Novel screw rod type nozzle with fused deposition forming technology

A fused deposition modeling, screw-type technology, applied in the field of 3D printing, can solve the problems of uneven silk material, clogging of the melt heater, affecting the continuity of product printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

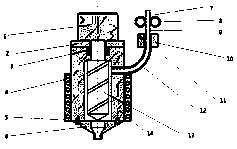

[0012] Below in conjunction with accompanying drawing this patent is described further:

[0013] As shown in the figure, a new type of fused deposition modeling technology screw nozzle, including stepping motor 1, motor end cover 2, rolling bearing 3, electromagnetic heating ring 4, bolt 5, nozzle 6, customized gear 7, U-shaped bearing 8 , Thermoplastic material 9, preheating device 10, heating rod 11, material channel 12, screw extrusion device 13, barrel 14.

[0014] The nozzle 6 is installed under the barrel 14 through the bolt 5, the outer side of the barrel 14 is provided with an electromagnetic heating ring 4, the inner side of the barrel 14 is provided with a screw extrusion device 13, and the top of the barrel 14 is provided with a motor end cover 2, A stepping motor 1 is arranged on the motor end cover 2, a rolling bearing 3 is arranged between the motor end cover 2 and the barrel 14, a material passage 12 is arranged on the side of the barrel 14, and a preheating Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com