Wave-energy piezoelectric power generation device based on fixed frequency and natural vibration

A piezoelectric power generation and power generation device technology, which is applied in the direction of ocean energy power generation, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the inconvenience of wave energy industrial production, frequency conversion or filtering Problems such as high instrument cost, to achieve the effect of improving the efficiency of electric energy collection and power generation, low price, and increasing utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

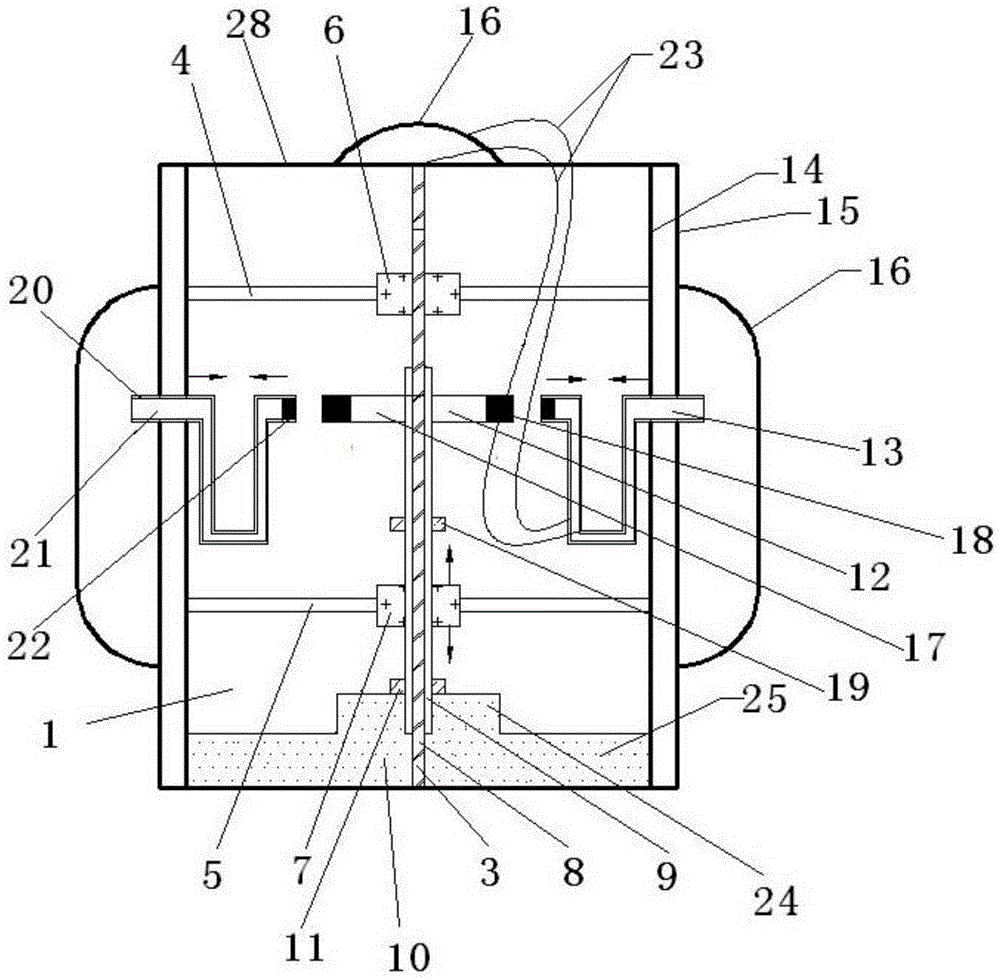

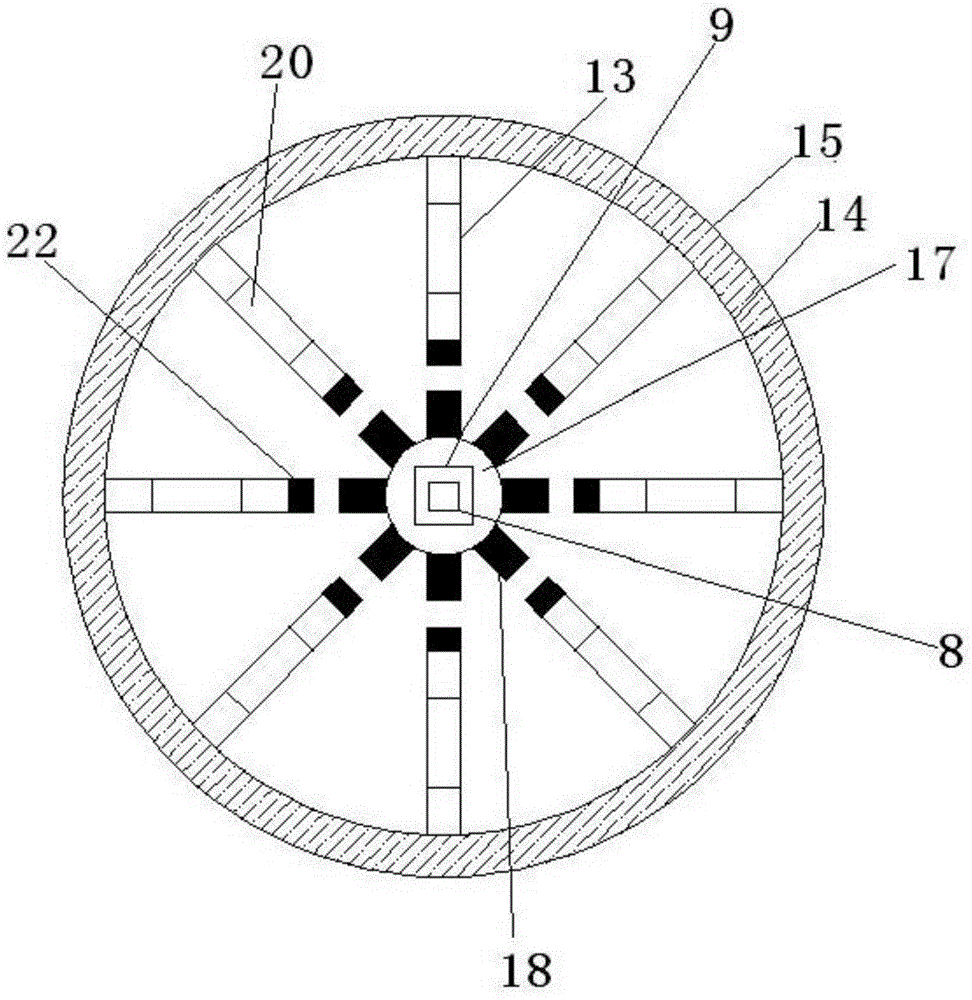

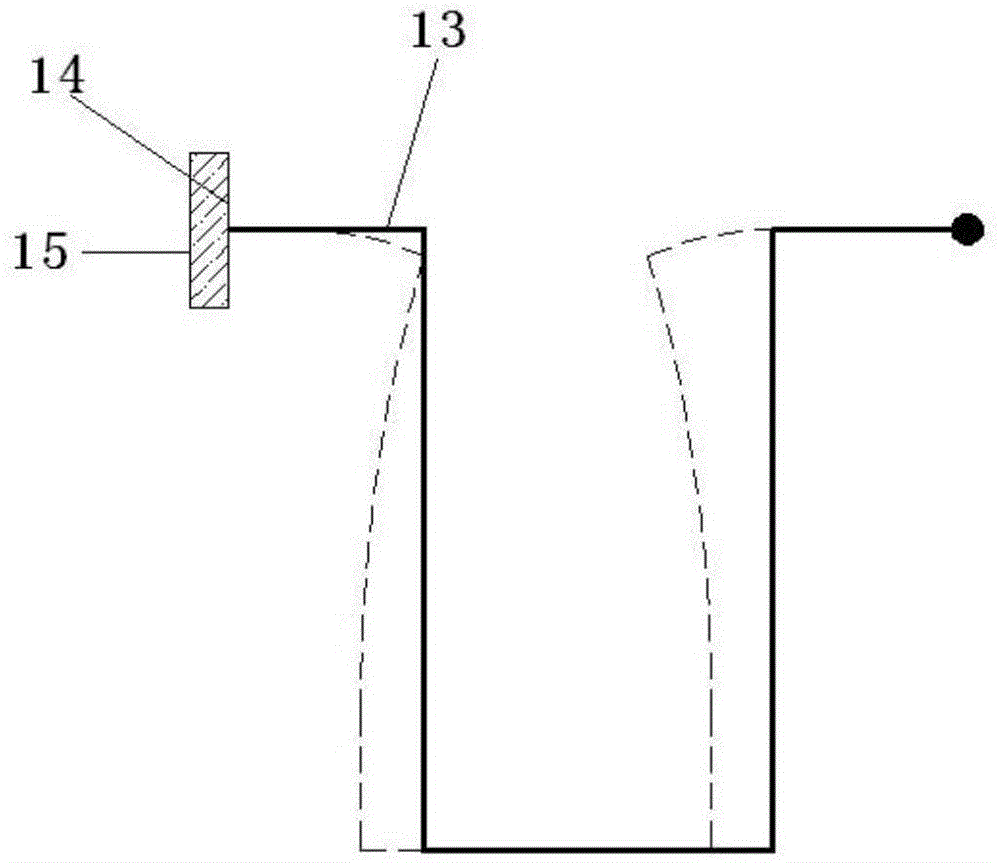

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as Figure 1~4 As shown, a wave energy piezoelectric power generation device based on constant frequency self-vibration is characterized in that it includes: a power generation device 1 and a fixing device 2 for fixing the power generation device on the sea surface; the power generation device includes a main shaft 3. The main shaft 3 is provided with an upper water baffle 4 and a lower water baffle 5, and both the upper water baffle 4 and the lower water baffle 5 pass through the main shaft 3 and pass through the upper fixed bearing 6 and the lower water baffle respectively. The fixed bearing 7 is fixed on the main shaft 3. The main shaft 3 includes an inner shaft 8 and an outer shaft 9 that is shorter than the inner shaft 8 and covers the inner shaft 8. The lower end of the outer shaft 9 is in contact with the vibration The float 10 is fixedly connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com