Technique method for improving product rate of reversible cold-rolled steel strip

A process method and technology for cold-rolled strip, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of low production efficiency, low production capacity, large waste of plates, etc., so as to improve the utilization rate and reduce production costs. , the effect of reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

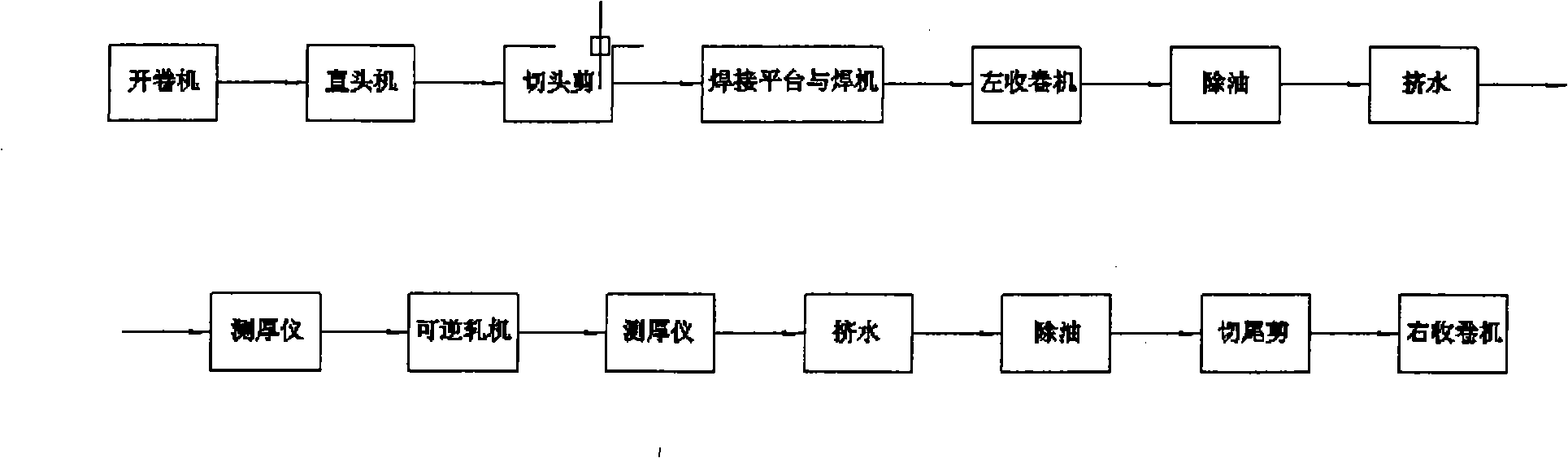

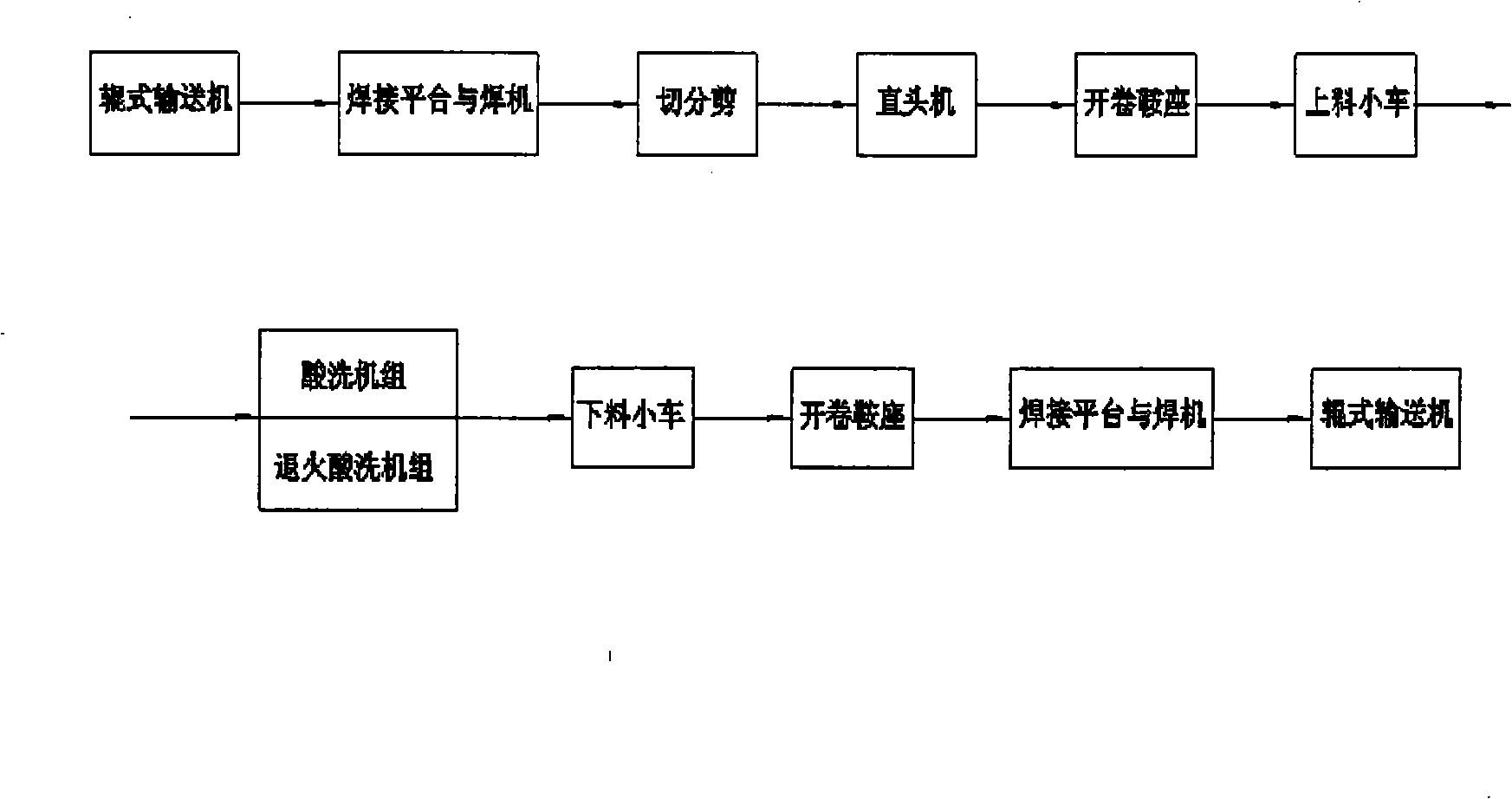

Image

Examples

Embodiment Construction

[0010] Put the steel coil on the saddle by a crane, place the steel coil on the saddle according to the position of the steel belt head, open the packing belt, the saddle is a device with a power roller, start its power to drive its power roller, so that The steel coil rotates to open the strip head of the steel coil, and the steel strip is sent to the cutting head through the straight head machine. The power roller stops, cuts off the irregular strip head, and then drives the power roller to rotate, and the strip head advances to reach the welding platform. Stop the movement of the leader at the appropriate position, and transport the leader belt of the required length to the welding platform through the roller conveying platform, and weld it together with the steel coil leader. The steel coil is driven to rotate, and the welded leader tape is rolled up. Then wait for the loading trolley to load the material, the loading trolley lifts the coil and places it on the reel of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com