Water/gas chamber energy storage system

An energy storage system and subdivision technology, which is applied in the direction of liquid variable capacity machinery, pump devices, engine components, etc., can solve the problems of high equipment cost and complex heat exchange system, so as to reduce the high cost of the system and control the output power , Solve the effect of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

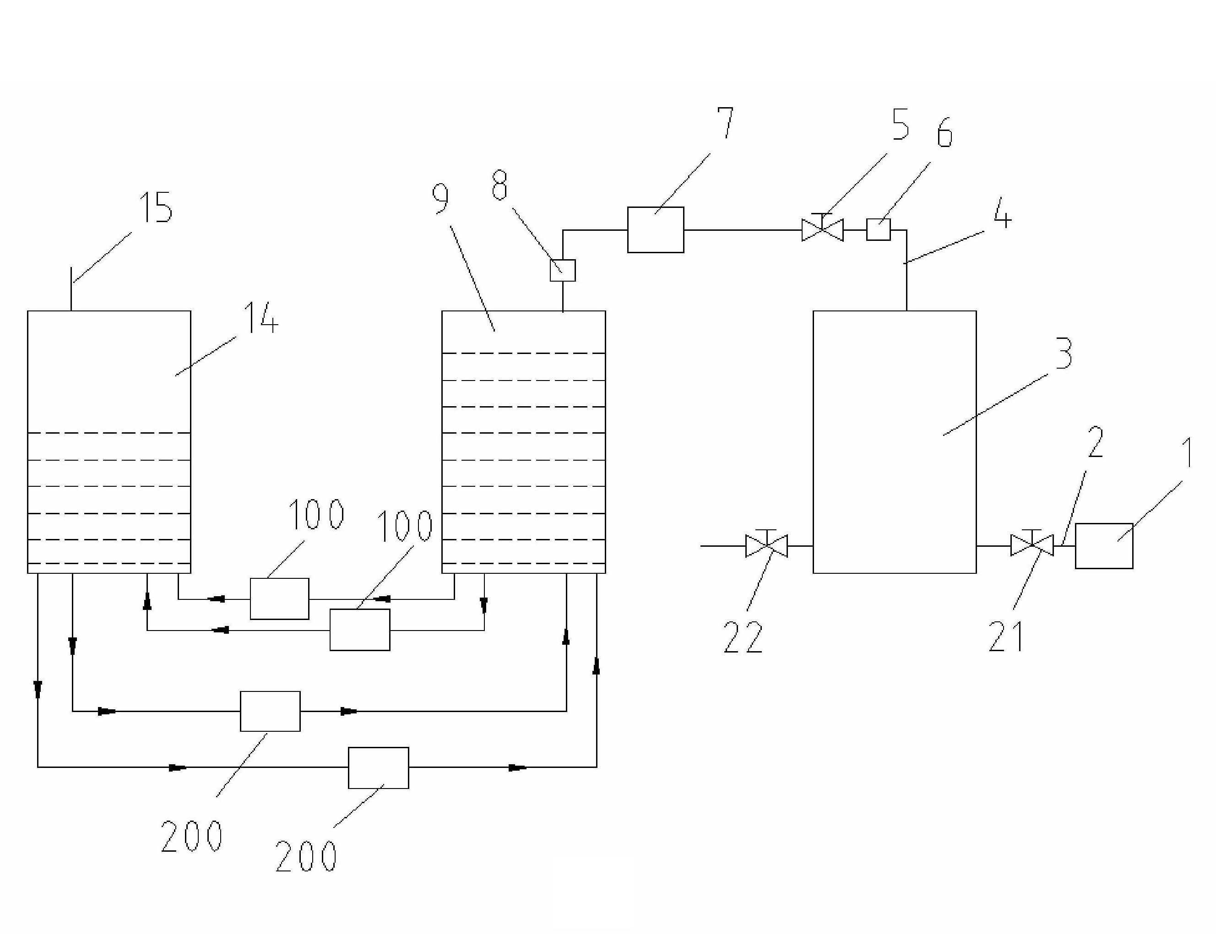

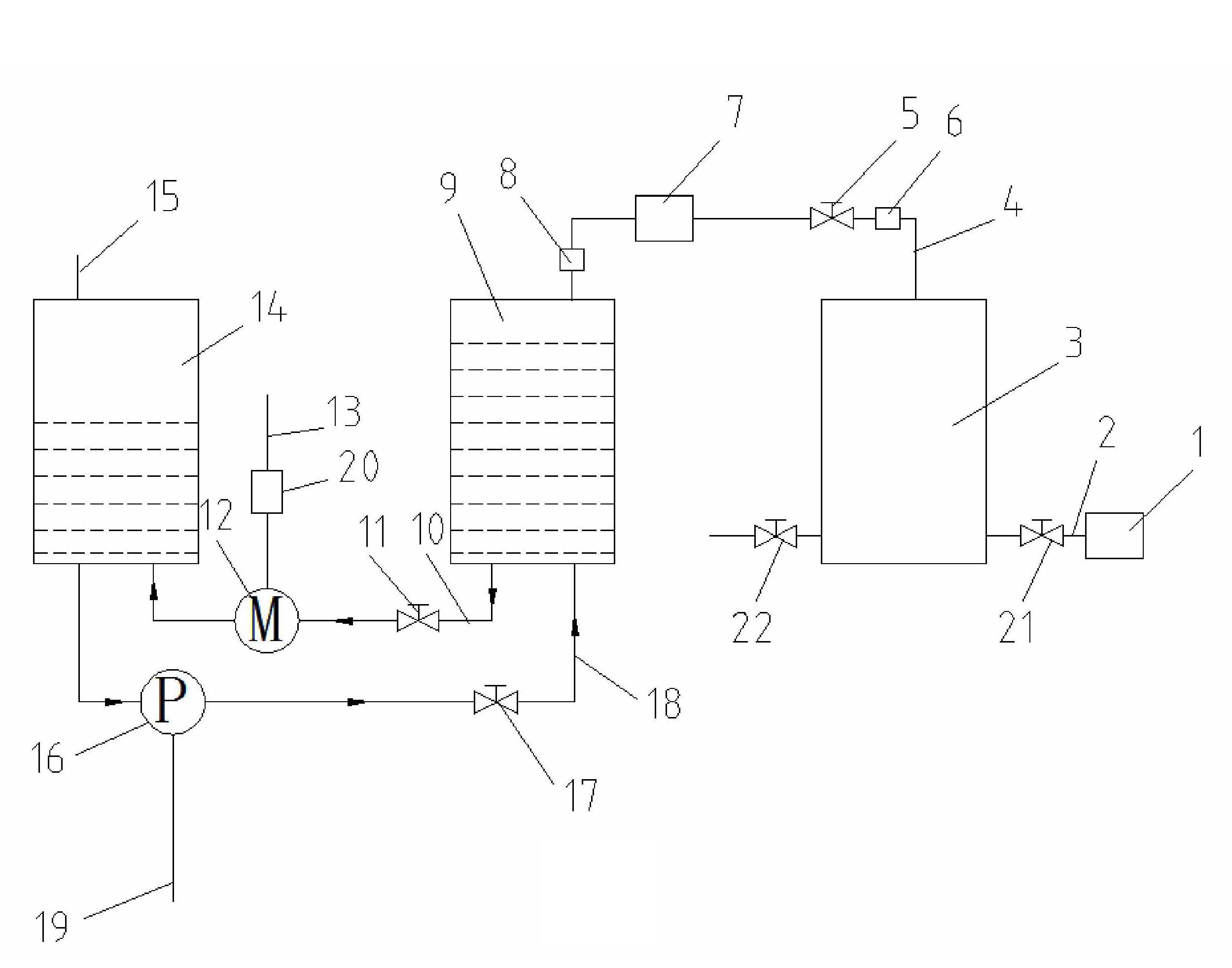

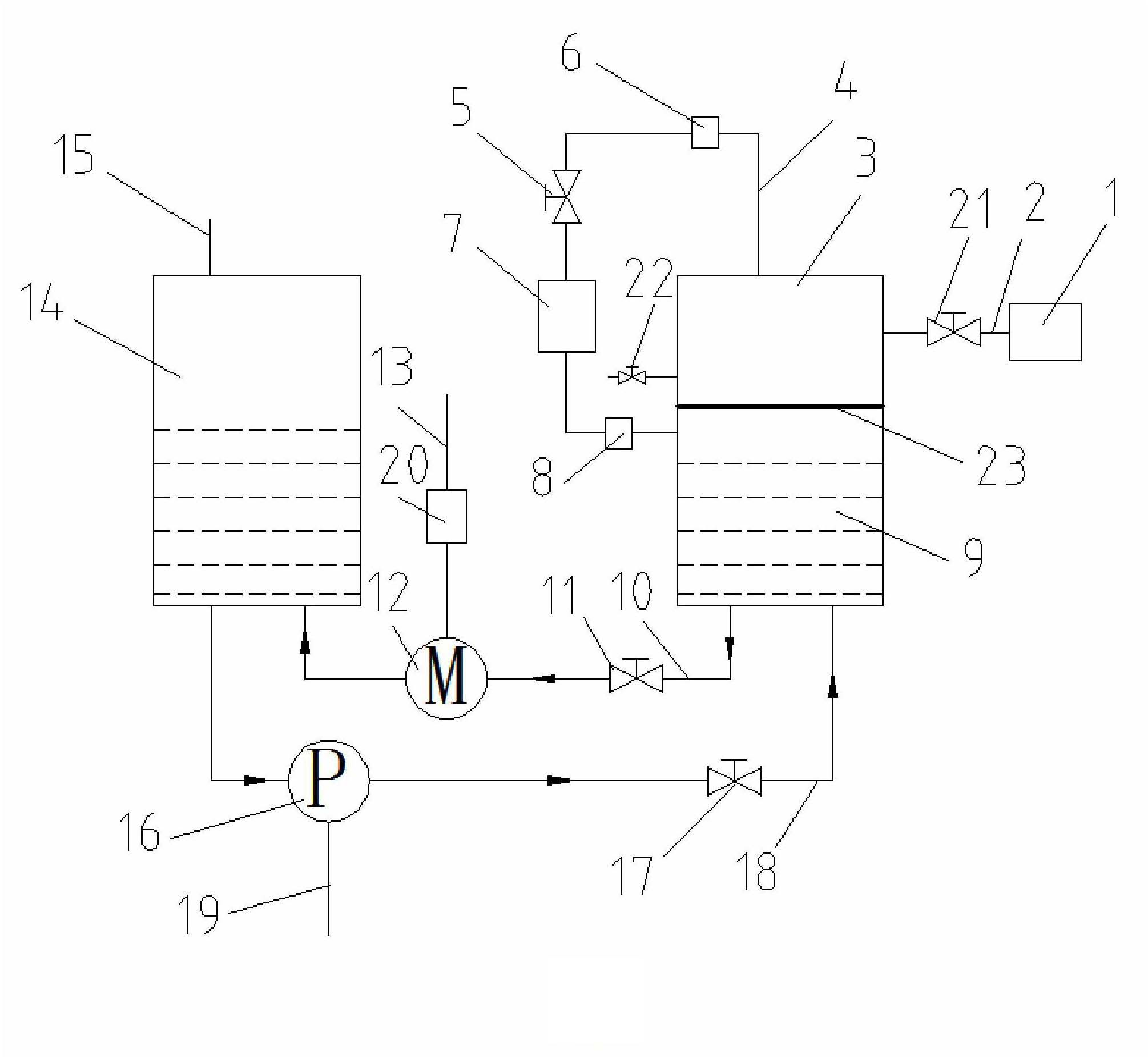

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a water-gas sub-chamber energy storage system, the system includes an air compressor pump unit 1, a high-pressure gas chamber 3, a high-pressure water chamber 9, a power generation / energy storage device 100 and a water storage chamber 14, wherein, the high-pressure gas chamber 3 and the high-pressure water chamber 9 are set independently, and the water storage chamber 14 communicates with the atmosphere,

[0029] Such as figure 1 As shown, the air compressor pump unit 1 communicates with the high-pressure gas chamber 3 through the first pipeline 2, the first pipeline 2 is provided with a first valve 21, and the air compressor pump unit 1 providing a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com