Sludge viscosity characterization method

A sludge and viscosity technology, applied in the field of sludge viscosity characterization, can solve problems such as safety, heat transfer efficiency reduction, sludge dynamic phenomenon characterization, etc., and achieve the effects of easy acquisition, large application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

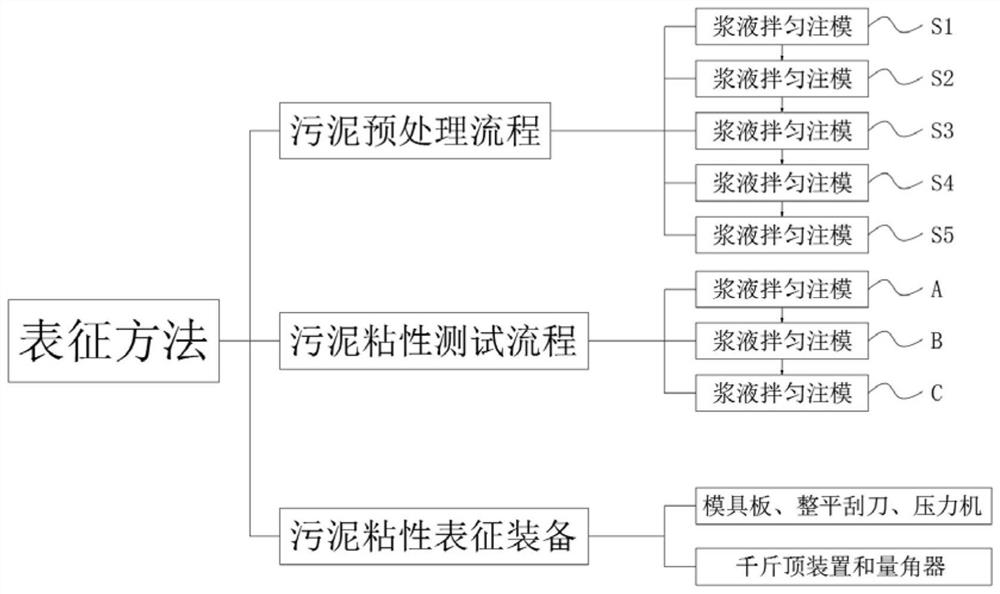

[0039] Embodiment 1: as Figure 1-2 As shown, the present invention provides a technical solution, a sludge viscosity characterization method, including sludge pretreatment process, sludge viscosity test process and sludge viscosity characterization equipment;

[0040] The sludge pretreatment process specifically includes the following steps:

[0041] S1, weighing the sludge into the mould;

[0042] S2, the scraper smoothes the sludge;

[0043] S3, applying pressure to the sludge;

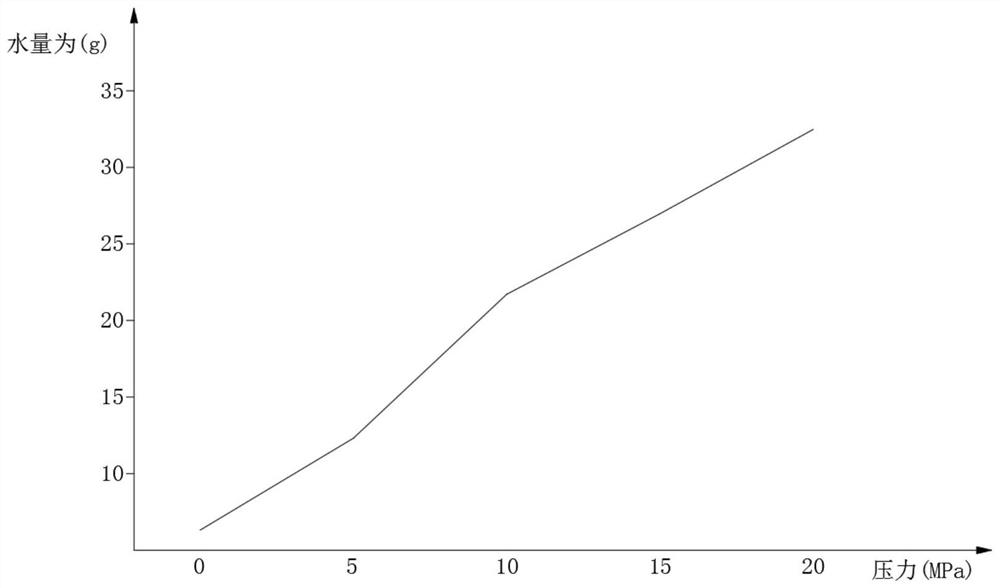

[0044] S4, observe and measure the water discharge;

[0045] S5. Measurement of sludge moisture content;

[0046] The sludge viscosity test process specifically includes the following steps:

[0047] A. Install the angle adjustment jack;

[0048] B. Measure the sludge sliding angle;

[0049] C. Sludge viscosity rating.

[0050] Based on the above technical solution, in S1, weighing sludge into the mold refers to weighing 100g of sludge first, and putting all the weighed sludge into the mold...

Embodiment 2

[0064] Embodiment 2: as Figure 1-2 As shown, the present invention provides a technical solution, a sludge viscosity characterization method, including sludge pretreatment process, sludge viscosity test process and sludge viscosity characterization equipment;

[0065] The sludge pretreatment process specifically includes the following steps:

[0066] S1, weighing the sludge into the mould;

[0067] S2, the scraper smoothes the sludge;

[0068] S3, applying pressure to the sludge;

[0069] S4, observe and measure the water discharge;

[0070] S5. Measurement of sludge moisture content;

[0071] The sludge viscosity test process specifically includes the following steps:

[0072] A. Install the angle adjustment jack;

[0073] B. Measure the sludge sliding angle;

[0074] C. Sludge viscosity rating.

[0075] Based on the above technical solution, in S1, weighing sludge into the mold refers to weighing 100g of sludge first, and putting all the weighed sludge into the mold...

Embodiment 3

[0089] Embodiment 3: as Figure 1-2 As shown, the present invention provides a technical solution, a sludge viscosity characterization method, including sludge pretreatment process, sludge viscosity test process and sludge viscosity characterization equipment;

[0090] The sludge pretreatment process specifically includes the following steps:

[0091] S1, weighing the sludge into the mould;

[0092] S2, the scraper smoothes the sludge;

[0093] S3, applying pressure to the sludge;

[0094] S4, observe and measure the water discharge;

[0095] S5. Measurement of sludge moisture content;

[0096] The sludge viscosity test process specifically includes the following steps:

[0097] A. Install the angle adjustment jack;

[0098] B. Measure the sludge sliding angle;

[0099] C. Sludge viscosity rating.

[0100] Based on the above technical solution, in S1, weighing sludge into the mold refers to weighing 100g of sludge first, and putting all the weighed sludge into the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com