Substrate stacked packaging structure and packaging method thereof

A packaging structure and substrate technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as complex functions, and achieve the effects of increasing electrical connection methods, reducing package size, and protecting pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The object of the present invention is to provide a packaging structure and packaging method with simple packaging process, small thickness and high integration.

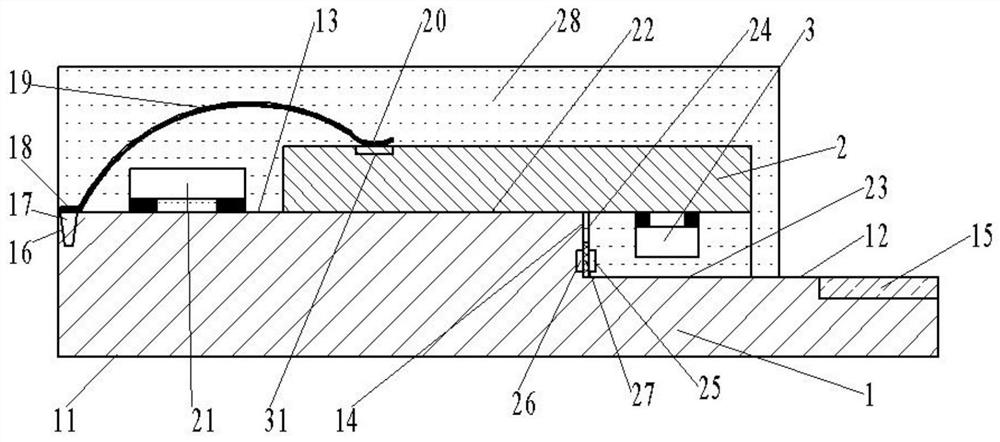

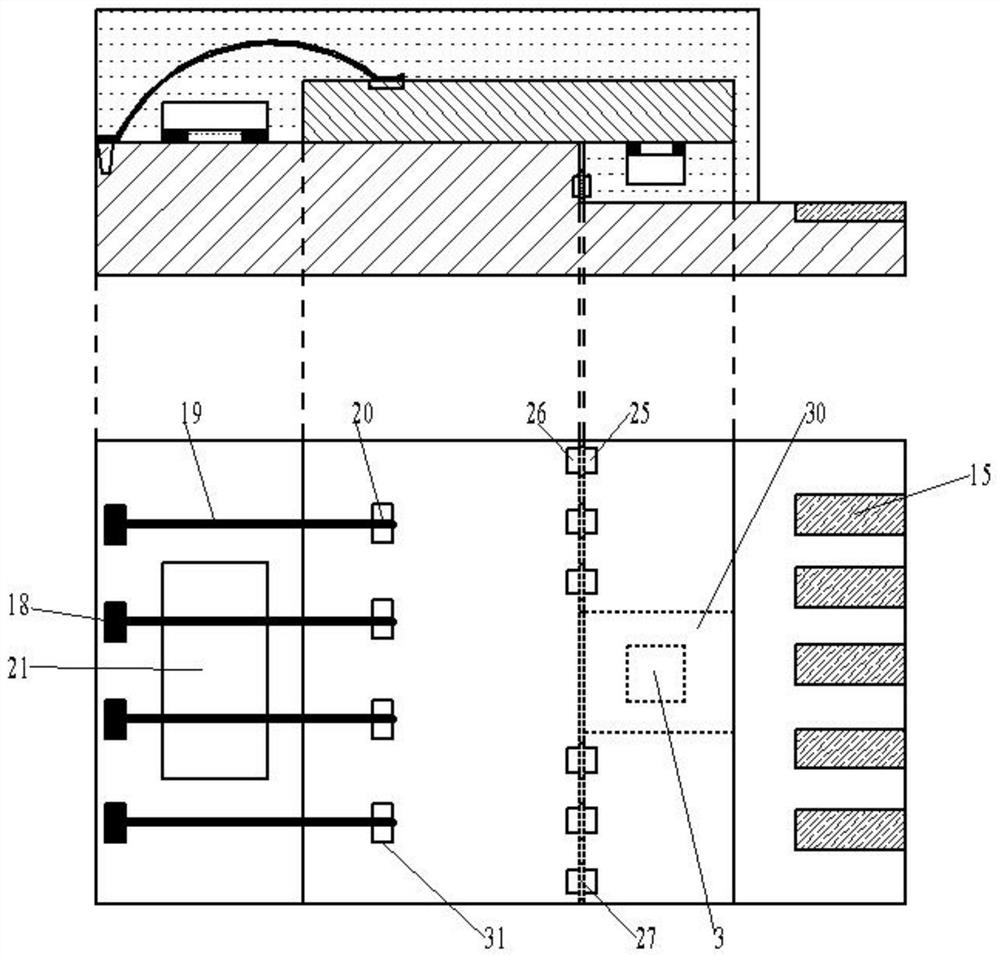

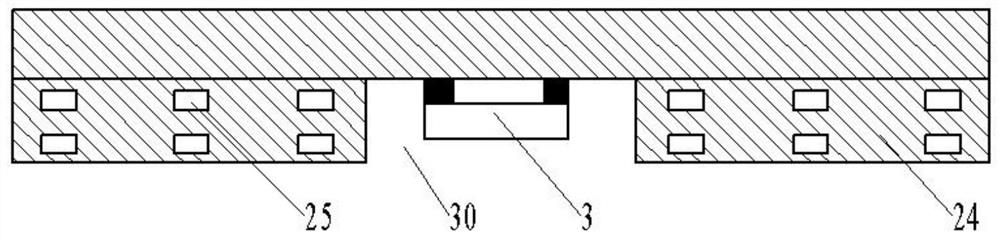

[0028] join Figure 1-4 , the through-hole substrate-on-substrate package structure of the present invention includes a first substrate 2 and a second substrate 1, the first substrate 2 is an additional substrate, and the second substrate 1 is a packaging substrate or a system board, both of which can make a PCB plate or ceramic substrate. Wherein the first substrate 2 includes a first bottom surface 22 and a second bottom surface 23, a first top surface opposite to the first and second bottom surfaces, and a first connecting surface 24 connecting the first and second bottom surfaces, The first bottom surface and the second bottom surface have a height difference, the first bottom surface 22, the second bottom surface 23 and the first connecting surface 24 form a first zigzag step, and the first connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com