Biotechnology capable of producing No. 380 admiralty fuel oil and application thereof

A technology for fuel oil and ships, which is applied in the direction of microorganisms, microorganisms, and methods based on microorganisms. It can solve the problems that the quality indicators are difficult to meet international standards, it is difficult to meet the needs of enterprises and markets, and the output is limited. It is easy to reproduce and popularize. , the effect of increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of microbial agent: the thermophilic denitrophilic Bacillus NG80-2 ( Geobacillus thermodenitrificans , the strain is preserved in the General Microbiology Center of the China Committee for the Collection of Microbial Cultures, and its preservation number is CGMCC No.1228) and Mycobacterium archaea ( Mycobacterium goodii sp., the strain was purchased from the American Culture Collection, and its preservation number is ATCC No. 700504) were inoculated into the culture medium sterilized by autoclaving at a ratio of 1:1000 (v / v), and vortexed at 50°C and 150rpm , airtight (oxygen) culture for 18 hours, and the obtained bacterial solution was mixed at a ratio of 1:1 by volume. The culture medium is: peptone 1.6%; yeast extract 1%; sodium chloride 0.5%; water balance.

Embodiment 2

[0024] Activation and expanded cultivation of microbial agents: Inoculate the mixed microbial agents at a ratio of 1:1000 (v / v) into the culture medium sterilized by autoclaving, vortex and stir at 50°C, 150rpm, and incubate in airtight (oxygenation) for 18 hours , to obtain activated microbial bacterial agents. The composition of the culture medium is: peptone 1.6%; yeast extract 1%; sodium chloride 0.5%; water balance.

Embodiment 3

[0026] Method 1 for the production of No. 380 ship fuel oil using microbial agents:

[0027] (1) Mix the activated 1% microbial agent, 50% oil slurry and the rest of the inorganic salt solution by weight percentage, vortex and stir at 40°C and greater than 50rpm, and seal the reaction for 24 hours;

[0028] (2) After the reaction, let it stand for more than 2 hours, and collect the oil layer with a separating funnel after the oil and water are separated. This oil product is the No. 380 marine fuel oil produced.

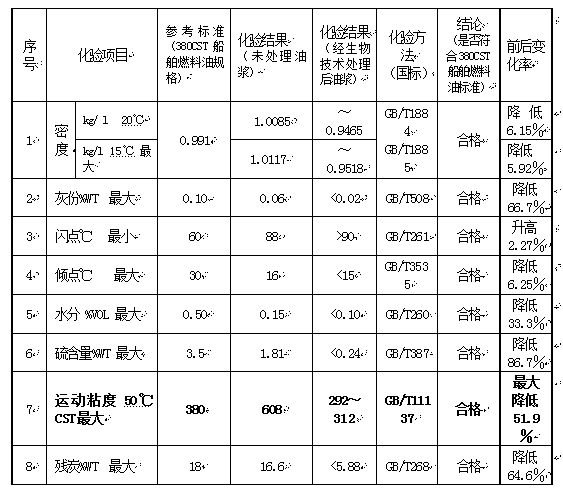

[0029] The test results show that the kinematic viscosity of the treated oil is 312, and other indicators also meet the quality standards of No. 380 marine fuel oil (Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com