Antimony powder production system

A production system and technology of antimony powder, applied in the field of antimony powder production equipment, can solve problems such as uneven cooling of antimony powder and insufficient cooling of antimony powder, and achieve the effects of improving safety performance, saving production costs, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

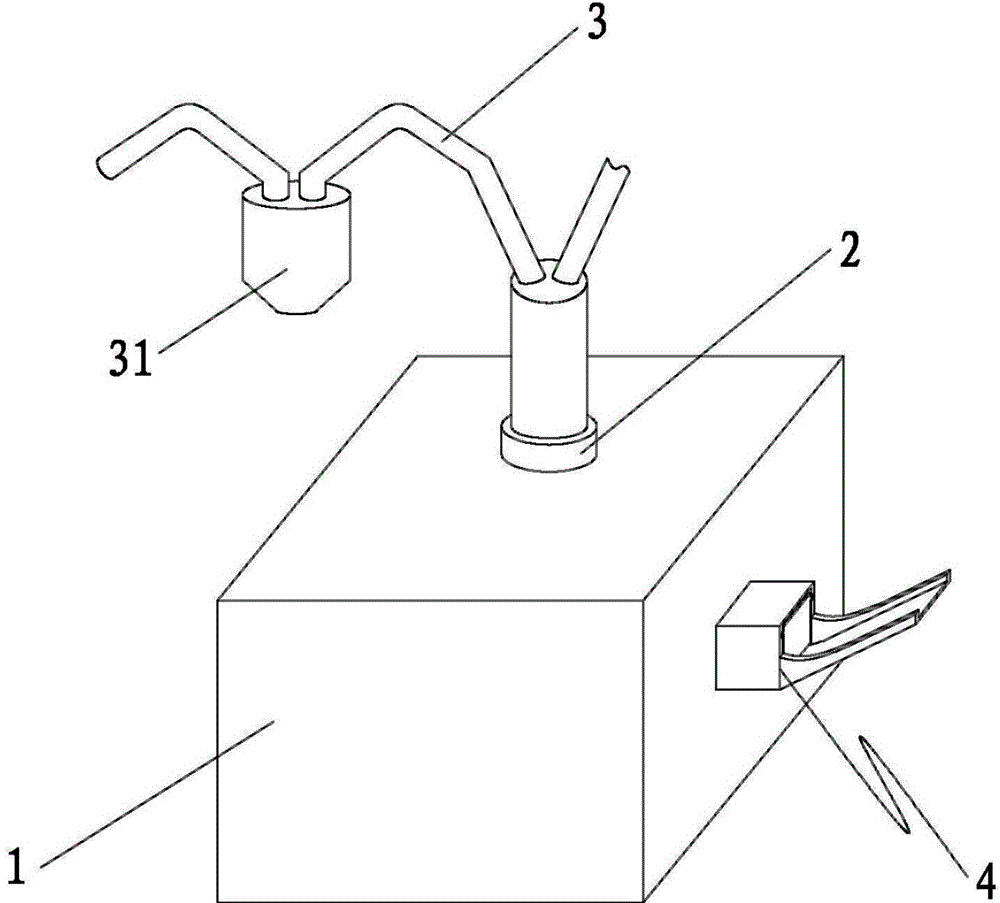

[0030] This embodiment provides a production system of antimony powder, please refer to Figure 1 to Figure 5 , the system includes: a smelting furnace 1, a water-cooled ascender 2 and an antimony powder transfer pipeline 3.

[0031] The water-cooled ascender 2 is arranged at the outlet of the antimony powder of the smelting furnace 1 , and the antimony powder transfer pipe 3 is connected with the water-cooled ascender 2 .

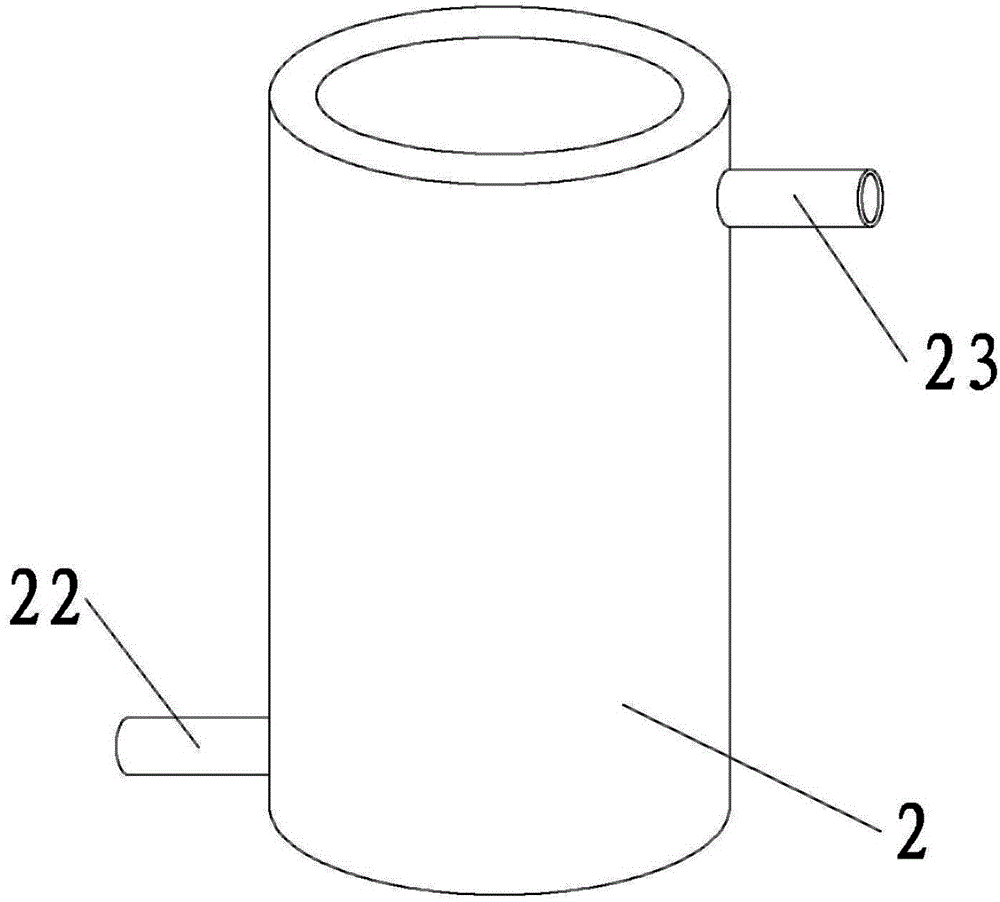

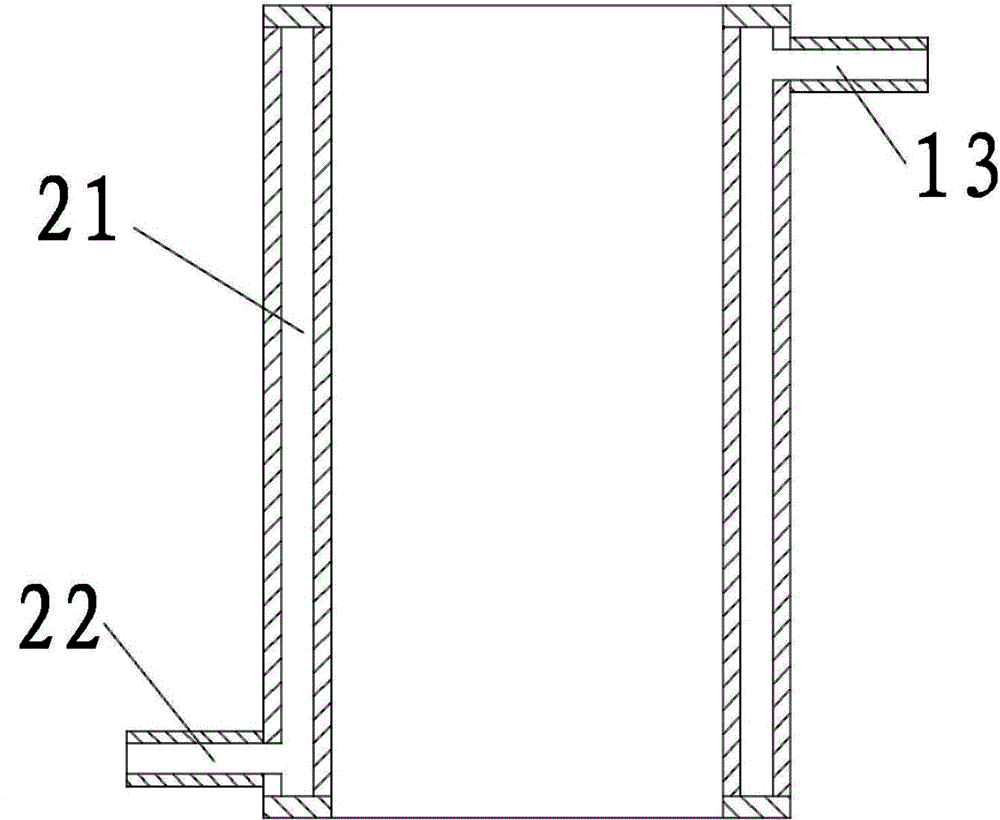

[0032] The cross-sectional shape of the powder outlet of the water-cooled riser 2 is oval, and a condensed water layer 21 is arranged in the peripheral wall of the water-cooled riser 2 .

[0033] The antimony powder transfer pipeline 3 is composed of multi-section bent pipes, and a tapered bucket 31 is arranged at the connection of the lower ends of every two sections of bent pipes.

[0034] A water inlet pipe 22 connected to the condensed water layer 21 is arranged on the outer wall of the water-cooled riser 2 near the bottom, and an outlet pipe 23 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com