Bottle billet forming part assembly with die cavity extending into die lip for matching and bottle billet die thereof

A technology of mold cavity and mold lip, which is applied in the field of preform molding parts assembly and preform mold, which can solve the problems of reduced strength of die lip cone surface, poor cooling effect, affecting service life, etc., and achieves improved connection stability , The cooling effect is fully uniform, and the cooling effect is uniform and sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

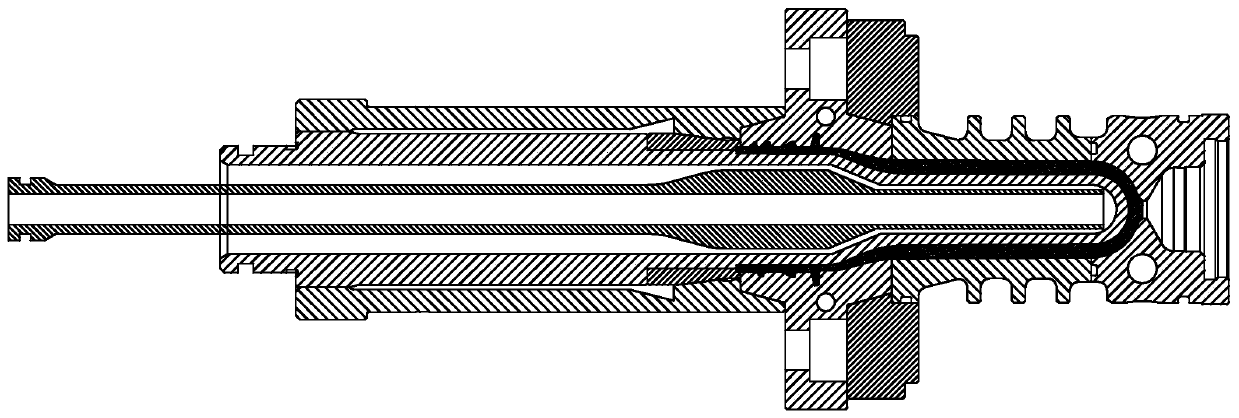

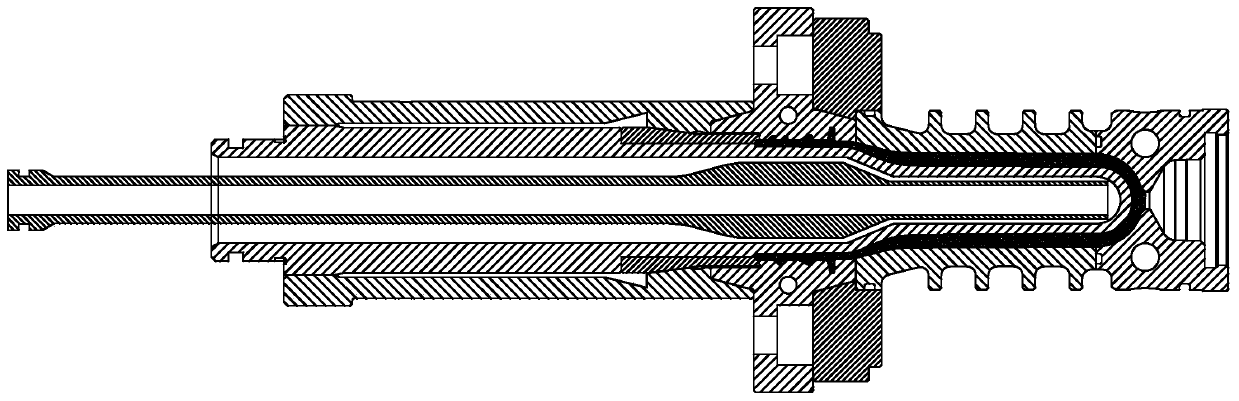

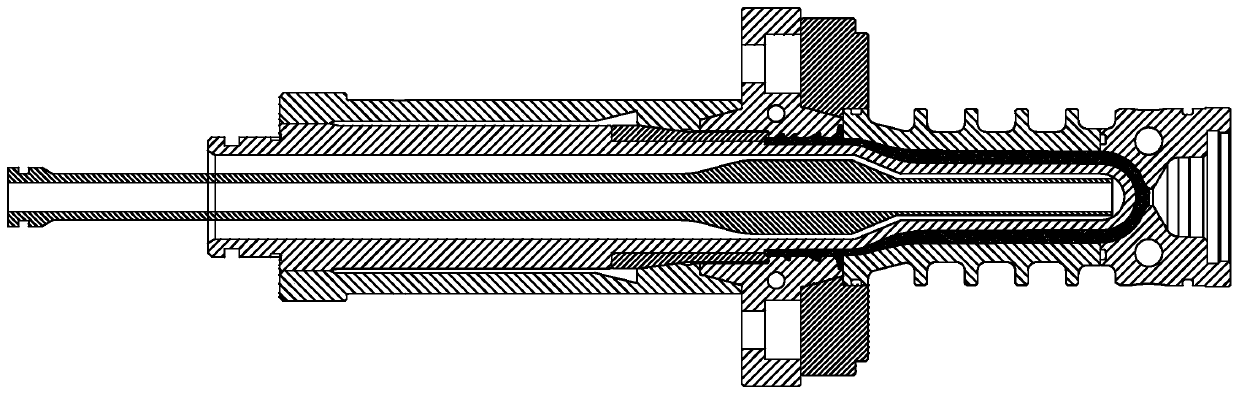

[0040] This embodiment discloses a bottle preform forming part assembly in which the mold cavity goes deep into the lip and fits, including a mold cavity 1, a mold lip 2, a mold core 3 and a mold cavity fastener 4, and the mold cavity fastener 4 is located at Between the mold cavity 1 and the die lip 2, the die lip 2 and the mold cavity fastener 4 adopt a taper fit, and the mold cavity fastener 4 is sleeved on the outer surface of the mold cavity 1 and the die lip 2 At the junction, the die lip 2 is provided with a die lip cooling channel 21, the end of the die cavity 1 is provided with a flange 11, and the end of the die lip 2 is provided with a fitting hole 22, and the fitting hole The position 22 is sleeved on the outer wall of the flange 11, and the mating end surface between the flange 11 and the matching hole 22 forms a billet parting surface 5, and the billet body parting surface 5 is arranged on the neck A1 of the billet body for forming In this embodiment, the flange ...

Embodiment 2

[0044] This embodiment discloses a preform mold in which the cavity is deeply matched with the lip, which includes a preform forming part assembly and a cavity bottom 6, the cavity bottom 6 is installed at the end of the cavity 1 away from the lip 2, so The bottom of the mold cavity 6 is provided with a bottom cavity 61 for forming the bottom of the preform, and the bottom of the cavity 6 is provided with a cooling channel 62 at the bottom of the cavity, and the cooling channel 62 at the bottom of the cavity surrounds the cavity at the bottom of the blank 61 peripheral settings. It also includes a core cooling pipe 7, which extends along the central axis of the core 3 to the inside of the core 3, and the core cooling pipe 7 is a U-shaped structure. The core cooling pipe 7 is provided with a hollow convex body 71 for improving the cooling effect of the mold core 3. The hollow convex body 71 is arranged at a position corresponding to the billet cavity 23. The core cooling pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com