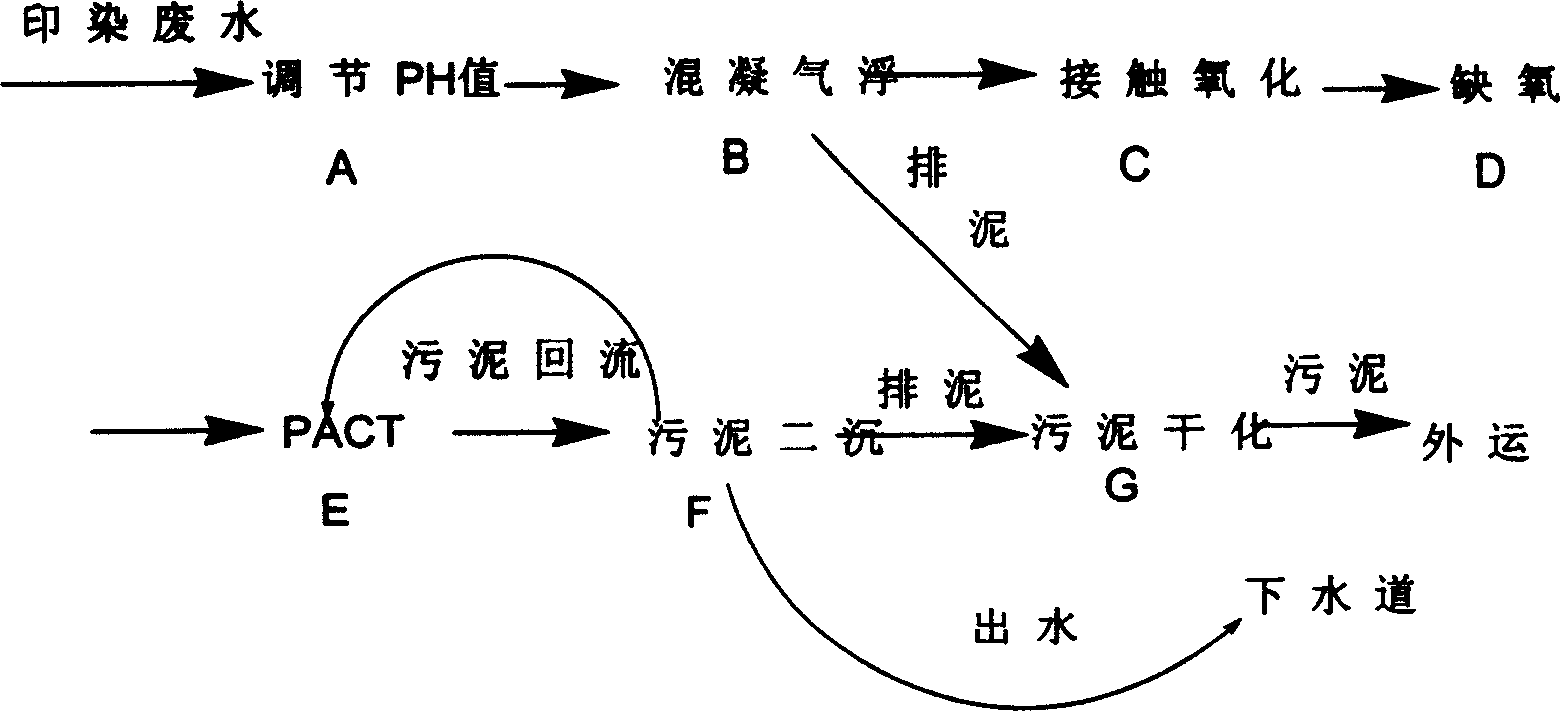

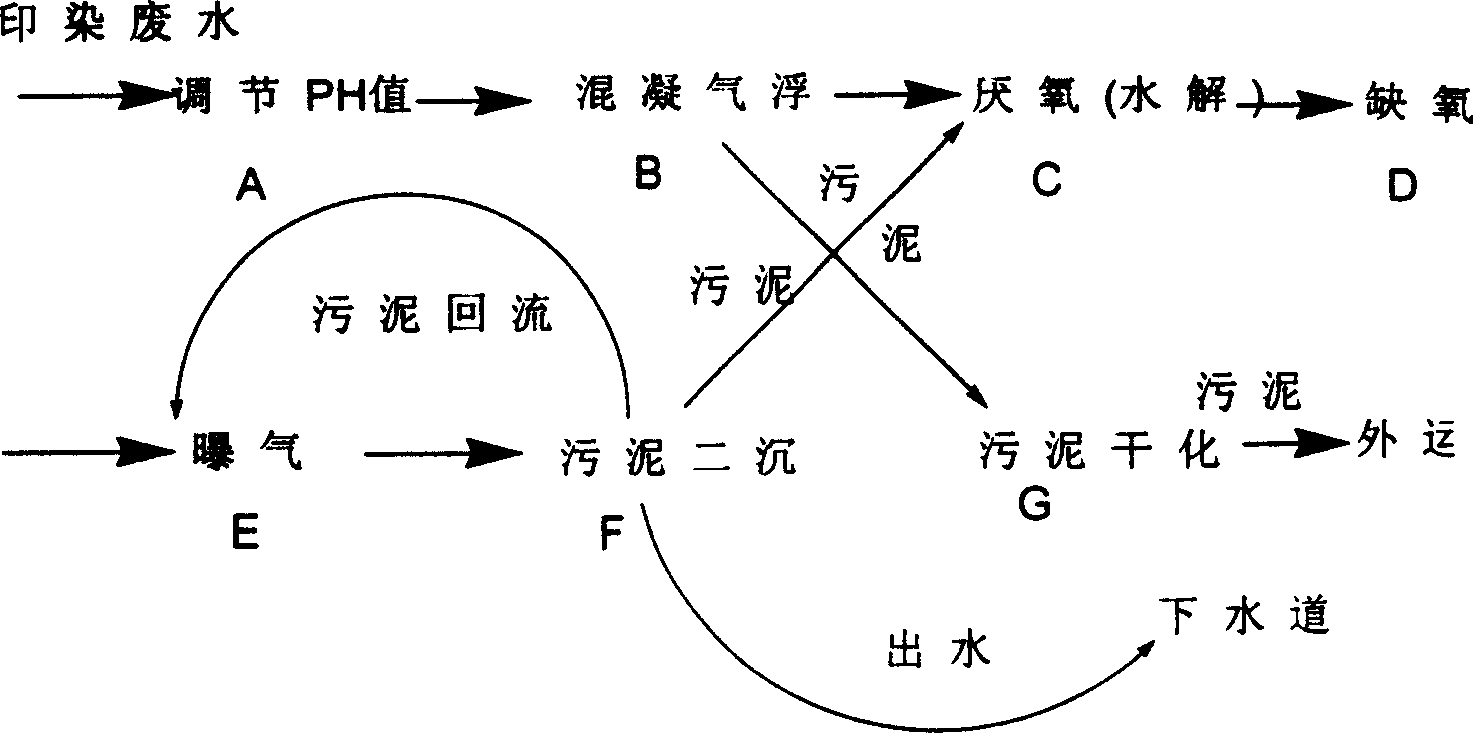

Printing and dyeing waste water disposal process

A technology for printing and dyeing wastewater and treatment process, which is used in flotation water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of convenient operation, good adaptability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples will help to understand the present invention, but do not limit the content of the present invention.

[0024] On the basis of the old technology, the following improvements are made:

[0025] 1. Stop the aeration of the contact oxidation tank (C), ie DO=0 mg / l.

[0026] 2. Stop adding activated carbon to the PACT (E) pool, and add some activated sludge.

[0027] 3. Stop the sludge from the secondary settling tank (F) from being discharged into the drying sludge facility.

[0028] 4. In the off-season, the amount of wastewater is small, and the process is converted. After two months, light green floating objects appear on the surface of the anaerobic pool (hydrolysis pool), which is the phenomenon of anaerobic bacteria production and growth. Synchronous monitoring and monitoring After four months of biological microscope inspection, all indicators improved, and after six months, COD and chroma were all up to the standard discharge (COD<100mg / l, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com