Method for producing yellow phosphorus with phosphor residue slag and ground phosphate rock

The technology of mud phosphorus slag and phosphate rock powder is applied in the field of yellow phosphorus production, which can solve the problems of wasting resources and polluting the environment, and achieves the effects of saving resources, increasing the content of SiO2, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

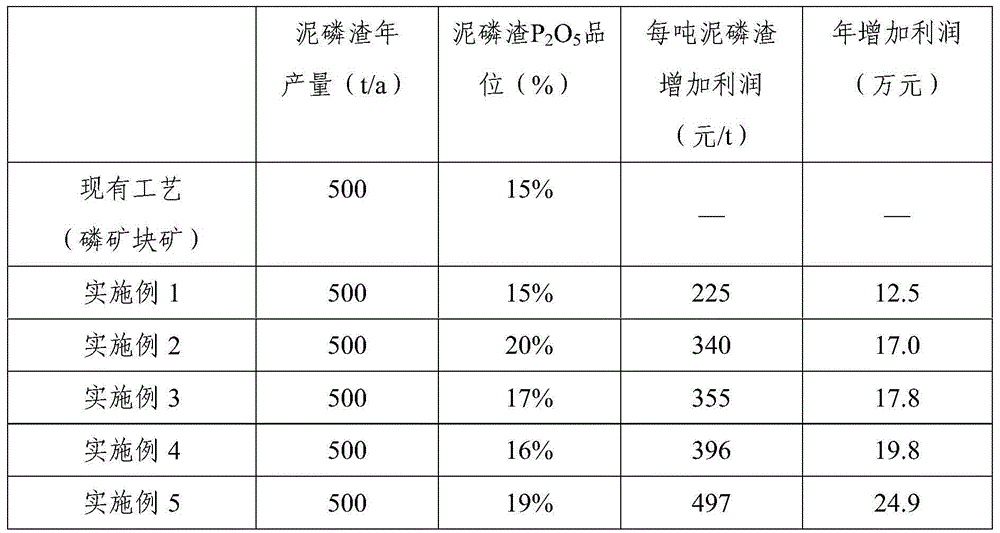

[0019] Embodiment 1 Utilizes the method for producing yellow phosphorus with sludge phosphorus slag and phosphate rock powder

[0020] with P 2 o 5 content of 15%, C content of 15%, SiO 2 3.35 tons of sludge phosphorus slag with a content of 36%, P 2 o 5 6.48 tons of phosphorus concentrate with a content of 30%, adding a binder of 1% of the total weight of sludge phosphorus slag and phosphorus concentrate to obtain a mixed material, pressing the mixed material into balls with a pressure of 19MPa, and sieving to obtain For phosphate rock pellets with a diameter of 5mm-30mm, the phosphate rock pellets are dried at 1000°C and consolidated by a consolidation machine, then mixed with 0.76 tons of coke, and finally sent to a yellow phosphorus electric furnace to react to obtain yellow phosphorus.

[0021] The compressive strength of finished phosphate rock pellets is 87kg / cm 2 , The drum index is 86%. A profit of 255 yuan will be realized per ton of mud phosphorus slag. The a...

Embodiment 2

[0022] Embodiment 2 The method for producing yellow phosphorus by utilizing sludge phosphorus slag and phosphate rock powder

[0023] with P 2 o 5 content of 20%, C content of 12%, SiO 2 3.46 tons of sludge phosphorus slag with a content of 32%, P 2 o 5 5.72 tons of phosphate rock powder with a content of 30%, adding a binder of 3% of the total weight of sludge phosphorus slag and phosphate concentrate to obtain a mixed material, which is pressed into balls with a pressure of 4MPa, and sieved to obtain Phosphate rock pellets with a diameter of 5mm-30mm are dried at 180°C and consolidated by a consolidation machine, then mixed with 0.85 tons of white coal, and finally sent to a yellow phosphorus electric furnace to react to produce yellow phosphorus.

[0024] The compressive strength of finished phosphate rock pellets is 87kg / cm 2 , The drum index is 86%. The profit of each ton of mud phosphorus slag will be 340 yuan. According to the annual processing of 500 tons of slu...

Embodiment 3

[0025] Embodiment 3 The method for producing yellow phosphorus by utilizing sludge phosphorus slag and phosphate rock powder

[0026] with P 2 o 5 content of 17%, C content of 13.5%, SiO 2 3.51 tons of sludge phosphorus slag with a content of 33%, P 2 o 5 6.01 tons of phosphorus concentrate with a content of 30%, adding a binder of 14.7% of the total weight of sludge phosphorus slag and phosphorus concentrate to obtain a mixed material, adding 0.76 tons of coking coal powder to the mixed material, and using a pressure of 15MPa The ball briquetting machine presses the mixed material into balls, screens and obtains phosphate rock pellets with a diameter of 5mm-30mm, and then sends the phosphate rock pellets to the yellow phosphorus electric furnace for reaction after being dried at 1200°C and consolidated by a consolidation machine. Produce yellow phosphorus.

[0027] The compressive strength of finished phosphate rock pellets is 87kg / cm 2 , The drum index is 86%. A profi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com