Preparation method of highly pure vanadium pentoxide

A vanadium pentoxide and high-purity technology, which is applied in the field of high-purity vanadium pentoxide preparation, can solve the problems of low continuous production, complicated impurity removal process and high production cost, and achieves low production cost, short production process, No running and dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

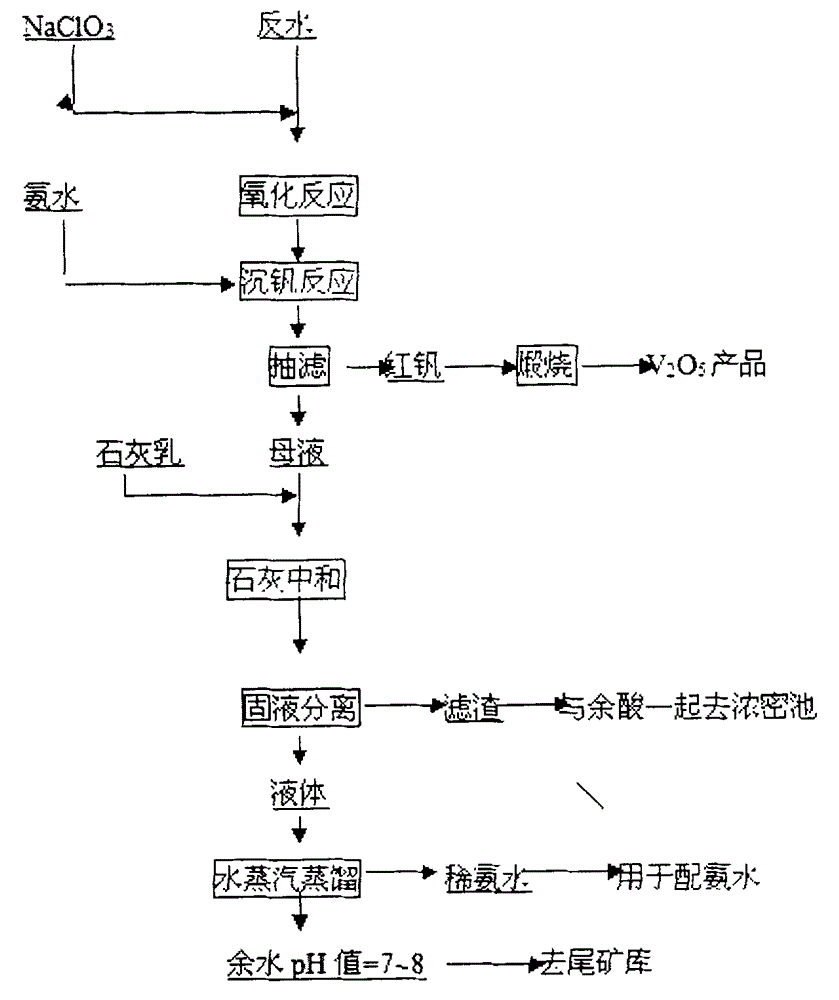

[0022] figure 1 It is a schematic flow chart of the all-wet vanadium extraction process, which is the prior art.

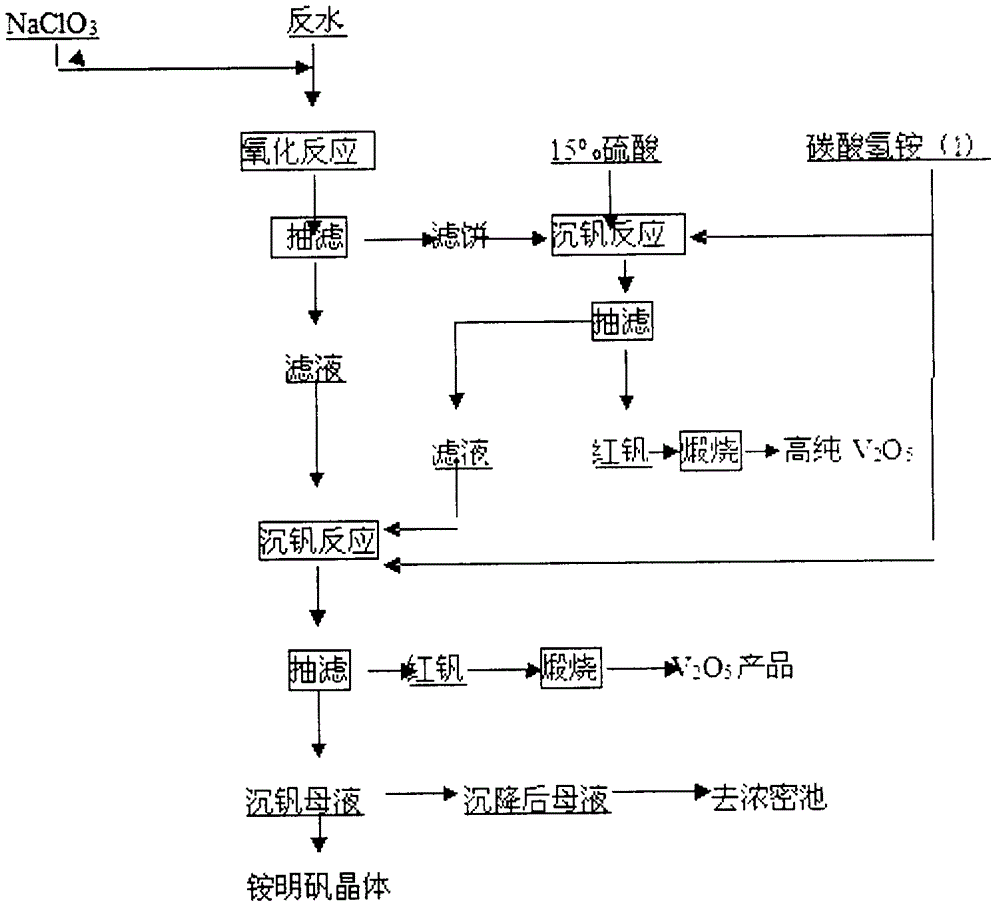

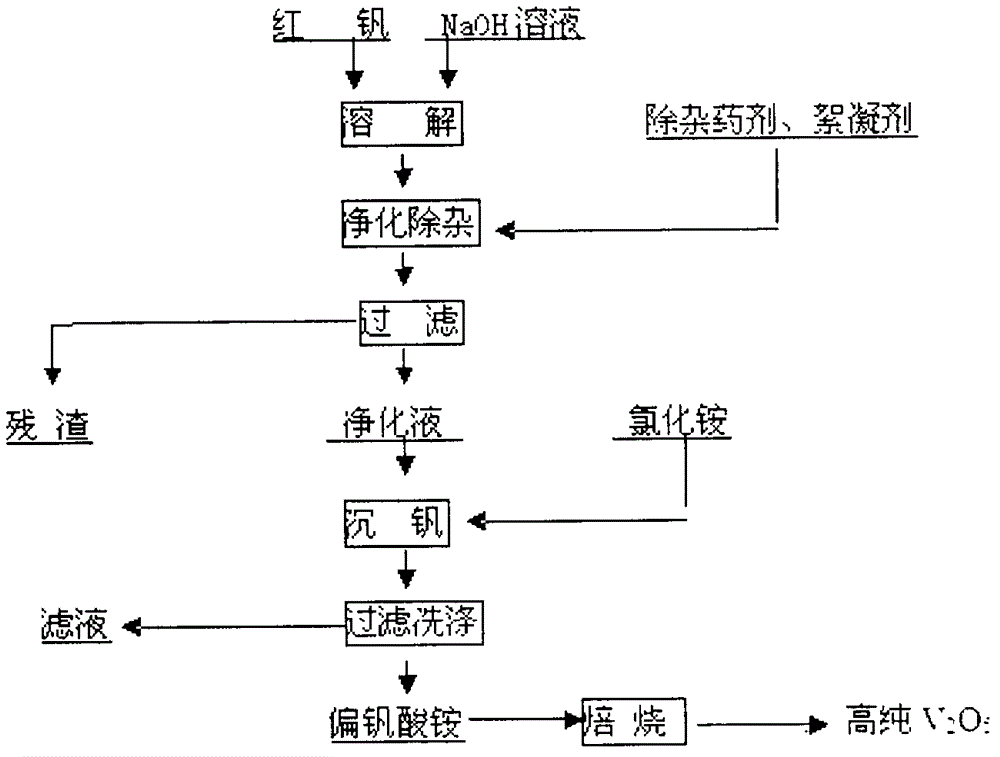

[0023] combine figure 2 : Polyvanadic acid supersaturation-precipitation transfer solution-ammonium bicarbonate precipitation transformation to prepare high-purity vanadium pentoxide;

[0024] Using the stripping water produced during the full-wet vanadium extraction process of stone coal vanadium ore as the raw material, the tetravalent vanadium in the solution is oxidized to pentavalent vanadium with the oxidant NaClO3 before the vanadium precipitation operation. The chemical reaction equation is as follows:

[0025] NaClO 3 +6VOSO 1 +3H 2 O=3(VO 2 ) 2 SO 4 +3H 2 SO 4 +NaCl

[0026] Because the solubility of pentavalent vanadium is very low (only 0.8g / L in aqueous solution), it d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com