Self-sealing box for trash compactors

a self-sealing box and trash compactor technology, applied in the field of boxes, can solve the problems of not meeting the functional performance of premium boxes, leakage or lack of box structural integrity, and achieve the effect of minimizing material usage and minimizing the number of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

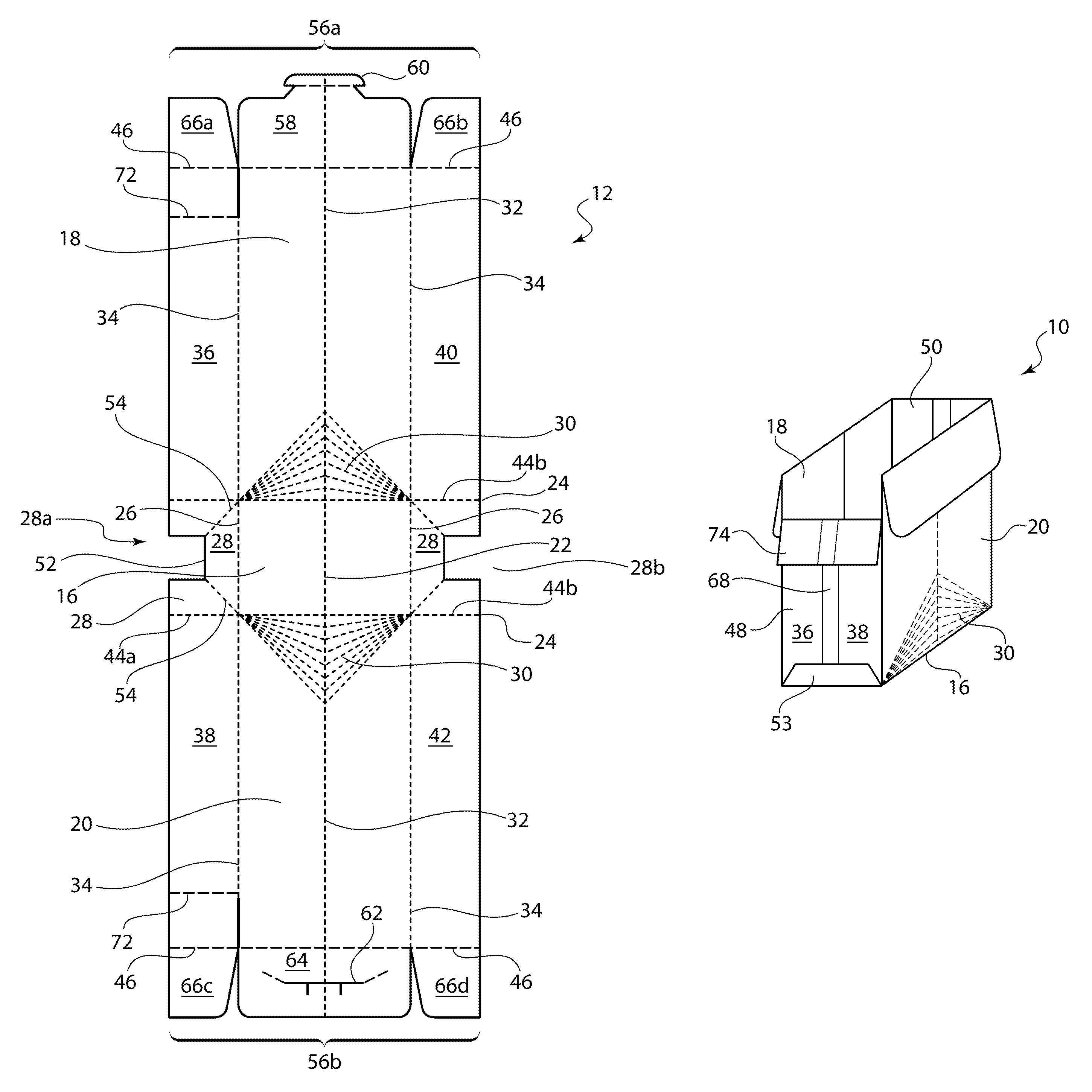

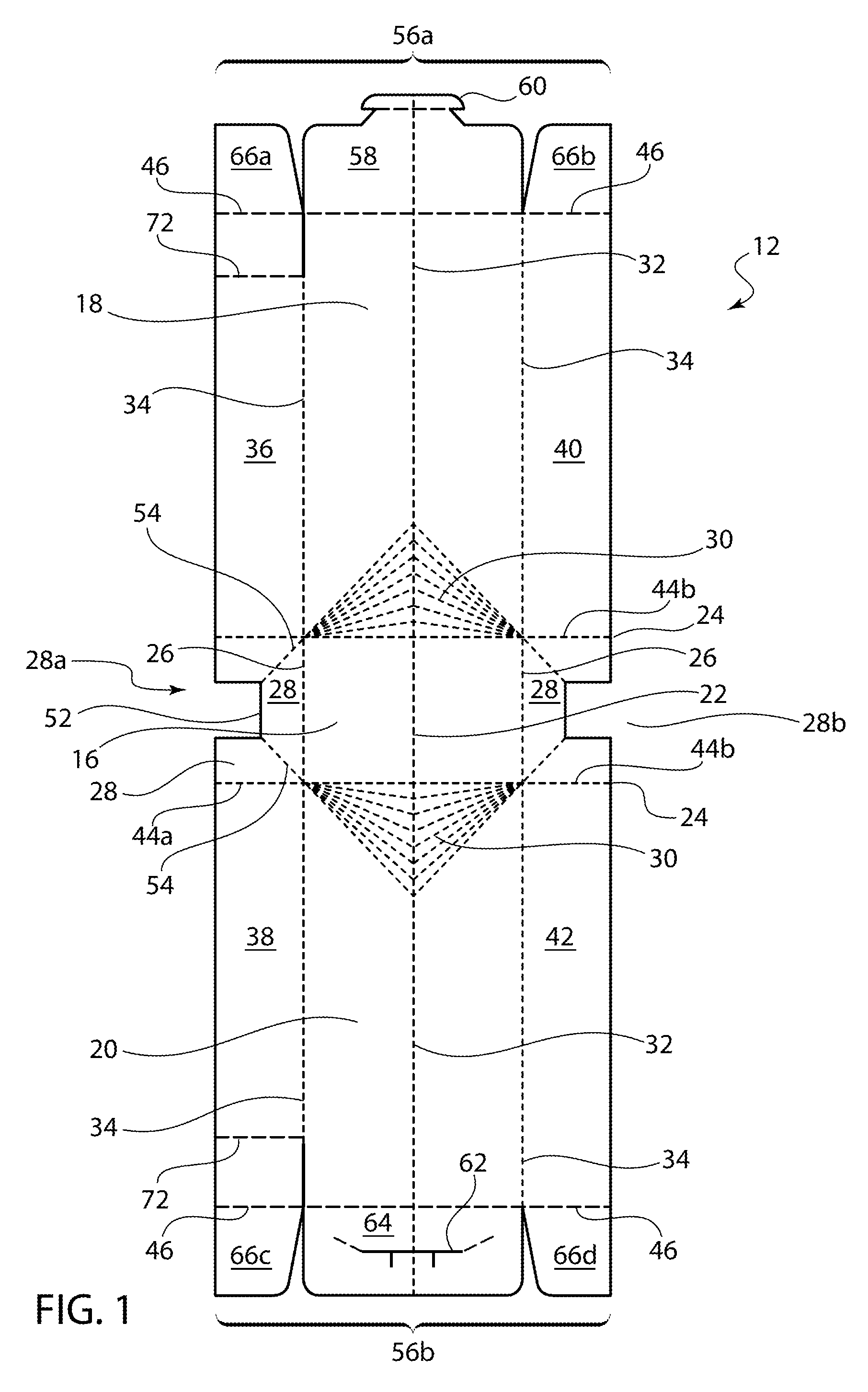

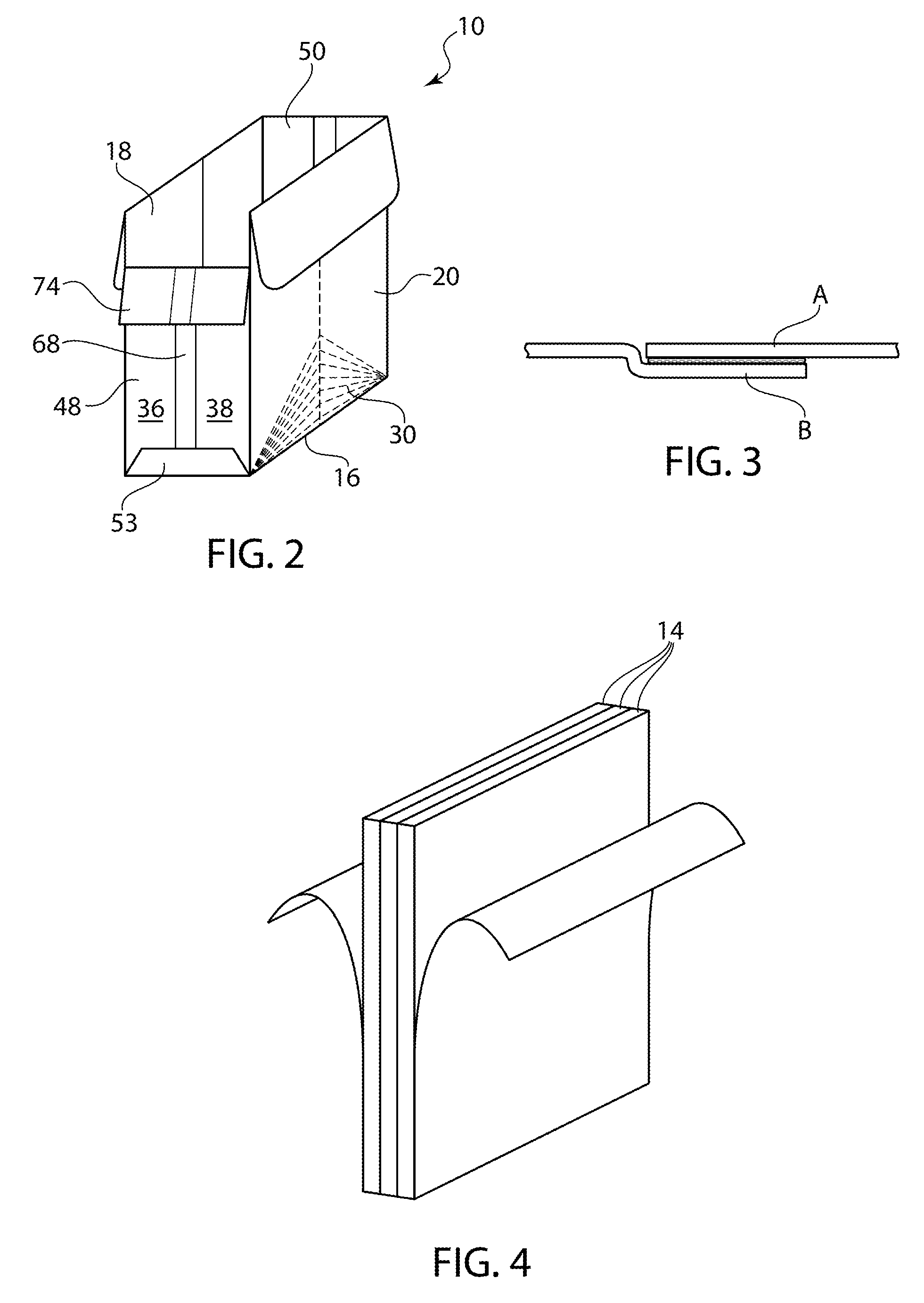

[0011]Embodiments of the invention provide a trash containment box 10 used in trash compactors that will resist leaking and tearing during and after multiple compactions. Furthermore, this box resists tearing and leaking until it reaches its final waste location. The trash compactor box 10 is formed from a single board construction 12. In a specific embodiment, rather than using the 3-piece design of the current premium box, the box 10 is formed from a single piece of flat, die cut polyethylene lined paperboard, referred to as a board construction 12. The board construction 12 incorporates a unique scoring / folding and overall pattern that is intended to minimize material usage while ensuring product structural integrity and positioning for leak-proof seams. Additionally, in place of secondary hot melt glue used in the current premium box, box 10 uses the existing thin, water proof polyethylene coating as the adhesive that holds the blank in the desired box shape and that creates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com