneret assembly mainly includes spinnerets, and each spinneret has holes. In this embodiment, each spinneret has 288 holes. The spinning box 1 is mainly used to maintain a uniform spinning temperature for the polyester melt, measure the amount of melt, mix the melt evenly and form a monofilament through the spinneret. The structure of the spinning box 1 follows the current The structure of the equipment is not the gist of the present invention, so it will not be described in detail here.

[0015] The windless zone 2 is mainly composed of heat ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com