One-component polyurethane foam caulk with quick-drying glue gun

A technology of polyurethane foam and caulking agent, which is applied in the direction of coatings and devices for coating liquid on the surface, etc., can solve the problems of unsatisfactory one-component polyurethane foam caulking agent, etc., and achieve uniform foam and density, convenient operation, The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

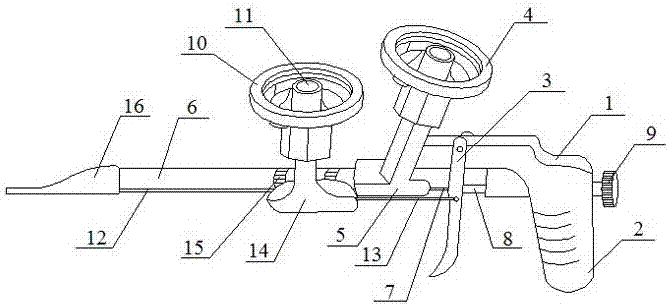

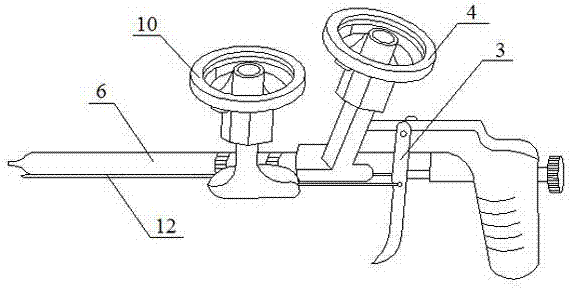

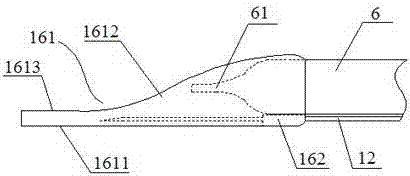

[0022] A quick-drying glue gun for one-component polyurethane foam caulking agent, its structure is as follows figure 1 with figure 2 As shown, it includes a gun body 1, a gun handle 2, a glue injection mechanism 4, a glue injection tube 6, a drying aid adding mechanism 10, a drying aid tube 12, a mixer 16 and a material discharge control mechanism. The gun handle 2 is set at the rear end of the gun body 1, the glue injection tube 6 is set at the front end of the gun body, the drying agent tube 12 is set at the lower left side of the glue injection tube, and is arranged side by side with the glue injection tube; the glue injection mechanism is set at the glue injection tube 6 and the gun body. Between the body 1, the drying aid adding mechanism is set on the glue injection pipe 6, and the discharge control mechanism is located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com