Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

a technology for semi-manufactured products and shoes, applied in the field of semi-manufactured shoes, clothing items and accessories, can solve the problems of inability to apply the known process to semi-manufactured products made of leather or fabric, inability to be joined with other materials, and permanent deterioration of the shoe upper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

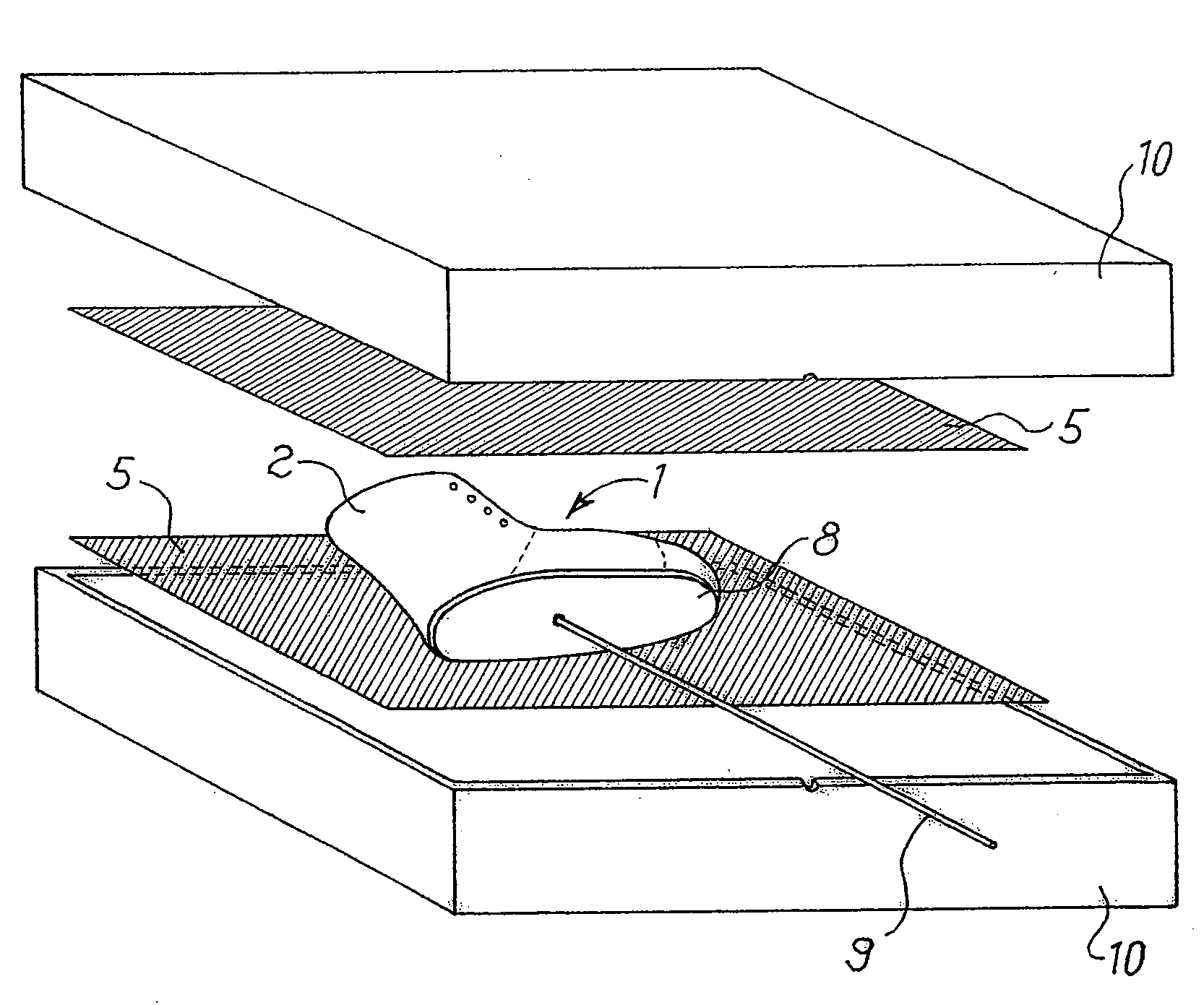

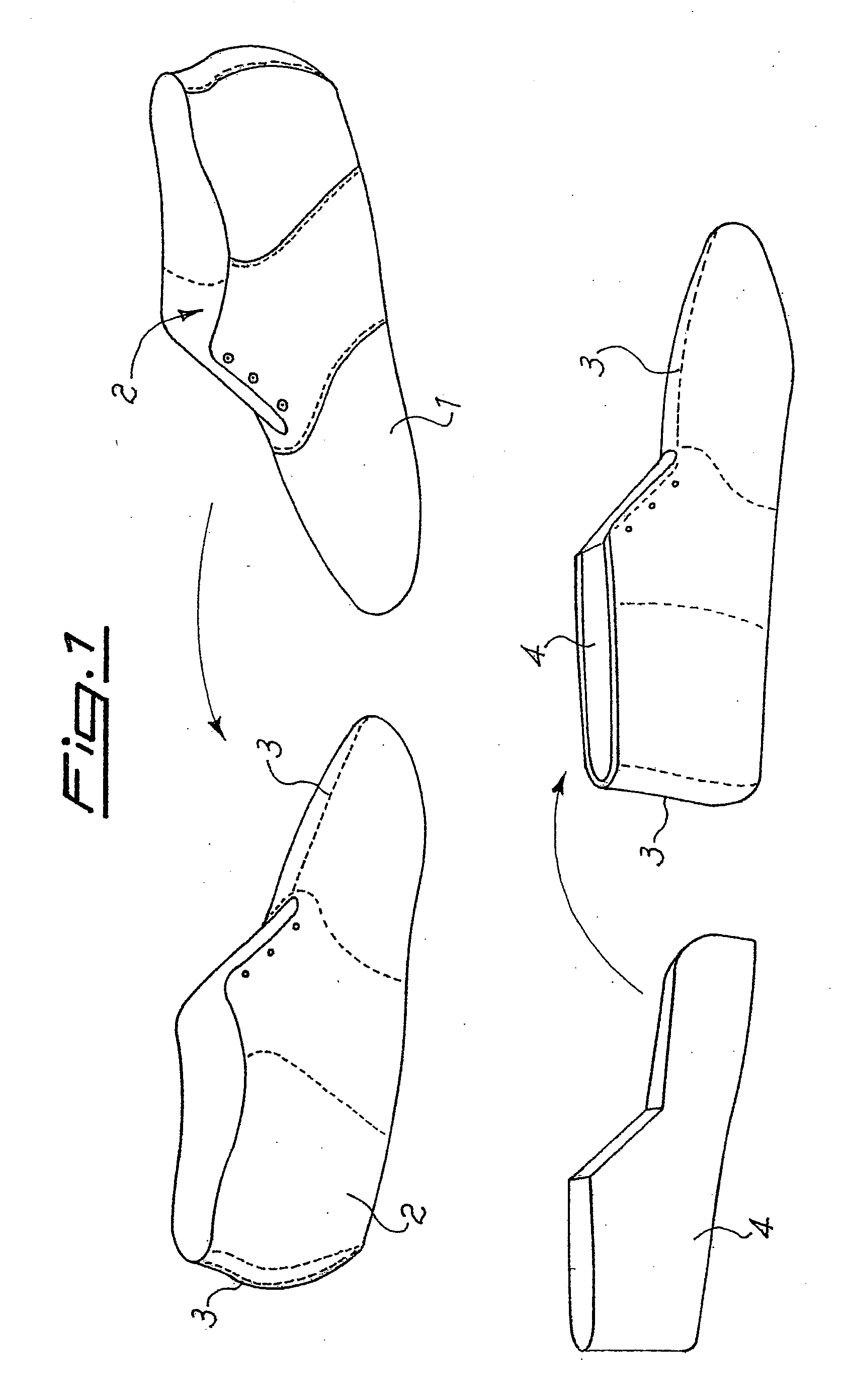

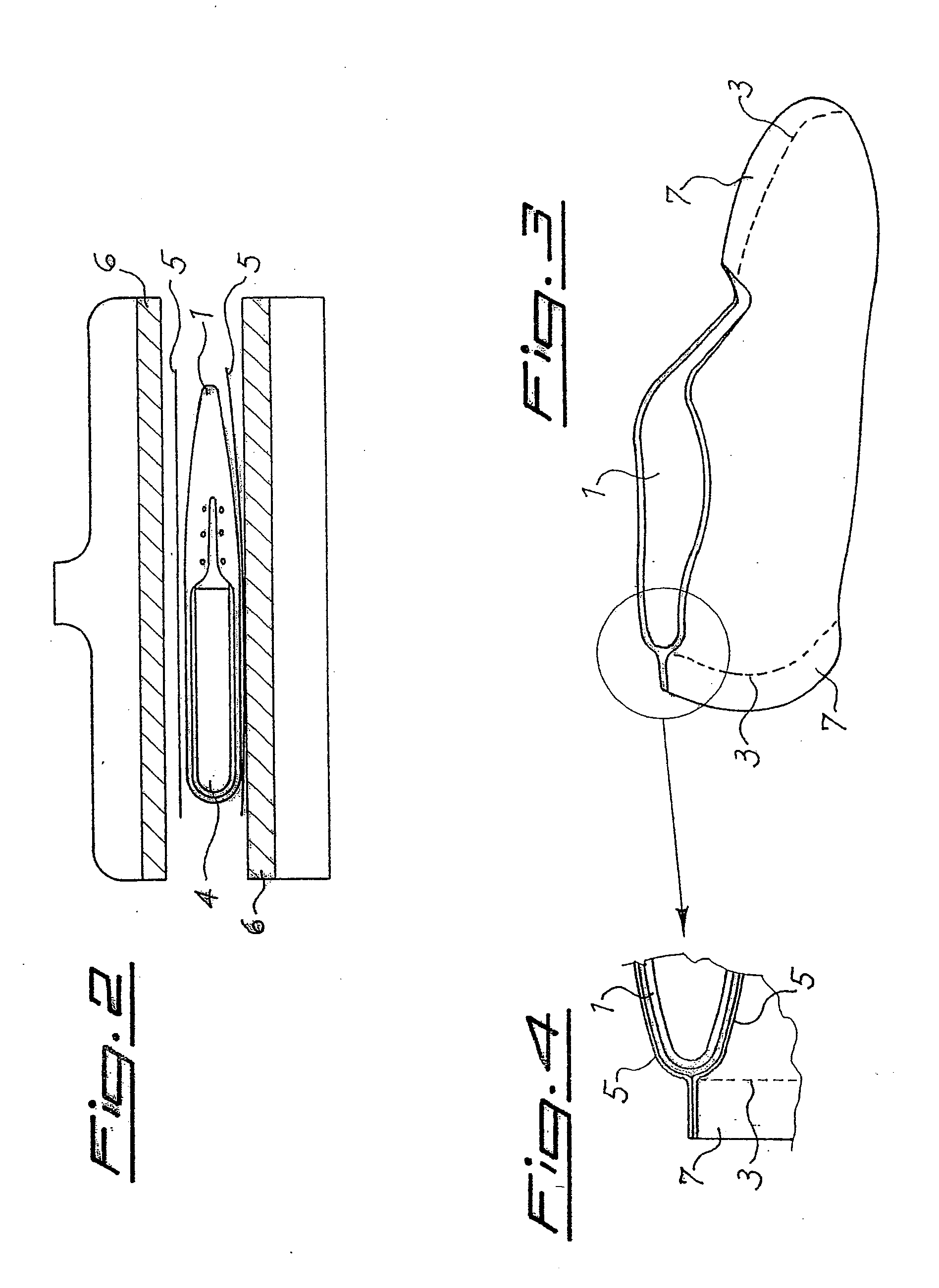

[0023]Referring to FIG. 1, it is seen that in the process according to the first embodiment of the invention a semimanufactured product made of leather or fabric having a three-dimensional conformation with at least one outer surface and one inner surface, for instance the shoe upper 1 of a shoe, is turned inside out so that its inner surface 2 is turned outwards. Afterwards, the shoe upper 1 turned inside out is folded and flattened along at least two lines 3, in particular corresponding to the intersection with a vertical symmetry plane, so as to obtain two opposing surfaces, which are substantially the same. This operation could already allow in itself to proceed with a lamination with flat presses, but the pressing caused by the pressure along the folding lines 3 could damage the shoe upper 1, especially if the latter is already provided with accessories, for instance metal loops or double appliqué, which create thickness irregularities and contact discontinuities between the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com