Mass tuned grain damper

A particle damper and tuning quality technology, which is applied to building components, shockproof and other directions, can solve the problems of high price of energy dissipation dampers, large local stress in the structure, inflexible installation position, etc. The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

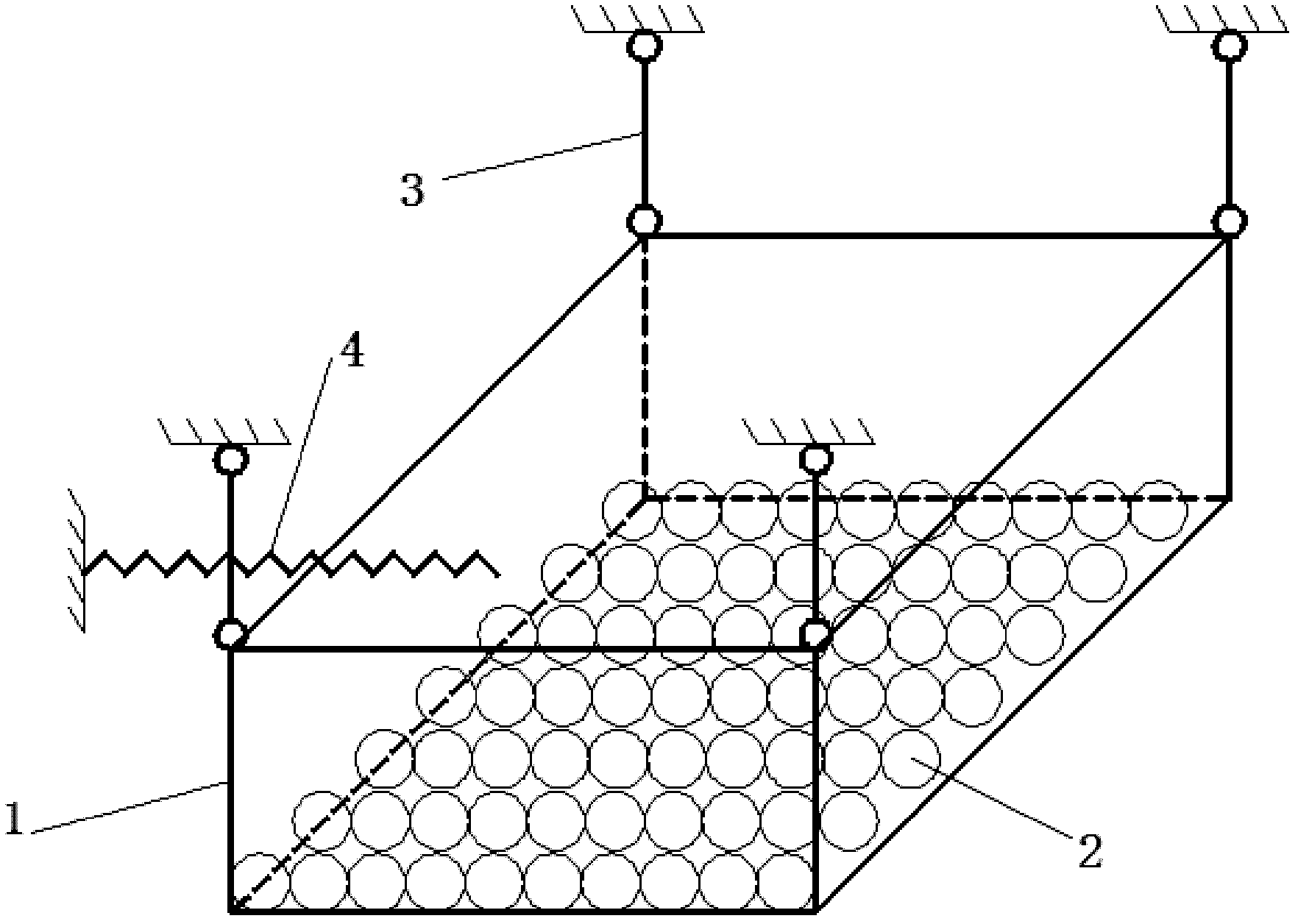

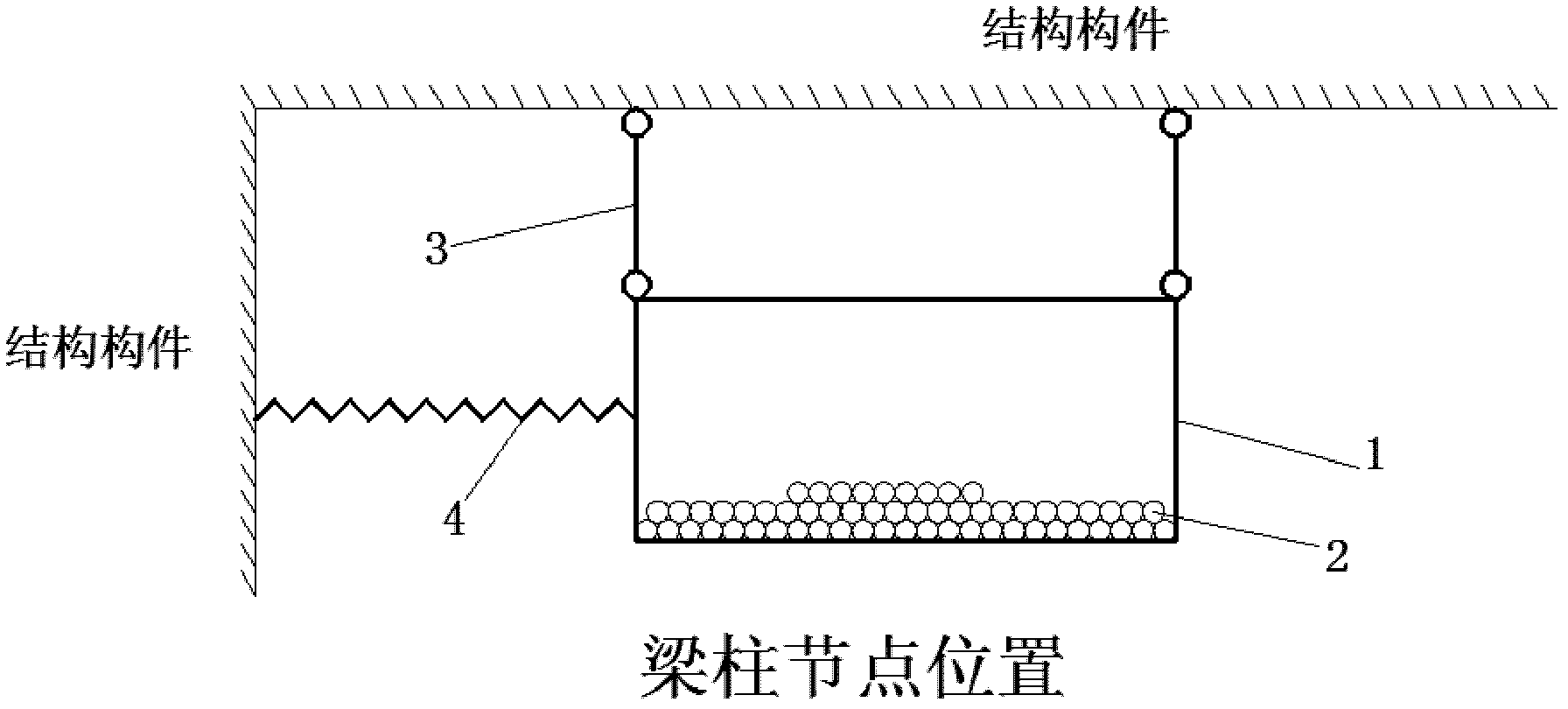

[0025] Such as figure 2 As shown, it is an embodiment of a tuned mass particle damper of the present invention, which mainly includes a damper cavity 1, a damping particle group 2 placed in the damper cavity at a certain stack height, a one-way hinge system 3, a reset The spring 4, and the embedded part embedded in the structural member.

[0026] The damper cavity 1 is a cuboid empty box welded by steel plates with a thickness of 3 mm to 5 mm. The damper cavity 1 and the embedded parts in the structural components are welded together through the one-way hinge system 3, and the damper is suspended from the building. Structural beam-column joints. The stacking height of the damping particle group 2 and the size of the damper cavity should be obtained according to the fundamental frequency of the structure or component based on relevant theories, and the stacking height of the damping particle group should not exceed 1 / 5 of the cavity height. Steel balls with a small friction ...

Embodiment 2

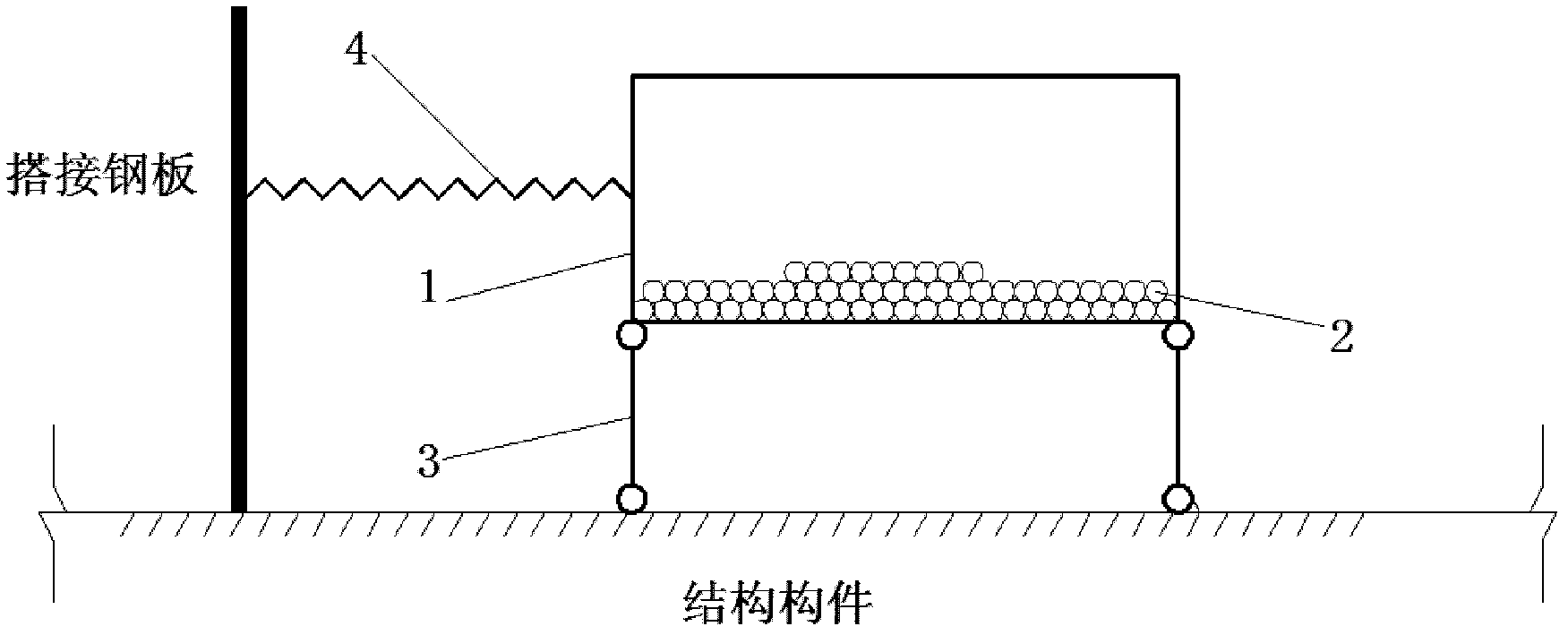

[0028] Such as image 3 As shown, it is an embodiment of a tuned mass particle damper of the present invention, which mainly includes a damper cavity 1, a damping particle group 2 placed in the damper cavity at a certain stack height, a one-way hinge system 3, a reset The spring 4, and the embedded parts and lapped steel plates pre-embedded in the structural components.

[0029] The damper cavity 1 is a cylindrical empty box welded by 3mm to 10mm thick steel plates. The damper is supported on the equipment floor of the building structure or the bottom plate of the box girder of the bridge structure by means of a one-way hinge system. The stacking height of the damping particle group 2 and the size of the damper cavity should be obtained according to the fundamental frequency of the structure or component based on relevant theories, and the stacking height of the damping particle group should not exceed 1 / 5 of the cavity height. As the damping particle material, steel balls wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com