Production line of integrated wallboard

A technology that integrates wall panels and production lines. It is used in metal processing, household components, household appliances, etc. It can solve the problems of simple device structure and poor wall panel molding, and achieve compact structure, efficient and convenient cutting, and sufficient and uniform cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

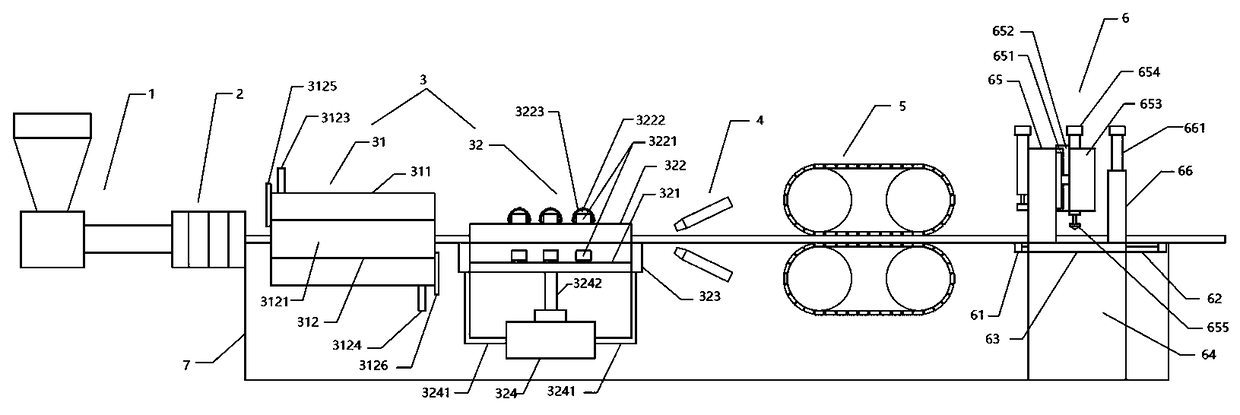

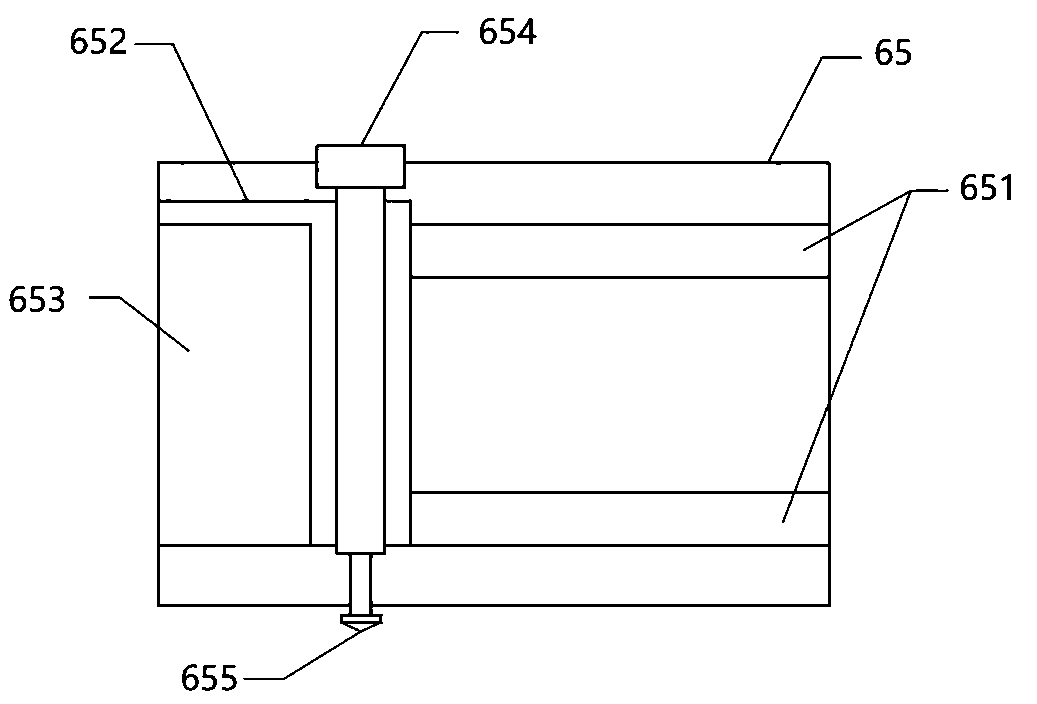

[0021] See figure 1 , the production line of integrated wallboard, including extruder 1, forming mold 2, conveyor frame 7, air knife 4 and tractor 5, forming mold 2 connected to extruder 1, air knife 4, tractor 5 connected to conveyor frame 7, it is characterized in that: it also includes a cooling mechanism 3 and a cutting mechanism 6 that are all connected to the conveying frame 7, the cooling mechanism 3, the air knife 4 tractor 5, and the cutting mechanism 6 are arranged in sequence, and the cooling mechanism 3 includes dry Type cooling device 31 and wet cooling device 32.

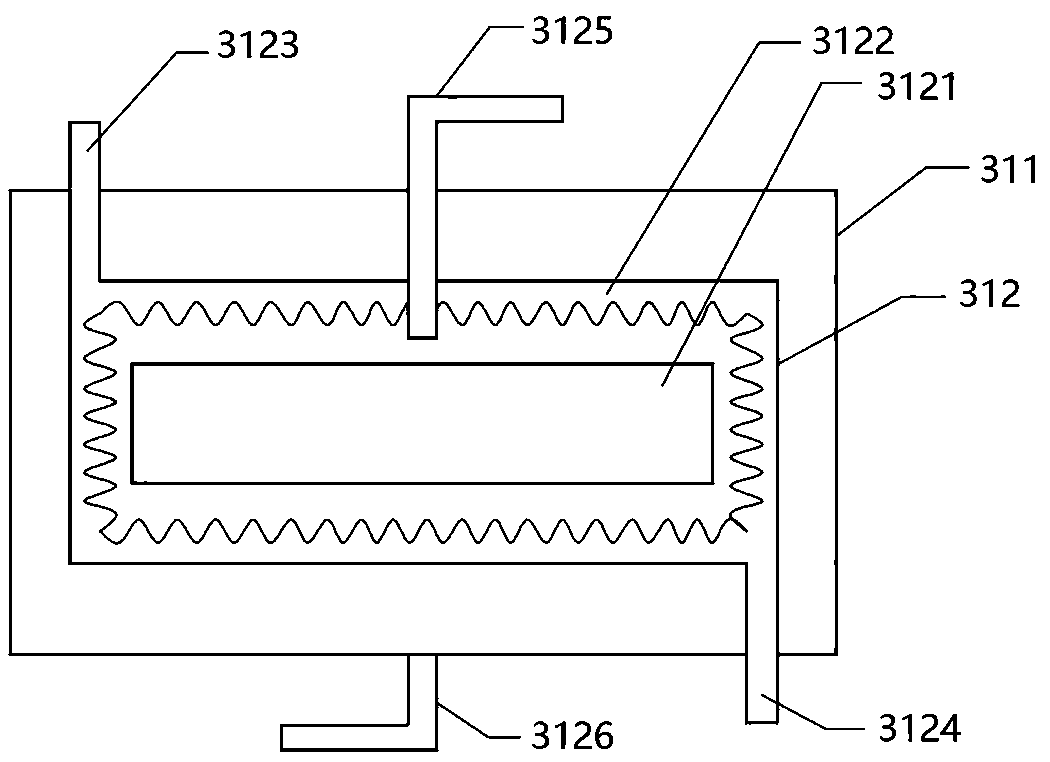

[0022] combine figure 2 , the dry cooling device 31 includes a first cooling installation seat 311 connected to the conveying frame 7 and a cooling calibrating sleeve 312 connected in the first cooling installation seat 311, and an axial through installation is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com