Preparation method of silicon negative plate

A silicon negative electrode and negative electrode technology, which is applied to battery electrodes, structural parts, electrical components, etc., can solve the problems of silicon negative electrode material falling off, high working voltage, hidden safety hazards, etc., to achieve bonding performance and reduce oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

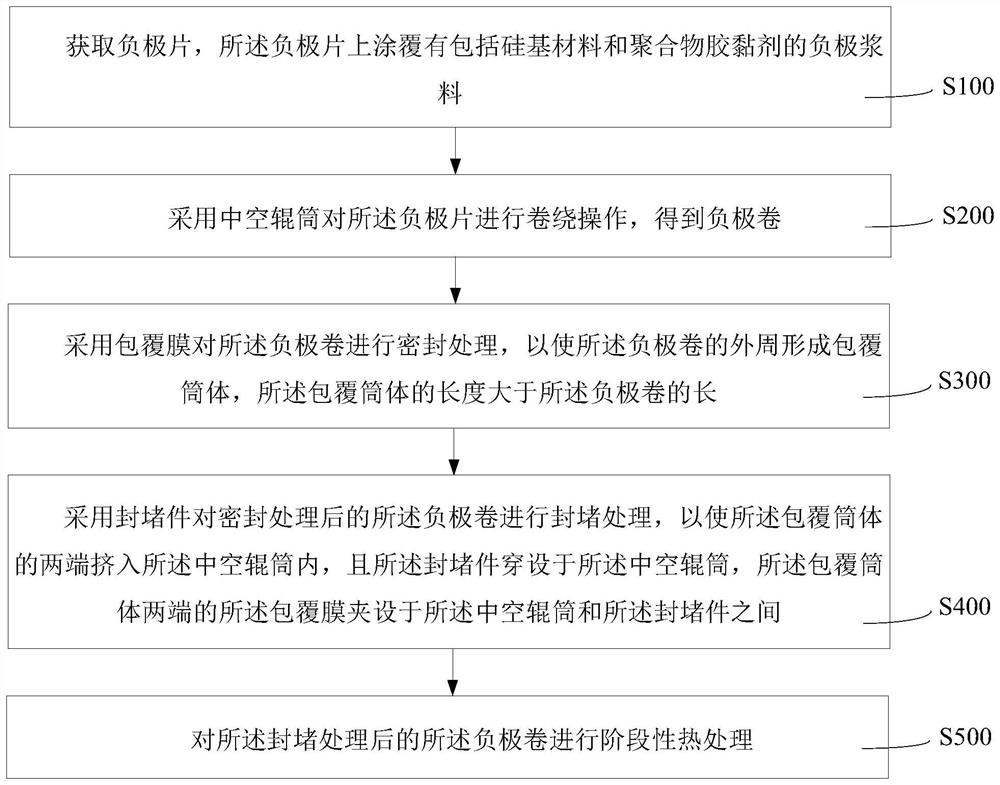

[0030] The present application provides a preparation method of a silicon negative electrode sheet. The preparation method of the above-mentioned silicon negative electrode sheet includes the following steps: obtaining a negative electrode sheet, and the negative electrode sheet is coated with a negative electrode slurry comprising a silicon-based negative electrode material and a polymer adhesive; and a hollow roller is used to wind the negative electrode sheet to obtain Negative electrode roll; use a coating film to seal the negative electrode roll, so that the outer circumference of the negative electrode roll forms a coating cylinder, and the length of the coating cylinder is greater than the length of the negative electrode roll; use a blocking member to seal the negative electrode roll. Blocking treatment, so that the two ends of the coating cylinder are squeezed into the hollow roller, and the blocking member is inserted through the hollow roller, and the coating film co...

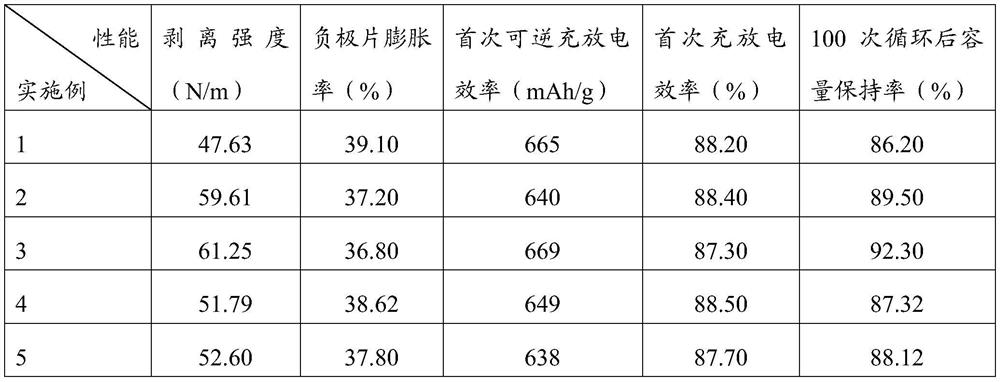

Embodiment 1

[0066] Disperse and mix 10kg of silicon oxide powder, a mixture of 2kg of Ketjen black and carbon nanotubes, and a mixture of 1kg of polyvinylidene fluoride and an appropriate amount of N-methylpyrrolidone to obtain a negative electrode slurry;

[0067] Coating the negative electrode slurry on the copper foil sheet, and then performing roll drying to obtain a negative electrode sheet;

[0068] The negative electrode coil was wound on the hollow roller, and then, the coating film with a thickness of 8 μm was wound on the negative electrode coil to form a coating cylinder, and then the two ends of the coating cylinder were squeezed into the hollow roller with a wooden stopper. inside and fix the covering film;

[0069] Put the sealed negative electrode coil into an oven, heat treatment for 15 minutes at a temperature of 110 °C, and then continue heat treatment for 15 minutes at a temperature of 150 °C, and then heat at a temperature of 250 °C. , and then continue heat treatment...

Embodiment 2

[0072] Disperse and mix 10kg of silicon oxide powder, a mixture of 2kg of Ketjen black and carbon nanotubes, and a mixture of 1kg of polyvinylidene fluoride and an appropriate amount of N-methylpyrrolidone to obtain a negative electrode slurry;

[0073] Coating the negative electrode slurry on the copper foil, then rolling and drying at 80°C for 2 hours to obtain a negative electrode sheet;

[0074] The negative electrode was wound on the hollow roller, and then, the coating film with a thickness of 10 μm was wound on the negative electrode to form a coating cylinder, and then the two ends of the coating cylinder were squeezed into the hollow roller with a wooden stopper. inside and fix the covering film;

[0075] Put the sealed negative electrode coil into an oven, heat treatment for 10 minutes at a temperature of 110 °C, and then continue to heat treatment for 10 minutes at a temperature of 150 °C, and then heat at a temperature of 250 °C. , and then continue to heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com