A weldable bonded composite metal damping tube and its preparation method

A composite metal and vibration damping tube technology, which is applied in the direction of metal layered products, chemical instruments and methods, tubular objects, etc., can solve the problems of high manufacturing cost, complicated manufacturing process, and the inability to realize welding of composite tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

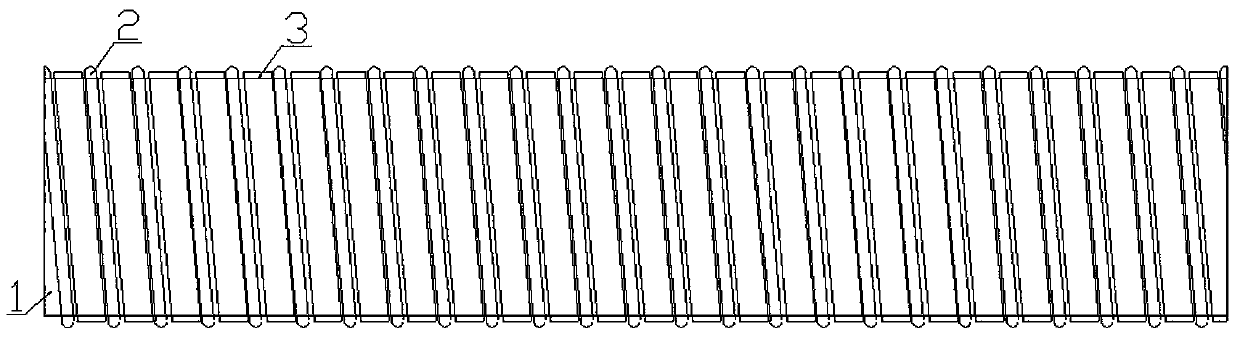

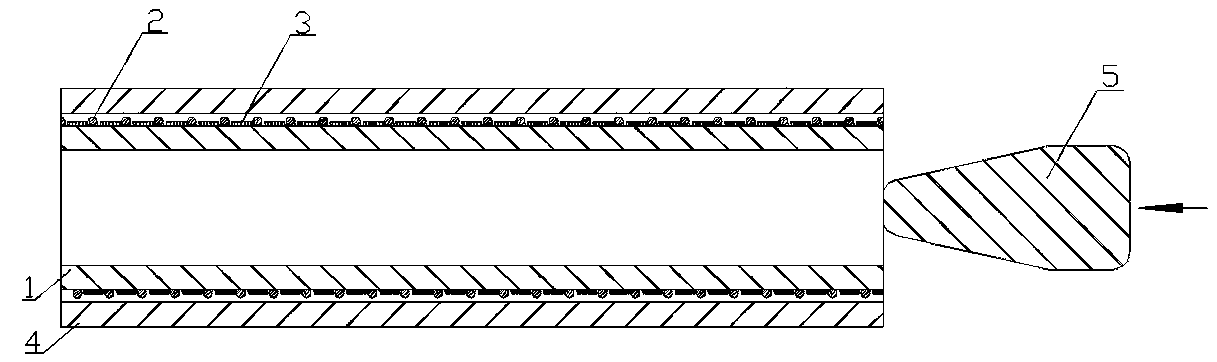

[0021] A method for preparing a weldable composite metal damping tube, the composite metal damping tube consists of an inner metal tube 1, an outer metal tube 4, and a wound metal wire between the inner metal tube 1 and the outer metal tube 4 2. Composed of solid polymer damping fillers, the manufacturing process of the composite metal damping tube is as follows: firstly, after cleaning the outer surface of the inner metal tube 1, passivating it with a chemical chromium-free passivation solution, and then turning the metal wire 2 into a Wrap the surface of the inner metal tube 1 in a spiral shape, and at the same time wrap the solid polymer damping film in the gap between the metal wires, and then insert the inner metal tube 1 wrapped with the metal wire and the solid polymer damping film into the inner layer. Surface-treated outer metal tube 4; preheat the above materials to 160°C to 200°C, after preheating for 20min to 30min, use the expansion cone 5 to expand the inner metal...

example 1

[0024] Select 304 stainless steel with an outer diameter of 32 mm and a wall thickness of 2 mm as the outer metal tube 4, select 304 stainless steel with an outer diameter of 29 mm and a wall thickness of 2 mm as the inner metal tube 1, and select an aluminum wire with a diameter of 1 mm as the winding wire 2 After the outer surface of the inner metal tube 1 is pickled with dilute sulfuric acid with a mass fraction of 10%, it is put into a chromium-free passivation solution for passivation treatment, and at the same time, the aluminum wire is treated with a sodium hydroxide solution with a mass fraction of 10% Afterwards, it is pickled with 10% dilute sulfuric acid by mass fraction and enters the chromium-free passivation solution for passivation treatment. After the treatment, the metal aluminum wire is spirally wound on the inner layer metal tube 1, and the distance between the spiral wires is The distance is 3 mm, and the solid polymer damping film 3 with a thickness of 0.3 ...

example 2

[0026] Select 409 stainless steel with an outer diameter of 40 mm and a wall thickness of 1.2 mm as the outer metal tube 4, select 409 stainless steel with an outer diameter of 38 mm and a wall thickness of 1.2 mm as the inner metal tube 1, and select an aluminum wire with a diameter of 0.5 mm. The outer surface of the metal pipe 1 is pickled with dilute sulfuric acid with a mass fraction of 10%, and then entered into a chromium-free passivation solution for passivation treatment. At the same time, the aluminum wire is treated with sodium hydroxide with a mass fraction of 10%, and then reused Pickling treatment with dilute sulfuric acid with a fraction of 10%, and then enter the chromium-free passivation solution for passivation treatment, and then wind the aluminum wire helically on the inner metal tube 1, the distance between the helixes is 3mm, and the thickness is A 0.2mm, 2mm wide solid polymer damping film tape is helically wound at the winding gap of the aluminum wire; p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com