Mold rapid cooling device and using method thereof

A rapid cooling and mold technology, applied in the field of mold cooling, can solve the problems of poor cooling effect and slow cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

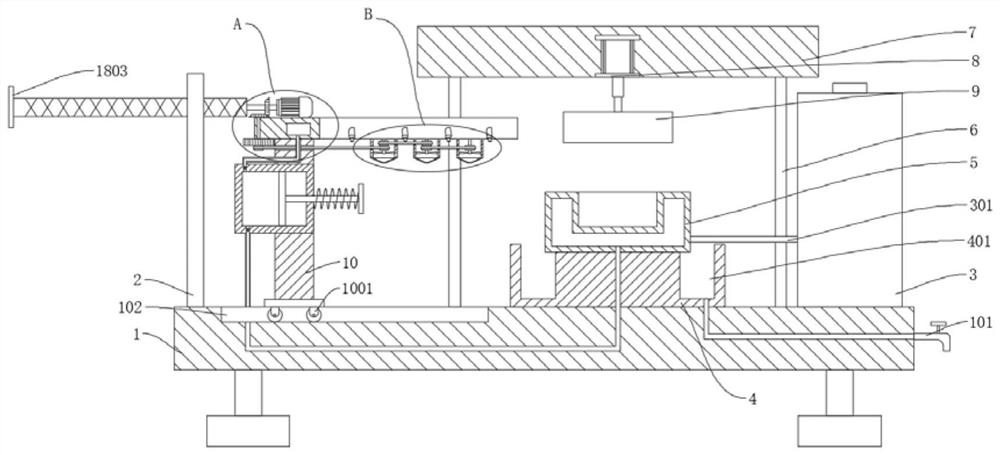

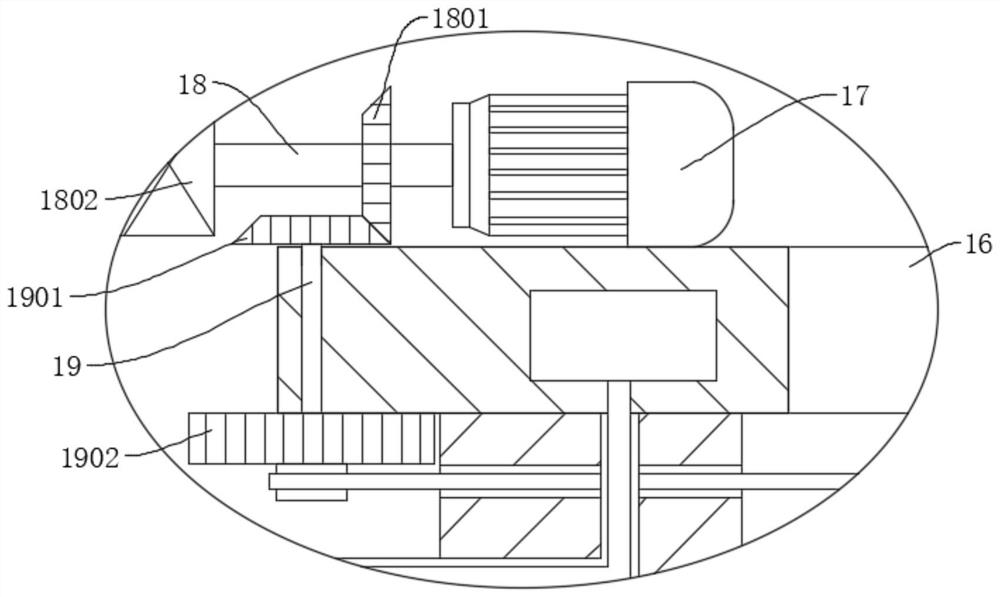

[0037]Referencefigure 1 ,figure 2 ,Figure 4 ,Figure 5 withFigure 7, A rapid mold cooling device, comprising a base 1, the outer wall of the base 1 is fixedly connected with a mold base 4, the top outer wall of the mold base 4 is fixedly connected with a lower mold 5, the outer wall of the base 1 is fixedly connected with a support rod 6, and the support rod 6 is away from the base 1. One end is fixedly connected to the top seat 7, the top seat 7 is provided with a cylinder 8, the output end of the cylinder 8 is fixedly connected to the upper mold 9, the base 1 is slidably connected with a stabilizer plate 10, and the stabilizer plate 10 is fixedly connected with a piston cylinder 11. The piston cylinder 11 is provided with a second water inlet pipe 1101 and a water outlet pipe 1102. The second water inlet pipe 1101 and the water outlet pipe 1102 are both provided with a one-way valve 1103. The piston cylinder 11 is slidably connected with a piston plate 12, and the outer wall of the...

Embodiment 2

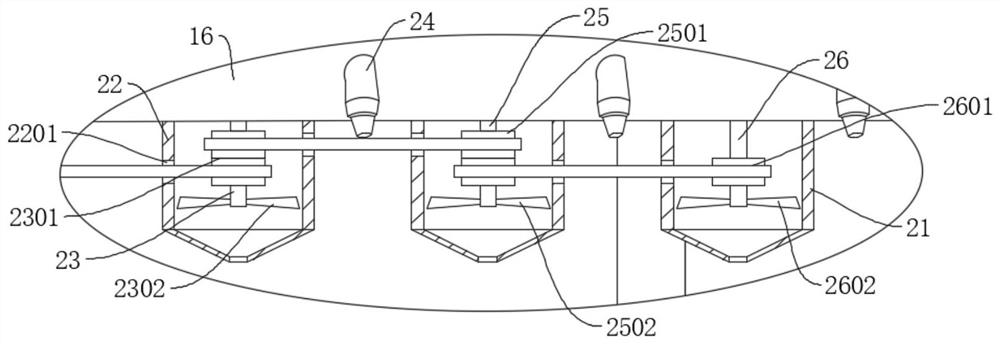

[0048]Reference mapimage 3 withFigure 6 , A rapid mold cooling device, comprising a base 1, the outer wall of the base 1 is fixedly connected with a mold base 4, the top outer wall of the mold base 4 is fixedly connected with a lower mold 5, the outer wall of the base 1 is fixedly connected with a support rod 6, and the support rod 6 is away from the base 1. One end is fixedly connected to the top seat 7, the top seat 7 is provided with a cylinder 8, the output end of the cylinder 8 is fixedly connected to the upper mold 9, the base 1 is slidably connected with a stabilizer plate 10, and the stabilizer plate 10 is fixedly connected with a piston cylinder 11. The piston cylinder 11 is provided with a second water inlet pipe 1101 and a water outlet pipe 1102. The second water inlet pipe 1101 and the water outlet pipe 1102 are both provided with a one-way valve 1103. The piston cylinder 11 is slidably connected with a piston plate 12, and the outer wall of the piston plate 12 is fixed....

Embodiment 3

[0059]Referencefigure 1 withFigure 4 , A rapid mold cooling device, comprising a base 1, the outer wall of the base 1 is fixedly connected with a mold base 4, the top outer wall of the mold base 4 is fixedly connected with a lower mold 5, the outer wall of the base 1 is fixedly connected with a support rod 6, and the support rod 6 is away from the base 1. One end is fixedly connected to the top seat 7, the top seat 7 is provided with a cylinder 8, the output end of the cylinder 8 is fixedly connected to the upper mold 9, the base 1 is slidably connected with a stabilizer plate 10, and the stabilizer plate 10 is fixedly connected with a piston cylinder 11. The piston cylinder 11 is provided with a second water inlet pipe 1101 and a water outlet pipe 1102. The second water inlet pipe 1101 and the water outlet pipe 1102 are both provided with a one-way valve 1103. The piston cylinder 11 is slidably connected with a piston plate 12, and the outer wall of the piston plate 12 is fixed. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com